Software solutions.

MV.IMAGING. MABRI.VISION develops the right software for your inspection processes.

Intelligent software for your vision test.

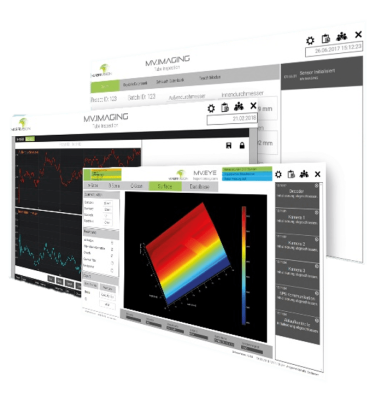

Everything at a glance – Our software platform MV.IMAGING offers a variety of visualization options. This gives you the best possible overview of processes and quality assurance in production.

High cycle rates require efficient programming, especially for more complex testing tasks. We use several technologies, in particular various parallelization mechanisms, to ensure consistent evaluation

Machine learning and artificial intelligence are more than just a marketing term at MABRI.VISION. During the design phase, our experts evaluate whether the use of AI solutions can meaningfully support the test.

Visualization.

Complete and clear.

- Test parameters & results

- Test metrics & status display

- Various graphics & illustrations

- Time history graphs

- Schematic illustrations for clear representation

- PASS / FAIL display

Inspection reports and protocols.

We enable you to record all relevant parameters at a glance. These can be arranged as desired and shown and hidden by the respective operator. All data can be exported as structured test reports in .csv, .xls or .pdf format.

2D and 3D graphics.

A picture is worth a thousand words. Thanks to our modern platforms, we have various modules to display even complex testing processes. Especially for 3D tests, we rely on the visual representation of test characteristics and results.

Statistics & process metrics.

Benefit from our in-depth know-how in the area of measurement technology and quality assurance.

We enable process support through various key figures and tools such as good part counters, error and measurement image memories, advance warning limits and batch-related statistics.

Our modern vision center software platform MV.IMAGING enables you to implement your requirements without compromise. We create batch reports directly for Excel and take over the visualization and calculation of process key figures.

Modular.

Basic equipment.

We have a comprehensive repertoire of standard building blocks that you can adapt and expand according to your requirements. Below you will find a selection of our standards:

- Modern visualization

- Audit trail and command log

- Export reports

- User management

- Databases for production orders and recipes

- Multilingualism

- Remote maintenance option

Interfaces.

In addition to various standard interfaces, we also implement your desired interfaces. We enable seamless integration of our testing into your overall process. Interfaces already used include:

- ProfiNet, ProfiBus, OPC UA

- Cameralink, GigE Vision, USB3 Vision, CoaXPress

- SMB Share, SFTP, MSSQL, Python, .NET, C/C++

- Various analog and digital I/O

Medical technology and special requirements.

In various areas such as medical technology and the semiconductor industry, there are special requirements for software. We have experience in these areas and do not shy away from complicated requirements.

- Secure and complete audit trail

- Advanced user management and connection to Windows AD

- Extended personal authorization model

- Documentation of software

High performance.

Higher data requires more computing power. In order to ensure the necessary calculations in the process cycle even with complex measuring procedures, MABRI.VISION relies on modern computer architectures with appropriate parallel algorithms.

This makes it possible for us to process the enormous measurement data from our high-speed microscopes and 3D sensors in real time.

Machine learning.

Advice

Our software framework MV.IMAGING offers you maximum flexibility. In addition to basic functionalities such as recording, evaluating and storing measurement data, individual software packages are available to you. Features such as user management, databases and data visualization are integrated according to your requirements.

Hybrid approaches

The technology is rapidly approaching the goal of solving entire applications using machine learning methods. We are already relying on hybrid approaches by using classic algorithms and methods in combination with deep neural networks. In this way, we ensure secure and effective data processing.

Modern platforms

In addition to state-of-the-art platforms such as TENSORFLOW, CUDA and HALCON, we also use our own technologies if your application requires it. This means we can guarantee you a flexible and modular application. Our goal in our work is always to find the best solution for your application.

Applications.

-

electronics

Inline shape testing of plugs & connectors

Inline inspection system for testing plugs, connectors and pin headers with up to 1000 contacts/min.

-

Automotive, metal processing

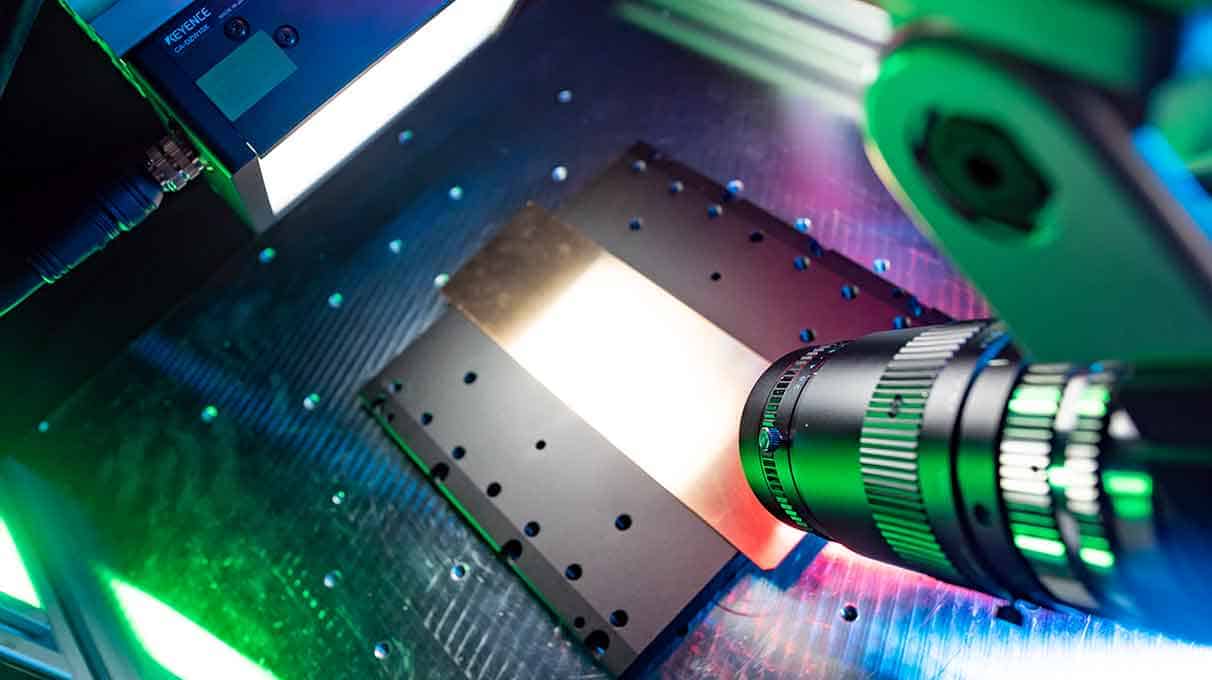

Defect inspection on metal surfaces.

Fully automatic detection of the smallest quirks, dents and scratches on metal surfaces in the process.

-

Automotive, metal processing

Inline inspection of surface defects on metal pipes.

Testing of the interior chips, welding seams, indoor and outdoor phase and coat and outdoor areas in the process.

-

Medical

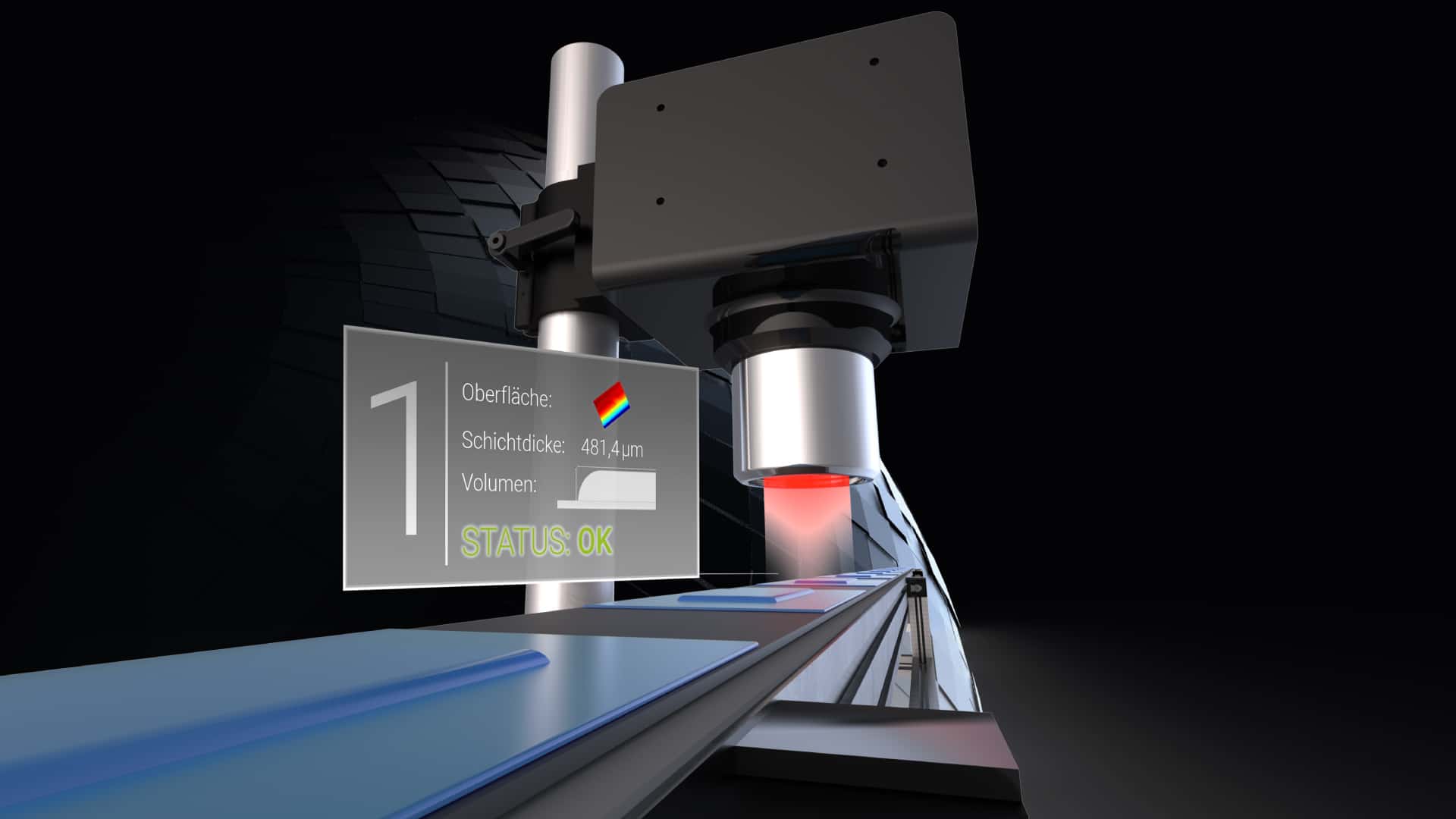

Inline layer thickness testing of plasters.

Inline test of multi-layered, transdermal paving.

Volume | Layer thickness | Form | Presence. -

Medical

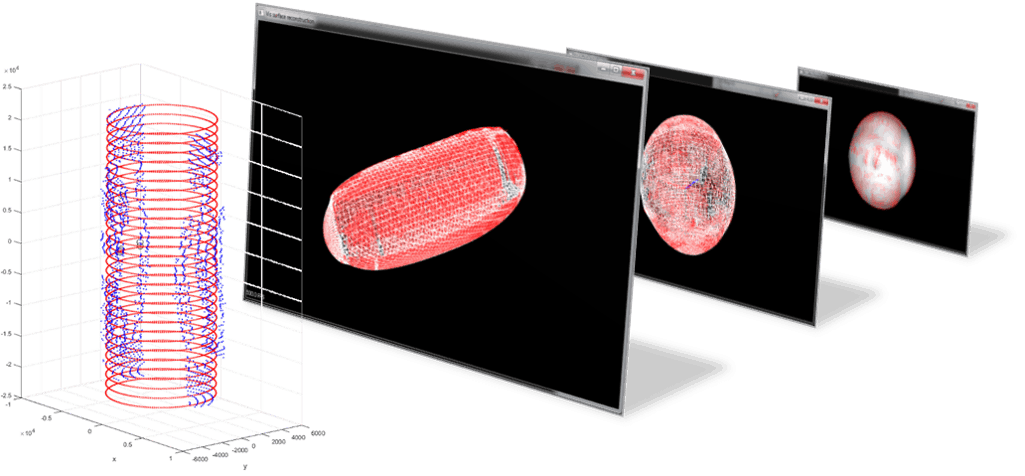

360° inline hose testing.

Testing of interior and outer diameter, wall thickness and geometry of semi-transparent hoses.

-

Medical

Testing of microstructures

Fully extensive quality control of injection molding microstructures from medical technology.

-

Automotive

Testing complex injection molded parts

100%quality control of injection molding parts and plastic metal connected in the automotive industry.

-

Automotive

QR/Datamatrix reading bridge for tires

Examination of lasered or molved QR/DataMatrix codes with the help of a reading bridge.

-

Automotive, metal processing

Testing shape and defects of castings.

Test systems for the shape test of cast parts as well as the detection of surface pores and lunkers.

-

Groceries

Inline 3D shape inspection of baked goods.

3D form test of baked goods. Measurement of length, width, height and count in one round.

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision