MV.CHECK CI2

Inline Formprüfung von Steckern & Verbindern

MV.CHECK CI2

Inline Formprüfung von Steckern & Verbindern

Mit der Anlage MV.CHECK CI2 bietet MABRI.VISION ein Inline-Inspektionssystem zur Prüfung von Steckern, Verbindern und Stiftleisten. Mit Geschwindigkeiten bis zu 1000 Kontakten/min sind präzise Prüfungen von Kontakten und Kodierungen im Produktionstakt möglich. Das System bietet alle gängigen Schnittstellen und lässt sich reibungslos in vorhandene Prozesse integrieren.

Anwendungen

- Steckerprüfung

- Prüfung von Verbindern

Prüfungen

- Kontakte

- Kodierung

- Vollständigkeit

- Varianten

Branchen

- Automotive

- Elektrotechnik

- Luft- & Raumfahrt

Prüfung Kontakte.

Die zuverlässige Prüfung von Taumelmaßen und Defekten, wie beispielsweise Verbiegungen von Kontakten findet im Takt der Produktion statt.

Prüfung Kodierung.

Das MABRI.VISION Prüfsystem MV.CHECK CI2 erfasst und prüft Kodierungen auf Ihren Bauteilen. So können sortenreine Produktionslose garantiert werden.

Vollständigkeit.

Gehen Sie bei der Inspektion Ihrer Stecker und Verbinder keine Kompromisse ein. Unser Prüfverfahren garantiert die zuverlässige Kontrolle der Vollständigkeit von Spritzgussteilen.

Varianten.

Die Anlage MV.CHECK CI2 bietet dank Rezeptdatenbanken neue Lösungen für die Prüfung unterschiedlicher Varianten. So können Sie alle Produktionsvarianten prüfen, ohne jeweils eine neue Softwarekonfiguration vornehmen zu müssen.

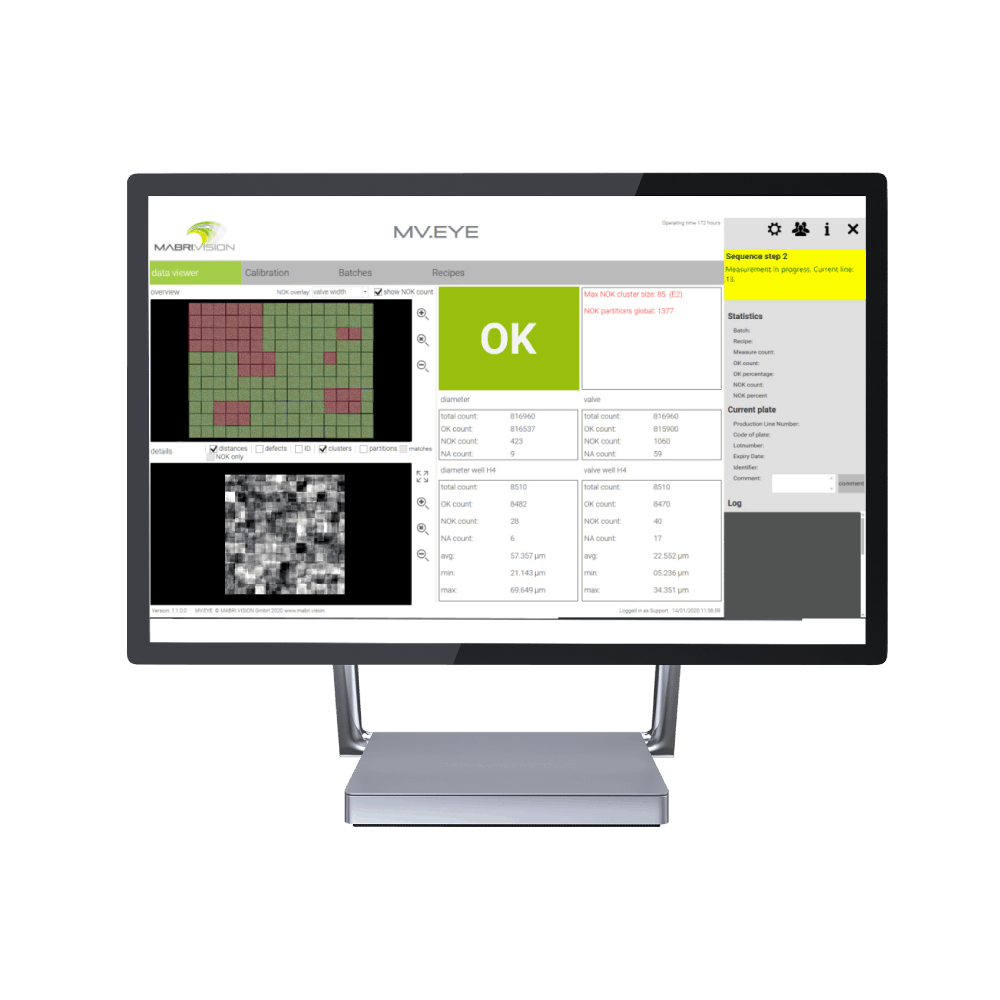

Dank der optischen Sensortechnologie des MV.CHECK CI2 Prüfsystems erfolgt die Erfassung aller Prüfmerkmale in Höchstgeschwindigkeit. Für die Maximierung des Durchsatzes erfolgt das Processing parallel zur Datenaufnahme.

Umfangreiche Statistiken sowie vielfältige Analyse-Tools unterstützen eine effiziente Bedienung. So lassen sich Optimierungspotenziale und Produktverbesserungen schnell erkennen und umsetzen.

Spezifikationen.

PRÜFUNG

| Prüfungen | Präsenz, Vollständigkeit, Maßhaltigkeit |

| Anwendung | Stecker, Verbinder, Wannen |

| Durchsatz | 1.000 Kontakte / min |

| Optische Auflösung | 5 µm (kleiner auf Anfrage) |

| Auflösung | 5104 x 4092 Pixel |

SCHNITTSTELLEN UND SOFTWARE

| Schnittstellen | ProfiNet, EtherNet |

| Interface | 22 Zoll, Monitor |

| Software | MV.IMAGING |

| Funktionen & Module | Rezepte, Datenbanken, Nutzermanagement |

ANLAGE (IN ABHÄNGIGKEIT DER AUSFÜHRUNG)

| Maße Anlage (B x T x H) | (800 x 800 x 1.600) mm³ |

| Gewicht | 160 kg |

| Nennleistung | 0,75 kW |

| Versorgung | 100 - 240 V |

Universell: vielfältig einsetzbar.

Elektrotechnik

100%-Qualitätsprüfung von Platinen und Steckern in der Elektrotechnik. Zuverlässige Prüfung von Kontakten in Höchstgeschwindigkeit für einen maximalen Durchsatz.

Automobilindustrie

Kompromisslose und inline-fähige Prüfung von Formteilen zum Einsatz in der Automobilindustrie. Es werden Geschwindigkeiten bis zu 1.000 Kontakten/min erreicht.

LUFT- & Raumfahrt

Die MABRI.VISION Prüfanlage MV.EYE CI1 eignet sich zur Highspeed-Prüfung von Bauteilen für die Luft- & Raumfahrt mit einer Vielzahl von Prüfmerkmalen.