Schwerpunkte

Inline-Messung von Barriereschichten

Prüflösungen für Verpackungen, Medizintechnik & Pharma

Zusammenfassung

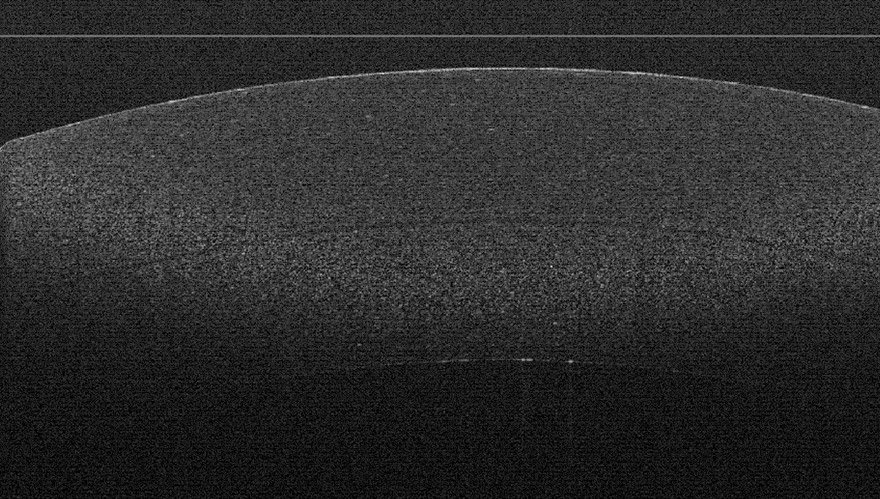

Die optische Prüfanlage MV.SENSE b1i misst Form und Wandstärke lichtdurchlässiger Kunststoffverpackungen. Die Inline-Prüfung erfolgt berührungslos im Takt der Produktion und ermöglicht so die 100-Prozent-Inline-Kontrolle von Verpackungsmaterial mit mehreren Schichten.

Ein wichtiges Anwendungsfeld ist die zerstörungsfreie Messung der Dicke von Barriereschichten, zum Beispiel aus Ethylen-Vinylalkohol-Copolymer (EVOH), in Lebensmittelverpackungen. Das Messsystem prüft die Gesamtschichtdicke sowie die Dicke der Sperrschicht.

Die hohe Messfrequenz von bis 200 kHz macht den Einsatz in Produktionsmaschinen für die 100-Prozent-Inlne-Kontrolle möglich. MABRI.VISION liefert unterschiedliche Systeme von der punktförmigen 1D-Messung bis zu 3D-Anlagen, die mit einer Messrate von bis zu 200 Hz ein großes Messfeld scannen.

Anwendungen

+ Prüfung von Kunststoffflaschen

+ Prüfung von Blistern

Prüfungen

+ Wandstärke

+ Form

+ Barriereschichten

+ Übergangsstellen

Branchen

+ Lebensmittel

+ Verpackung

+ Pharma

+ Medizintechnik

Was prüfen wir?

Die modulare Prüfplattform MV.EYE bietet Ihnen eine Prüflösungen für sämtliche Prozessschritte bei der Fertigung von Stahl- und Edelstrahlrohren

-

Wandstärkeprüfung

<p>Die Prüfung lässt sich an allen Verpackungen aus semitransparenten Kunststoffen durchführen.</p>

-

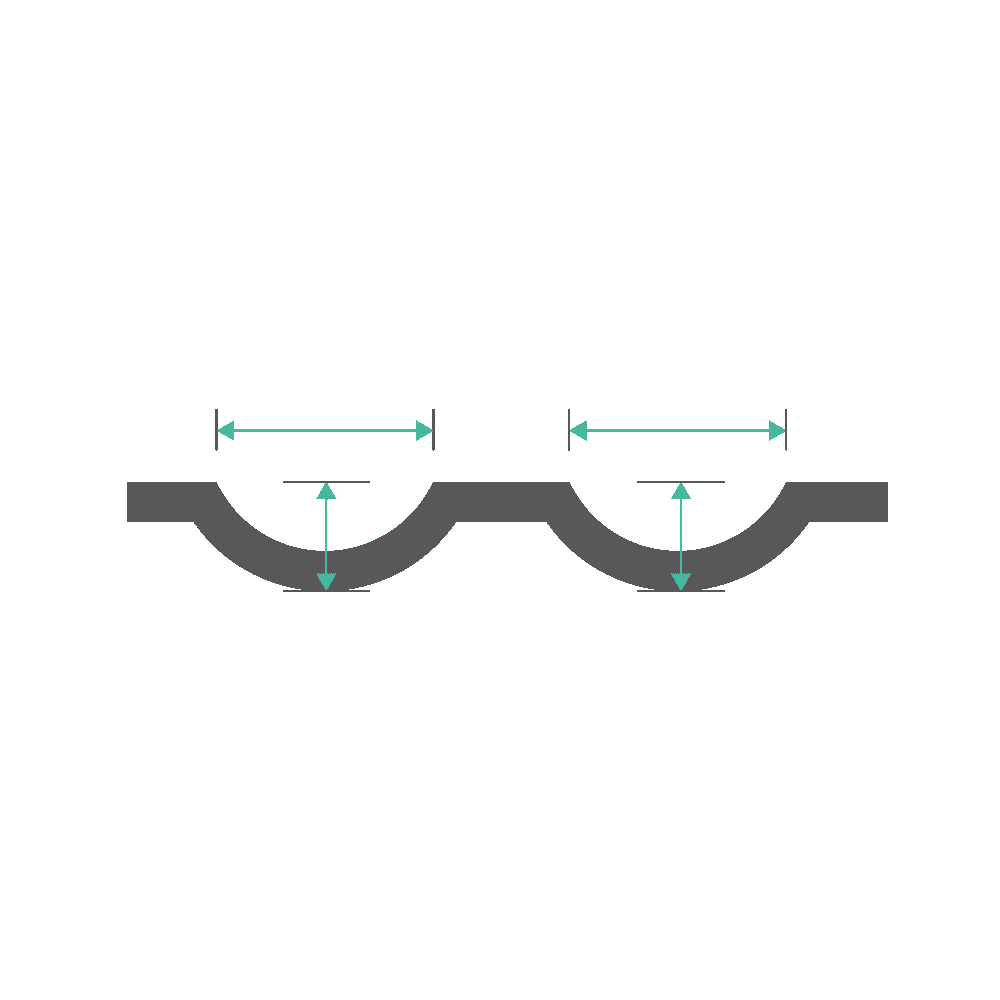

Formprüfung

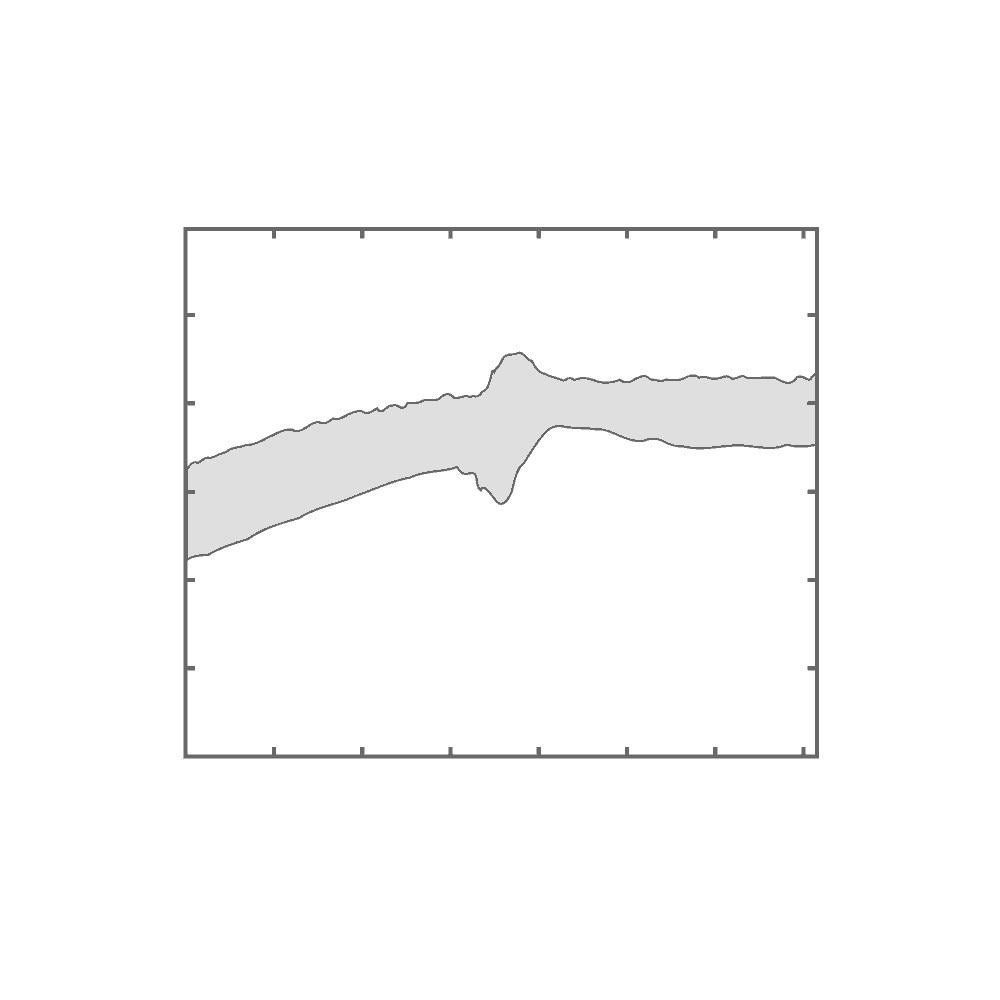

<p>Die Querschnittsbilder können insbesondere zur Formprüfung von Folien, wie Blister, eigesetzt werden. Es können Breite und Höhe von feinen Strukturen genau geprüft werden.</p>

-

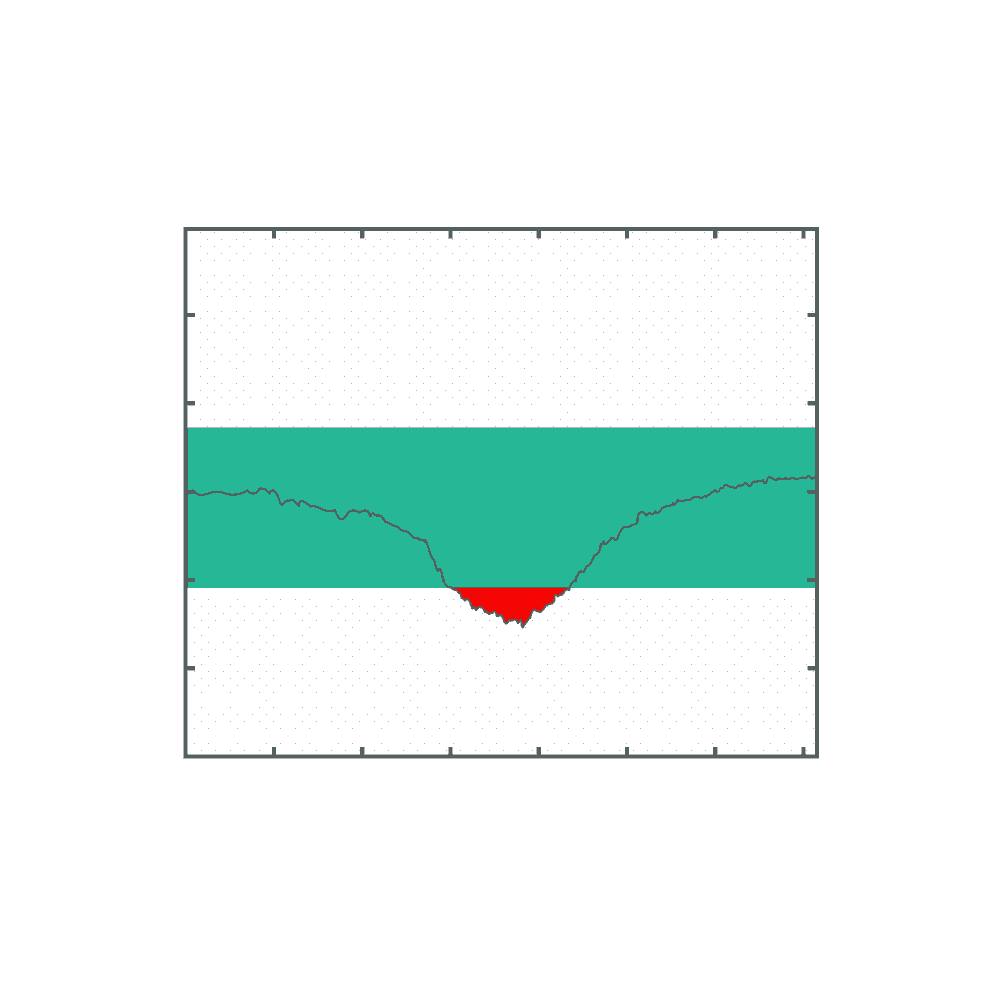

Prüfung von Mehrschichten

<p>Bei Wandstärken ab 10µm lassen sich einzelne Schichten auflösen. Im Fertigungsprozess können Toleranzen innenliegender Schichten inline und zerstörungsfrei geprüft werden.</p>

-

1D-, 2D- oder 3D-Sensoren

<p>Je nach Applikation bieten wir Ihnen die passenden Sensoren. Grundsätzlich kann in 1D, 2D und 3D gemessen werden. Unsere Experten legen Ihre Prüfanlage passend aus. So erhalten Sie die beste Lösung für Ihre Anwendung.</p>

-

berührungslos

<p>Die MABRI.VISION Sensoren prüfen absolut berührungslos. Das rein optische Verfahren nutzt niederenergetische Strahlung und verhindert dadurch beispielsweise die Aushärtung von Klebematerialien.</p>

-

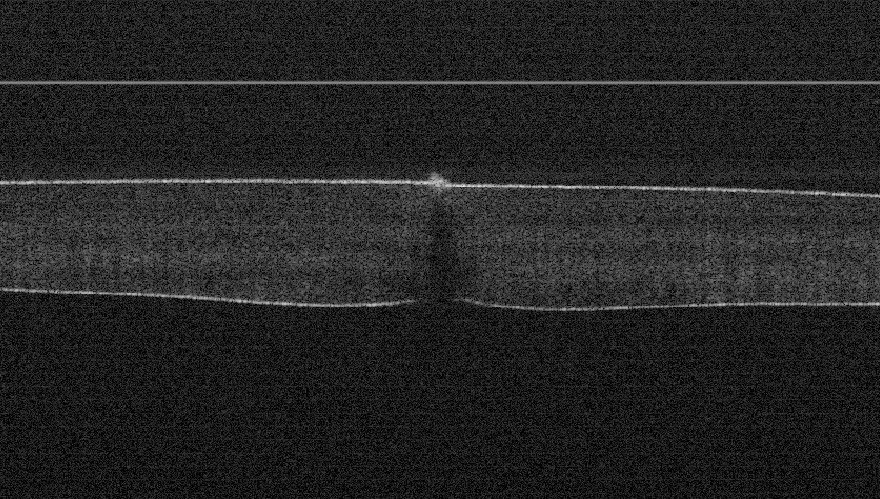

Prüfung von Übergangsstellen

<p>Qualitätsmängel wie sichtbare Nahtstellen oder Sollbruchstellen an Kunststoffverpackungen werden durch unsere Prüfanlage zuverlässig erkannt. Analysedaten ermöglichen Ihnen die Anpassung und Verbesserung Ihrer Werkzeuge.</p>

Universell: vielfältig einsetzbar

Blister

Im Bereich der Pharmaindustrie kommen tiefgezogene Verpackungen zum Einsatz – diese lassen sich mit dem MV.SENSE b1i-System vollumfänglich prüfen.

Flaschen

Das MABRI.VISION-Prüfsystem lässt sich optimal zur Prüfung von Kunststoffflaschen einsetzen und liefert Daten über Form, Wandstärke und Qualitätsmängel.

Folien

Setzen Sie auf eine 100%-Qualitätskontrolle und gewährleisten Sie durch den Einsatz von MABRI.VISION Prüftechnik hochwertige und fehlerfreie Erzeugnisse.

Beispielanwendungen

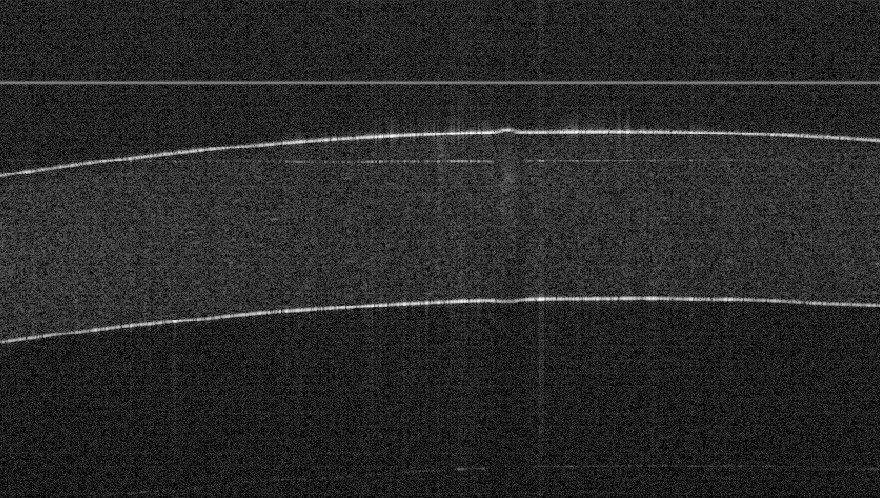

Beim Extrusionsblasformen prüfen wir Wandstärke und Nahtbereiche an kritischen Stellen. So können bereits in frühem Stadium des Prozesses Defekte wie beispielsweise Dünnstellen erkannt werden, die später zur Rissbildung führen können.

Beim Streckblasen von Verpackungen ist eine gleichmäßige Materialverteilung und Abformung ausschlaggebend für die spätere Funktion. Die Sensoren von MABRI.VISION werden zur Wandstärkeprüfung im Fertigungsprozess eingesetzt.

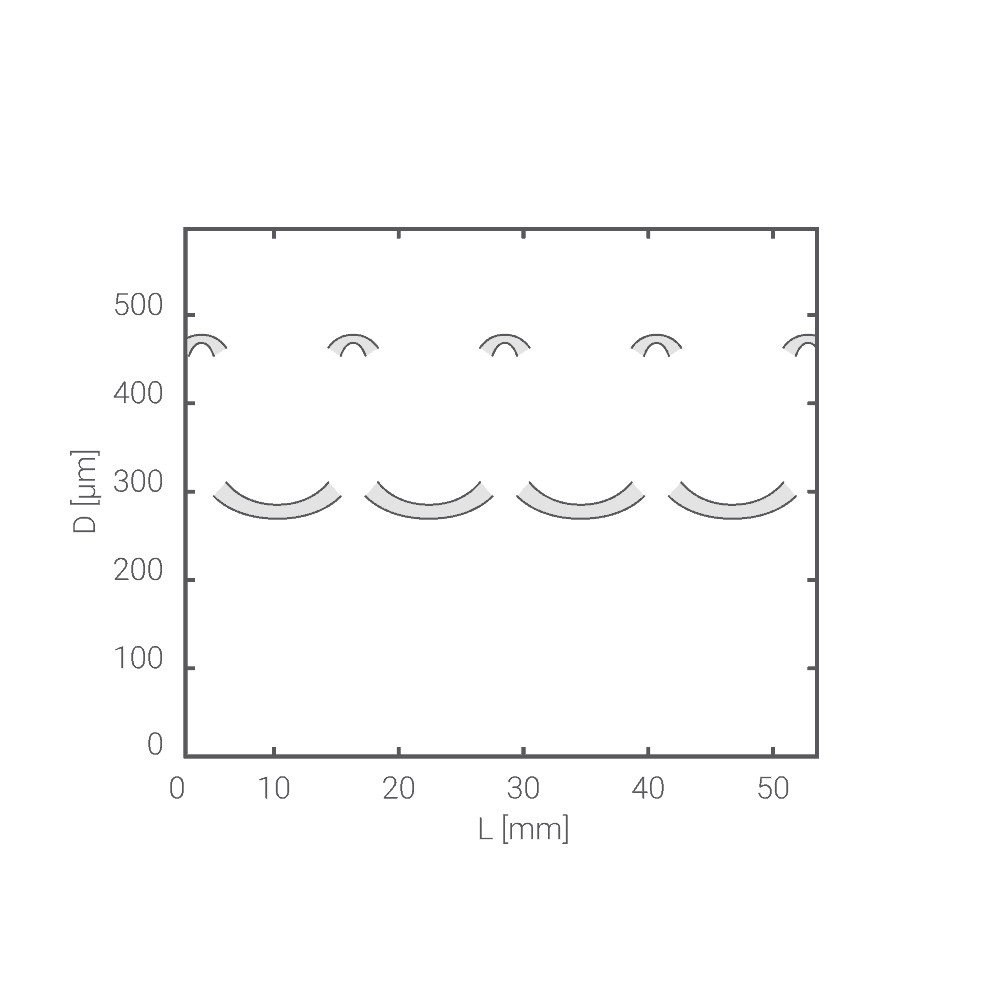

Die MABRI.VISION Sensoren eigenen sich neben der Wandstärkenprüfung auch zur Prüfung von Folienstrukturen. Die Signalerfassung erfolgt dabei mit der gleichen Optik. Dadurch werden Abschattungseffekte vermieden, die bei klassischen Laser-Profilsensoren auftreten.