industrial OCT sensors

We provide you with industrial OCT sensors for the quality inspection of your production goods with our MV.SENSE inspection system.

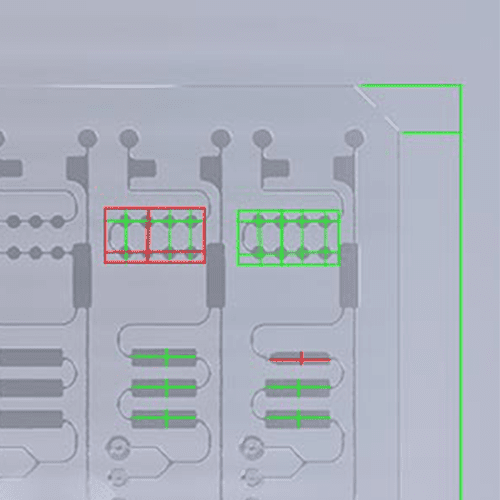

The miniaturization of microcomponents, sensors, actuators and sensor systems, micropumps and injection molded components enables the production of highly integrated products in the smallest of spaces. The quality requirements result in the highest demands on high-tech production processes in order to reliably detect common errors such as anomalies, defects, deformations, assembly, bridges, cracks and burrs. Our machine vision solutions and testing systems are specialized in testing miniaturized components and quickly identifying errors and defects. We rely on the latest optical technologies in order to be able to represent an optimal compromise between speed, resolution and efficiency. Our software platform is optimized for extreme data throughput and also allows several million features to be checked in the process. In addition to classic testing criteria, we rely on AI-supported algorithms to reliably detect anomalies in sensors, microfluidic systems, wafers and other miniaturized components. With our OCT-based systems we can also generate optical cross-sectional images to record layer thicknesses. Our systems can be operated stand-alone and inline in an automated production landscape.

Microstructuring and micro material processing with UKP lasers is used in many industries. Our inspection systems are used for fast inline inspections of microstructure sizes in laser material processing.

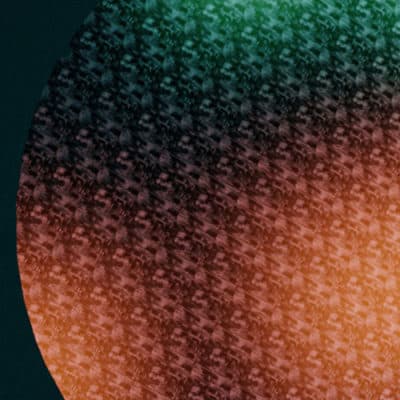

Wafers can also be structured in 3D in order to be able to produce tools and miniaturized components. With our testing systems we record the structural sizes and detect anomalies.

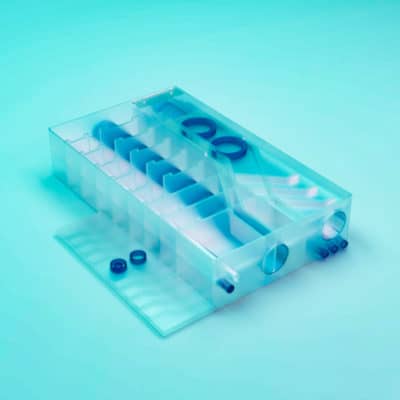

Our test systems solve the challenges that arise in the large-scale production of microfluidic systems and lab-on-a-chip applications.

We offer solutions for 2D / 3D inspection of micro arrays. Areas of application are microlenses, stacks, sequencing, LOAC, fluidics, sensors and medical instruments.

When manufacturing miniaturized sensors, features of a few micrometers must be recorded. Our test systems and high-speed microscopes can also record these properties under production conditions.

There are many challenges to overcome when miniaturizing injection molding processes. We offer testing solutions to be able to test defects and features in the smallest of spaces

We build turnkey testing systems for our customers. From the initial concept through all the necessary qualification steps to service, we offer a solution from a single source. Together with our customers, we design efficient testing processes that fit seamlessly into your production.

Smart automation solutions are particularly in demand in the microtechnology segment. When collecting, evaluating, displaying and storing data, we use our own data pipelines that are optimized for maximum data rates. This means that even extreme numbers of test characteristics can be reliably recorded.

We carefully design our systems according to the needs of our customers and their testing processes. Our goal is to achieve an optimal compromise between precision and speed. To do this, we rely on parallelization and innovative technologies such as TDI, OCT and AI. This allows us to quickly examine macroscopic surfaces microscopically.

We provide you with industrial OCT sensors for the quality inspection of your production goods with our MV.SENSE inspection system.

Machine Vision: MABRI.VISION develops and builds machine vision inspection systems and solutions for your production processes.

MABRI.VISION offers an inline-capable and cycle time-neutral high-speed microscope for automated testing of microstructured components.

High-precision 3D surface inspection system to optimize your quality assurance with high-precision and 20nm resolution: Our MV.EYE CR1

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

Copyright 2015 – 2024 MABRI.VISION GmbH | All Rights Reserved

You have to load the content of Recaptcha to send the form. Please note that data is replaced with third -party providers.

More informationYou are currently seeing a placeholder from Instagram . To access the actual content, click the button below. Please note that data is passed on to third -party providers.

More informationYou have to load the content of Recaptcha to send the form. Please note that data is replaced with third -party providers.

More informationYou are currently seeing a placeholder of gymnastics . To access the actual content, click the button below. Please note that data is passed on to third -party providers.

More information