MV.EYE MS1

Defect inspection on metal surfaces.

MV.EYE MS1

Defect inspection on metal surfaces.

When inspecting metal surfaces, MABRI.VISION relies on the powerful detection functions of the Lumitrax vision platform with an integrated line camera.

The MV.EYE MS1 inspection system enables the fully automatic detection of the smallest quirks, dents and scratches in the process. Thanks to innovative lighting technology and the combination with a linear axis, surfaces can be scanned at top speed and surface defects can be reliably detected.

Applications

- Defect detection on metal strips

- Surface defects on functional surfaces

Inspections

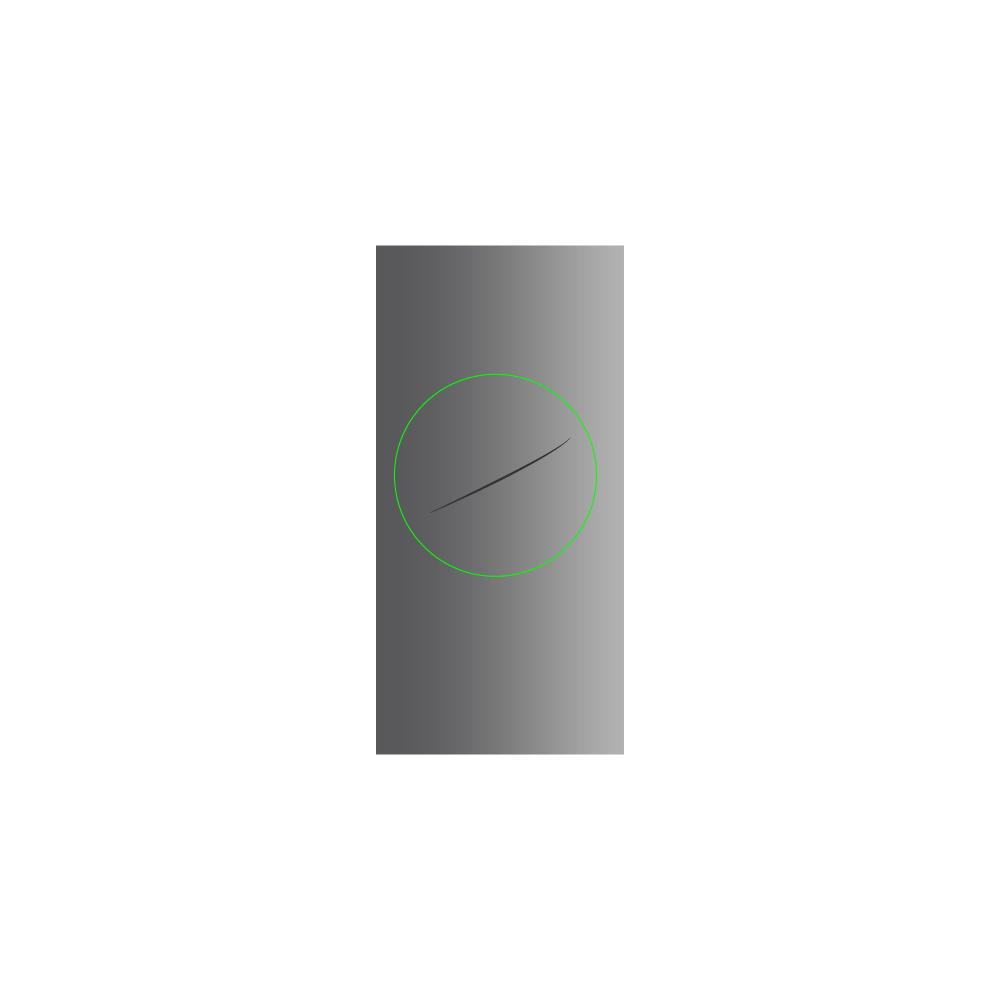

- scratch

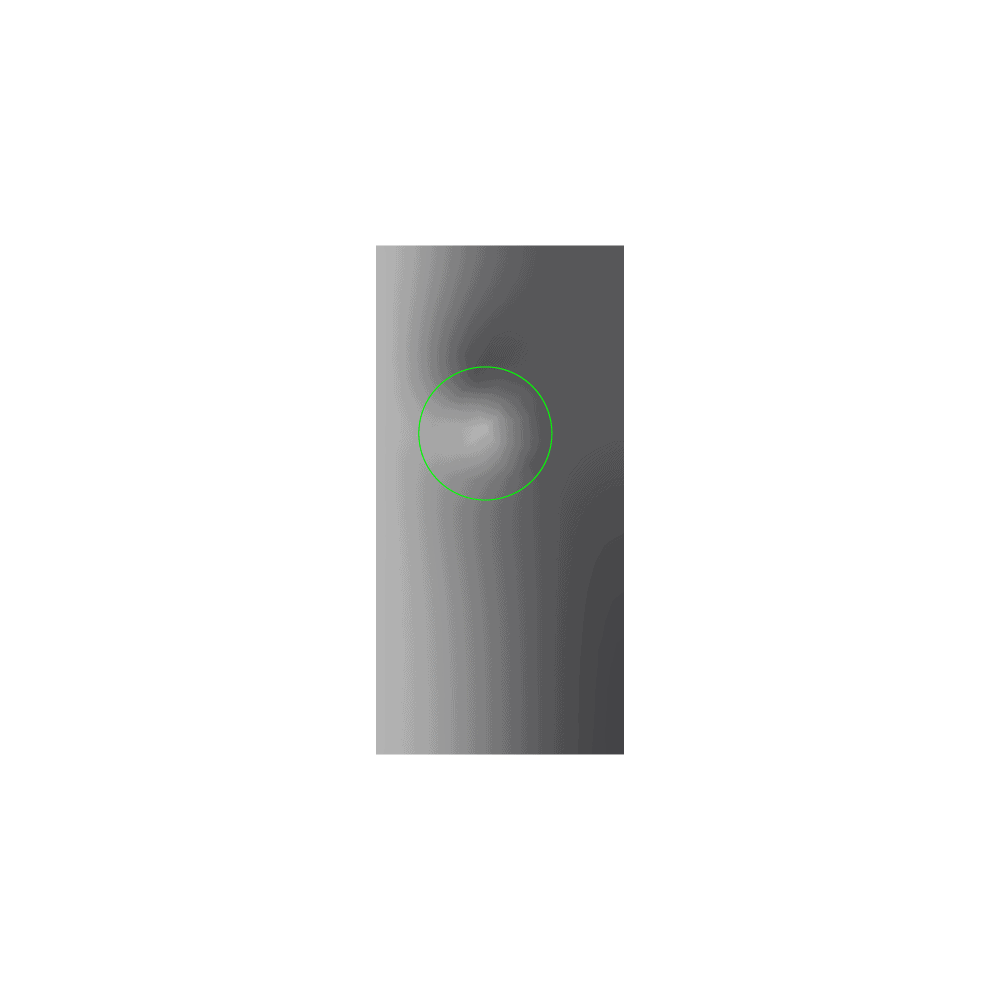

- bumps

- Dents

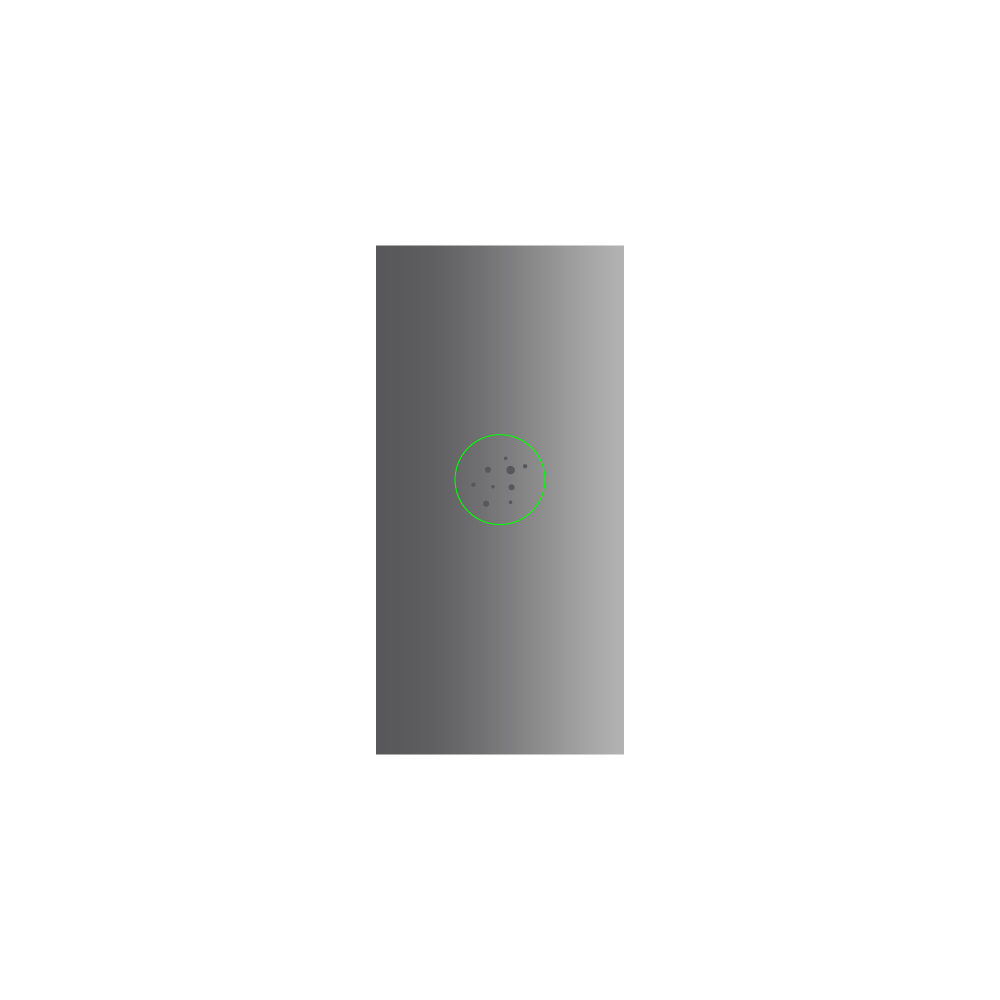

- impurities

Industry sectors

- Metal processing

- power supply

- Automotive industry

Scoring and scratches.

Grooves and scratches are frequently occurring defects, particularly on functional surfaces and sealing surfaces. With the MABRI.VISION testing system MV.EYE MS1, scratches and grooves in the micrometer range are reliably detected.

Dents and blemishes.

Avoiding dents and flaws is a challenge in the production of rolled tape goods. The MABRI.VISION technology even detects dents and flaws that can otherwise only be detected using a white light microscope.

Foreign particles.

Through the combination of high-performance cameras and special lighting, the smallest foreign particles can be detected reliably and with high precision. The technology enables large-scale testing at the same time as the process.

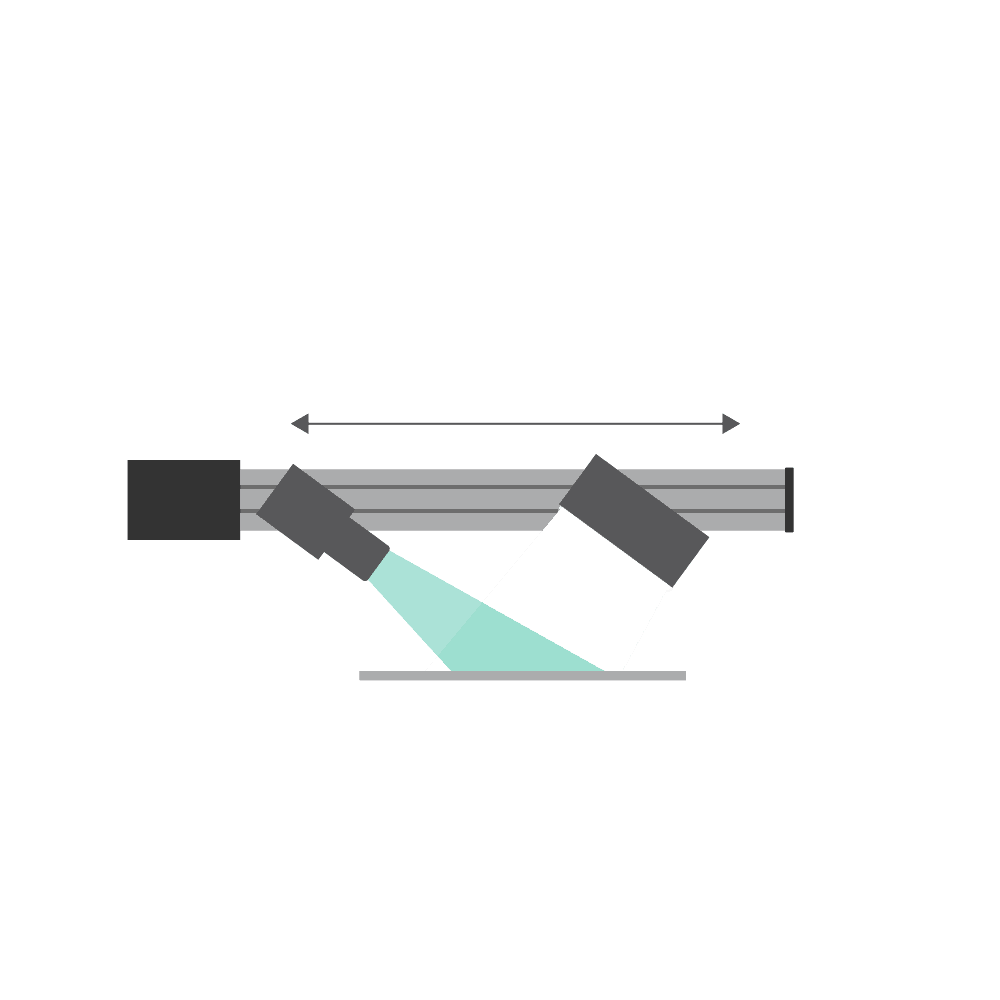

linear scanning unit.

Do your products require static surface testing? MABRI.VISION offers the solution by combining the MV.EYE MS1 testing system with a linear scanning unit.

Process integration.

The combination with an encoder allows you to check the surface of components during the process. The MV.EYE MS1 testing system detects defects from continuous movement and with the highest precision.

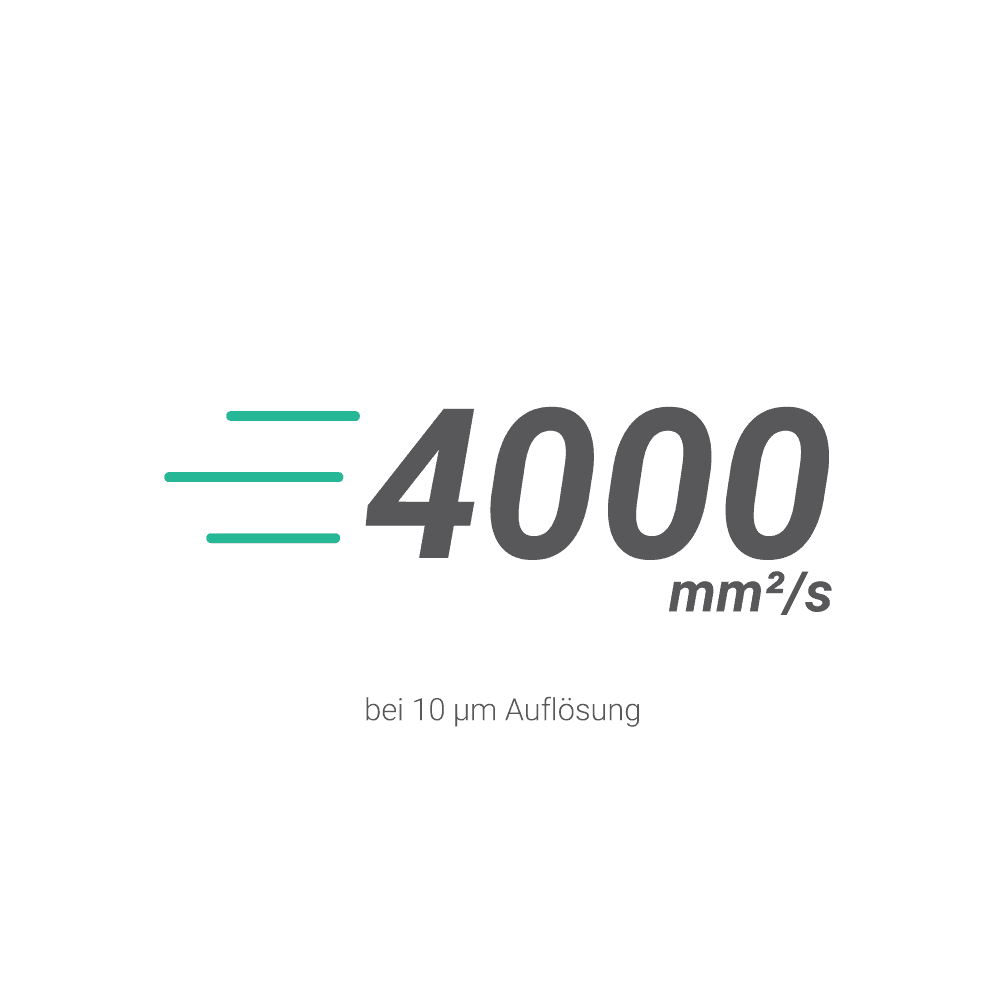

fast.

Thanks to the innovative lighting technology based on rapid light modulation, the testing process reaches extreme speeds. Improve your cycle times with high-speed automated checks.

precise

Universal: can be used in a variety of ways.

Metal processing

The MABRI.VISION testing system is ideal for testing metal surfaces at high speed and for detecting defects in the micrometer range.

automobile

The MV.EYE MS1 testing system is used in the automotive industry due to its fast measuring cycle and uncompromising integration into existing production processes.

Aerospace

By using innovative lighting technology and combining it with a linear axis, large-area tests can also be carried out with high precision.

Specifications

TEST

| Type of examinee | metal surfaces |

| Dimensions of test specimen | up to 500 mm with one camera |

| materials | Metal e.g. steel, aluminum |

| Inspections | Scratches, grooves, dents, foreign particles |

INTERFACES AND SOFTWARE

| Interfaces | ProfiNet, EtherNet |

| operating system | Keyence, Windows optional |

| software | MV.IMAGING, Keyence |

ATTACHMENT

| Line camera pixels | 2048; 4096; 8192 |

| Measuring rate | up to 142,800 lines per second |

| Illumination width (mm) | 120,2; 324; 526 |

| Field width | up to 500 mm with one camera |

| care | 24V; 240W |

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision