Medical technology, pharmaceuticals, life sciences

High-precision testing of injection molded components

MABRI.VISION builds and develops high-quality machine vision solutions and modular testing systems for your production processes. During the production of injection molded components, errors often occur that lead to defective components. Our modular testing systems for plastic and injection molded parts reliably detect defective components and sort them out.

What are we checking?

Incompletely filled molding

We use 2D and 3D tests to record the completeness of molded parts in critical areas, such as thin areas or points far from the gate. We offer inline testing solutions for even the smallest structures on precision molded parts.

Sink marks

Sink marks and demoulding problems can have a negative impact on the appearance and function of molded parts. Using highly precise surface testing methods, our testing systems record the smallest shape deviations during the process.

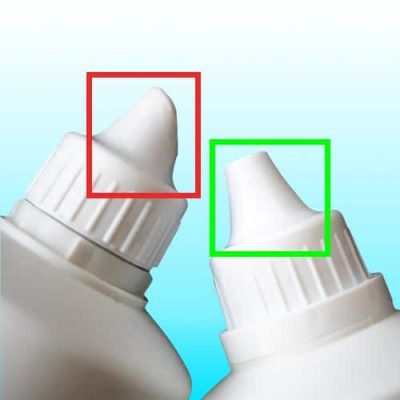

ridge (webbed membrane)

Due to the process, burrs and webbing can occur during molding processes. These effects can have a disruptive effect on functionality, particularly in multi-component processes. With our testing systems, we capture critical contours and can thus detect burr formation early in the process.

Form inspection, dimensional accuracy

MABRI.VISION offers solutions for 100% inline component measurement of complex molded parts. In particular, components with pins for electronic contacting must be checked for dimensional accuracy in terms of shape and position for automated assembly processes.

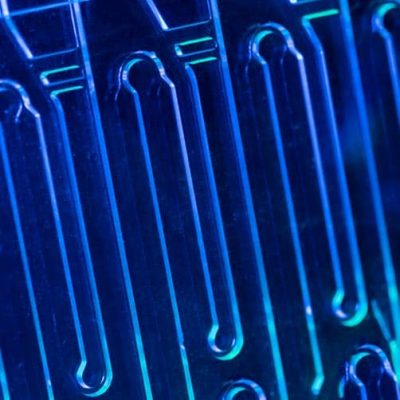

Structure sizes

Even if the shapes are subject to small variance in injection molding processes, even the smallest changes can have a major effect on the function. With our testing systems, we record structural variables such as channel widths for in-vitro diagnostics in order to minimize variances in flow properties and volume.

Defects

A variety of factors such as inclusions, diesel effect, dark spots, weld lines and streaks can have a direct influence on the functional elements of the molded parts. Depending on the inspection task, we record the surfaces and evaluate the data using classic and AI-based vision tools to detect the smallest defects.

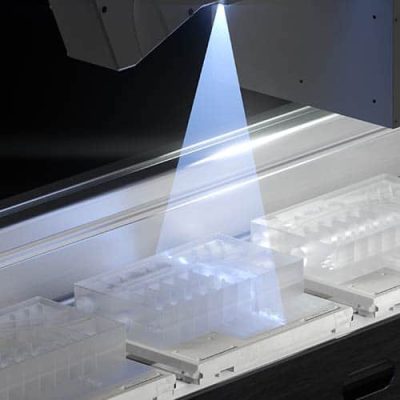

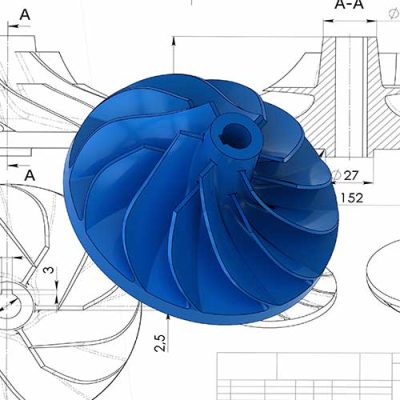

3D shape

If the dimensional accuracy of shapes, functional surfaces or contact points needs to be checked in 3D space, MABRI.VISION offers testing systems with high-precision profile cut sensors. Thanks to the short-wave blue laser, the measuring method achieves repeatability of up to 0.3µm. Almost any material and surface texture can be tested in this way.

silicone

Silicone has many applications in medical technology due to its material properties: highly flexible, long service life and biologically well tolerated. This presents manufacturing technology with many challenges. We use our computer vision system to check silicone components for microdefects, shape and inclusions.

2D code, data matrix

In the process, a large number of 2D codes, e.g. Capturing data matrix codes at different working distances can be challenging for classic readers. MABRI.VISION has developed a platform for 2D codes (QR code, data matrix code) that is optimized for throughput and reading rate.

Cavity number

If subsequent production processes or product quality depend on the cavity, the cavity number must be recorded at crucial points. MABRI.VISION offers vision solutions that can reliably record the cavity number through smart lighting concepts and deep learning.

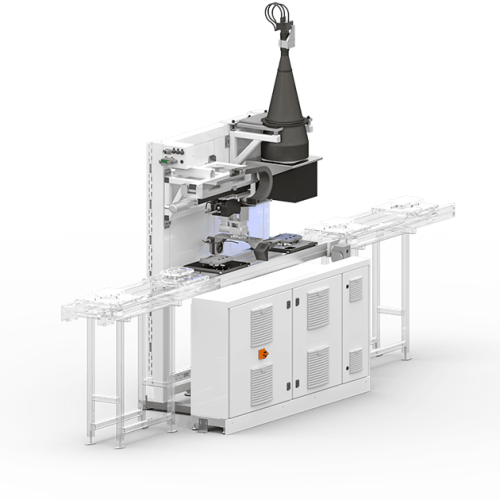

Our solutions for testing injection molded components

MABRI.VISION specializes in the development and implementation of complete vision solutions for use in production and research. Whether 100% testing directly on the product carrier system or in the clean room: by combining different high-performance optics, we meet your individual testing requirements.

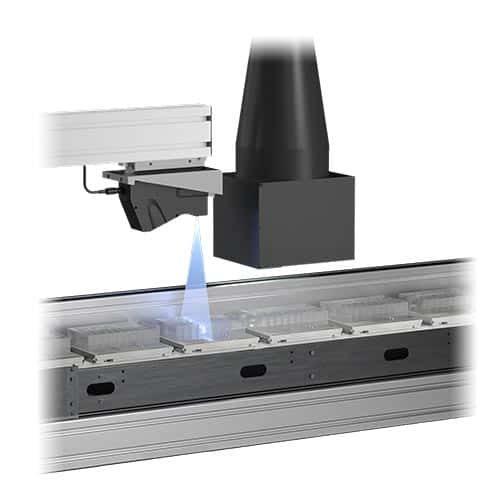

Testing on the goods carrier system

Combination of 2D and 3D tests for comprehensive 100% inline component measurement on the product carrier.

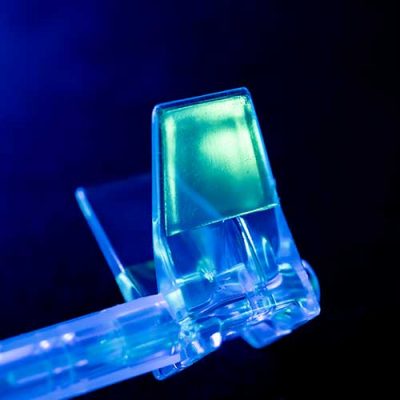

Inline high-speed microscopy

Our high-speed microscopy platform enables the smallest injection molding structures to be examined at the same time as the process.

Computer Vision 2D/3D

Are you looking for a solution to be integrated into your process? We offer a wide range of vision solutions.

Testing on the rotary clock

Our rotary testing system enables a variety of tests in the smallest of spaces, with manual or automatic loading.

Applications and implementations for injection molded parts

Microstructures In Vitro Diagnostics

On injection molded components for in-vitro diagnostics (digital PCR), we use our high-speed microscope to inspect channel closures, channel structures, patency, filling points, defects, particle entry and flatness at up to 1 million test points per component.

Plug connections and contacts

In the process (high-speed) we check connector housings for possible defects using telecentric matrix cameras. We also record the presence, sway and position of contacts in time. For products with variants, we check the coding and locking devices.

3D component inspection | Medical technology

Using high-precision profile cutting sensors, we record the 3D shape of medical components during the process and check for micro-defects and the smallest shape deviations.

Micro-defects in silicone sealing rings

The sealing properties of silicone rings can be affected by defects and process-related errors such as burr formation. Using a combination of 3D profile cutting and camera technology, we check silicone rings for micro-defects and dimensional accuracy.

Cavity number capture

Due to the tool or the material, the cavity numbers can be very faint and therefore difficult to read. With optimized lighting and AI, our vision system reliably reads the number of cavities during the process, even with the slightest differences in contrast.

Why MABRI.VISION

MABRI.VISION builds and develops high-quality machine vision solutions and modular testing systems for your production processes. Our modular system enables us to provide solutions for your testing tasks quickly and efficiently.

Innovative solutions, our passion!

Innovative solutions, our passion!

Innovation is the foundation for continuous growth in modern industry. We live this out every day and begins in the minds of our team of experts. The focus is always on the benefits and requirements of our customers. We passionately implement testing processes that range from AI-based computer vision solutions to 100% inline component measurement of sophisticated products. We rely on the latest generations of advanced technologies for our measurement technology. With this philosophy we want to make production processes more efficient and dynamic.

AI, processing, control - one software platform

AI, processing, control - one software platform

With the goals of Industry 4.0 and a continuous improvement process, the demands on test automation, interfaces and efficient evaluation algorithms are increasing. We at MABRI.VISION have recognized this trend and are taking it one step further. Our software team develops modular software platforms that combine all the components of modern testing systems. If necessary, we can expand evaluation algorithms with neural networks, map fast interfaces to system controls and integrate audit trails, batch reports, history graphs or databases as required.

A strong team, always there for you.

A strong team, always there for you.

As a customer, you are always at the forefront for us. Our team of vision experts, construction, software development, electrical, assembly and support is always there for you. Thanks to modern business processes and IT solutions, speed is a central goal. With our service solutions including 24/7 support, we support your production with efficient solutions.

End-to-end solutions, everything from a single source.

End-to-end solutions, everything from a single source.

You think in processes, we think in solutions: that's why we offer our customers turnkey testing systems that can be seamlessly integrated into your production processes. Our experts advise on planning and design at the beginning of a project. If technologies need to be evaluated, we carry out feasibility studies and inline tests. At MABRI.VISION we offer system design, programming and automation from a single source. We can optimize complex evaluations and tests directly with the system control and all customer interfaces.