Medical technology, pharmaceuticals, life sciences

High-precision 3D surface inspection system MV.EYE CR1

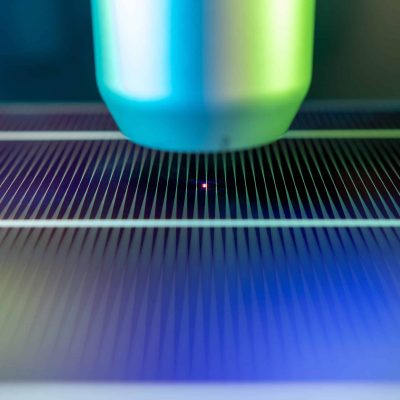

The MV.EYE CR1 inspection system makes it possible to scan the surfaces of products and components quickly and with high precision using a 3D chromatic confocal line sensor. With 192 measuring points in a line and a measuring frequency of up to 6,000 Hz, even larger test areas with a very high point density can be scanned quickly. Testing processes that require up to several hours with classic confocal point sensors can be implemented in minutes with the new MV.EYE CR1 testing system.

3D surface inspection with 20nm resolution

The areas of application range from surface testing and shape testing of wafers, defect testing and roughness testing on metal parts or shape testing of precise injection molded components to gap dimension testing in the assembly processes of premium products. If the z-measuring range of the sensor is not sufficient, it can be expanded almost as desired by moving the sensor vertically.

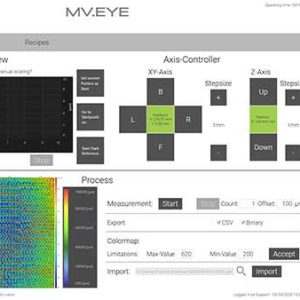

The stand-alone testing system with integrated controller and granite table is particularly suitable for use in testing laboratories, but can also be operated directly in production. Scanning processes can be automated in the software and saved in recipes. If a connection to an automated process is planned, this can be implemented via common industry interfaces. The MV.EYE CR1 testing system creates reports for quality assurance through a direct connection to the MountainsMap evaluation software from Digital Surf.

The testing system for automated production processes

Previous inspection processes with point sensors can be reduced from hours to minutes with the new MV.EYE CR1 platform. The generated 3D surface data achieve a resolution of 20nm in z. Thanks to an intelligent and modular combination of different high-performance optics, a wide range of tests can be carried out, making the test system suitable as a reliable complete solution in various areas of application.

.

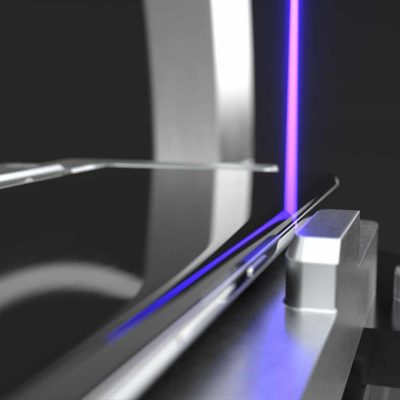

chromatic line sensor

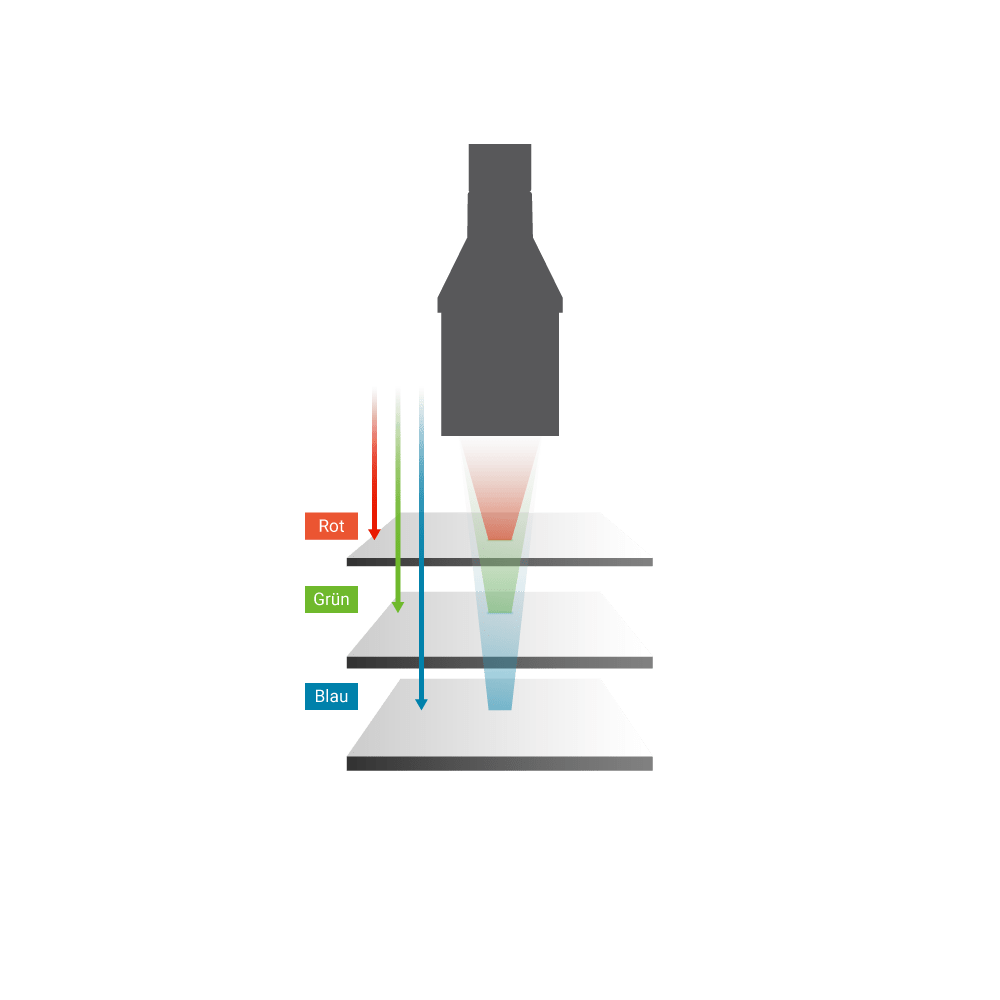

In terms of measuring principle, a chromatic confocal line sensor behaves like a classic confocal point sensor. The line layout allows 192 measuring points to be recorded simultaneously, which enables very high measuring speeds.

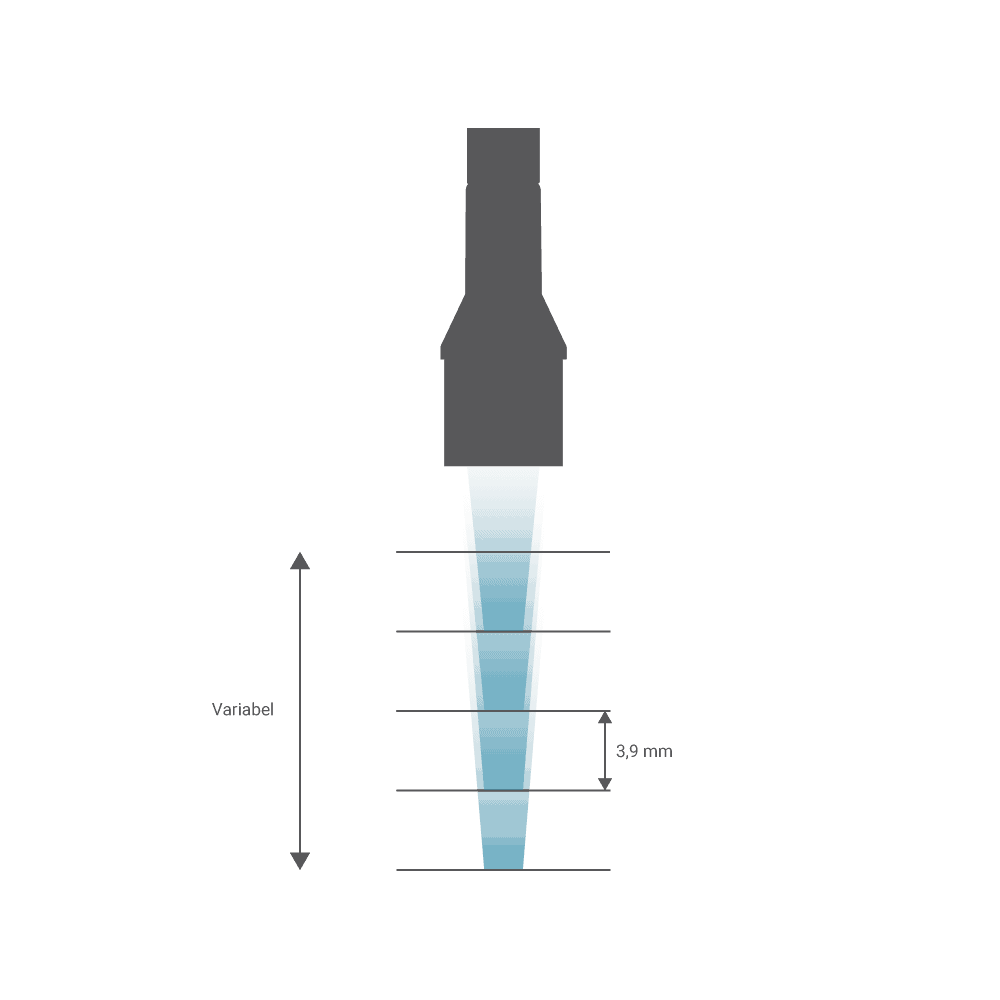

extreme Z measuring range

The Z measuring range of the MV.EYE CR1 testing system ranges from 500 µm to 3mm depending on the measuring head and can be further increased and adapted to your testing requirements by flexible scaling of the Z axis.

Check large areas quickly

With 192 measuring points in a line and a measuring frequency of up to 6,000 Hz, even larger test areas with a very high point density can be scanned quickly. The portal system scans 200 x 200 mm² as standard and can be expanded as required.

Automated processes

The stand-alone testing system with integrated controller and granite table is particularly suitable for use in testing laboratories, but can also be operated directly in production. Scanning processes can be automated in the software and saved in recipes

Connection to Mountains Map

The MV.EYE CR1 testing system creates reports for quality assurance through a direct connection to the MountainsMap evaluation software from Digital Surf. The evaluation options range from geometric tests to roughness measurements.

The MABRI.VISION inspection system MV.EYE CR1 is characterized by the precise inspection of large surfaces in the shortest possible time. The maintenance-free and robust sensor carries out reliable distance and thickness measurements and is designed for industrial use.

The Z measuring range of the MV.EYE CR1 testing system ranges from 500 µm to 3mm depending on the measuring head and can be further increased and adapted to your testing requirements by flexible scaling of the Z axis.

Thanks to the modular structure, the axes of the MABRI.VISION measuring system and their dimensions can be scaled and designed as required. A granite table is used for maximum dampening.

The MABRI.VISION testing system MV.EYE CR1 can be smoothly integrated into your production processes. We provide the necessary software interfaces and support you in automating your testing process.

The use of a chromatic confocable sensor enables extremely high measuring speeds. Up to 2,000 lines can be checked per second. With up to 192 measuring points / line, a measuring rate of 384,000 points / second is achieved.

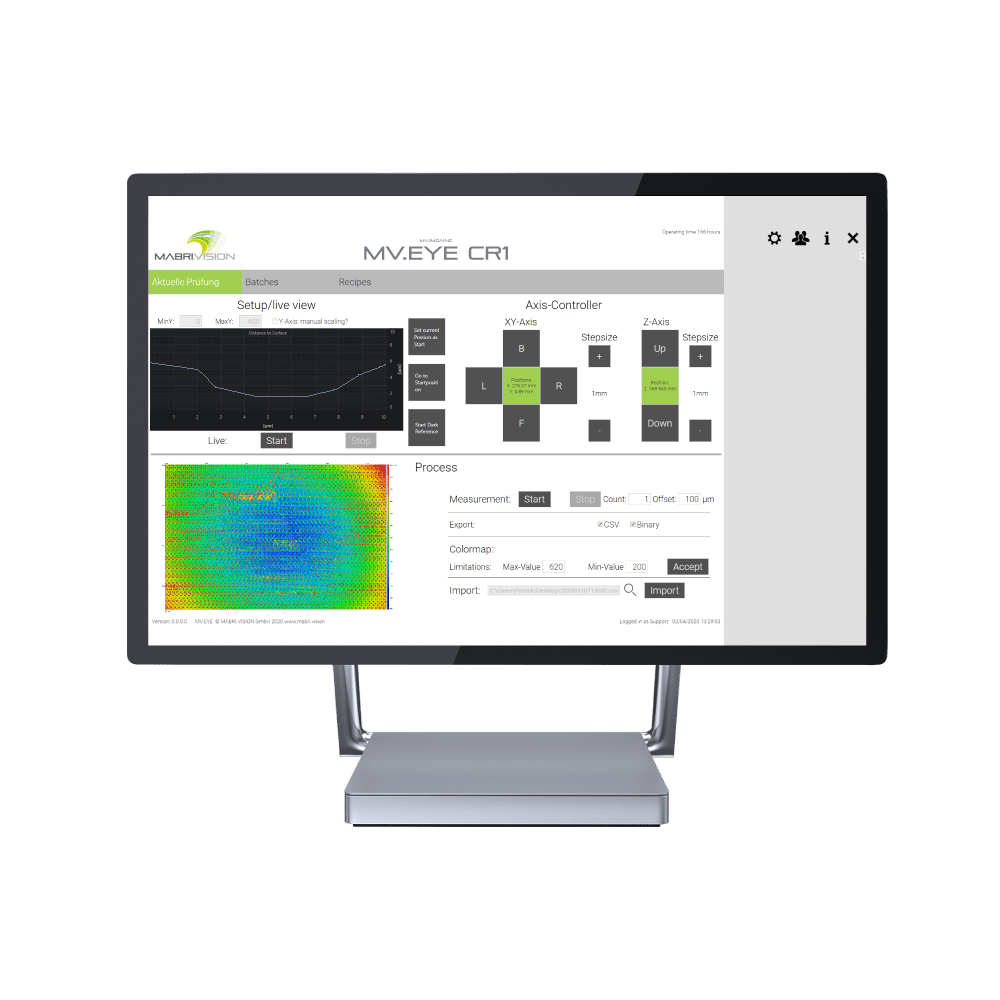

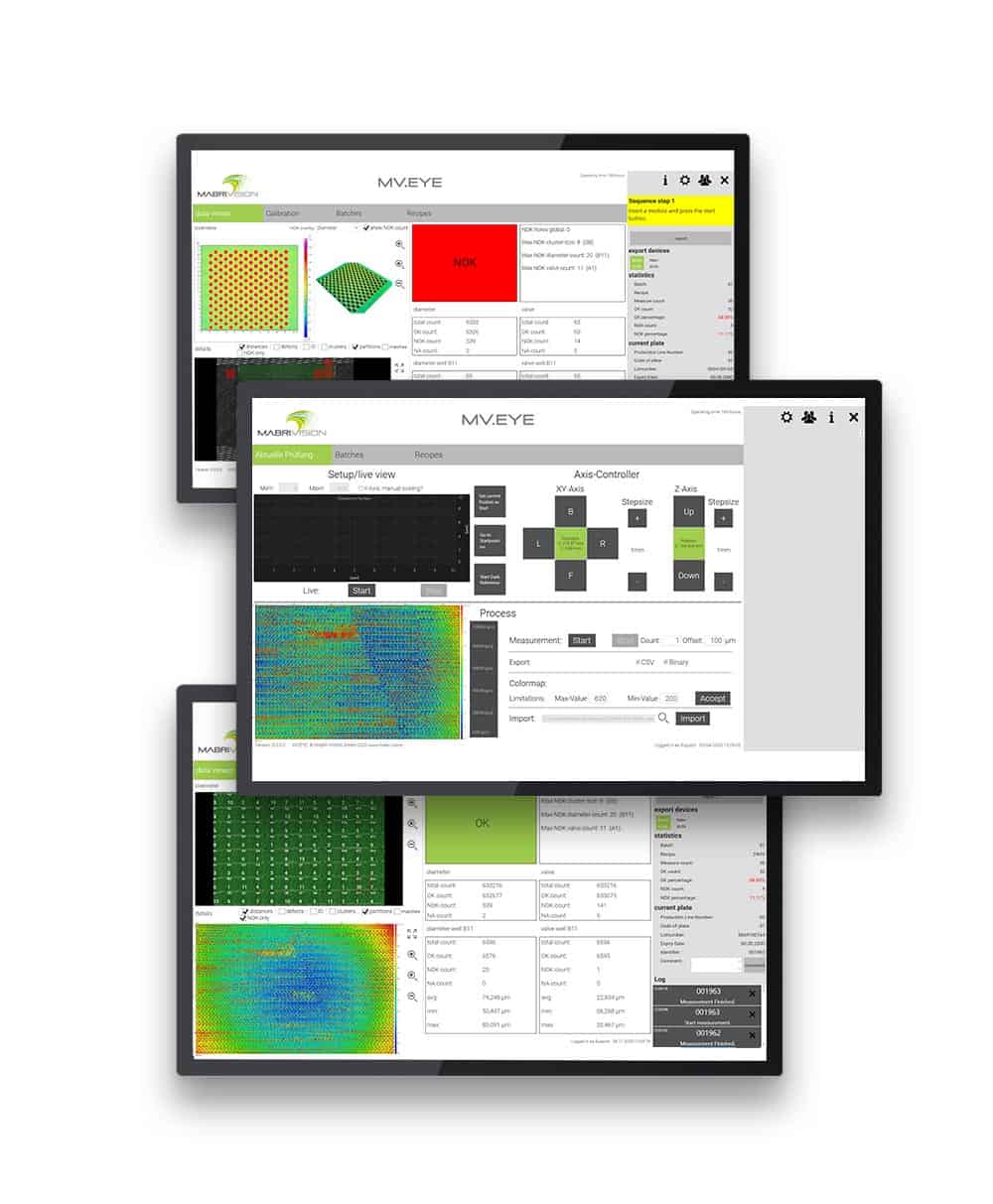

The MABRI.VISION software MV.IMAGING is characterized by intuitive operation and uncomplicated feedback. Extensive interfaces are available to the user. The software modules are designed for automated testing.

software

Modular

The MABRI.VISION software is also designed to be modular. In addition to a variety of standard modules, we are happy to expand the software with suitable modules for your application. All common interfaces are available for seamless integration into your production process.

Databases

The MV.IMAGING software supports your quality assurance through the use of databases for production orders and recipes. The database interface is based on the specific requirements of your tests and evaluations. All data can be exported as structured test reports in .csv, .xls or .pdf format.

Statistics/evaluation

Our software platform offers a variety of visualization options. You maintain an overview of production processes and quality assurance through meaningful statistics. Our software experts are familiar with the specific requirements of different industries and design the software for process support using insightful key figures and useful tools such as good part counters, error and measurement image memories and advance warning limits.

Universal: can be used in a variety of ways.

Medical technology

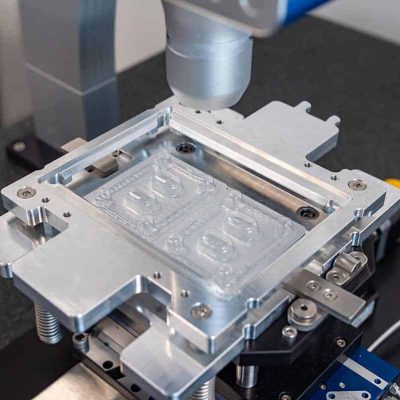

In the field of medical technology, the MV.EYE CR1 testing system is used to check microstructures in molded plastic components due to its fast measuring process.

Semiconductor technology

The MABRI.VISION inspection system MV.EYE CR1 can be optimally used for wafer inspection. Large surfaces can also be recorded in a very short time.

Tool making

By using chromatic-confocal sensors, the MV.EYE CR1 testing system enables high-precision testing of molds during production cycles.

Application examples

MABRI.VISION builds and develops high-quality machine vision solutions and modular testing systems for your production processes. Our modular system enables us to provide solutions for your testing tasks quickly and efficiently.

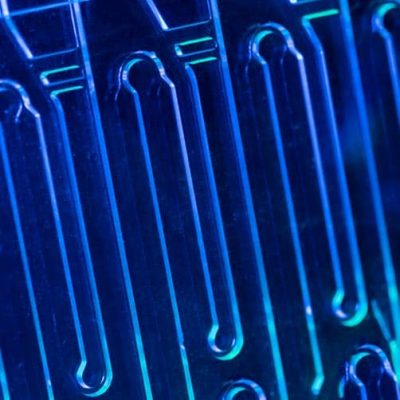

Lab on a chip

MV.EYE CR1 is used in the field of testing microstructures and microfluidics. Micro and macro defects on injection molded structures are detected and evaluated. This allows cell culture vessels and slides to be tested at high speed.

Gap check on cell phone displays

The test system is suitable for testing gaps between the display and the housing. Regardless of whether it is rounded "edge" displays or conventional displays, the MV.eye CR1 test system is also able to recognize the smallest target deviations, both inline and offline.

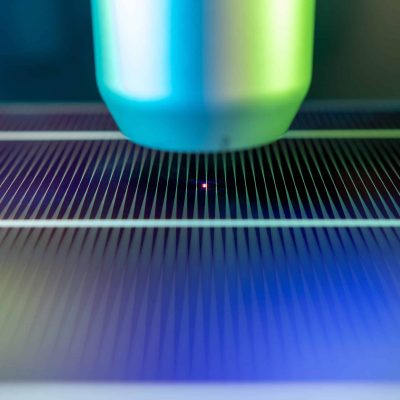

Fine metal masks for OLED production

Detection of contamination and defects on FMMs. The test takes place before the first use and between individual usage cycles and cleaning.

wafer warp

Inline and offline detection of wafer warp, defects and contamination with connected real-time evaluation.

Roughness test

Inline and offline roughness testing on medical technology products such as screws for dental implants and artificial joints.

Specifications

Test

| Number of points per line | 192 |

| Scan frequency | 2,000 Hz (optionally 6,000 Hz) |

| Measuring rate | up to 384,000 points/second |

| Measuring spot diameter | from 2 µm |

| Lateral resolution | from 1 µm |

| Axial resolution | from 20 nm |

| Scan area | 200x200mm² |

| Line width sensor | 0.96mm to 4.78mm |

| Z measuring range individual measurement | 200µm - 4.78mm |

| Z measuring range | up to 3mm |

Interfaces and software

| Interfaces | ProfiNet, Ethernet |

| interface | 24 inch monitor, touch |

| software | MV.IMAGING + CR module |

| operating system | Windows 10 |

Attachment

| operating temperatur | 10° to 40° |

| rated capacity | 2.3kW |

| care | 230 V, 10 A |

| Sensor protection class | IP50 |

| Dimensions (W x D x H) | 1,000mm x 800mm x 1,500mm |

| Weight | 350kg |

Why MABRI.VISION

MABRI.VISION builds and develops high-quality machine vision solutions and modular testing systems for your production processes. Our modular system enables us to provide solutions for your testing tasks quickly and efficiently.

Innovative solutions, our passion!

Innovative solutions, our passion!

Innovation is the foundation for continuous growth in modern industry. We live this out every day and begins in the minds of our team of experts. The focus is always on the benefits and requirements of our customers. We passionately implement testing processes that range from AI-based computer vision solutions to 100% inline component measurement of sophisticated products. We rely on the latest generations of advanced technologies for our measurement technology. With this philosophy we want to make production processes more efficient and dynamic.

AI, processing, control - one software platform

AI, processing, control - one software platform

With the goals of Industry 4.0 and a continuous improvement process, the demands on test automation, interfaces and efficient evaluation algorithms are increasing. We at MABRI.VISION have recognized this trend and are taking it one step further. Our software team develops modular software platforms that combine all the components of modern testing systems. If necessary, we can expand evaluation algorithms with neural networks, map fast interfaces to system controls and integrate audit trails, batch reports, history graphs or databases as required.

A strong team, always there for you.

A strong team, always there for you.

As a customer, you are always at the forefront for us. Our team of vision experts, construction, software development, electrical, assembly and support is always there for you. Thanks to modern business processes and IT solutions, speed is a central goal. With our service solutions including 24/7 support, we support your production with efficient solutions.

End-to-end solutions, everything from a single source.

End-to-end solutions, everything from a single source.

You think in processes, we think in solutions: that's why we offer our customers turnkey testing systems that can be seamlessly integrated into your production processes. Our experts advise on planning and design at the beginning of a project. If technologies need to be evaluated, we carry out feasibility studies and inline tests. At MABRI.VISION we offer system design, programming and automation from a single source. We can optimize complex evaluations and tests directly with the system control and all customer interfaces.