MV.EYE BI1

Inline 3D-Formprüfung von Backwaren.

MV.EYE BI1

Inline 3D-Formprüfung von Backwaren.

Das MABRI.VISION Prüfsystem für die 3D-Formprüfung ermöglicht eine vollumfängliche Prüfung der Länge, Breite und Höhe von Backwaren. Durch den Einsatz von 3D-Profillasern werden hochauflösende 3D-Informationen der Prüfobjekte generiert.

Mit bis zu 40.000 Einheiten/Std lässt sich die Prüfung in Ihren Produktionsprozess einbinden. Die Anzahl der eingesetzten 3D-Profilsensoren wird an die Anforderungen Ihrer Produktion angepasst: so kann auch auf breiten Förderbändern eine lückenlose Prüfung sichergestellt werden.

Anwendungen

- Prüfung von Backwaren

Prüfungen

- Form

- Höhe

- Präsenz

- Anzahl

Branchen

- Lebensmittel

Behalten Sie durch die präzise Erfassung aller produzierten Einheiten die Übersicht über Ihre Produktion und erkennen Sie Optimierungspotenziale.

Unser Prüfsystem erfasst neben den exakten Längen und Breiten von Backwaren den Kernversatz und prüft, ob Abweichungen im Toleranzbereich liegen.

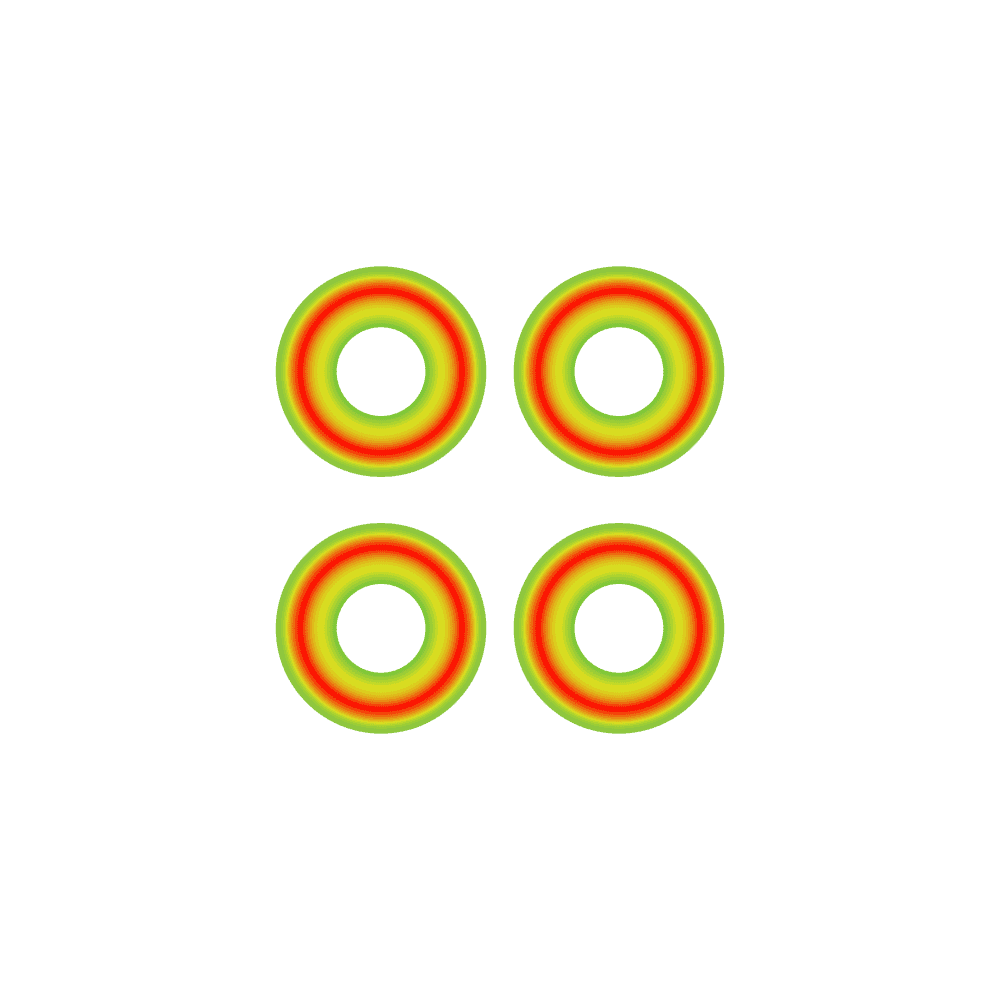

Die Höhe der Prüfobjekte wird durch 3D-Profillaser erfasst. So kann geprüft werden, ob die Backwaren gleichmäßig aufgegangen sind und die Sollmaße erfüllen.

Unsere Anlage ermöglicht die Prüfung vielfältiger Variationen von Backerzeugnissen. Das gegenüber Oberflächenstrukturen robuste Sensorverfahren liefert hochpräzise Ergebnisse, unabhängig von Farbe und Struktur der Prüfobjekte.

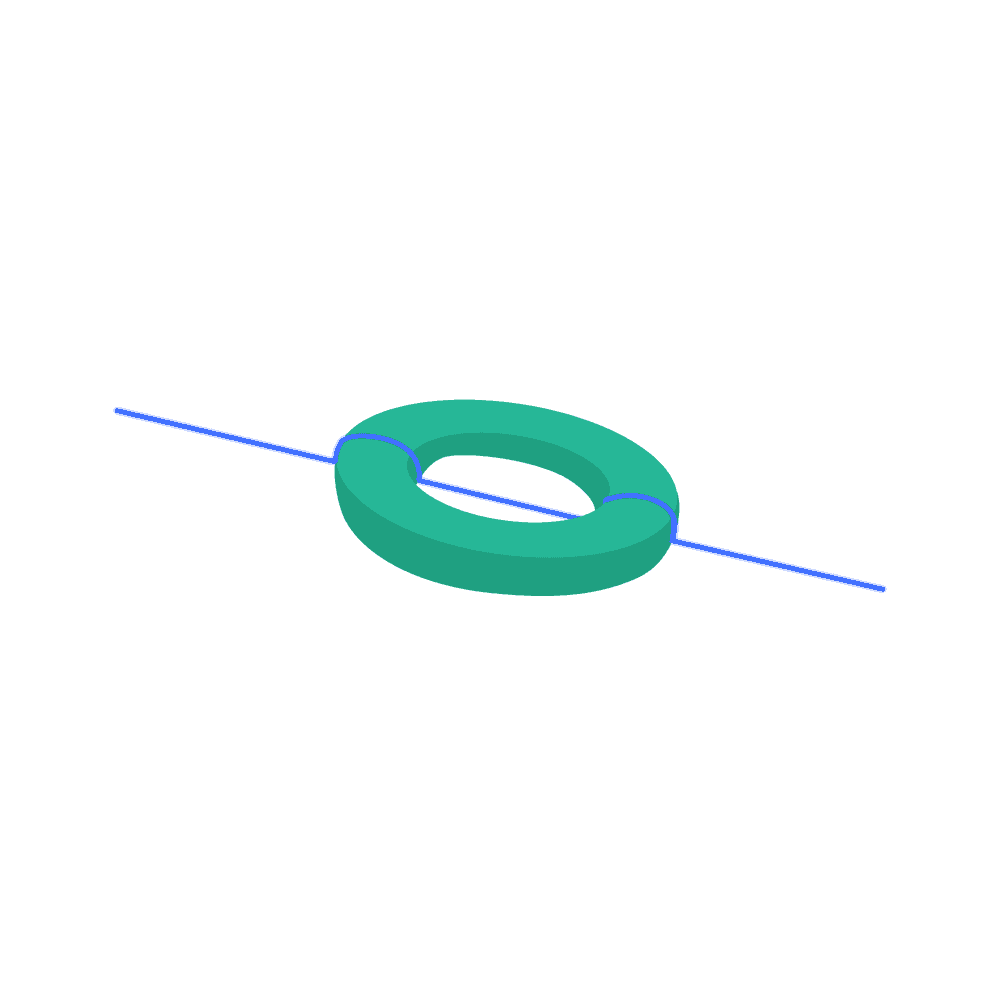

Dank der optischen Sensortechnologie unseres Prüfsystems können beliebige Formen und Prüfmerkmale erkannt werden. Prüfen Sie vielfältiges Gebäck, von Bagels über Croissants bis hin zu Brötchen verschiedenster Ausprägungen.

Für eine schnelle Inline-Prüfung setzen wir auf den Einsatz von 3D-Profillasern, welche 3D-Informationen über die Prüfobjekte liefern und eine berührungslose und kompromisslose Qualitätskontrolle ermöglichen.

Spezifikationen.

PRÜFUNG

| Art der Prüflinge | Backwaren |

| Geschwindigkeit | bis zu 40.000 Einheiten / Std |

| Prüfungen | Länge, Breite, Höhe, Volumen, Form |

| Arbeitsabstand | 980 ± 400 mm |

| Linienbreite | 300 - 720 mm |

| Wiederholgenauigkeit z-Achse | 10 µm |

| Wiederholgenauigkeit x-Achse | 25 µm |

| Lichtquelle | 405 nm (blau), Laser |

ANLAGE

| Maße (B x T x H) | (530 x 1.750 x 2.360) mm³ |

| Gewicht | 350 kg |

| Nennleistung | 1,9 kW |

| Versorgung | 100 - 240 V |

SCHNITTSTELLEN UND SOFTWARE

| Schnittstellen | ProfiNet, EtherNet, Digital I/O |

| Interface | 24 Zoll Monitor, Touch |

| Betriebssystem | Windows, Keyence |

| Software | MV.IMAGING, Keyence |

Universell: vielfältig einsetzbar.

BACKWAREN

Setzen Sie die MABRI.VISION Prüfanlage in der Produktion von Backwaren ein und erfassen Sie Form, Farbe und Struktur der Erzeugnisse – egal ob Bagel, Croissant oder Brötchen.

SÜSSWAREN

Die inline-fähige Prüfanlage MV.EYE BI1 lässt sich optimal zur Prüfung von Süßwaren, Pralinen oder Fruchtgummis einsetzen. Erhalten Sie zuverlässige Daten über Mengen und Formen.

OBST & GEMÜSE

Gewährleisten Sie auch im Bereich von frischen Lebensmitteln eine lückenlose Prüfung, unabhängig von Farbe oder Struktur. Ein 3D-Profillaser ermöglicht dabei Höchstgeschwindigkeiten.