Anwendung.

Flexibler Rundtaktprüfer.

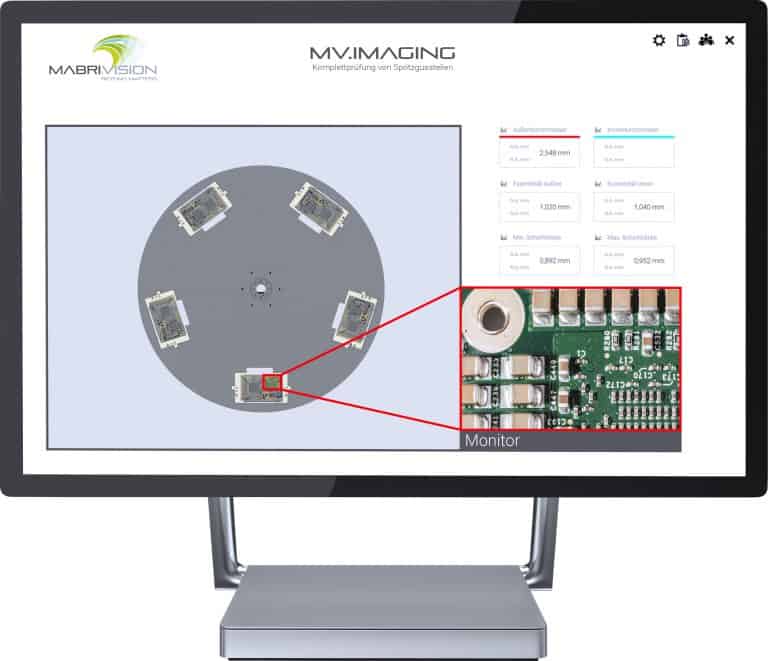

Prüfung komplexer Spritzgussteile für Zulieferer der Elektromobilität

Anforderung

Die Vielfalt der in der Automobilindustrie zu prüfenden Bauteile reicht von Steckern und Platinen bis hin zu komplexen Spritzgussteilen und Kunststoff-Metall-Verbunden. Der Prüfvorgang eines Bauteils mit knapp 70 Prüfmerkmalen kann dabei mit einem herkömmlichen Messgerät bis zu vier Minuten in Anspruch nehmen. Für eine fortlaufende Prüfung ist eine inlinefähige Anlage mit einem durchschnittlichen Messzyklus von drei Sekunden nötig.

Anwendungen

- Vollumfängliche Qualitätskontrolle von Spritzgussteilen und Kunststoff-Metall-Verbunden in der Automobilindustrie.

Ziele

- Automatisierte Prüfanlage

- Inlinefähige Vision Lösung

- Prüfung von komplexen Bauteilen

- Prüfung im Takt der Produktion

- Erkennung von Oberflächendefekten

- Erkennung von Verschmutzungen

Kategorien

- Bildverarbeitung

- Qualitätssicherung

- Automobilindustrie

Technologien

- OCT

- Optisches Mikrometer

- Lichtschnittsensorik

- Mikroskopie

- TensorFlow

- Halcon

- Barcode Reader

Lösungen

- Rundtakttisch

- Multimodales Prüfsystem

- 3D-Prüfung mit Lichtschnittsensoren

- Präzise Höhenmessung mit optischem Mikrometer

- Prüfung von bis zu 200 Merkmalen im Takt

- Interface zur Visualisierung der Prüfung

Technische Daten:

- Hochauflösendes Kamerabild

- Optisches Mikrometer

- Triangulationssensor

- Schnittstellen (ProfiNet, Digital I/O)

- Datenbanken

- Datenfusion von 2D und 3D Messdaten

Vorteile.

Die Prüfanlage MV.EYE i2 ist ein flexibler Rundtaktprüfer und lebt von der Kombination aus verschiedenen Technologien – Bildgebung, Laser-Triangulation und optische Mikrometer. Was MABRI.VISION mit dieser Anlage bietet geht weit über präzise Messergebnisse und Schnelligkeit hinaus. Hinzu kommen Multimodalität, kundenspezifische und platzsparende Lösungen, hohe Skalierbarkeit und die Datenfusion von 2D und 3D Messdaten.

Prüfung im Produktionstakt

Eine inline-fähige Komplettlösung für eine vollumfängliche Qualitätskontrolle in Ihrer Produktion.

Multimodalität

Ein optimales Prüfergebnis durch die Kombination verschiedener Technologien.

Hohe Skalierbarkeit

Eine umfassende Prüfung im Takt der Produktion und auf Ihre Produktionsmengen angepasst.

Komplettprüfung von komplexen Spritzgussteilen

bis zu

bis zu

bis zu

Kontakt.

Benötigen Sie weitere Informationen über eine bestimmte Produktgruppe oder haben Sie eine konkrete Produktanfrage? Nutzen Sie unser Kontaktformular oder rufen Sie uns an.

- MABRI.VISION GmbH Dennewartstrasse 25 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision