Vision Services

Innovative solutions - our passion. MABRI.VISION develops and builds machine vision solutions and test systems for your production processes.

Our vision know-how.

TECHNOLOGIES

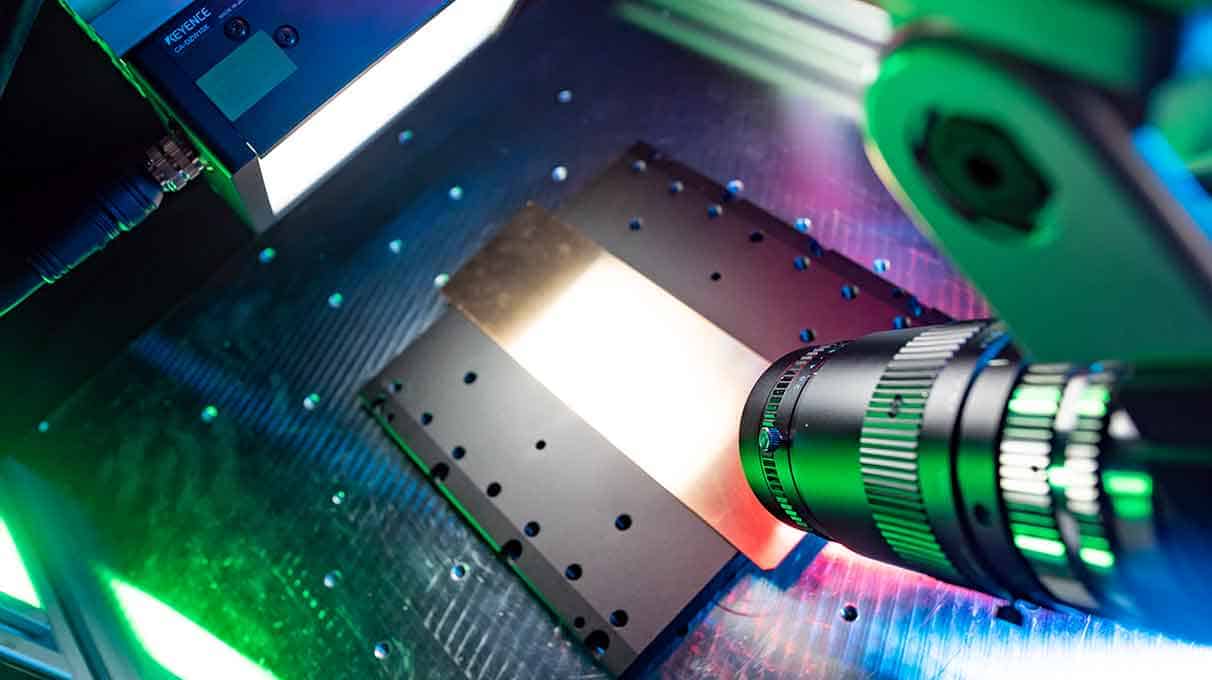

We adapt to your requirements. Our experts use your data to develop a concept for implementing the testing process. We have a wide range of state-of-the-art technologies at our disposal.

Integration & Service

We support you in installing and programming your vision testing process. Our in-house programming department ensures that your commissioning runs smoothly.

FEASIBILITIES

Which technology is best suited for your exam and how can it be implemented in the best possible way? We rely on freely available and special solutions to enable the required testing.

ADVICE & INTERPRETATION

Our experts will advise you quickly and competently. Following the design, the corresponding optical components are put together, tested and coordinated with one another.

Our technologies.

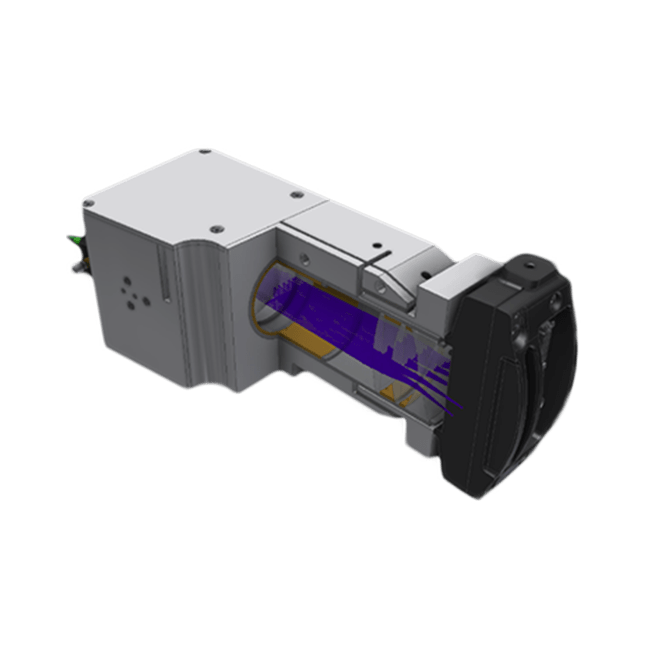

Point sensor and scanning

- surface

- Wall thickness

- Layer thickness

Line and matrix cameras

- Component measurement

- Shape & tolerances

- Defects

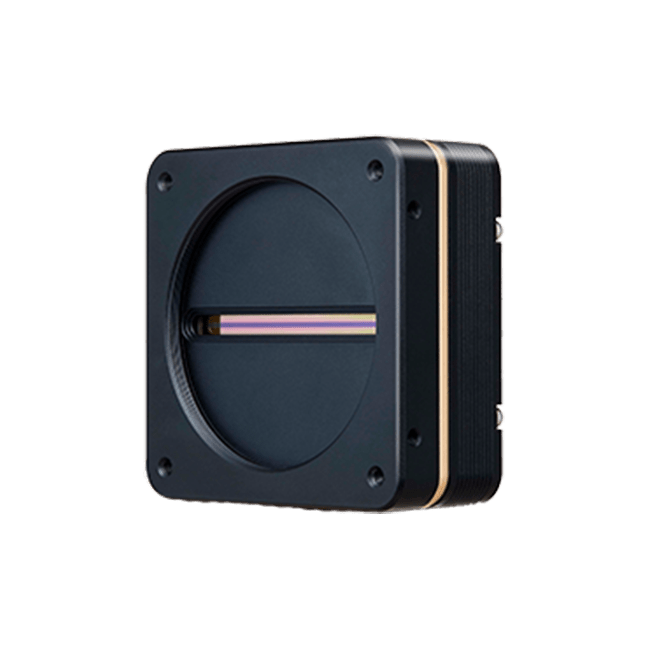

TDI high-speed microscopy

- presence

- Dimensional accuracy

- Defects

3D triangulation sensor

- 3D inspection

- Location & presence check

- Quirks & dents

3D structured light

- 3D presence

- Surface defects

- Foreign body detection

AI and neural networks

- Complex error patterns

- Large product variants

- Object detection

Optics design & simulation

- Ray paths

- Optimal images

- Compact beam shaping

Our platforms.

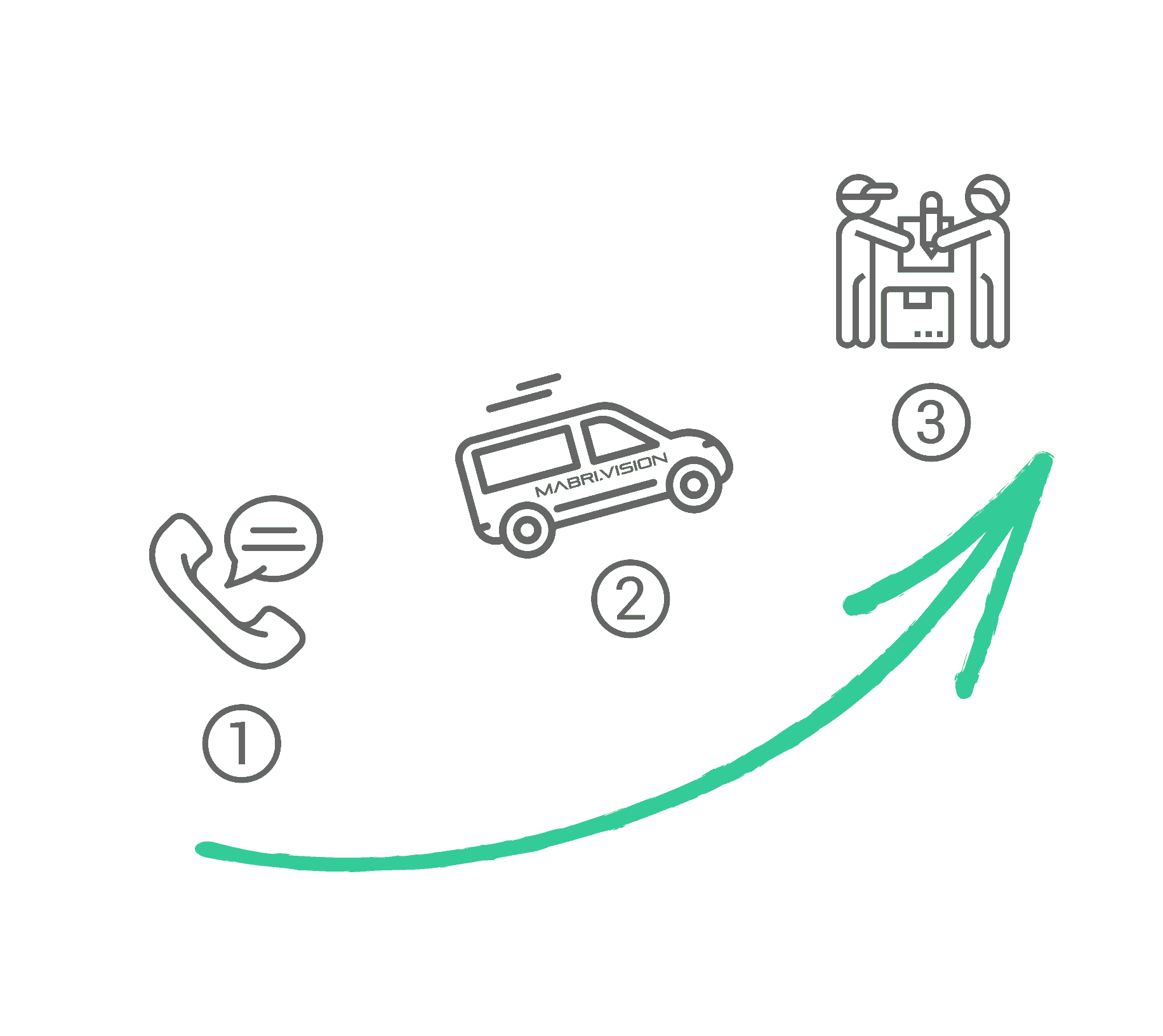

Integration & Service.

Do you need support when commissioning your machine vision system? Our experts will support you in installing and programming your vision testing process.

We offer services for various vision platforms. Including Keyence CV-X / XG-X and Halcon.

Our possible uses.

Daily assignments

- Hourly billing

- Short-term availability

- Commissioning & system troubleshooting

Multi-day assignments

- Based on effort or daily flat rate

- Commissioning

- Process optimization

Quotas

- From 5 days

- Available over 1 year

- Optional: guaranteed availability

Travel costs and expenses are billed according to expenditure.

Operation area.

We are active for you throughout Germany. We also offer integration services for your international locations upon request.

Feasibility studies.

Appropriate technology for testing.

Which technology is best suited for your exam? In our test laboratory we can use all common machine vision technologies to optimally design the camera, lens and sensors. We also have access to test devices from our partners through collaborations.

Optimal implementation of the testing process.

According to your specifications, we design the test setups so that production environments are simulated as realistically as possible. Our goal is to create the most robust and efficient testing process possible. Our team is also happy to take on complex challenges.

Comprehensive analysis of the possibilities.

A clear definition of boundary samples and test tasks is crucial for the implementation of the test process. We ensure that the dimensions are sufficient to ensure the subsequent performance of the testing process.

Advice and interpretation.

Optimal design and selection of the appropriate measurement method are crucial for a reliable machine vision solution. Only with correctly dimensioned components can the relevant features be reliably identified.

Benefit from our know-how in the planning and design of vision testing processes.

Applications.

-

electronics

Inline shape testing of plugs & connectors

Inline inspection system for testing plugs, connectors and pin headers with up to 1000 contacts/min.

-

Automotive, metal processing

Defect inspection on metal surfaces.

Fully automatic detection of the smallest quirks, dents and scratches on metal surfaces in the process.

-

Automotive, metal processing

Inline inspection of surface defects on metal pipes.

Testing of the interior chips, welding seams, indoor and outdoor phase and coat and outdoor areas in the process.

-

Medical

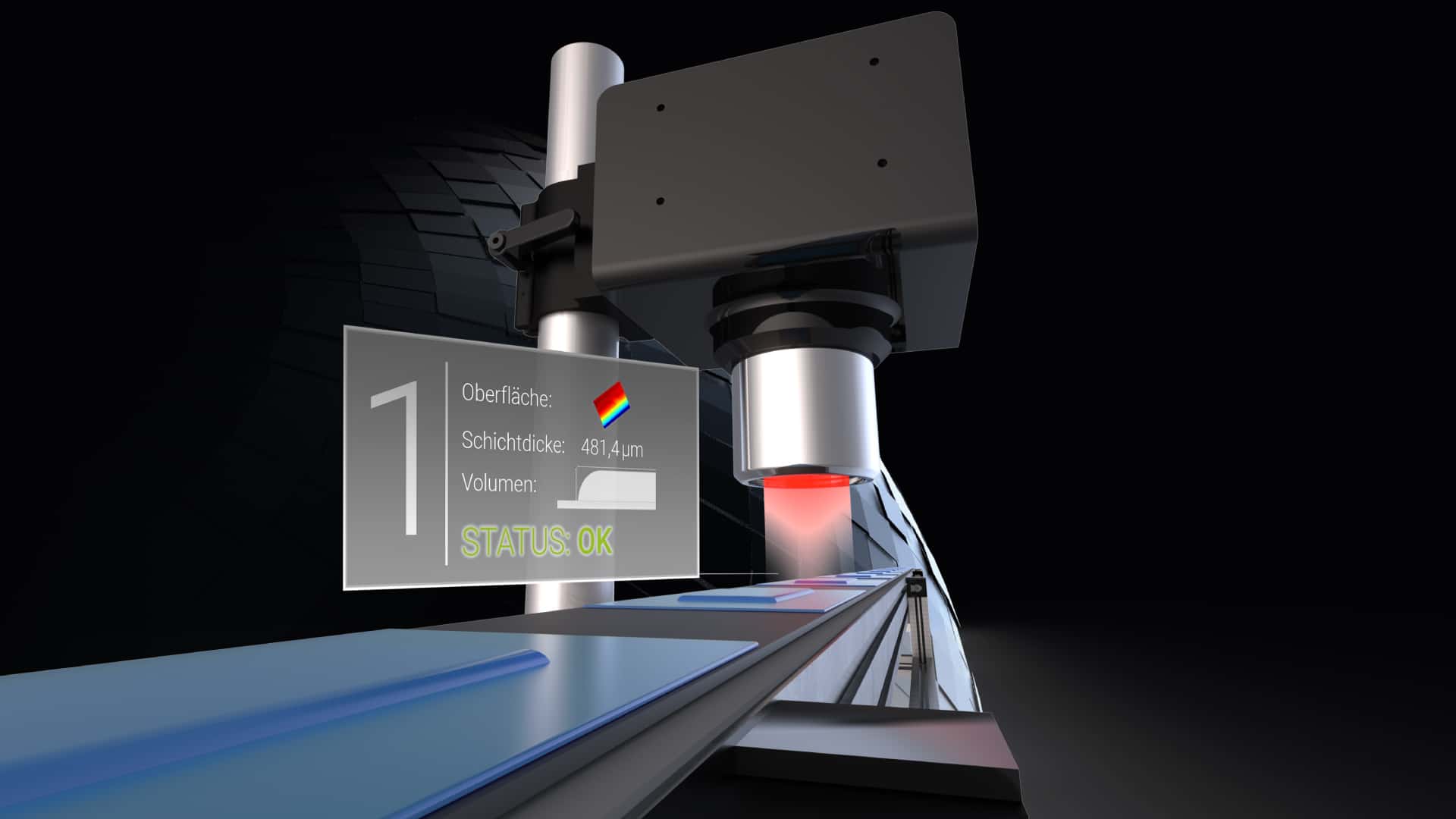

Inline layer thickness testing of plasters.

Inline test of multi-layered, transdermal paving.

Volume | Layer thickness | Form | Presence. -

Medical

360° inline hose testing.

Testing of interior and outer diameter, wall thickness and geometry of semi-transparent hoses.

-

Medical

Testing of microstructures

Fully extensive quality control of injection molding microstructures from medical technology.

-

Automotive

Testing complex injection molded parts

100%quality control of injection molding parts and plastic metal connected in the automotive industry.

-

Automotive

QR/Datamatrix reading bridge for tires

Examination of lasered or molved QR/DataMatrix codes with the help of a reading bridge.

-

Automotive, metal processing

Testing shape and defects of castings.

Test systems for the shape test of cast parts as well as the detection of surface pores and lunkers.

-

Groceries

Inline 3D shape inspection of baked goods.

3D form test of baked goods. Measurement of length, width, height and count in one round.

Information material.

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision