3D surface | Spacing | Layer thickness

MV.SENSE. We develop and integrate optical sensors for high-precision surface and wall thickness testing.

3D surface | Spacing | Layer thickness

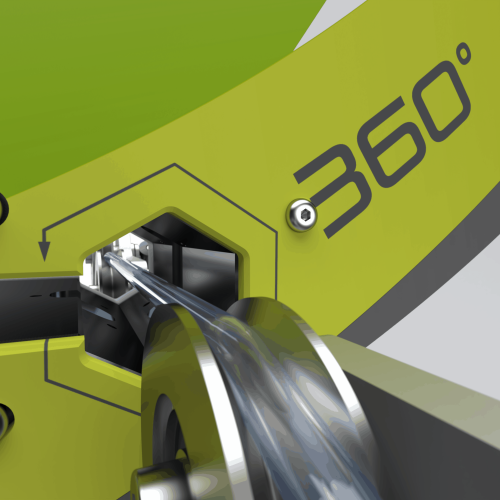

360° inline hose testing

Hose wall thickness testing system measures outer diameter, inner diameter and wall thickness in one measurement, completely without contact.

Chromatic confocal sensors

industrial OCT sensors

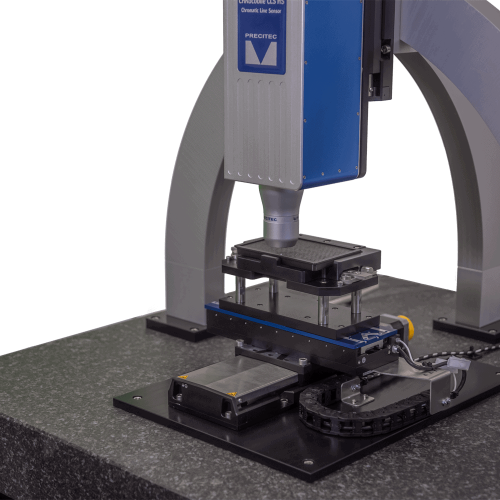

High-precision 3D surface inspection system MV.EYE CR1

optical inspection with the highest precision

Sensors for industrial applications

Our MV.SENSE sensors and sensor systems are designed for use in production environments. Test results are provided via Digital I/O or Profinet/Ethernet.

Non-contact and extremely precise

Do you want to inspect surfaces and wall thicknesses with micrometer precision? The OCT and chromatic confocal sensors we use are particularly suitable for high-precision inspection processes with large working distances.

We build solutions

We offer design, planning, and construction of sensor systems, testing systems, and testing processes – all from a single source. Do you need customized data analysis? Contact our team; we'd be happy to assist you.

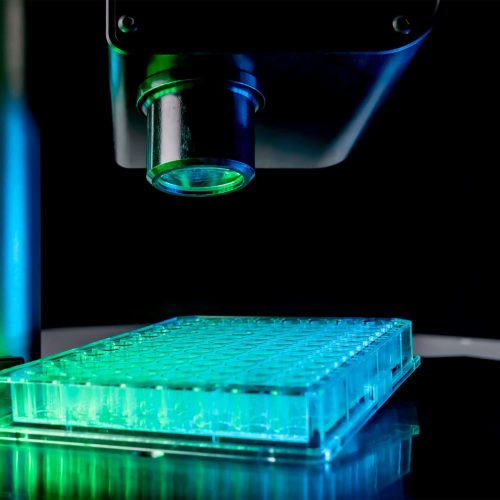

OCT sensors

The MV.SENSE series of interferometric sensors are specifically designed for industrial use.

Whether surface inspection or layer thickness measurement of translucent materials or volumetric analyses – the various scanning functions result in diverse applications, such as in the packaging technology, automotive, pharmaceutical and medical technology industries.

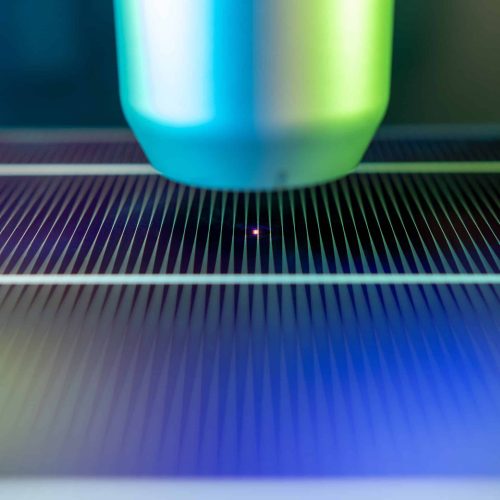

Chromatic confocal sensors

Chromatic confocal sensors can be flexibly used for surface measurements of a wide variety of materials. They are capable of performing precise distance and thickness measurements on reflective, transparent, semi-transparent, opaque, and diffuse materials.

MABRI.VISION enables, for example, the testing of gap dimensions in safety glass or seamless quality control in the packaging industry through the use of chromatic confocal sensors.

Feasibility studies

Suitable technology for your inspection

Which technology is best suited for your application? In our test lab, we can utilize all common machine vision technologies to optimally configure the camera, lens, and sensors. Furthermore, through collaborations, we have access to test equipment from our partners.

Optimal implementation of the testing process

Based on your specifications, we design the test setups to replicate the production environment as realistically as possible. Our goal is to create a robust and efficient testing process. Our team is happy to take on even complex challenges.

Comprehensive analysis of the possibilities

A clear definition of limit patterns and test tasks is crucial for the implementation of the testing process. Particular attention is paid to ensuring adequate dimensioning of all key components to guarantee subsequent performance in everyday industrial use.

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision