Medical technology, pharmaceuticals, life sciences

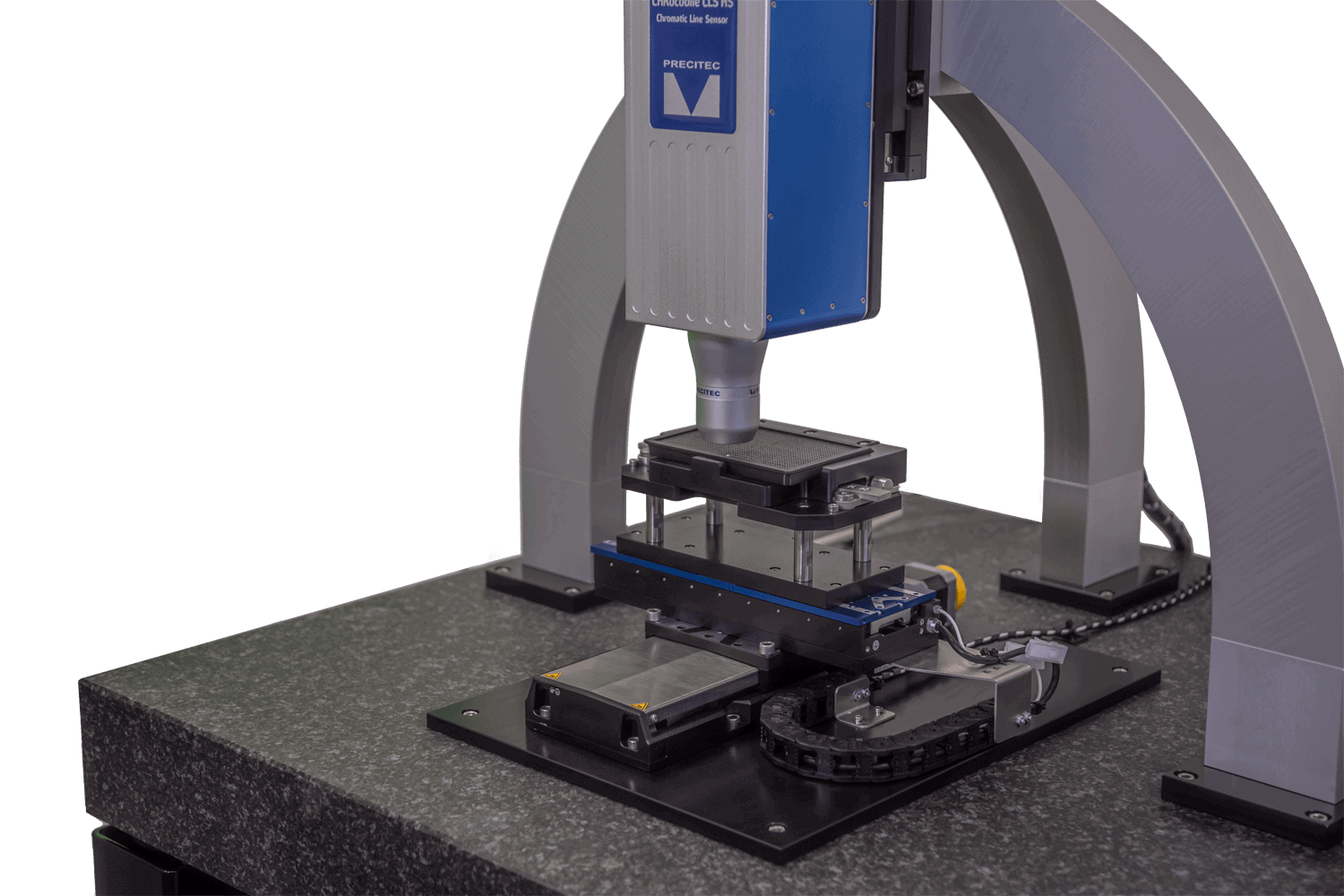

High-precision 3D surface inspection system MV.EYE CR1

3D surface inspection with 20nm resolution

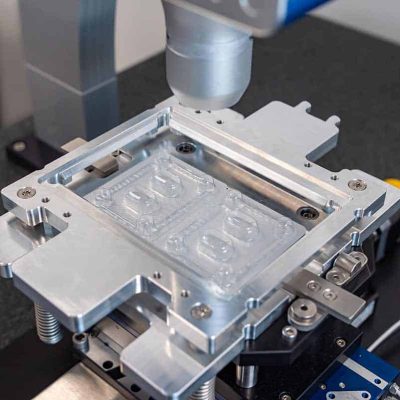

The applications range from surface and form inspection of wafers, defect and roughness testing on metal parts, and form inspection of precision injection-molded components to gap measurement during the assembly of premium products. If the sensor's z-measuring range is insufficient, it can be extended almost indefinitely by vertically adjusting the sensor.

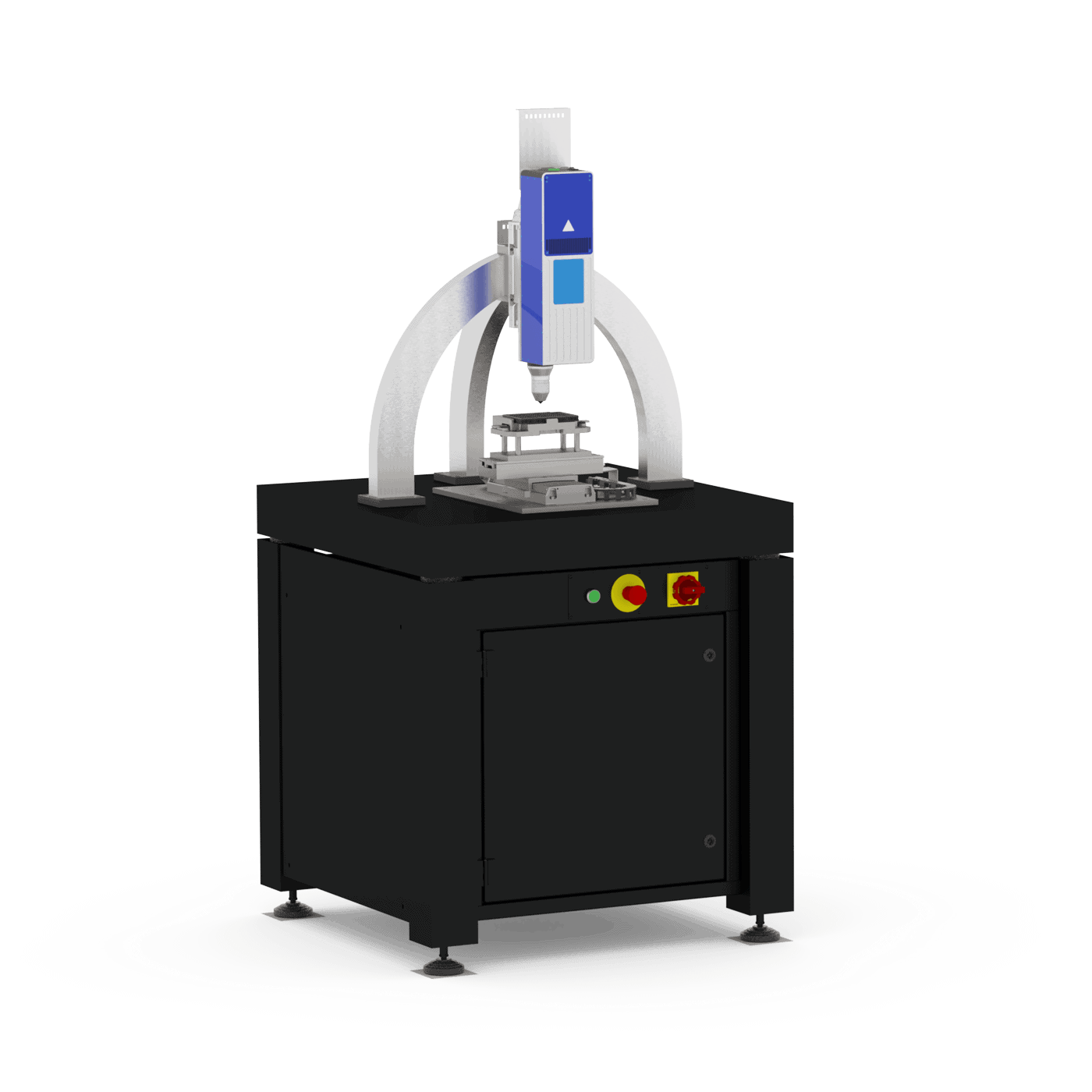

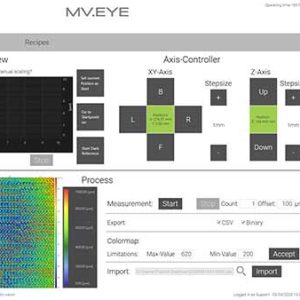

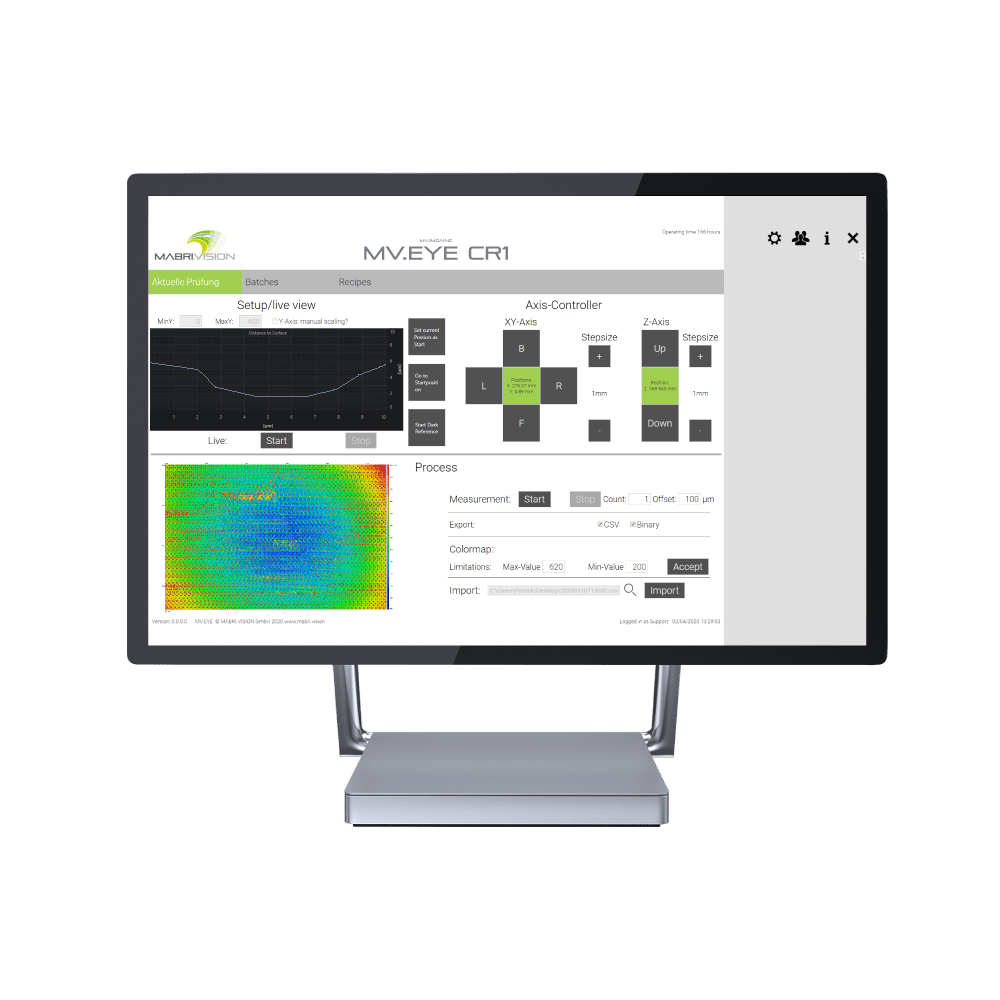

The stand-alone inspection system with integrated controller and granite table is particularly suitable for use in testing laboratories but can also be operated directly in production. Scanning processes can be automated and saved as recipes in the software. If integration with an automated process is planned, this can be implemented via standard industrial interfaces. The MV.EYE CR1 inspection system generates quality assurance reports through a direct connection to Digital Surf's MountainsMap evaluation software.

The testing system for automated production processes

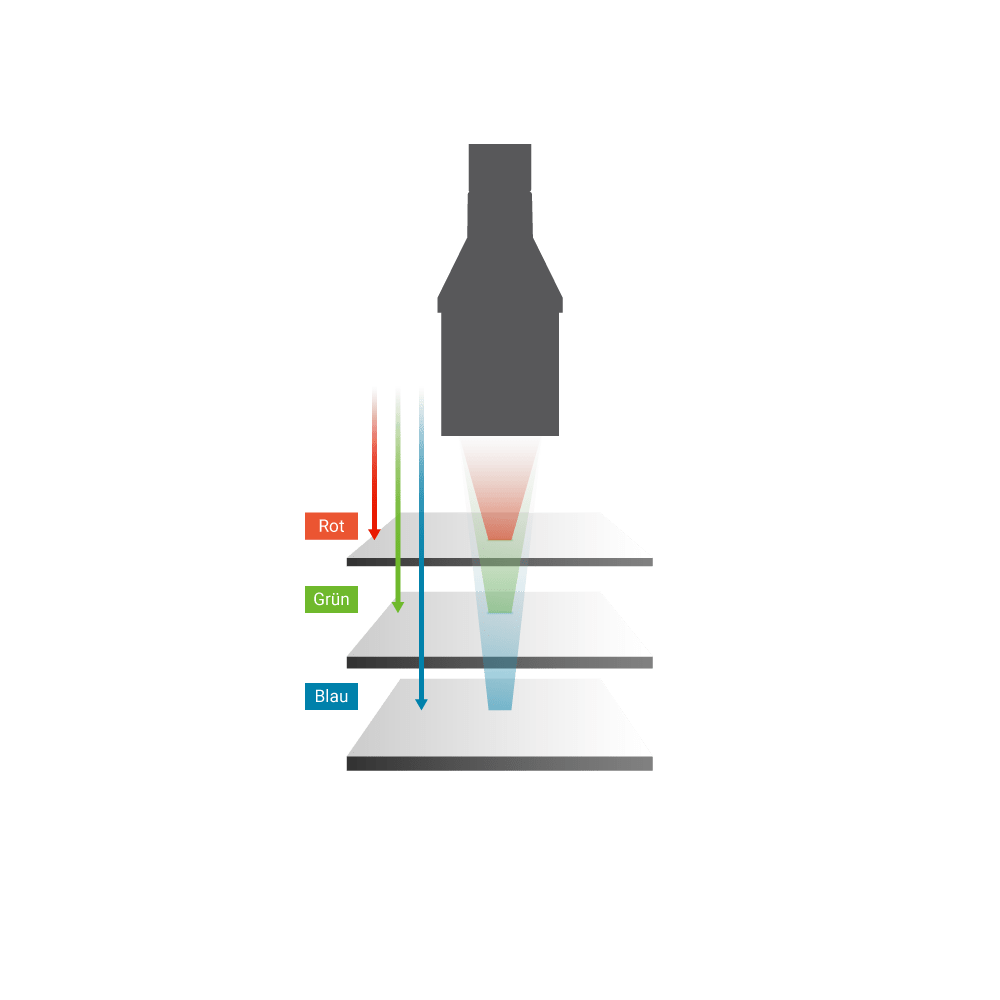

chromatic line sensor

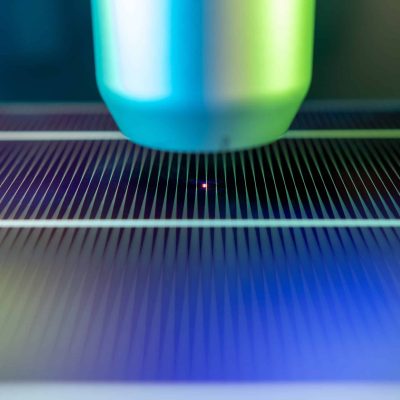

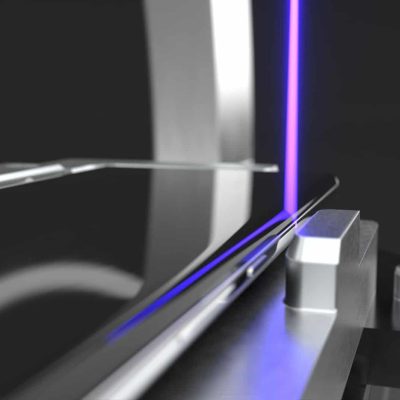

A chromatic confocal line sensor behaves in terms of measurement principle like a classic confocal point sensor. The line layout allows for the simultaneous acquisition of 192 measurement points, enabling very high measurement speeds.

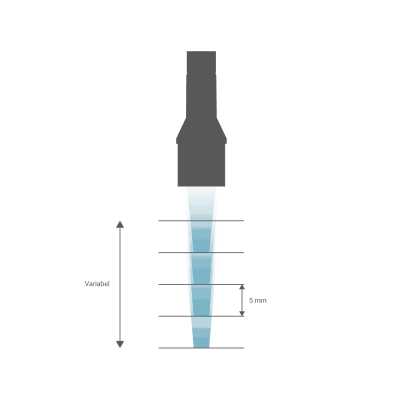

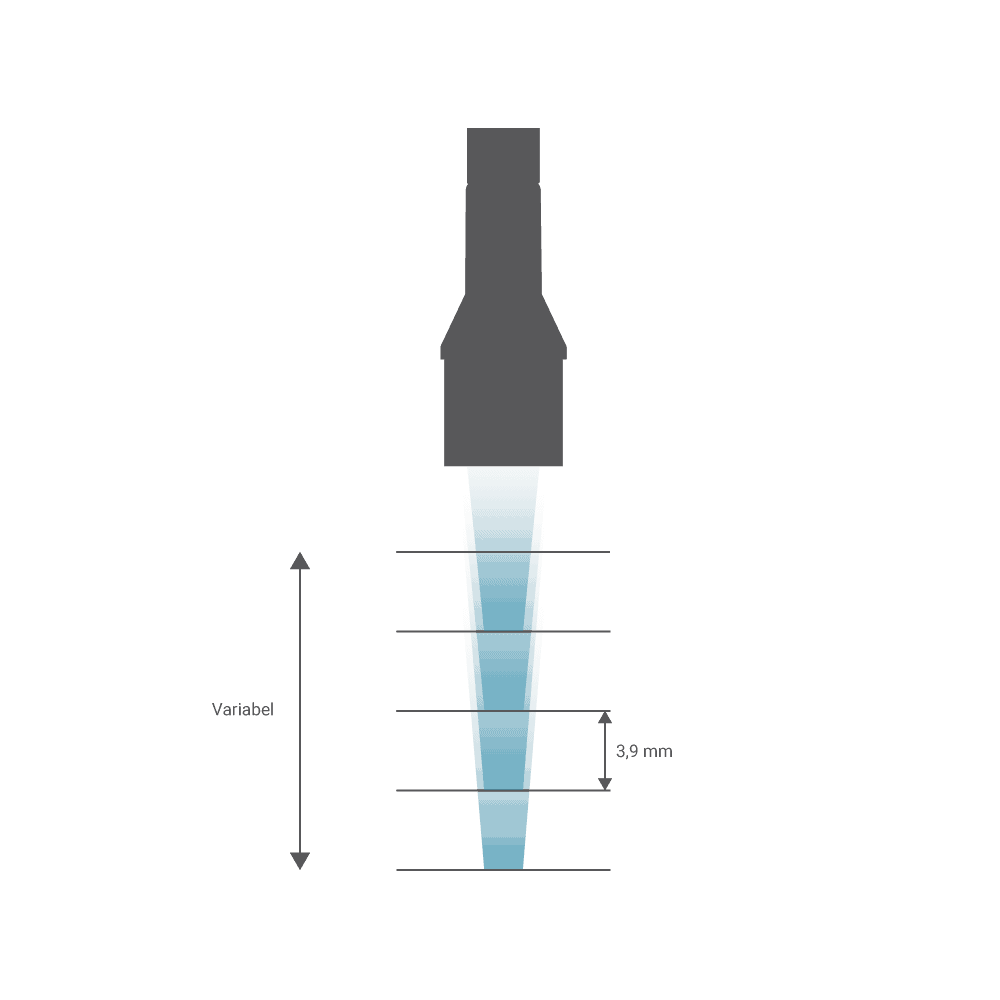

extreme Z-measuring range

Depending on the measuring head, the Z-measuring range of the MV.EYE CR1 testing system extends from 500 µm to 3 mm and can be further increased and adapted to your testing requirements by flexible scaling of the Z-axis.

Quickly inspect large areas

With 192 measuring points in a line and a measuring frequency of up to 6,000 Hz, even large test areas with a very high point density can be scanned quickly. The gantry system scans 200 x 200 mm² as standard and can be expanded as needed.

Automated processes

The stand-alone testing system with integrated controller and granite table is particularly suitable for use in testing laboratories, but can also be operated directly in production. The software allows scanning processes to be automated and saved as recipes

Connection to Mountains Map

The MV.EYE CR1 inspection system generates quality assurance reports through a direct connection to Digital Surf's MountainsMap evaluation software. Evaluation options range from geometric inspections to roughness measurements.

chromatic line sensor

The MABRI.VISION MV.EYE CR1 testing system is characterized by its precise testing of large surfaces in a very short time. The maintenance-free and robust sensor performs reliable distance and thickness measurements and is designed for industrial use.

extreme Z-measuring range

Depending on the measuring head, the Z-measuring range of the MV.EYE CR1 testing system extends from 500 µm to 3 mm and can be further increased and adapted to your testing requirements by flexible scaling of the Z-axis.

scalable platform

Thanks to its modular design, the axes of the MABRI.VISION measuring system, as well as their dimensions, can be scaled and configured as needed. A granite table is used for maximum damping.

Integrable

The MABRI.VISION MV.EYE CR1 testing system can be seamlessly integrated into your production processes. We provide the necessary software interfaces and support you in automating your testing process.

Extremely fast

The use of a chromatic confocal sensor enables extremely high measurement speeds. Up to 2,000 lines can be inspected per second. With up to 192 measuring points per line, a measurement rate of 384,000 points per second is achieved.

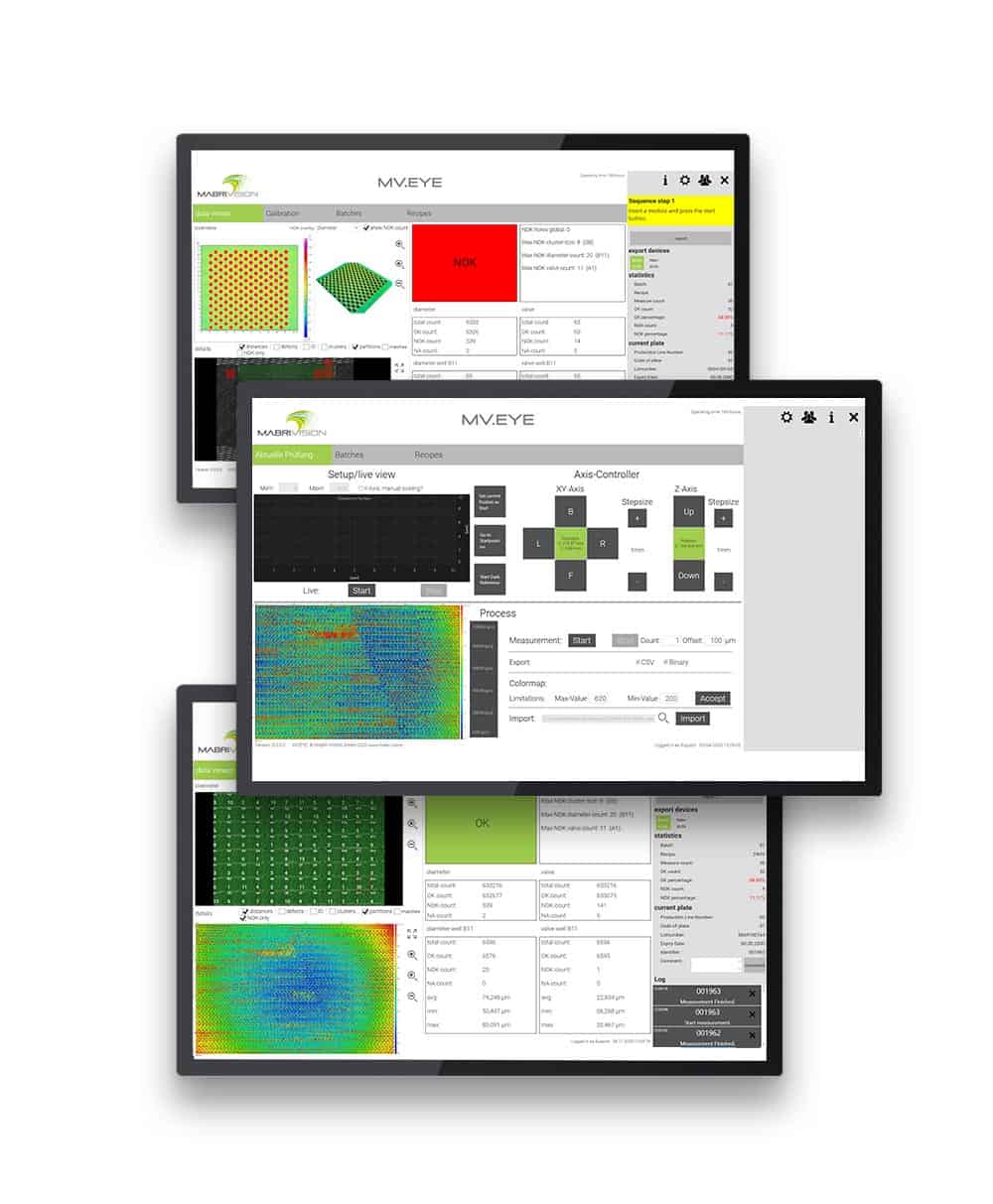

Smart evaluation.

MABRI.VISION's MV.IMAGING software is characterized by its intuitive operation and straightforward feedback. Extensive interfaces are available to the user. The software modules are designed for automated testing.

software

Modular

MABRI.VISION software is designed modularly. In addition to a wide range of standard components, we are happy to extend the software with suitable modules for your application. All common interfaces are available for seamless integration into your production process.

Databases

The MV.IMAGING software supports your quality assurance through the use of databases for production orders and recipes. The database interface is tailored to the specific requirements of your tests and evaluations. All data can be exported as structured test reports in .csv, .xls, or .pdf format.

Statistics / Analysis

Universal: versatile in its applications.

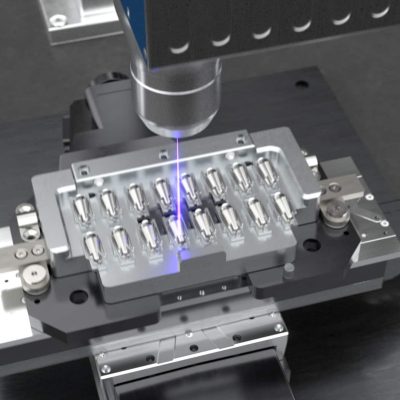

Medical technology

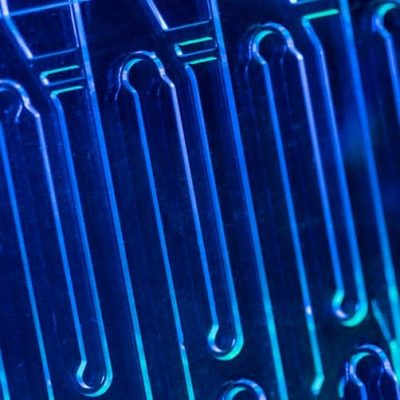

In the field of medical technology, the MV.EYE CR1 testing system is used to check microstructures in molded plastic components due to its fast measurement process.

Semiconductor technology

The MABRI.VISION MV.EYE CR1 inspection system is ideally suited for wafer inspection. Even large surfaces can be scanned in a very short time.

Toolmaking

By using chromatic confocal sensors, the MV.EYE CR1 testing system enables highly precise inspection of mold tools in the production cycle.

Application examples

MABRI.VISION builds and develops high-quality machine vision solutions and modular testing systems for your production processes. Our modular system enables us to quickly and efficiently provide solutions for your testing tasks.

Lab-on-a-Chip

The MV.EYE CR1 is used in the inspection of microstructures and microfluidics. It detects and evaluates micro- and macro-defects on injection-molded structures, enabling high-speed inspection of cell culture vessels and slides.

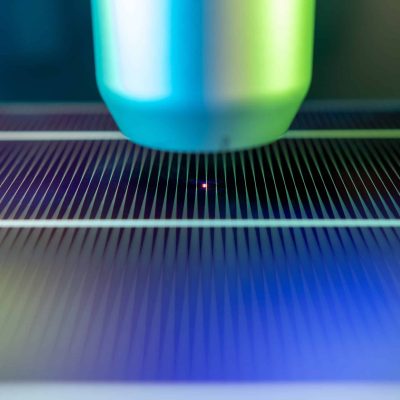

Wafer warp

Inline and offline detection of wafer warp, defects and contamination with integrated real-time evaluation.

Roughness testing

Inline and offline roughness testing on medical technology products such as screws for dental implants and artificial joints.

Gap check on cell phone displays

The testing system is suitable for checking gap dimensions between the display and the housing. Whether rounded "edge" displays or conventional displays, the MV.EYE CR1 testing system is capable of detecting even the smallest deviations from the target dimensions, both inline and offline.

Fine-metal masks for OLED production

Detection of contamination and defects on FMMs. The test takes place before initial use and between individual usage cycles and cleaning.

Specifications

Test