Aachen Corporate Run 2025

MABRI.VISION at the Aachen Corporate Run 2025: Our employees participated successfully in this year's Aachen Corporate Run with great motivation, energy, and team spirit. Events like this demonstrate once again..

MABRI.VISION at the Aachen Corporate Run 2025: Our employees participated successfully in this year's Aachen Corporate Run with great motivation, energy, and team spirit. Events like this demonstrate once again..

Visit from Denso: We had a visit from our partner DENSO last week. It was an exciting exchange that once again showed us how valuable strong partnerships are for the

Conclusion: Machine vision is changing quality assurance – sustainably. Automated image processing systems enable more precise, faster, and more consistent inspection processes. They create the foundation for data-driven optimization in the..

What are the limitations and challenges of machine vision? Machine vision is powerful – but not a sure thing. The systems require careful planning and adaptation

Where is machine vision used today? Machine vision is used in a wide variety of industries, including: Medical technology: testing of miniaturized implants, diagnostic systems

5 advantages that machine vision offers in quality assurance: Higher precision and repeatability. Machine vision systems work independently of human factors such as fatigue or subjective perception.

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

What types of defects can be detected using machine vision? Machine vision systems detect a wide variety of deviations – with a speed and accuracy that

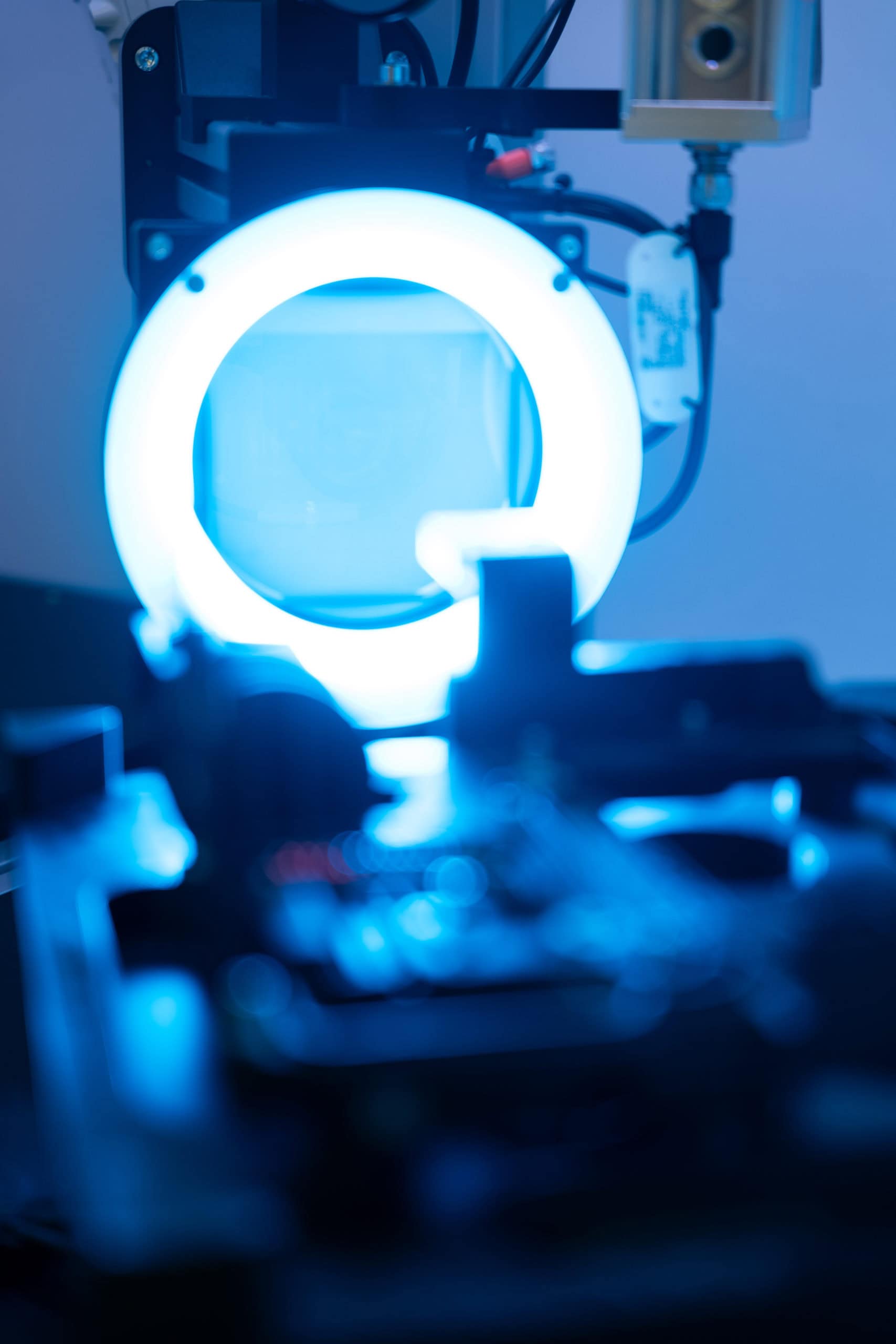

How do machine vision systems work? Machine vision refers to systems that capture images of products or processes, automatically analyze them, and derive decisions from this analysis. In contrast to

How Machine Vision is Changing Quality Assurance The demands on industrial quality assurance are constantly increasing: ever more complex products, tighter tolerances and a growing need for traceability are putting traditional methods to the test

The Importance of Automated Quality Control: In an increasingly complex and competitive world, ensuring quality in all production and service processes is essential. It is more

https://mabri.vision/wp-content/uploads/2025/06/PKE.mp4 3rd PKE Logistics Day At the PKE Logistics Day, we demonstrate how modern image processing and AI make logistics smarter and more efficient. Our systems support companies in..

Success story: Testing system for microfluidic chips in digital PCR systems. In digital PCR systems, microfluidic chips are crucial for precise and reproducible results. A leading life science provider relies on..

Why manual inspection is no longer competitive: In modern manufacturing, precise and efficient quality checks are essential. However, the question arises: What is

How Machine Vision is Changing the Production Landscape: Industry 4.0 represents the fourth industrial revolution – the comprehensive digitalization and networking of industrial processes. This involves..

Success story: Testing system for high-precision miniaturized medical components. In medical technology, every detail counts – often on the scale of just a few micrometers. A leading manufacturer of miniaturized medical components relies on..

In manufacturing, every detail counts. Even the smallest errors can have major consequences. With MABRI.VISION's machine vision inspection systems, you can detect defects early. Reliably and automatically

https://mabri.vision/wp-content/uploads/2025/07/Die-Zukunft-der-Fertigung-Warum-Machine-Vision-entscheidend-ist_Web.mp4 Why Machine Vision is Crucial Errors in production cost time, materials – and ultimately trust. In an industrial world that is becoming increasingly precise,

An insight into our work and vision: A few days ago, we had the pleasure of welcoming the Aachen Economic Development Agency to our offices. As an innovative company that

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

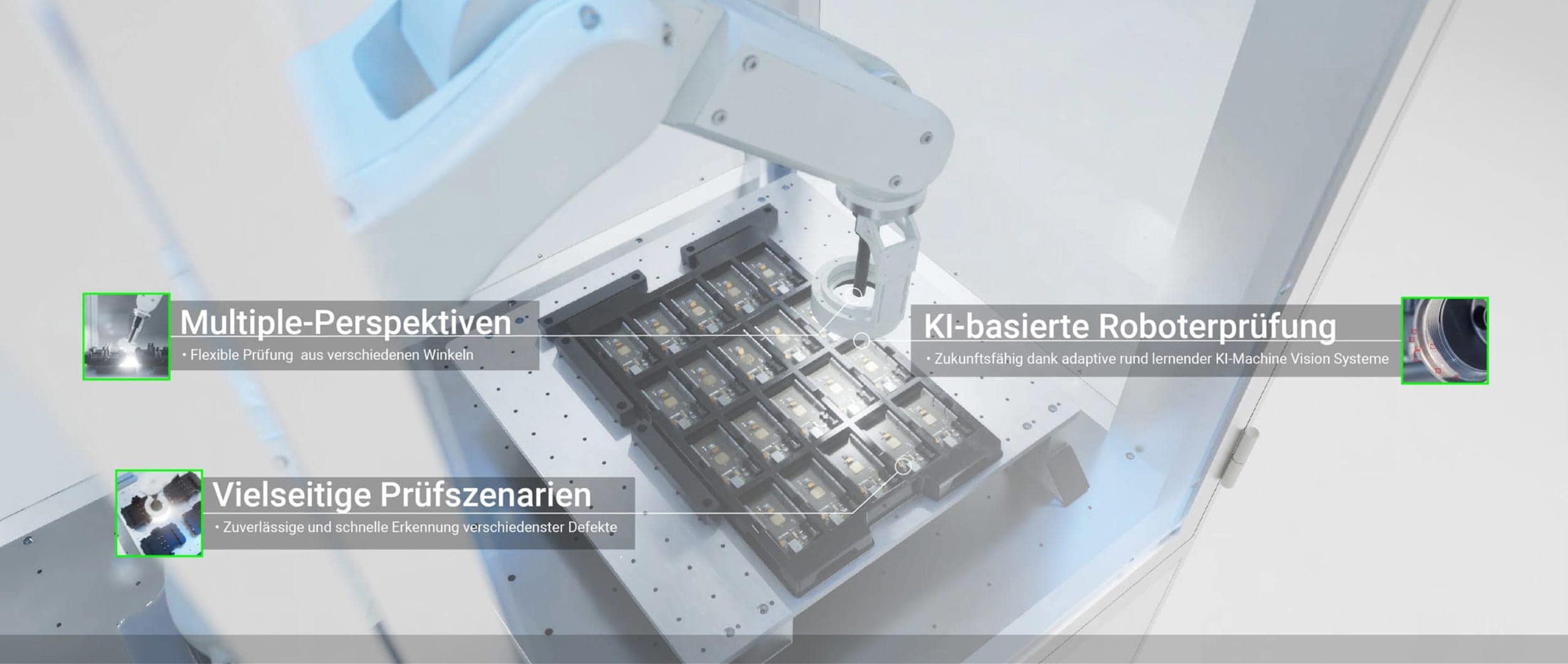

Automated quality inspection redefined! At MABRI.VISION, we rely on the precision and reliability of DENSO Robotics for our ROBOT.SPECTOR. The advantages: Flexible inspection processes, minimal errors, and

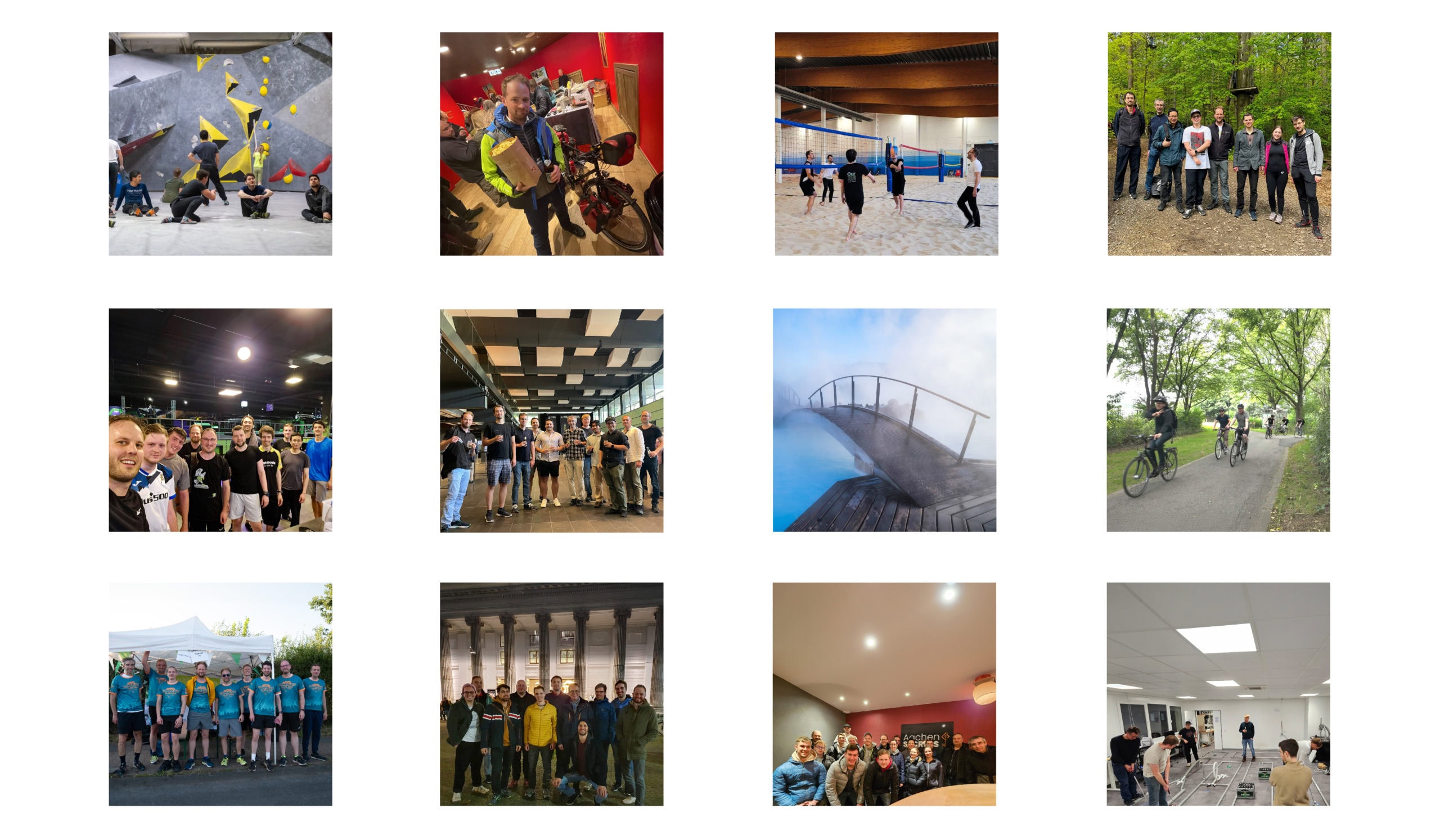

MV.EVENTS 2024: A year full of unforgettable experiences! The year 2024 was very special for us at MABRI.VISION! With our MV.EVENTS, we had something special every month

MABRI.VISION wishes you a happy new year! 2024 was a year full of exciting projects, challenges, and successes. We are incredibly grateful for our amazing partners and customers

Christmas party at MABRI.VISION Yesterday we ended the year with our traditional Christmas party – an evening full of delicious food, a great atmosphere, and team spirit! A special

MV.EVENTS December Minigolf Challenge at MABRI.VISION! This month's MV.EVENTS featured minigolf – right here at our premises! Our hallways were transformed into minigolf courses

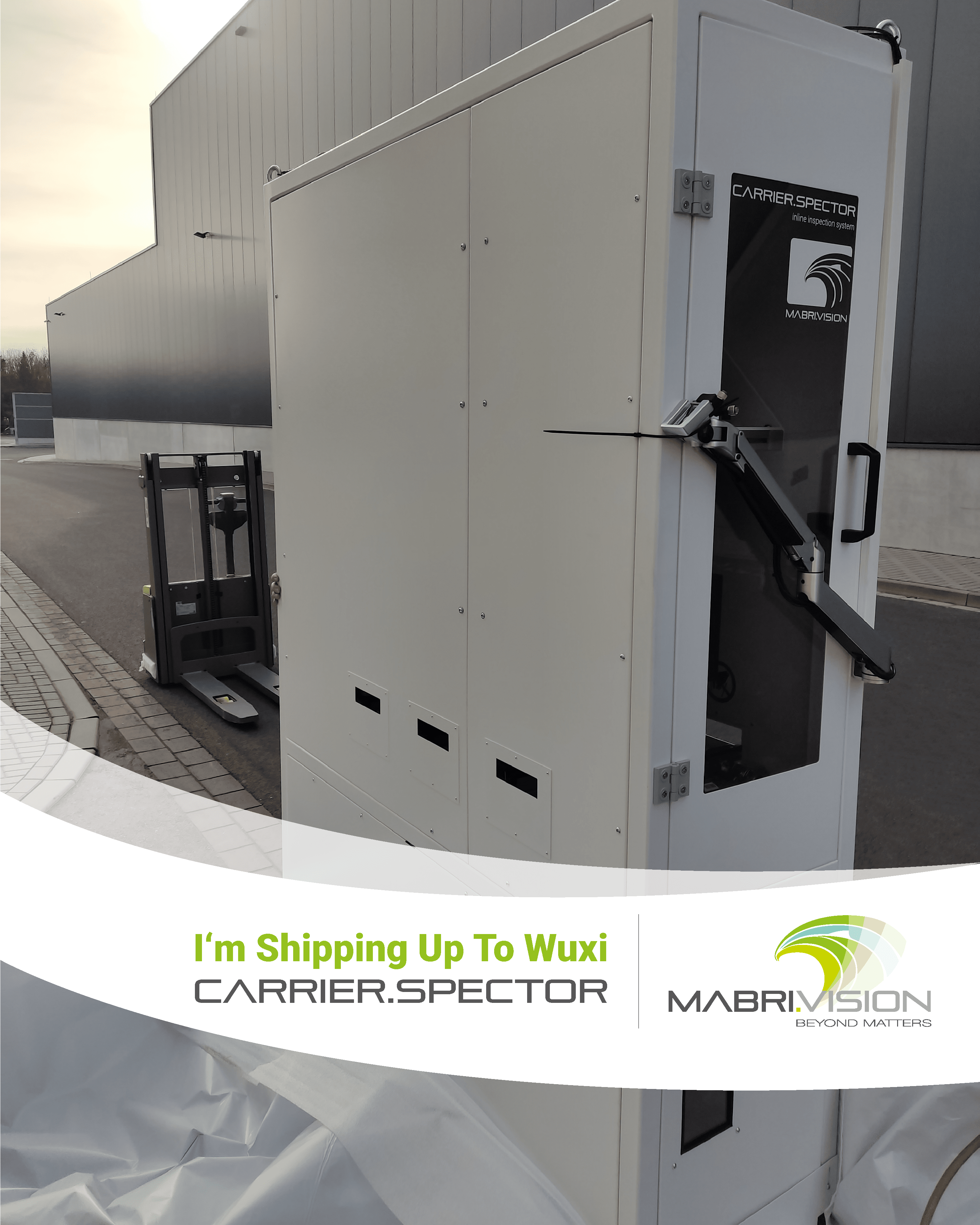

Ready for delivery and commissioning! We are pleased to send another plant developed and built by MABRI.VISION on its way to its destination!

MV.EVENTS November: Teamwork in an exciting way! In November, we at MABRI.VISION had a great opportunity to strengthen team spirit in a completely new way!

MV.EVENTS October: Science meets Creativity! For our monthly MV.EVENTS event in October, we attended the Science Slam in Aachen. The event was a unique opportunity to experience science in a refreshing way

Future visions and strong partnerships: Our review of VISION Stuttgart. VISION Stuttgart has once again demonstrated how important such events are for personal exchange

Fire protection in safe hands at MABRI.VISION. We are pleased that several dedicated employees have successfully completed our fire safety training! Thanks to this voluntary training,

Successful professional development at MABRI.VISION! Last week, our dedicated employees successfully completed an intensive three-day Festo training course, gaining valuable knowledge in the field of..

MABRI.VISION at VISION 2024: The trade fair was an outstanding event for MABRI.VISION! Together with our partner Hikrobot, we presented innovative products at our joint booth

A look back at the "All about Automation" trade fair! Last week, the MABRI.VISION team had the great opportunity to participate in the All About Automation trade fair in Düsseldorf.

MV.EVENTS September On September 22nd, our MABRI.VISION team participated fully in the Aachen Corporate Run – one of the largest and most popular corporate runs in the region

MV.EVENTS August In August, we brought our team together in a special way at our monthly MV.EVENTS event: with a joint bike tour along the beautiful Vennbahn

Tomorrow's the day! MEDevice Boston 2024 begins, and we at MABRI.VISION are ready to present our latest developments in medical technology. Visit us!

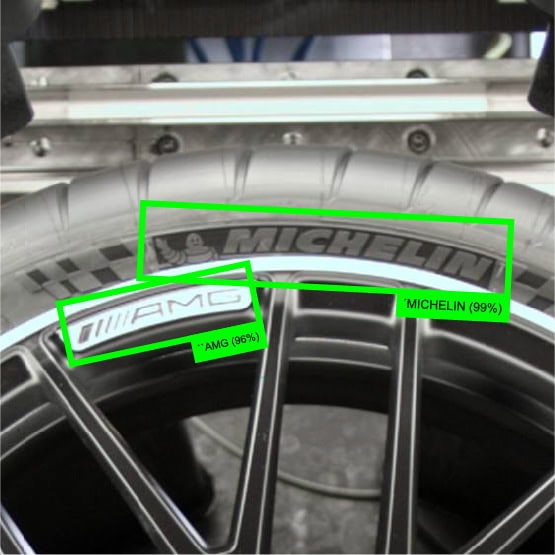

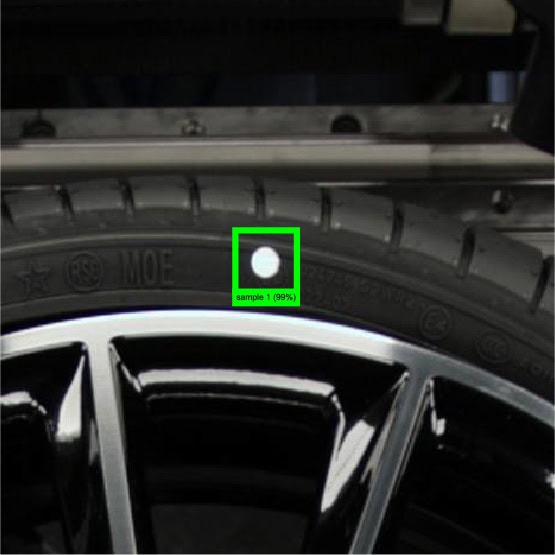

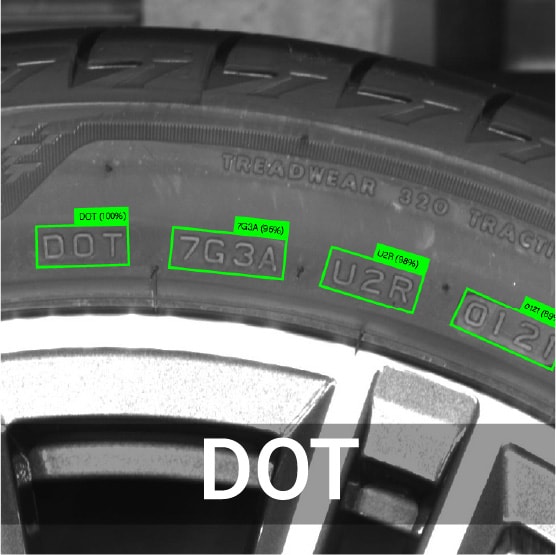

Advanced symbol recognition on tires – technology for safety and accuracy. Precise symbol recognition is a core function of the VISION.SPECTOR TIRE EOL. This innovative technology enables the

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

MEDevice Boston 2024 is just around the corner! Visit us at our booth on September 25th and 26th. MABRI.VISION looks forward to showing you our latest innovations

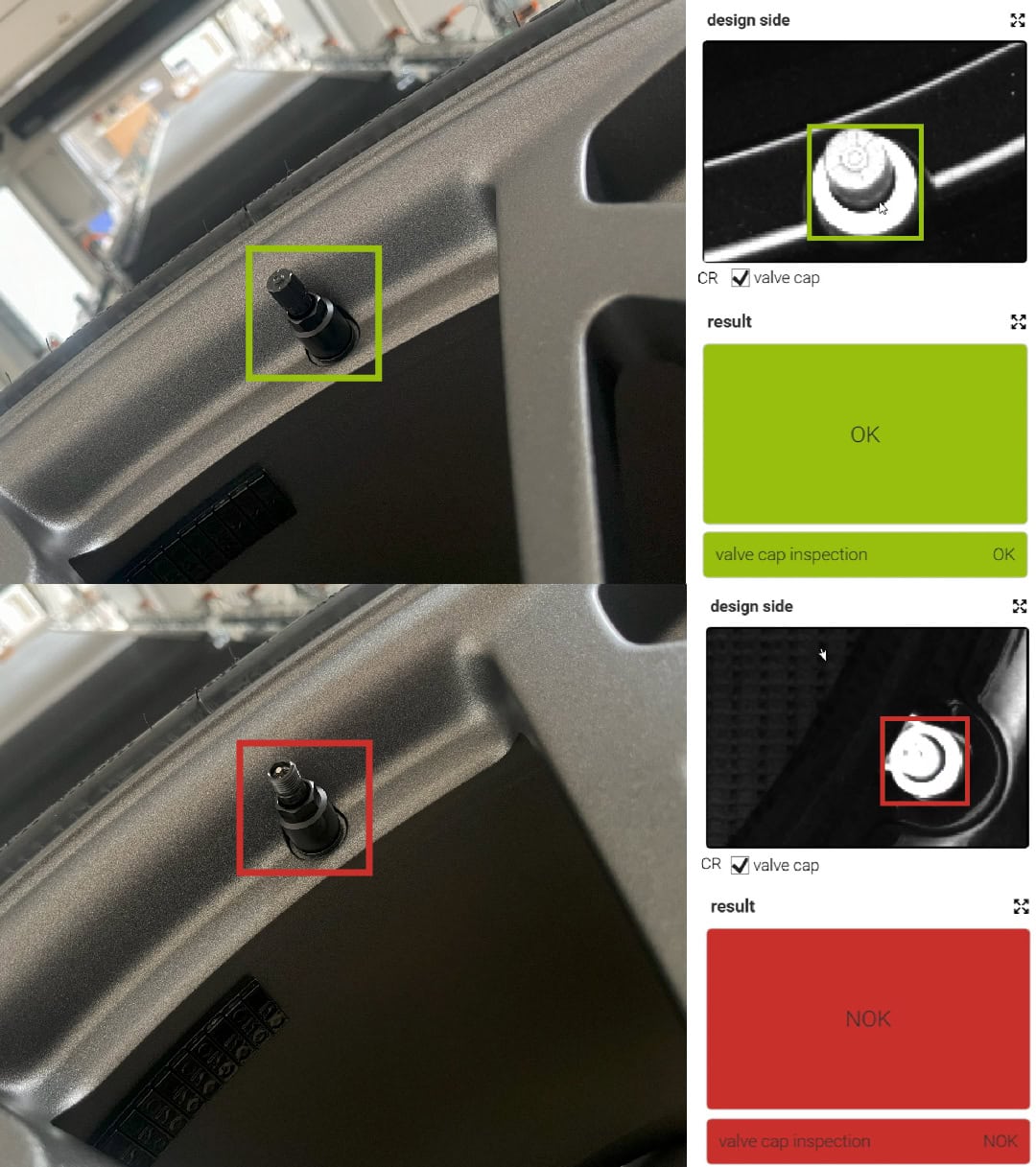

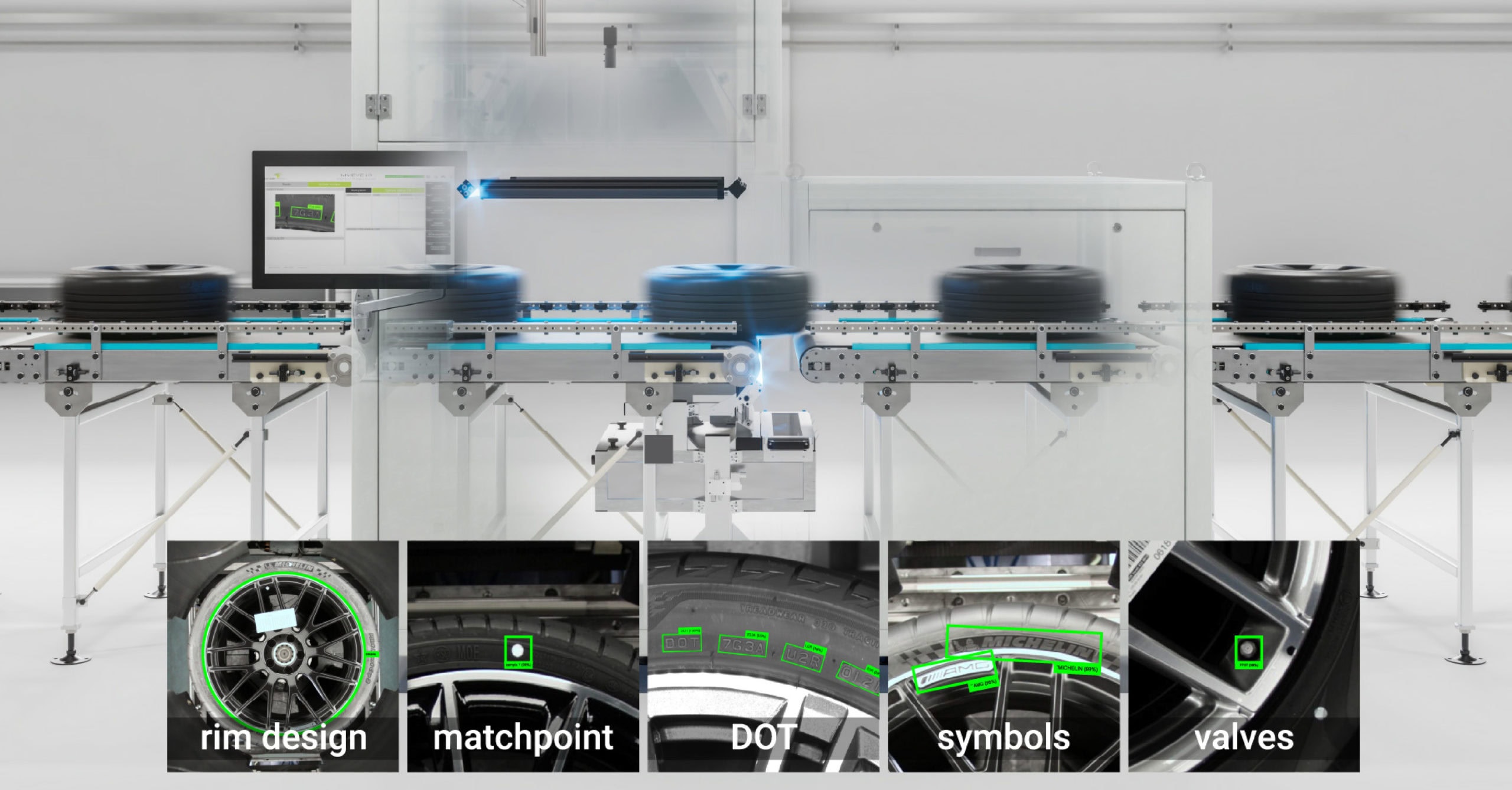

Our VISION.SPECTOR TIRE series features advanced valve detection – a critical detail essential for the safety and functionality of every wheel

Visit to Niederrhein Automation GmbH: Our Managing Director, Dr. Ulrich Marx, visited our partner, Niederrhein Automation GmbH, last week

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

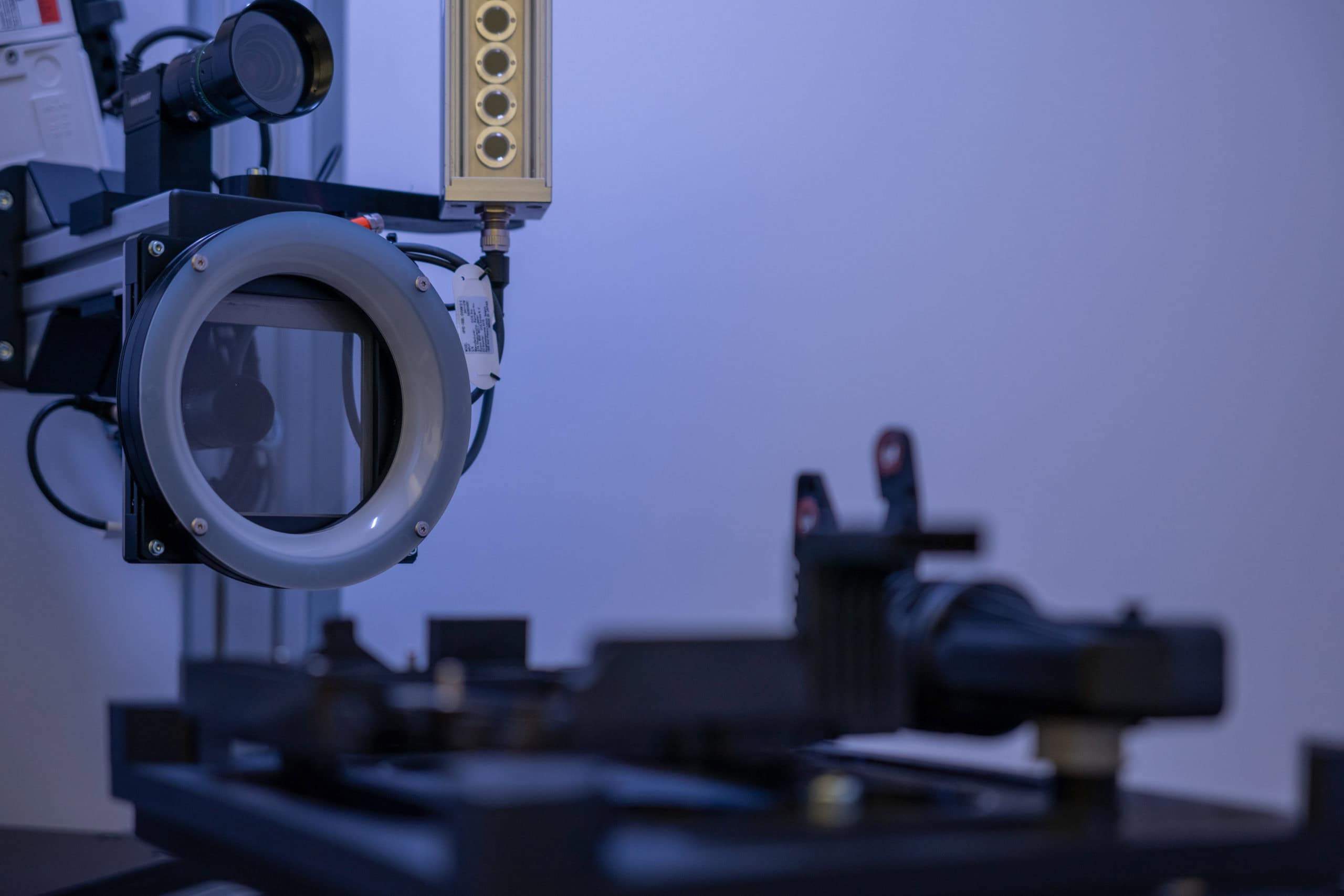

Machine Vision Software Our machine vision software is used in the VISION.SPECTOR TIRE, VISION.SPECTOR TIRE DOT and VISION.SPECTOR TIRE EOL testing systems. It combines efficiency and

High-resolution imaging for optimal quality assurance. Today we highlight the advantages of high-resolution imaging and storage. Our systems, including VISION.SPECTOR TIRE, VISION.SPECTOR TIRE DOT, and

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

MV.EVENTS July: A relaxing day at the Carolus Therme Aachen. MABRI.VISION's monthly employee event took us to the beautiful Carolus Therme in Aachen this July

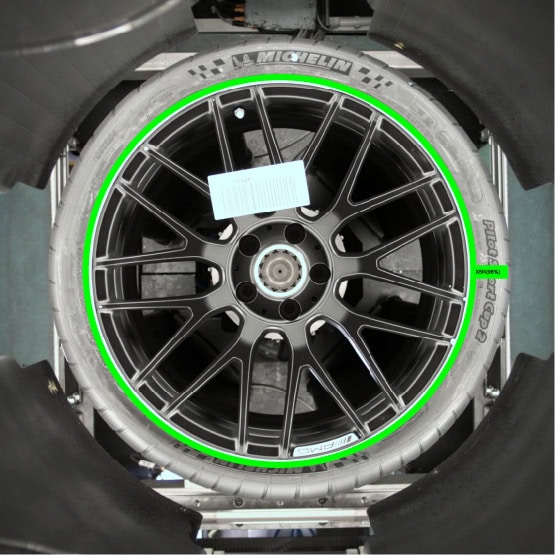

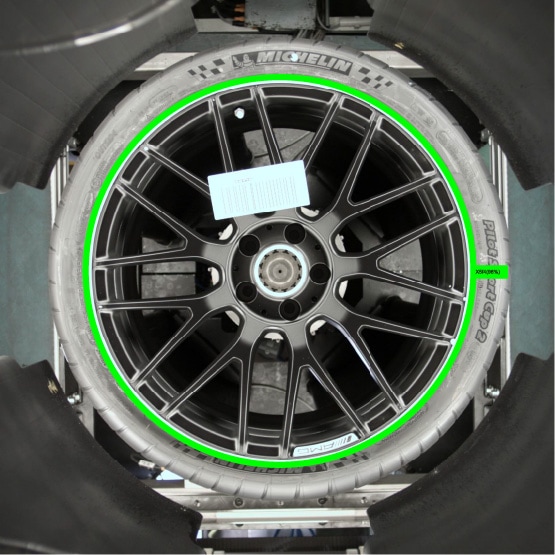

Rim design recognition with MABRI.VISION technology: The VISION.SPECTOR TIRE and the VISION.SPECTOR TIRE EOL ensure that each wheel is equipped with the precisely prescribed rim design

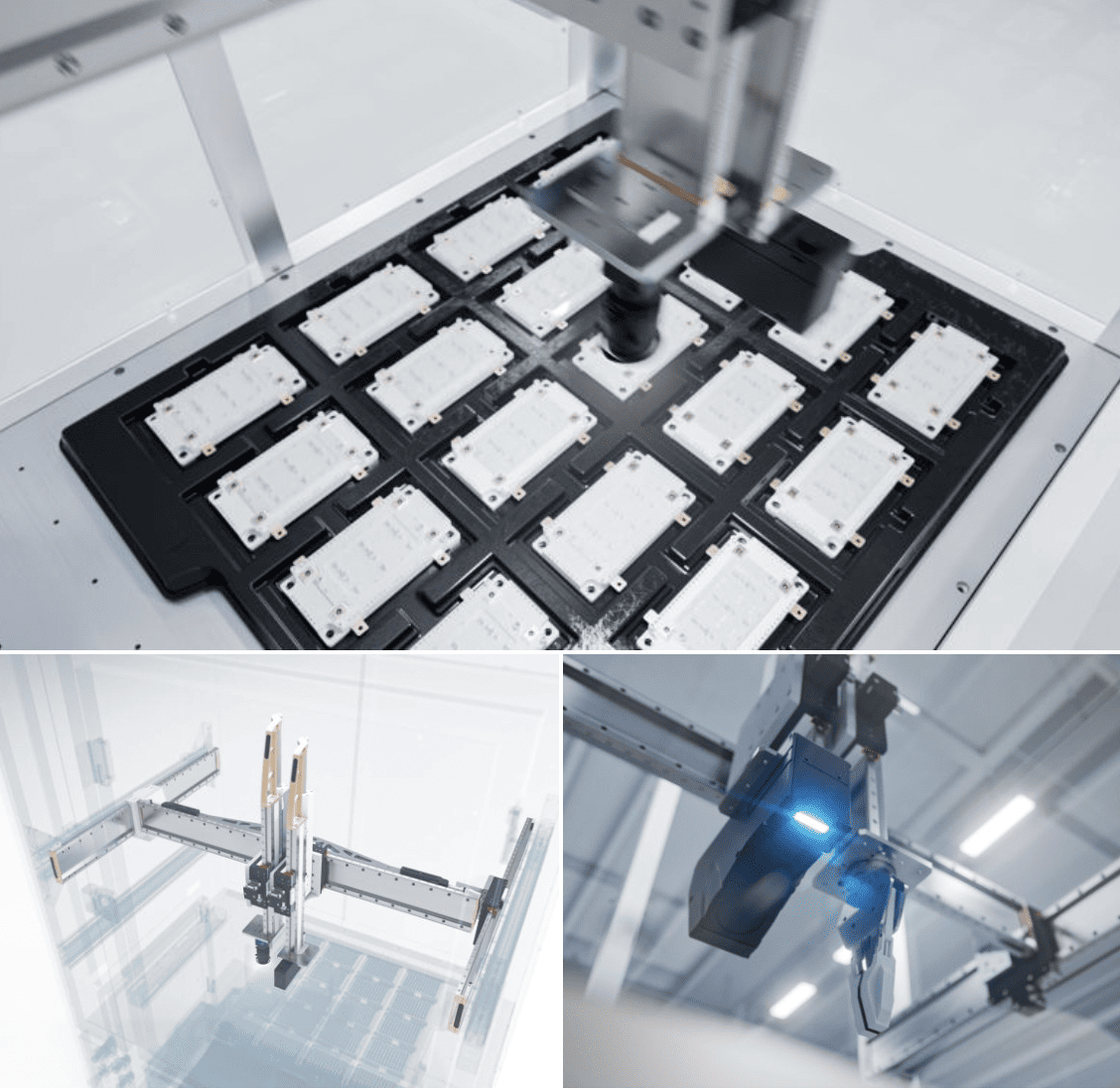

Increased production output with the ROBOT.SPECTOR! The ROBOT.SPECTOR is our answer to the growing challenges in modern production and quality assurance. Self-regulating testing processes: The ROBOT.SPECTOR enables..

Focus Match Points: Precise positioning for optimal performance. This feature of our VISION.SPECTOR TIRE and VISION.SPECTOR TIRE EOL ensures that every mounting and balancing is perfect

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

Quality assurance with SchauML – A step forward for the quality control of yard goods! The overarching goal of the SchauML research project was to develop the economically viable use of automated

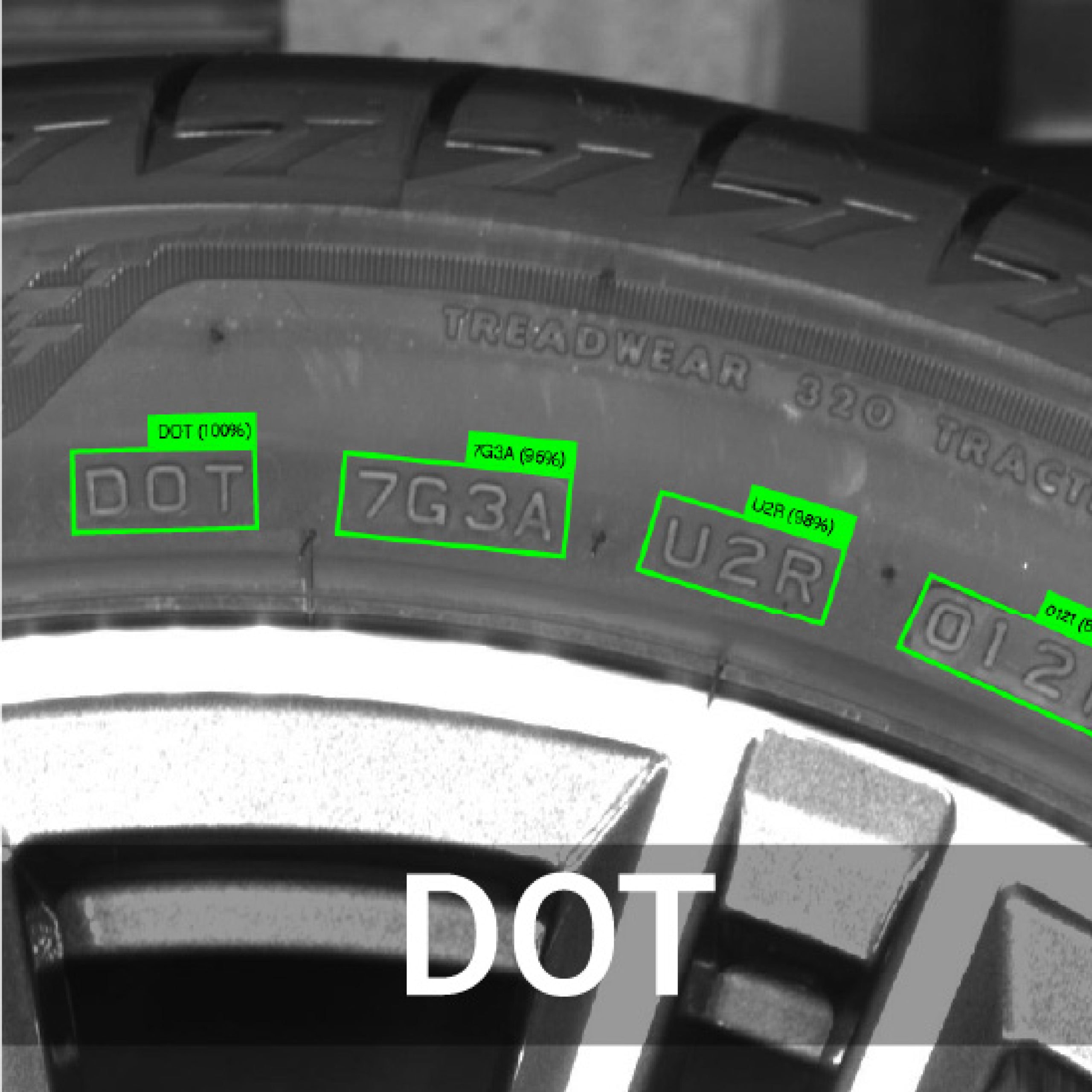

A key function for quality control: Our VISION.SPECTOR TIRE DOT and VISION.SPECTOR TIRE EOL systems feature advanced AI-powered recognition of DOT and DOM codes

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

AI-controlled robot inspection with the ROBOT.SPECTOR. Our ROBOT.SPECTOR is characterized by the combination of proven image processing technology and the innovative potential of AI-based deep learning. Integration

MV.EVENTS in June at the 8th Symphony Concert – Black Pepper at the Eurogress Aachen. After the sporting adventures of the last few months, things were a bit quieter in June

Discover the application areas of the VISION.SPECTOR Tire series. Our state-of-the-art TIRE DOT and VISION.SPECTOR TIRE EOL testing systems offer versatile applications for optimizing wheel mounting and tire inspection

Tailor-made testing technology for maximum quality assurance with the ROBOT.SPECTOR. The ROBOT.SPECTOR – Tailor-made testing technology for maximum quality assurance. In the dynamic world of manufacturing, it is crucial to

Quality control with the VISION.SPECTOR TIRE EOL. Our VISION.SPECTOR TIRE EOL is a complete solution for end-of-line quality control. This system combines modern technology with efficient design

Improve your quality control and product inspection with the ROBOT.SPECTOR. The ROBOT.SPECTOR was specifically designed to meet the challenges of modern manufacturing and production environments. Versatile application possibilities

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

Efficiency and precision with the VISION.SPECTOR DOT. The VISION.SPECTOR DOT is our established solution for the precise reading of DOT and DOM markings. Ideal for integration

Successful deployment in Malaysia We are proud to have completed a successful two-week deployment at a leading manufacturer of augmented reality in Penang, Malaysia.

Optimize your wheel testing with the VISION.SPECTOR TIRE. The VISION.SPECTOR TIRE – our proven solution for precise wheel testing, ideal as a standalone unit or as an integrated system

MV.EVENTS at Superfly Air Sports in Aachen in May. This month we had the pleasure of hosting our team at one of the most versatile leisure facilities in Aachen

A day full of adventure and team spirit! We spent our monthly MV.EVENTS event in April at the Aachen climbing forest. Under brilliant sunshine, we were able to tackle the various courses

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

Hannover Messe 2024: Reflections on the Hannover Messe by the managing directors of MABRI.VISION GmbH, Dr. Nicolai Brill and Dr. Ulrich Marx. Yesterday, the

Research project: Digital monitoring of spotted wing drosophila infestations. Innovative. Sustainable. Effective. At MABRI.VISION, we are proud to research pioneering solutions for viticulture. In collaboration with

MABRI.VISION at the B2Run Aachen 2024: Our MABRI.VISION team did it! Together they mastered the challenge of reaching the finish line and demonstrating team spirit

Beach volleyball and team spirit: A look back at our monthly employee event! Last Friday, we had the pleasure of kicking off our MV.EVENTS employee event at "dieHalle Aachen" with a round of beach volleyball

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

Mabri.Vision at Tire Expo '24 in Hanover. Meet MABRI.VISION GmbH at the Tire Technology Expo 2024. We, the team behind MABRI.VISION, bring innovation

Visit us at Tire Expo '24 Hannover! We're presenting: Our latest development in automated wheel and tire testing – VISION.SPECTOR TIRE

An unforgettable evening with "Elsewhere in Africa"... at the cinema last week, as part of the monthly MV.EVENT series. During the film, Anselm, the creative director, guided us through the film

Alaaf (and Helau) – ROBOT.SPECTOR DMC is celebrating! Even our technology is taking a humorous break today! Imagine, our ROBOT.SPECTOR

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

Last Friday we showed our creative side and climbed high together – quite literally!

mabri.visions profile picture

It was beautiful 😂 Respect to all runners who battled through this miserable weather 🫡🌧️ #firmenlaufaachen2023 #firmenlaufaachen #firmenlauf #ichwerdeallesgebenfuermeinunternehmen #scheisswetter

Discover with Dr. Nicolai Brill how MABRI.VISION tests internal rotationally symmetrical surfaces in a cycle-neutral manner.

Better late than never 😅

We sincerely thank you for the invitation to the #digitalSUMMIT2023 in Aachen!

We had a lot of fun and we're already looking forward to next year!

Many thanks to the organizers and the entire #digitalHUBAachen eV team ✌️

In our latest video, we present the current generation of our VISION.SPECTOR CI inline inspection system. This state-of-the-art system sets new standards in the quality control of plugs, connectors, and pin headers.

In a world where production speed and quality must go hand in hand, we present the GANTRY.SPECTOR – your machine vision portal system for maximum precision.

"For about seven and a half years, I've had the pleasure of being part of the MABRI team, where, as a development and project manager, I've been involved in many exciting projects. We check every conceivable component or material for production defects and always adapt our systems to the customer's needs.".

Meet our HR manager, Lisa. She'll tell you exciting details about her administrative tasks at MABRI.VISION and give you a little glimpse behind the scenes.

Meet Daniel, one of our developers for the ROBOT.SPECTOR. Discover in our latest video how he combines innovation and passion. Stay tuned to learn more!

“For about four months now, I have had the pleasure of being part of the MABRI team, where I work in the exciting world of image processing. Our work ranges from traditional methods to advanced approaches such as artificial intelligence and deep learning.”.

We're thrilled to report a successful showcase at Automatica 2023! MABRI.VISION's innovative vision technology was warmly received, sparking interesting discussions and forming meaningful connections.

Automatica is THE leading international trade fair for automation and robotics, bringing together professionals, visionaries and enthusiasts every year to explore the latest advances in automation technology.

Hello, dear LinkedIn community,

MABRI.VISION GmbH will be participating in #automatica2023 in Munich next week, from June 26th to 30th – the world's leading trade fair for intelligent automation and robotics.

How can we enable machines to see, learn, and understand? Find the answers at the Vision Expert Huddles, a presentation forum for industrial image processing at the upcoming automatica 2023 – the leading trade fair for intelligent automation and robotics, taking place in Munich from June 27 to 30, 2023.

BioChip Berlin 2023 has come to an end. We would like to extend our sincere thanks to the organizers! The conference was a fantastic platform for exchange and discussion in the world of microfluidics.

MABRI.VISION stands for modular machine vision solutions and systems that rely on innovative software and hardware technologies to make inspection processes more efficient. Let's take a closer look at TDI technology today.

📍 We're live at Control 2023 in Stuttgart! 🎉💡

Visit us in Hall 7 – Booth 7310-2 and discover our machine vision solutions! ✨🔧

In our weekly series “What We Test”, we present various exciting areas in which our inspection systems are used. Today, we focus on our VISION.SPECTOR, which we are currently training to detect foreign objects in bulk material, specifically in walnuts.

🎉 Don't let defects bring you down – Choose MABRI.VISION and visit us at the Control trade fair 2023 in Stuttgart! 🎉

We are very excited about the release of our MICRO.SPECTOR! 👁

This innovative testing system enables 100% surface component testing with microscopic resolution and is the result of hard work and dedication from our team.

mabri.vision

🎉 Winner of the job fair competition 🎉

A huge thank you to everyone who attended the digitalHEROES job fair on April 20, 2023, at digitalCHURCH! It was a fantastic evening full of exciting encounters and inspiring conversations! 🚀

mabri.vision

👉 Are you looking for the perfect job and employer in an innovative environment? Then you've come to the right place! Come and discover the future of the Aachen area and become a digital HERO! 🦸♀️🦸♂️

Today we want to present to you the following topic:

Optical inspection systems for high content detection and code proofing.🕵♂️

Click on the video below to achieve a behind-the-scenes look 👀 at MABRI.VISION.

Use the VISION.SPECTOR from MABRI.VISION to examine defects and anomalies in tissue structures

In our series "What We Test," we showcase a new and exciting area each month where our testing systems are used. This time, we're focusing on defects, specifically in tissue structures.

We wish you a happy Easter with hopefully beautiful weather and a full Easter basket on Easter Sunday!

Check for microscopically small defects and anomalies in production

In our series "What We Test," we showcase a new and exciting area each month where our testing systems are used. This time, we're focusing on microscopic defects.

Today we're introducing our MICRO.SPECTOR. A testing system that can fully automatically inspect microstructured components and products for defects, shape deviations, and dimensional accuracy under cleanroom conditions.

Here at MABRI.VISION GmbH, we can no longer keep our incredible new development to ourselves! It's time to introduce you to the fantastic, breathtaking, and absolutely discreet HARVEY.SPECTOR!

Our LINE.SPECTOR was stationed at the factory for several years, reading and verifying QR codes on tires. Now it's back and has been upgraded to include a DOT reading bridge!

Electronic components perform key functions in a rapidly growing number of products. The necessary production capacities place the highest demands on quality requirements in order to reliably detect common defects such as housing breaks, bending, runout, incorrect component placement, mold defects, burrs, and undermolding.

Today is a big day for us! Our CARRIER.SPECTOR has set off for Wuxi, China! We are proud that our equipment continues to advance industry and technology standards.

For these tasks, we prefer to rely on high-precision positioning technology with linear motor axes from Switzerland in our MICRO.SPECTOR and VISION.SPECTOR testing systems.

In collaboration with the Society for the Promotion of Applied Informatics (GFaI) eV and the ITA Institute for Textile Technology of RWTH Aachen University, we have developed a testing system for the automated detection and classification of draping defects in different fiber materials.

Discover the LINE.SPECTOR, the optical inspection system from MABRI.VISION that enables reliable code detection and verification. In our video, we show you how we can make your production more efficient and significantly increase code read rates.

At MABRI.VISION, we have expanded our OCT system product family with the high-resolution MV.SENSE b1i, which is particularly suitable for testing thin barrier layers in film systems. With our modular system platform for automating QC processes, we develop customized solutions to make the testing of films and their products more efficient.

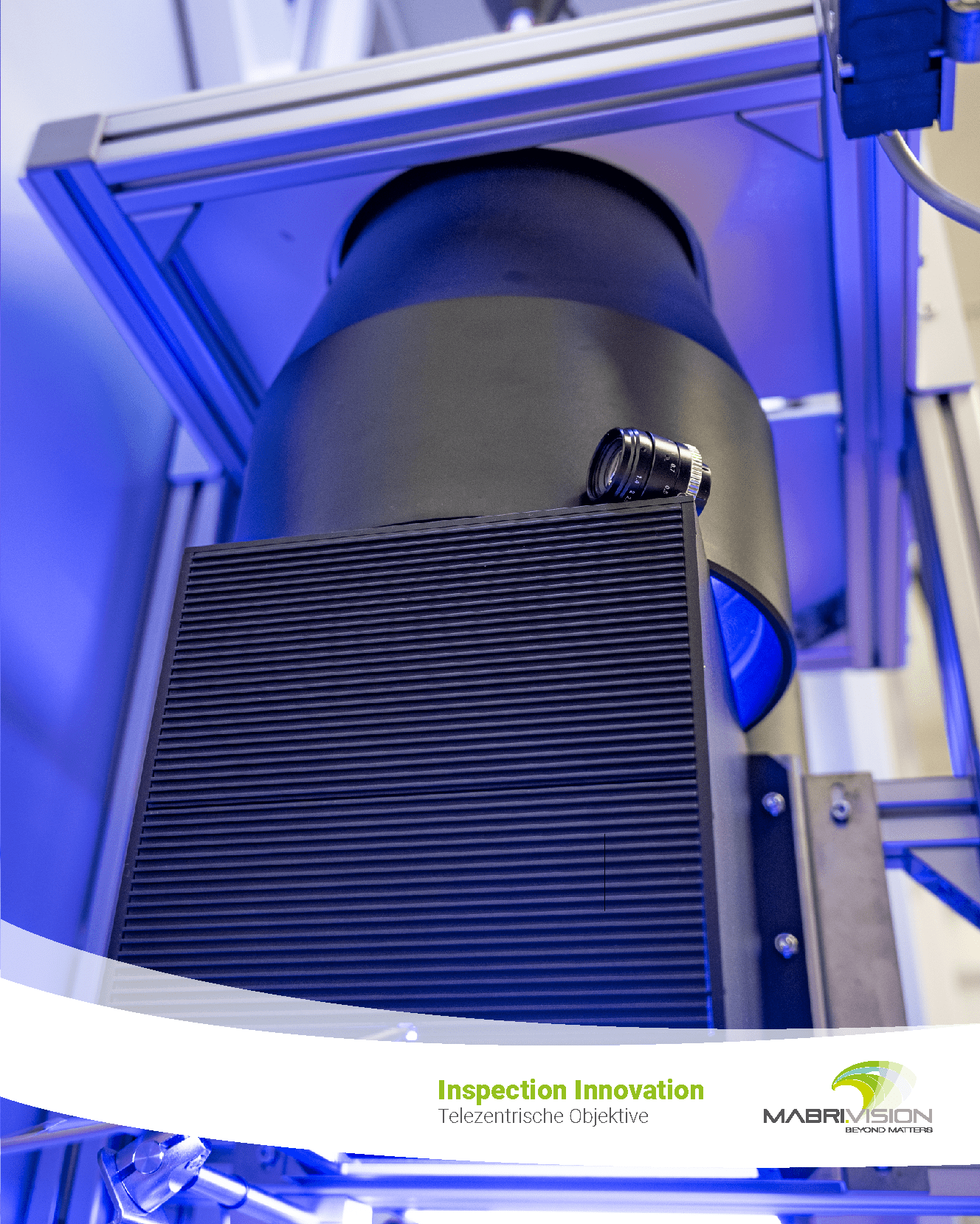

Our large telecentric lenses enable us to capture and measure image fields of up to 200x160mm² in a single shot with high resolution, even with different component heights.

View this post on Instagram. A post shared by MABRI.VISION GmbH (@mabri.vision)

detect defects on internal surfaces with the VISION.SPECTOR PI1

Quality assurance is a crucial factor in the manufacturing industry, especially for castings used in safety-relevant areas.

How do we plan our plants? What steps do we take in the design and development process? We asked our colleague Vitus Merx!

In our Tech Talk on the topic of plant engineering and development, you will gain interesting insights into the processes of MABRI.VISION.

Events MABRI.VISION wishes you a happy and successful New Year 2023! Dear customers and colleagues, the new year is finally here and we would like to..

The MABRI.VISION team wishes you and your families a Merry Christmas and a Happy New Year

MABRI.VISION is now part of the digitalhub Aachen! MABRI.VISION is proud to be part of the digitalhub Aachen, one of the leading technology and innovation centers in Germany.

COMPAMED | Trade Fair for Medical Technology MABRI.VISION is pleased to be one of the 500 exhibitors at Compamed in Düsseldorf. Compamed is one of the leading international trade fairs for medical technology

COMPAMED | Trade Fair for Medical Technology MABRI.VISION is pleased to be one of the 500 exhibitors at Compamed in Düsseldorf. Compamed is one of the leading

Mid-Week Coffee Break: Together with the IVAM professional association and interested members, we discussed automated quality control. Thanks to everyone involved! Our meeting was a great success

VISION | World's Leading Trade Fair for Machine Vision MABRI.VISION is pleased to be exhibiting at VISION, the world's leading trade fair for machine vision, in Stuttgart from October 4th to 6th, 2022. Here you can see our

IKV | International Colloquium for Plastics Technology The MABRI.VISION team is pleased to welcome you to the International Colloquium for Plastics Technology in Aachen from September 7th to 8th, 2022

DEEP.MV | Deep Learning platform At MABRI.VISION, we, as a young, innovative team of experts, rely on the latest machine vision technologies and machine learning to solve problems

MABRI.VISION joins IVAM Microtechnology Network! We are proud and delighted to now be a member of the international microtechnology association! As representatives in the high-tech industry, we

Insights from PCIM EUROPE in Nuremberg. Thank you, PCIM! We gained many interesting insights and had great conversations at the PCIM trade fair in Nuremberg last week

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

You are currently viewing placeholder content from the default source. To access the actual content, click the button below. Please note that data will be transferred

Meet us at PCIM EUROPE in Nuremberg! The MABRI.VISION team looks forward to welcoming you to PCIM EUROPE from May 10th to 12th, 2022

The multimodal MABRI.VISION system MV.EYE i2 inspects the form and position tolerances of complex components with high precision inline and in sync with production. A typical measurement cycle, which also detects surface defects and contamination, among other things, takes only three seconds.

Reducing pesticide use through early detection of spotted wing drosophila infestation. In cooperation with the Rhineland-Palatinate Rural Service Center and 3win Maschinenbau GmbH, MABRI.VISION is introducing a

Traffic flow has changed. MABRI.VISION can now be reached via a changed traffic flow at the TRIWO Technology Park. Our premises can now be found via signage which

We are pleased that the MABRI.VISION cleanroom system for microstructure testing has been featured in a report on Plastverarbeiter-Online.

News from MABRI.VISION warmly welcomes you! An eventful month has passed since our move to the new office building in the TRIWO Technopark in Aachen. The energetic

News: MABRI.VISION moves to new premises in Aachen. At the end of July, the time has come: MABRI.VISION is moving. The year 2019 was characterized by steady growth for us

What can we contribute to help in the current situation? The MABRI.VISION team asked themselves this question and decided to support the Aachen-based movement fightCorona.ac.

News: We are still available for you! The health of our fellow human beings is very important to us. Therefore, MABRI.VISION has initiated all necessary measures to protect customers and

News, Trade Fair: Postponement of the International Colloquium on Plastics Technology 2020. The IKV Aachen has decided to postpone the 30th International Colloquium on Plastics Technology, which was originally scheduled for March 11 and 12

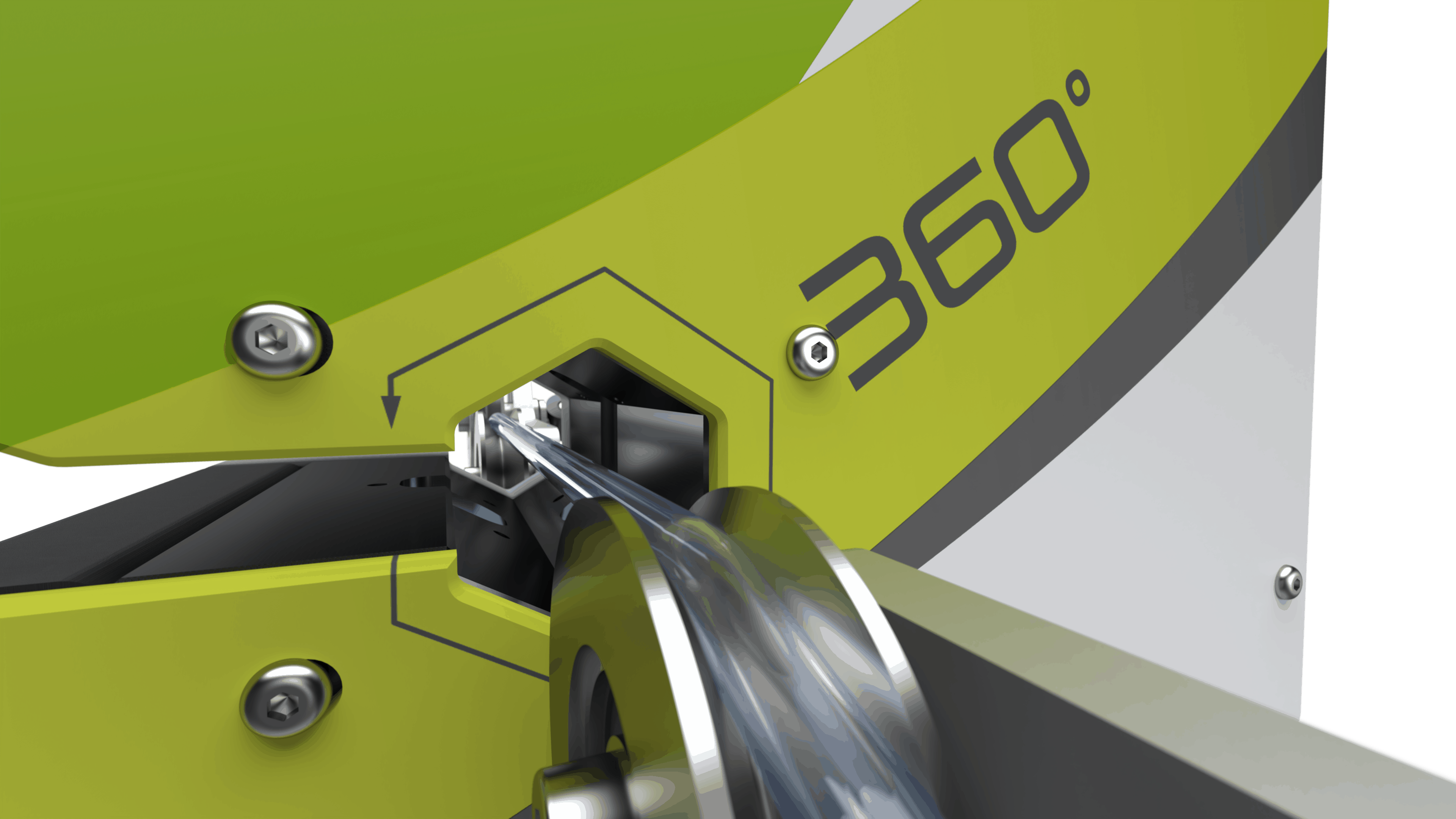

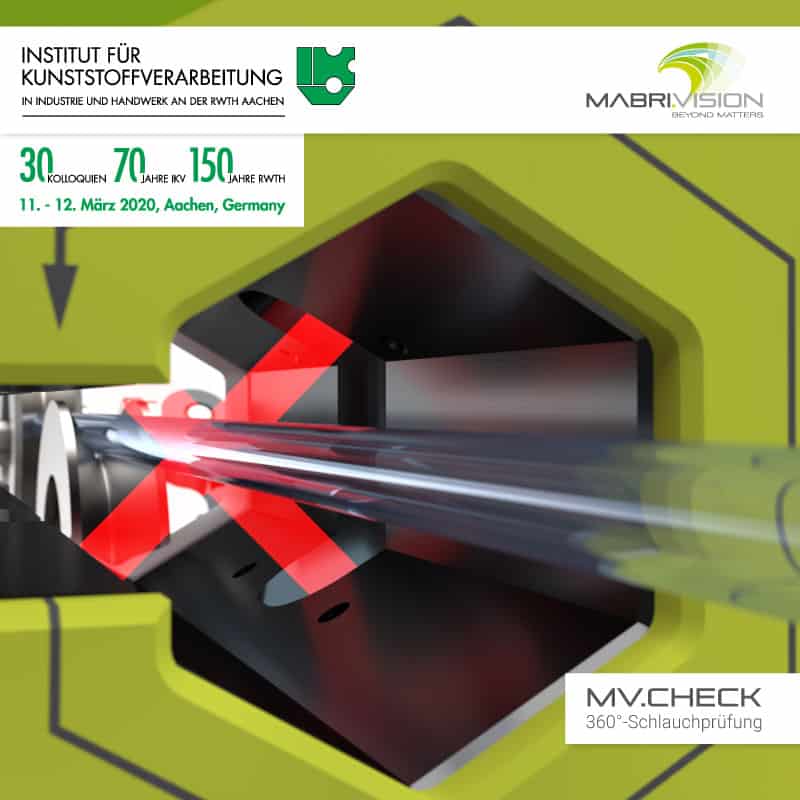

Trade fair, product The INLINE.SECTOR F1 at the IKV 2020 On March 11th and 12th, 2020, MABRI.VISION will be represented at the 30th IKV Colloquium in Aachen.

The 30th International Colloquium on Plastics Technology in Aachen will take place on March 11th and 12th at the Eurogress Aachen, and MABRI.VISION will be present

MABRI.VISION Trade Fair - Trade Fair Dates 2020 We look forward to seeing you at the following trade fairs in 2020: IKV: The 30th International Colloquium for Plastics Technology in Aachen

Team Motivated Start to 2020 The past year, 2019, was defined by a continuous increase in challenges and successes. For this reason, we were able to..

News Year in Review 2019 Year in Review 2019: Before we too embark on the year-end celebrations, we take the opportunity to pause and reflect on the MABRI.VISION fiscal year

Team Christmas Party 2019 This year's MABRI.VISION Christmas party took place on December 13th in our hall. It was festively decorated – complete with a Christmas tree and atmospheric lights

At Sea – Our 2019 Team Event The undisputed highlight of the year for MABRI.VISION employees is the team event at sea, which took place in October 2019

TRADE FAIR REVIEW: productronica 2019 We look back on a successful trade fair year in 2019. productronica 2019, which attracted over 44,000 industry professionals, provided a fitting finale

TRADE FAIR Successful trade fair launch in Munich We have had a successful start to the trade fair. Since Tuesday, November 12, 2019, productronica has been attracting industry experts from all over the world to Munich. Here