Industry-independent solutions for production

Complete optical inspection for production

MABRI.VISION builds and develops innovative machine vision solutions and modular systems for your production processes and end-of-line inspections. Modern manufacturing increasingly demands that inspection processes be mapped inline and with 100% accuracy. This is where our inspection concepts come in.

Complete optical inspection for production

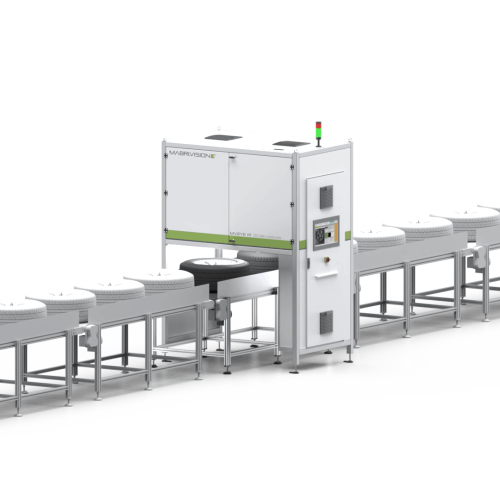

Rotary indexer test systems

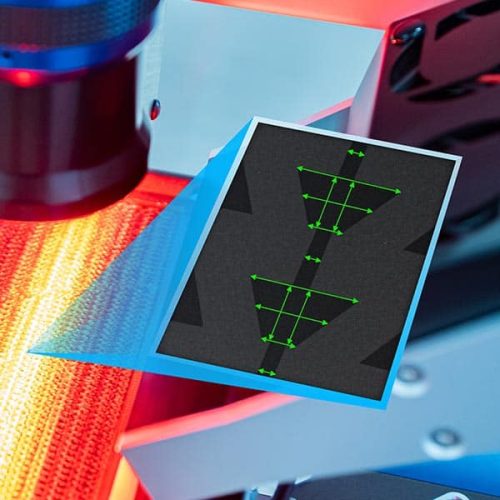

READING BRIDGES | MODULAR TESTING SYSTEM

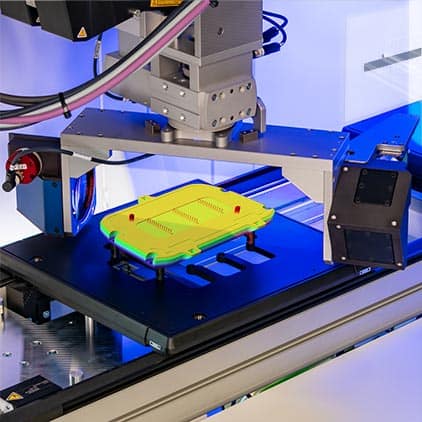

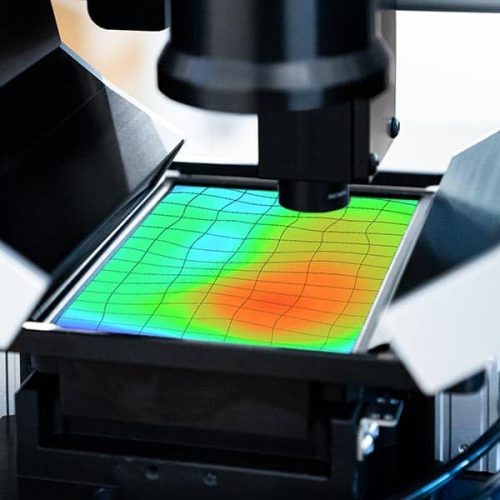

INLINE 2D/3D MEASUREMENT ON THE CARRIER MV.EYE I2 WT

We offer 2D/3D measurement on the workpiece carrier for your quality assurance with our MV.EYE i2 WT inspection system. Seamless and directly on the workpiece carrier.

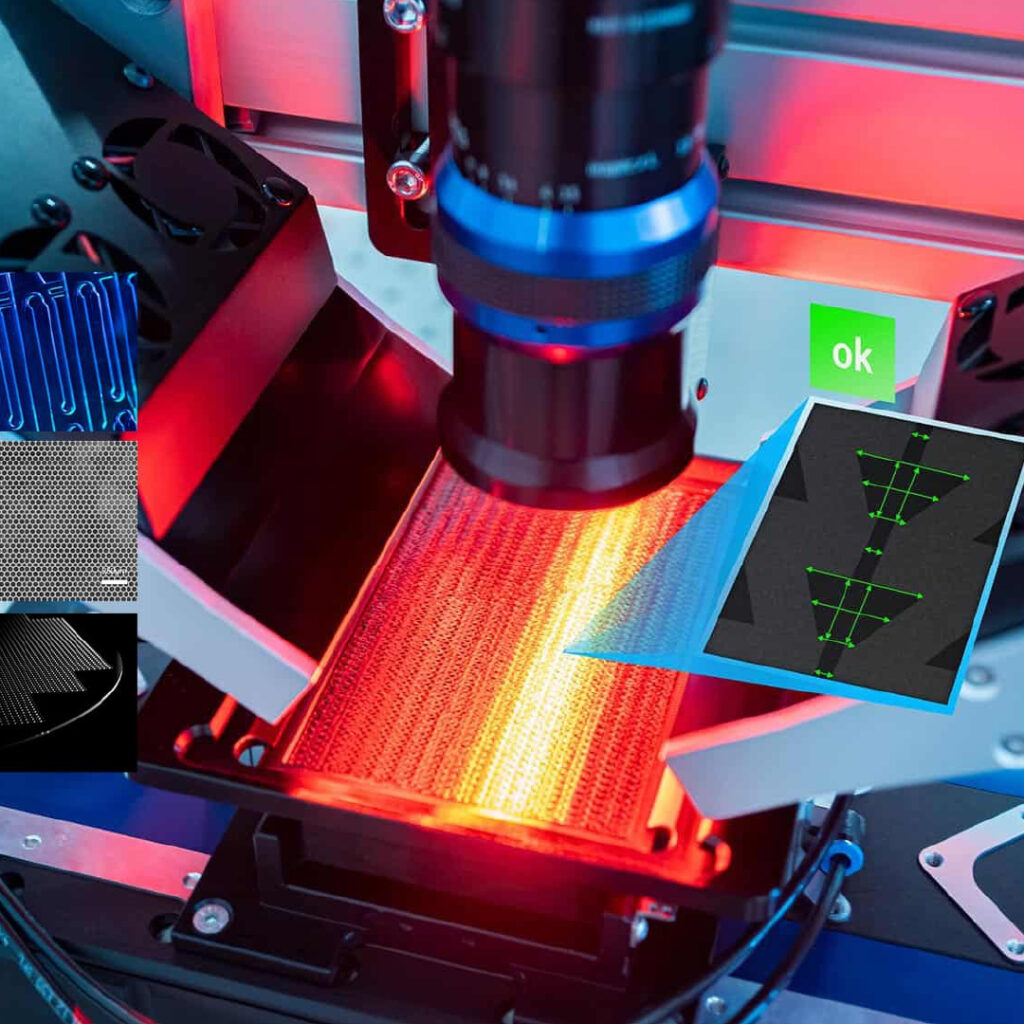

HIGH-SPEED MICROSCOPE | AUTOMATED TESTING

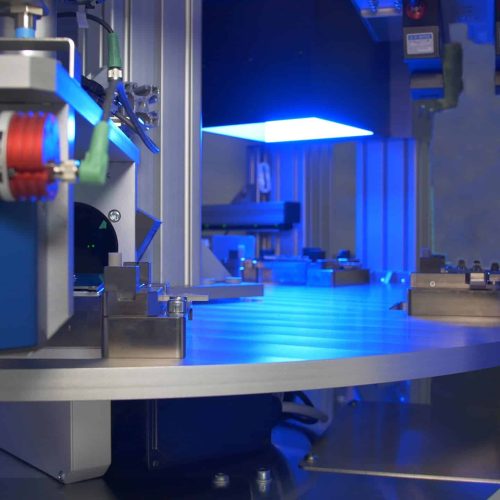

Flexible testing platforms

Inspection of the goods carrier system

Testing on workpiece carriers is easily and modularly implemented thanks to the controlled handling of the items being tested. MABRI.VISION offers systems with and without workpiece carrier systems for flexible integration into existing processes.

Testing on the conveyor belt

Conveyor belts or roller conveyors are used in many production processes. Due to their good visual accessibility, reading bridges and individual camera systems are particularly suitable for this purpose.

Testing of continuous belt processes

Continuous processes, e.g. from the textile or printing industries, offer many advantages for camera and measuring technology because the feed rate can be used for continuous data acquisition.

Testing of bottle/can transport systems

Processes for bottles, cans and other containers usually offer good optical accessibility, allowing for the integration of MABRI.VISION's measurement technology.

Automatic loading

In addition to the option of manual loading, for example for rotary indexing systems, MABRI.VISION offers the necessary automation technology and loading systems to automate even complex testing processes within the production cycle. This includes robotic systems and customized solutions.

Individual solutions

MABRI.VISION offers optical measurement solutions for industry-specific and individual production processes. Our vision experts will be happy to advise you.

What are we testing?

Various component characteristics, defects

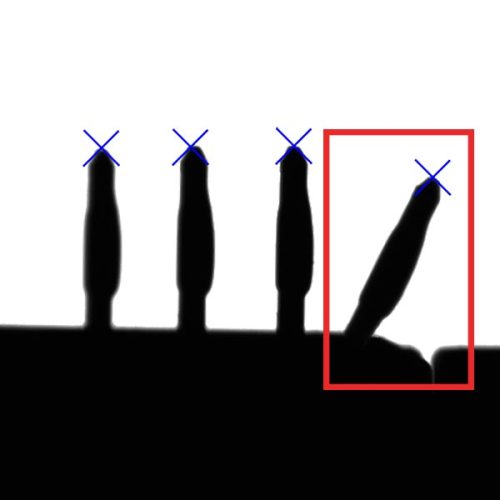

Pin bending

Contacts and base plate drilling

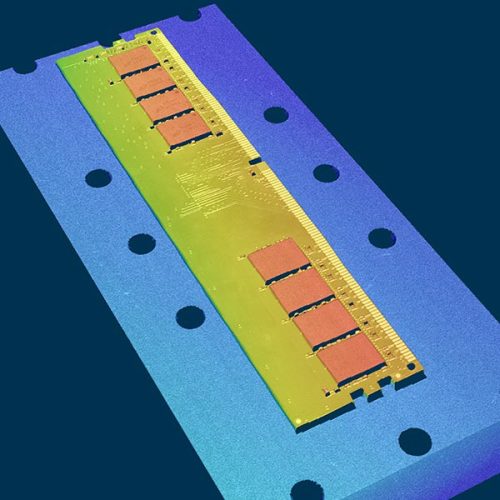

Have your components of varying sizes inspected at different stations using the MV.EYE i2 inspection system. A 3D profile measurement using a triangulation sensor generates pinpoint height information and dimensional accuracy. Obtain 3D measurement data via contact positions.

Contact height

Surface pores

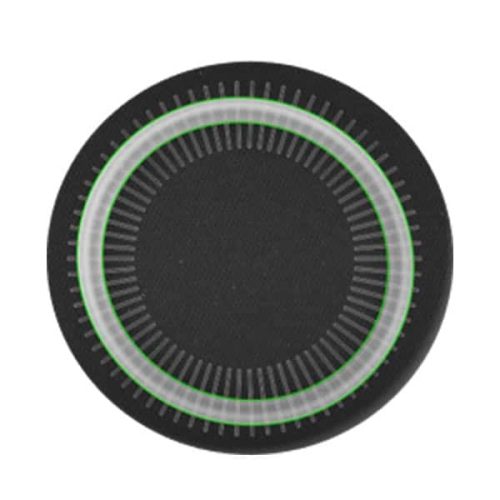

diameter

Diameter testing can be performed at various locations and with different sensors. While 2D testing is quick to integrate and cost-effective, 3D testing delivers precise results even for complex structures.

Defects

Grooves and scratches

Dents and scratches

Foreign particles

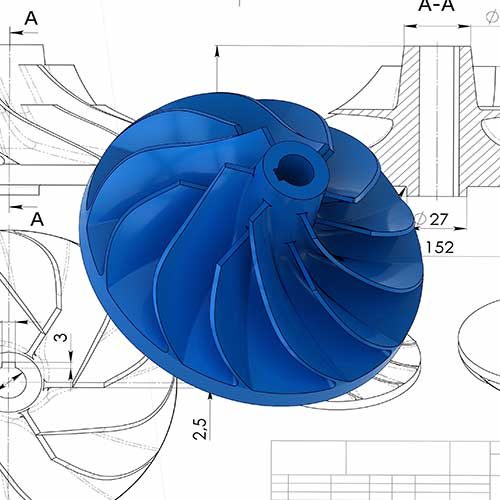

Shape, dimensional accuracy (selection)

Shape deviations

Structural parameters

Even though injection molding processes result in only slight variations in shape, the smallest changes can have a significant impact on function. Our testing systems allow us to measure structural dimensions and channel widths for in-vitro diagnostics, minimizing variations in flow characteristics and volume.

Altitude deviations

3D shape

DIAMETER, ROUNDNESS AND OVALITY

Application examples

IGBT and power modules

IGBT modules or power modules are usually complex components requiring testing of multiple parameters. MABRI.VISION offers complete measurement solutions for 100% comprehensive testing during production cycles.

Connectors and contacts

Testing of stator housings

Using high-precision profile cutting sensors, we capture the 3D shape of complex components during the process and check for micro-defects and the smallest shape deviations.

Microstructures

Even though injection molding processes result in only slight variations in shape, the smallest changes can have a significant impact on function. Our testing systems allow us to measure structural parameters, such as channel widths for in-vitro diagnostics, in order to minimize variations in flow characteristics and volume.

DMC reading in logistics

The MABRI.VISION MV.EYE K1 reading bridge enables reliable detection and reading of 2D codes, such as Data Matrix and QR codes. The robust system can be integrated into your production environment and, thanks to its modular design, can be adapted to your needs for car and truck applications.

Testing of stainless steel tubes

MABRI.VISION has developed the MV.EYE PI1 optical inspection system for detecting defects on metal pipes. By using multiple optics and a high-speed focusing system, defects inside the pipe and at the weld seam, for example, can be detected.

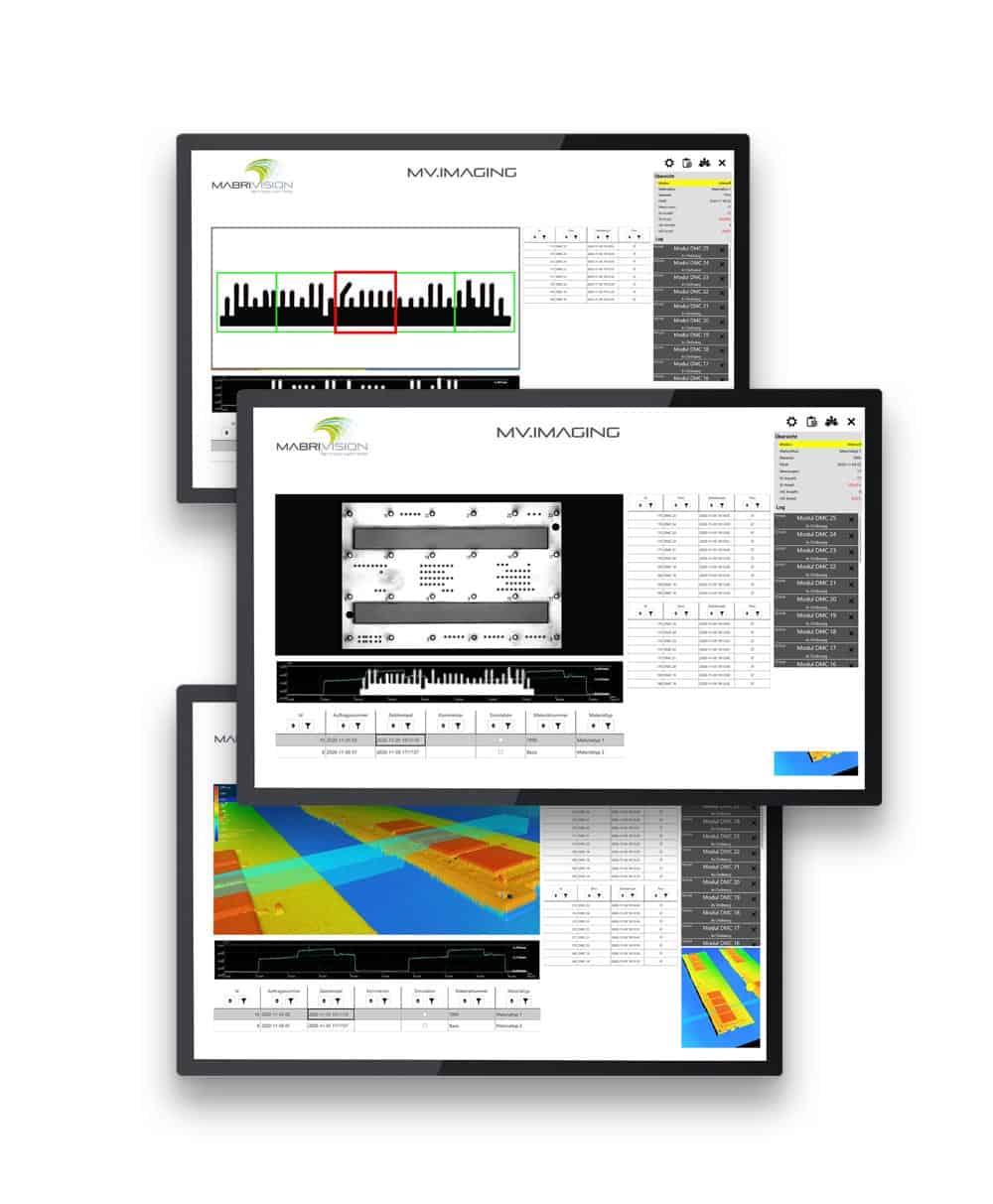

software

Intuitive user interface

We offer you a modern and modular user interface. A touch interface with full HD resolution provides ample overview and space for visualizing relevant process parameters.

Made for production

We achieve the balance between industrial software and a modern user experience by combining various platforms and technologies in our framework. This allows us to map real-time processes and the familiar Windows environment into a single system. As a result, you can operate our testing systems efficiently and with minimal training. Features include:

- Process indicators and visualization of relevant results

- Seamless tracking through result exports and databases

- Batch management

- Calibration and evaluation options

- Integration through all industry interfaces

- Advanced user management with audit trail

Artificial intelligence

At MABRI.VISION, machine learning and artificial intelligence are more than just marketing terms. Our experts assess during the design phase whether the use of AI solutions can meaningfully support the testing process.

Our software modules

The MABRI.VISION software platform MV.IMAGING is designed for maximum flexibility. Various modules from the areas of interface, database, and reporting can be integrated as needed and adapted to the requirements of your inspections.

Evaluation

statistics

Clear presentation of all relevant tests through the MABRI.VISION statistics module.

Trend graphs

Real-time overview of various measured variables. Both threshold values and tolerances are displayed.

Data fusion

Data fusion enables the combination of test results from different measurement systems.

Coordinate transformer

Software module for a clean switch between different coordinate systems.

database

Recipe database

The recipe database contains all relevant information for checking your production orders.

Results database

MV.IMAGING software module for long-term storage of your exam results.

Batch management

Both tests and result analyses can be performed on a batch basis.

Reports

MABRI.VISION software module for creating reports for enhanced quality management.

interface

User management

User management allows for the clear definition of different levels of rights.

Results display

Clear visualization of results for the operator with different display options.

Audit trail

We offer a comprehensive audit trail function, especially for the medical technology and pharmaceutical industries.

Change Log

A change log module ensures complete documentation of all parameter changes.

Universal: versatile in its applications

automobile

In the automotive industry, MABRI.VISION end-of-line testing systems are used due to their fast measurement cycle and integration into existing transfer systems.

Medical technology

In medical technology, 100% testing of all products is essential. MABRI.VISION end-of-line testing systems meet the industry's requirements.

Electrical engineering

Reliably test products with a wide range of test features, such as connectors and circuit boards, during the production process and at high speed.

Our testing modules

MABRI.VISION end-of-line testing systems can be flexibly equipped with a wide variety of different testing modules. To create the right solution for your application, a broad selection of testing systems is offered.

geometry

In-person exam.

The most advanced camera technology is used for the attendance check.

Location check.

Non-contact identification of the position, regardless of the manufacturing material of the test specimens.

Form inspection.

MABRI.VISION End of Line inspection systems inspect 2D and 3D shapes during the ongoing process.

Altitude test.

Precise height measurement. Even the finest structures can be measured using high-performance optics.

surface

Defect testing.

The use of 2D and 3D sensors allows for the targeted detection of damage to components.

Scratch test.

Scratches are reliably detected and characterized by various camera systems.

Scratches and dents.

The MABRI.VISION testing technology identifies even the smallest indentations on functional surfaces.

Microstructure analysis.

Enabling rapid and large-scale testing of microstructured surfaces.

Deep Learning

OCR.

The MV.IMAGING OCR software module is used to check lettering for distortions.

Anomaly check.

The module reliably detects structural defects in textiles, patterns and grids.

Neural networks.

Creation of self-learning systems through the use of neural networks for reliable defect detection.

Why MABRI.VISION

Innovative solutions, our passion!

Innovative solutions, our passion!

AI, Processing, Control - a software platform

AI, Processing, Control - a software platform

A strong team, always there for you.

A strong team, always there for you.

End-to-end solutions, all from a single source.

End-to-end solutions, all from a single source.

contact

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision