3D surface measurement technology for production.

3D surface measurement technology for production.

The MABRI.VISION platform for 3D surface measurement technology is suitable for use in industrial production and is characterized by the combination of fast axis systems with chromatic-confocal sensors. This enables high-precision surface measurement of a wide variety of materials.

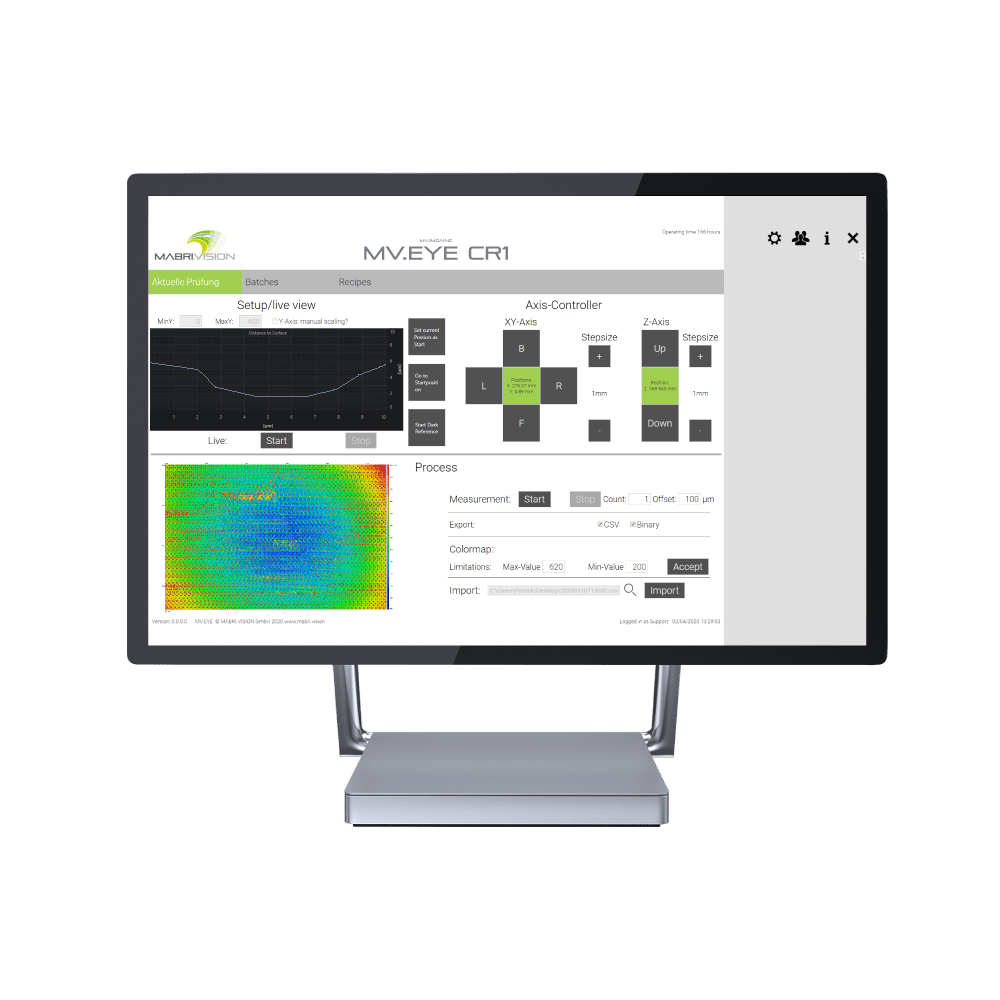

You benefit from a testing system that supports your production through automation and comprehensive evaluation options. Visualization of your data is possible via MountainsMap.

The MABRI.VISION testing platform for 3D surface measurements was developed for use in production processes. All common software interfaces are available for integration.

MABRI.VISION relies on the use of fast and extremely precise axis systems in order to be able to scan as precisely and efficiently as possible. The system achieves a bidirectional repeatability of ± 0.05 µm.

The axes of the MABRI.VISION test platform can be scaled and designed as desired thanks to the modular structure. This gives you a precisely fitting measuring range for your test items.

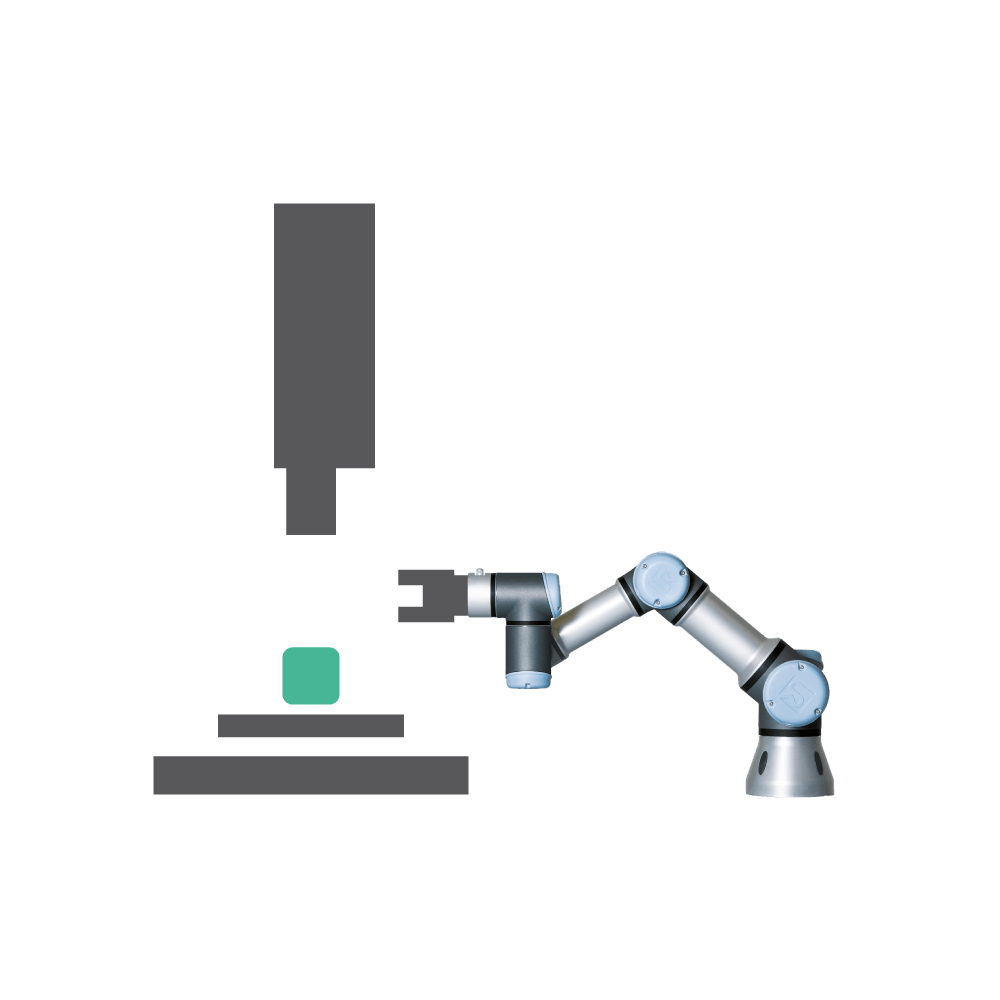

The MABRI.VISION platform for 3D testing of surfaces supports you in automating your production and testing processes through automated loading of the testing system and sorting of test specimens according to OK/NOK.

The use of chromatic-confocal sensors enables tests to be carried out at top speed. The test system achieves a measuring rate of 384,000 points / second and is suitable for tests in the production cycle.

In addition to the testing system, MABRI.VISION also offers automated evaluation of measurement data. Benefit from quick program changes, diverse analysis tools and comprehensive results databases.

Specifications

TEST

| Number of points per line | 192 |

| Scan frequency | 2,000 Hz (opt. 6,000 Hz) |

| Measuring rate | up to 1,152,000 points/s |

| Measuring spot diameter | from 2 µm |

| Lateral resolution | from 1 µm |

| Axial resolution | from 20 nm |

| Scan area | 200x200mm² |

| Line width sensor | 0.96mm - 4.78mm |

| Z measuring range individual measurement | 200µm - 4.78mm |

| Z measuring range | up to 50mm |

INTERFACES AND SOFTWARE

| Interfaces | ProfiNet, Ethernet |

| interface | 24 inch monitor, touch |

| operating system | Windows 10 |

| software | MV.IMAGING + CR module |

ATTACHMENT

| operating temperatur | 10°C - 40°C |

| rated capacity | 2.3kW |

| care | 230 V, 10 A |

| Sensor protection class | IP50 |

| Dimensions (W x D x H) | 1,000mm x 800mm x 1,500mm |

| Weight | 350kg |

Universal: can be used in a variety of ways.

medical technology

100% quality control is required in the production of medical technology. MABRI.VISION enables 3D surface inspections with the highest precision.

semiconductor technology

The MABRI.VISION testing platform is used in wafer production. The scalable structure enables the detection of large surfaces in the shortest possible time.

tool making

Carrying out automated testing of molds requires speed and maximum precision - requirements that MABRI.VISION unconditionally meets.

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 in 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision