With our system for testing suspension springs, you are able to check height offsets in sync.

Quality characteristics such as spring diameters are detected and verified in a single test run. We guarantee a repeatability of 10 μm.

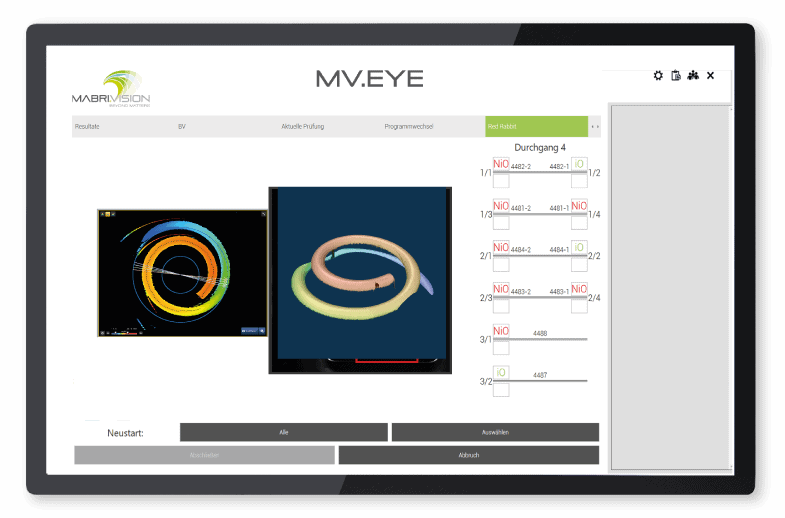

The inline-capable testing system detects the position, angle, and number of turns.

MABRI.VISION uses state-of-the-art triangulation sensors to create a 3D profile map of the spring eye.

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.