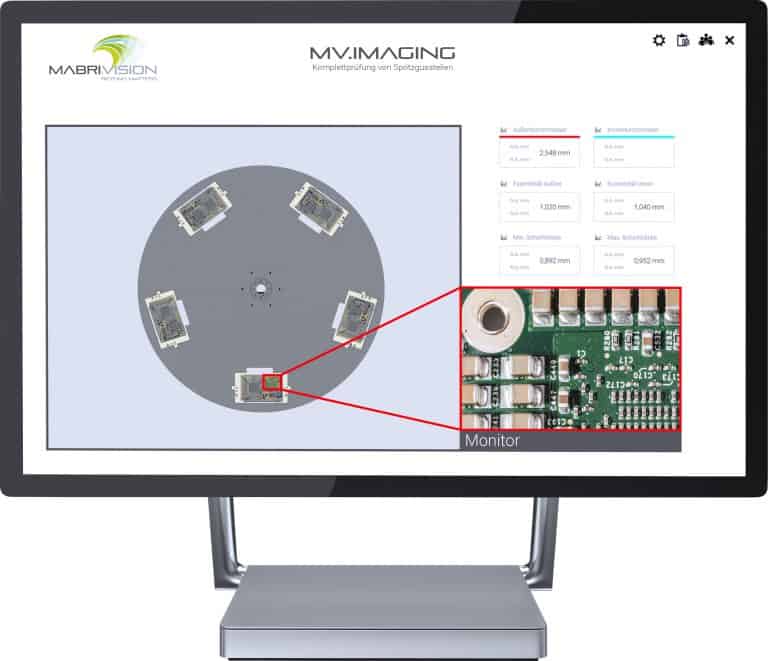

Application.

Flexible rotary cycle tester.

Testing complex injection molded parts for electromobility suppliers

Requirement

The variety of components to be tested in the automotive industry ranges from connectors and circuit boards to complex injection molded parts and plastic-metal composites. The testing process of a component with almost 70 test characteristics can take up to four minutes with a conventional measuring device. For continuous testing, an inline-capable system with an average measuring cycle of three seconds is required.

Applications

- Comprehensive quality control of injection molded parts and plastic-metal composites in the automotive industry.

Goals

- Automated testing system

- Inline capable vision solution

- Testing of complex components

- Testing in line with production

- Detection of surface defects

- Detection of contamination

Categories

- Image processing

- quality assurance

- Automotive industry

Technologies

- OCT

- Optical micrometer

- Light section sensors

- microscopy

- TensorFlow

- Halcon

- Barcode reader

solutions

- Rotary table

- Multimodal testing system

- 3D inspection with light section sensors

- Precise height measurement with optical micrometer

- Testing of up to 200 features at a time

- Interface for visualizing the test

Technical data:

- High resolution camera image

- Optical micrometer

- Triangulation sensor

- Interfaces (ProfiNet, Digital I/O)

- Databases

- Data fusion of 2D and 3D measurement data

Advantages.

The MV.EYE i2 testing system is a flexible rotary tester and relies on the combination of different technologies – imaging, laser triangulation and optical micrometers. What MABRI.VISION offers with this system goes far beyond precise measurement results and speed. Added to this are multimodality, customer-specific and space-saving solutions, high scalability and data fusion of 2D and 3D measurement data.

Testing in production cycle

An inline-capable complete solution for a comprehensive quality control in your production.

Multimodality

An optimal test result through the combination of different technologies.

High scalability

A comprehensive test in line with production and adapted to your production quantities.

Complete testing of complex injection molded parts

up to

up to

up to

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Dennewartstrasse 25 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision