What we check

Shape and dimensional accuracy

Classic Machine Vision Solutions

Checking form and dimensional accuracy is an important part of quality control in industrial manufacturing. Particularly in the field of machine vision, special testing methods and techniques are frequently used to ensure compliance with tolerances and dimensional specifications.

One way to check shape and dimensional accuracy is to use optical measurement methods, in which the part to be inspected is photographed with a camera and the dimensions are automatically determined using image processing software. This method offers the advantage of being fast and precise, and it does not require any physical contact with the part.

Alternatively, non-contact 3D scanners can be used to measure the shape of the part. These methods are particularly suitable for inspecting complex geometries and for monitoring manufacturing processes in real time.

Do you have any questions? Contact us

Our sales team will be happy to assist you

+49 241 56 527 930

info@mabri.vision

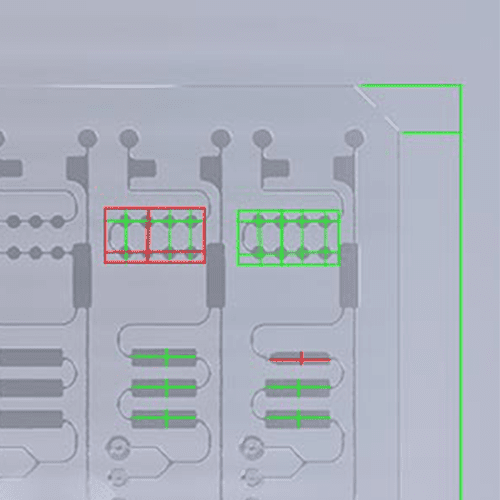

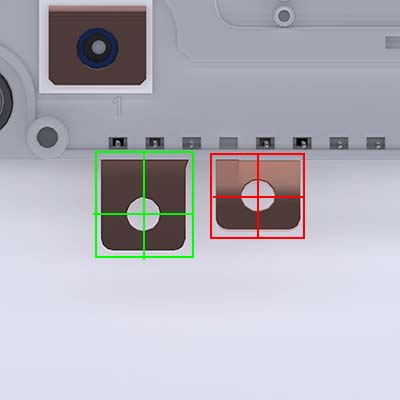

2D Shape Inspection

2D form inspection in the field of industrial machine vision encompasses methods in which the shape of a part is measured using 2D images. Telecentric optics are often employed to determine distances and dimensions of objects with high precision. A light beam is emitted parallel to the optical axis of the camera system, capturing the object's image from the perspective of the camera lens. This offers the advantage that the distances in the image are independent of the object's distance and size, resulting in highly accurate measurements.

Channels

- Shape of the canal structures

- Position (X,Y)

- Distances

Pads

- Form of the structures

- diameter

- Distances

- Deformations

Stamped parts

- Form of the structures

- diameter

- Distances

- Position

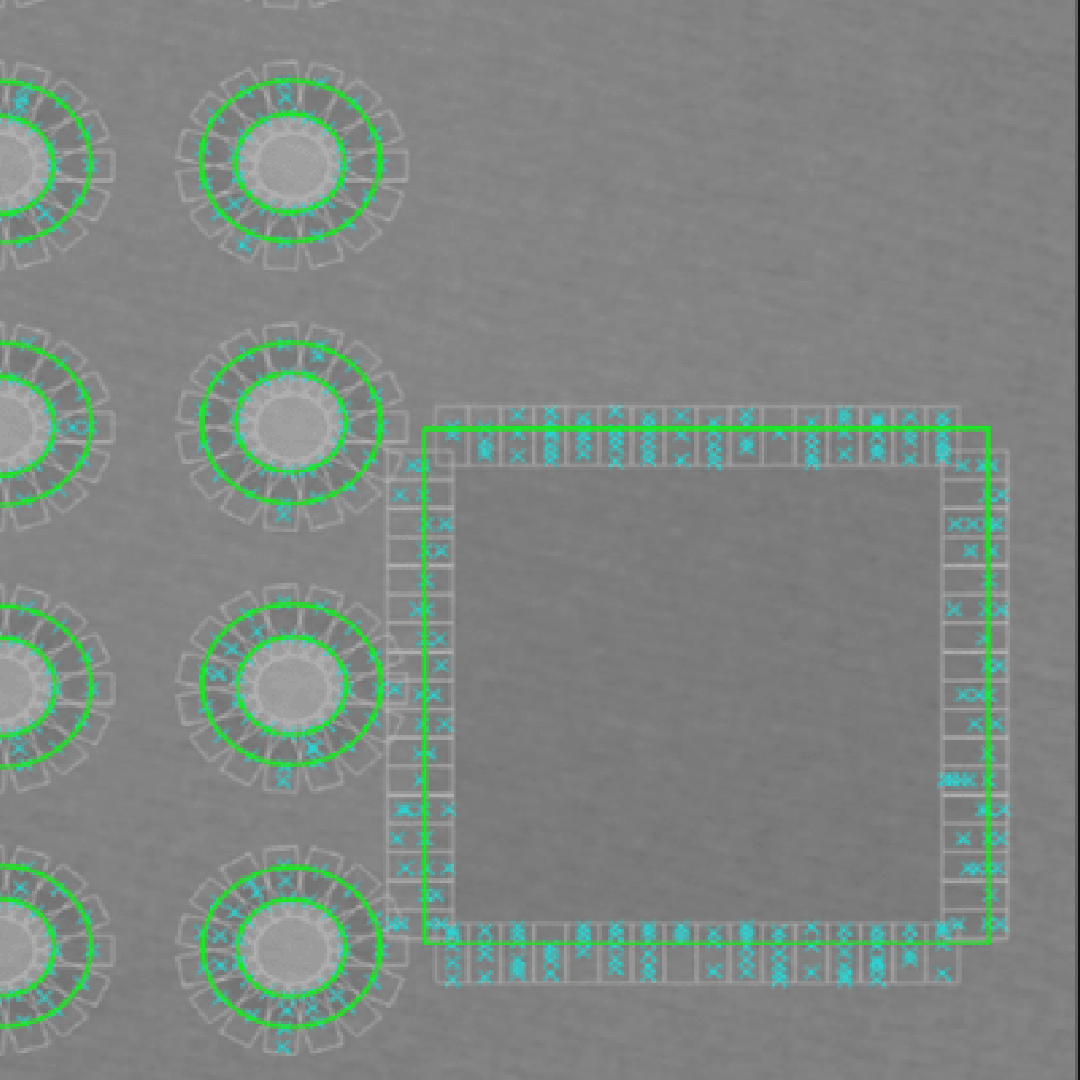

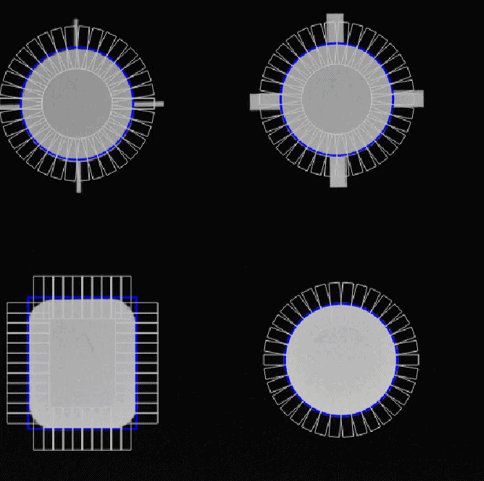

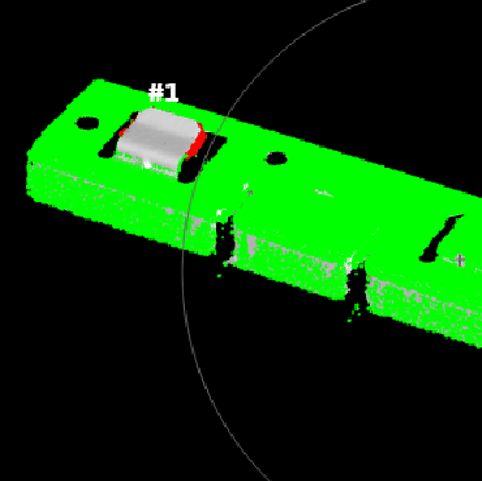

3D Shape Inspection

3D shape inspection is a core component of industrial machine vision, where the shape of a part is measured using 3D scanners or optical methods. This method offers the advantage of being fast, precise, and suitable even for complex geometries, thus playing a crucial role in the quality control of industrial manufacturing processes.

Terminals

- 3D deformation of contacts

- diameter

- Position (X,Y)

- Height (Z)

Pins

- 3D bending of pins

- Pin position (X,Y)

- Pin height (Z)

- tumbling circle

Lattice studs

- 3D forming of sheet metal parts

- Position (X,Y)

- Height (Z)