Precise positioning of sensitive components in trays, wire mesh containers, or other transport media. From small electronic parts to large, complex components.

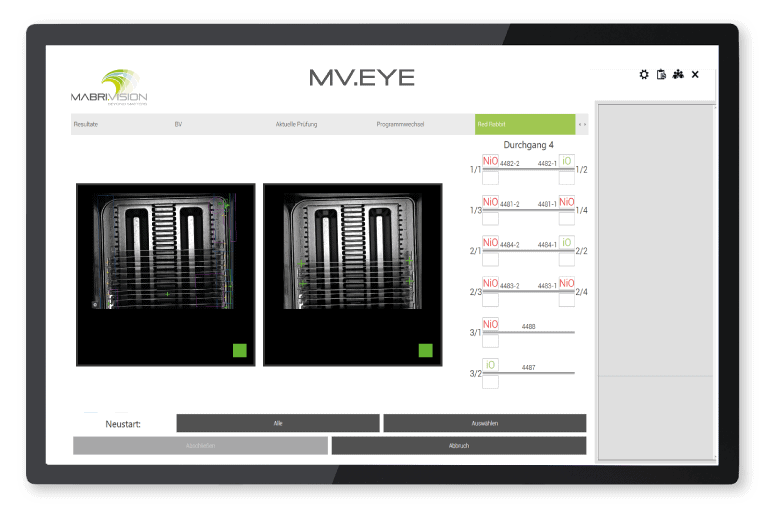

By using multiple cameras and comparing all available motion data in real time, precise positioning of the parts and transport media is ensured at all times.

Additionally, the systems can be expanded to include features such as counting or traceability, for example by integrating a 2D code reader.

Defect and position testing is possible through optional sensor extensions. 2D and 3D sensors can be used to test complex test specimens.

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.