ROBOT.SPECTOR

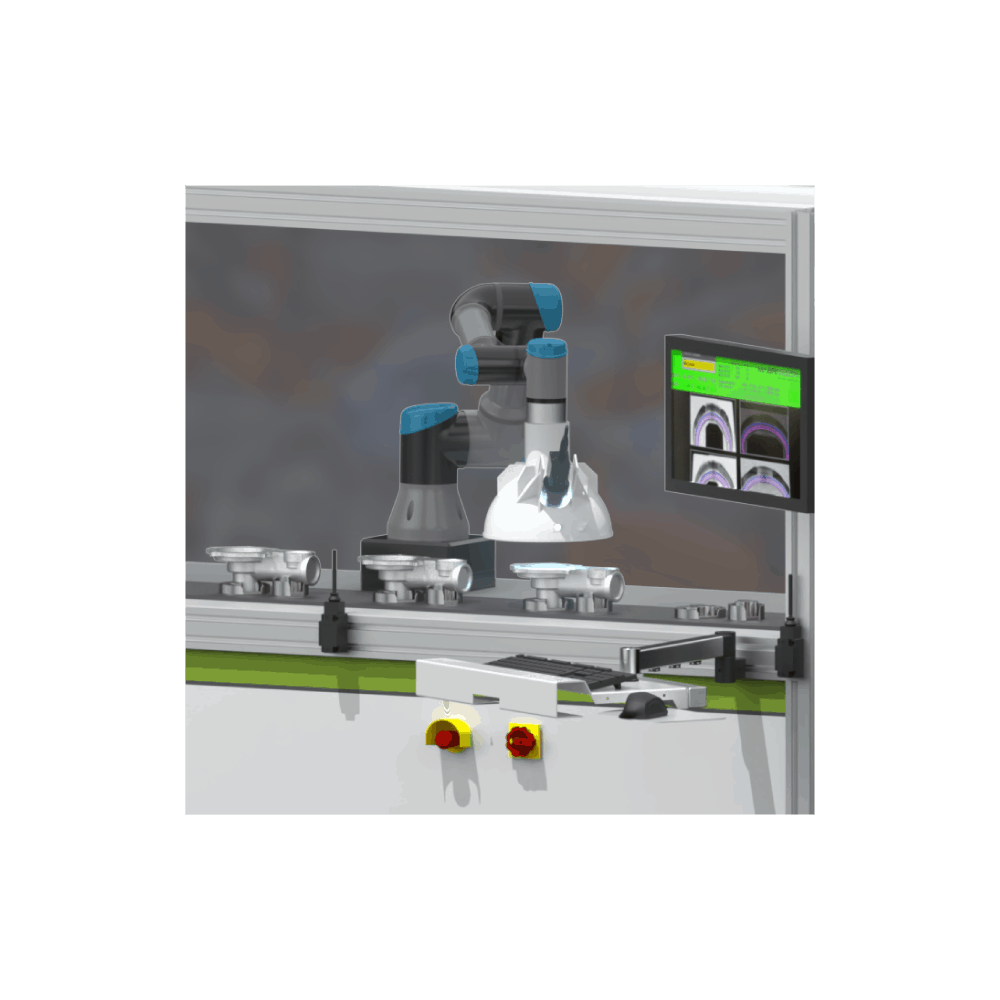

Robot-guided sensor technology.

Robot-guided measurement technology.

By using robot-guided sensors, MABRI.VISION enables flexible and quick inspections of multiple perspectives on a component and thus guarantees seamless quality control.

The robot can be equipped with different testing technologies, such as high-resolution cameras or triangulation sensors. In this way, your special testing requirements can be met in the best possible way and even difficult-to-access areas of components can be tested at the same time as the process.

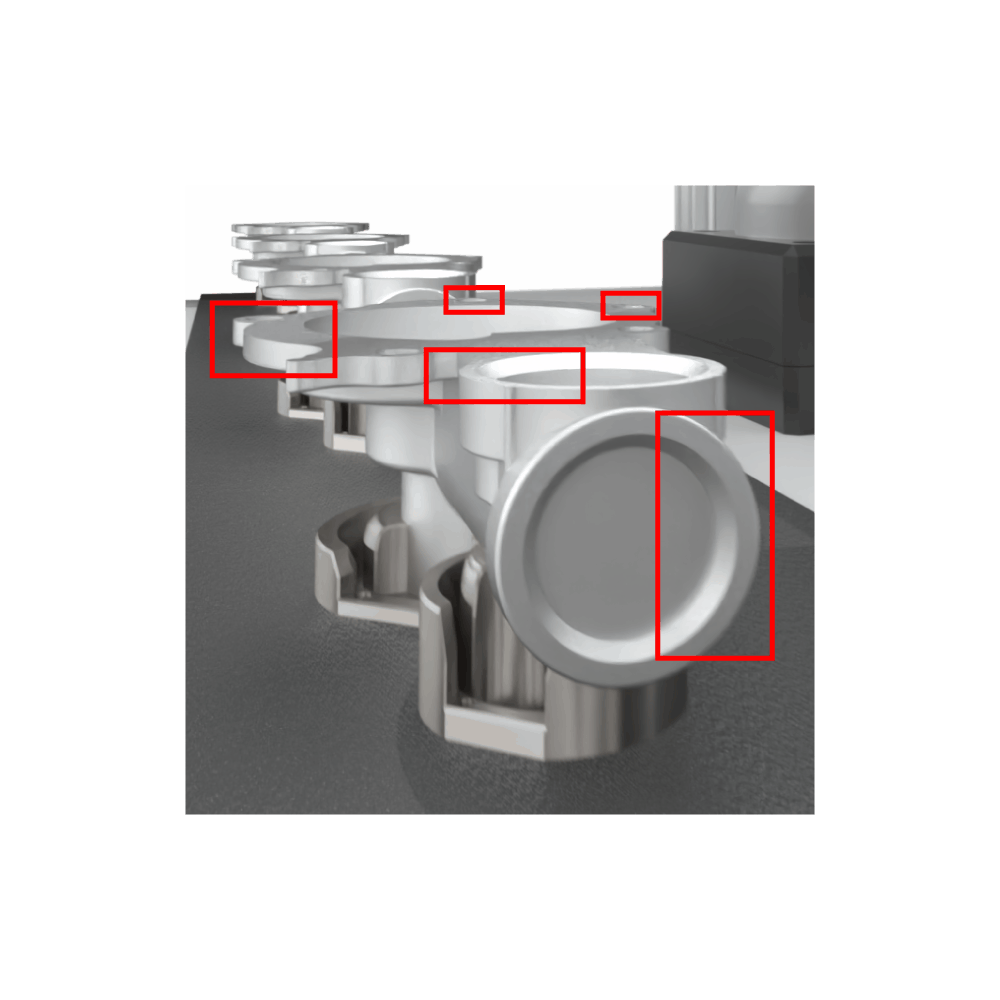

Multi-test points.

Robotics enables uncomplicated inspection of components from different perspectives. The technology is used that captures your test characteristics in the best possible way.

Any orientations.

Check your components or products regardless of their location: thanks to robot-guided sensors, all test characteristics can be recorded despite testing during production cycles.

Collaborative workplaces.

Whether for sorting or gripping the test part: fully automatic removal of parts using a gripper arm offers significant cost and time savings in production and testing processes.

Dimensional accuracy.

Uncompromising dimensional accuracy testing from different angles. Optimize your production through 100% testing of components and products.

Defect inspection.

Reliable and quick detection of defects and contamination. By using gripper arms, damaged components can be sorted out immediately.

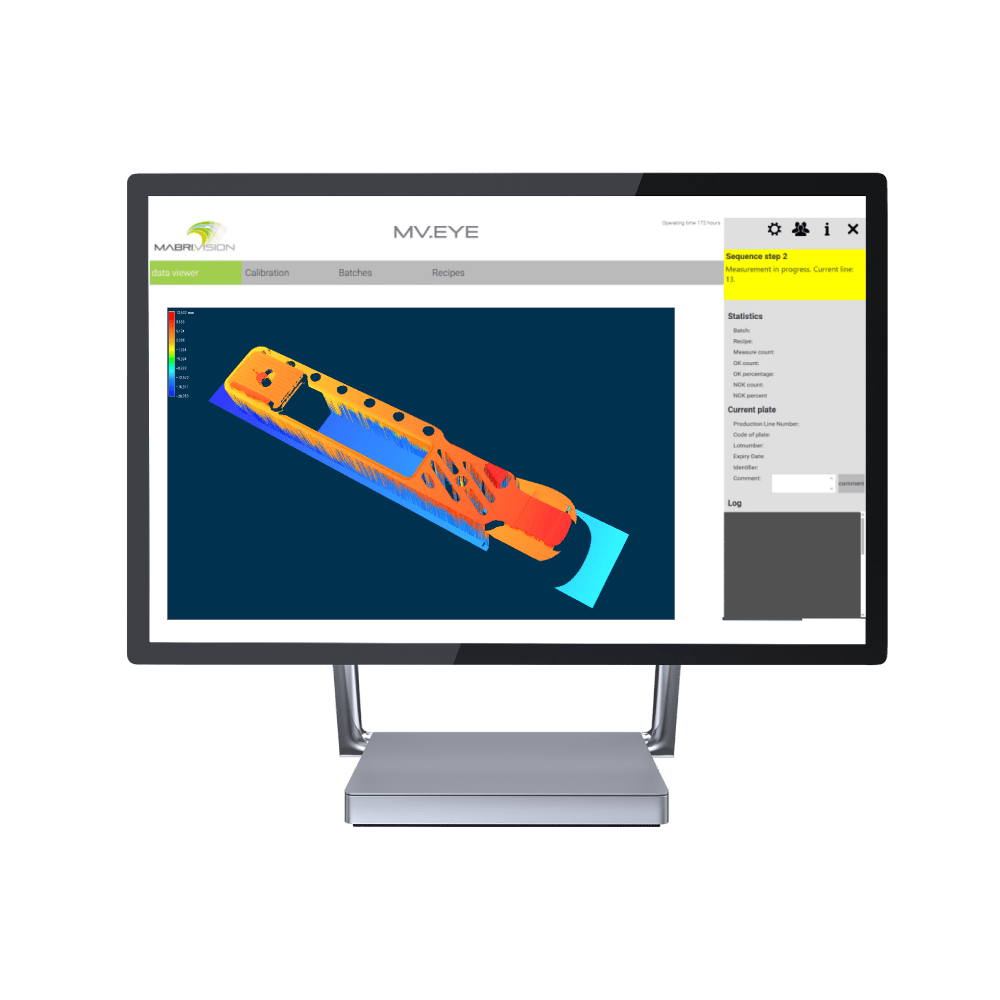

3D inspection.

Your testing requirements form our benchmark. At your request, we combine robot-guided sensor technology with the latest technologies for 3D testing.

Universal: can be used in a variety of ways.

metal processing

Do not compromise on quality control and remain flexible even with components that are difficult to access.

plastic technology

From inspection to identifying and sorting parts, make your production more efficient with robotics.

automotive industry

Flexibility and collaboration form the basis for production, inspections and assembly in the automotive sector.

Electrical engineering

Presence, position tolerances, sway circles – the tests in the field of electrical engineering are diverse and can be implemented using robotics.