The MABRI.VISION system combines innovative measurement technology with a robot connection, enabling the integration of a pick & place process into your production.

The inline-capable testing system can be integrated into your existing production line. Testing is performed in sync with the production cycle and is adapted to your process requirements.

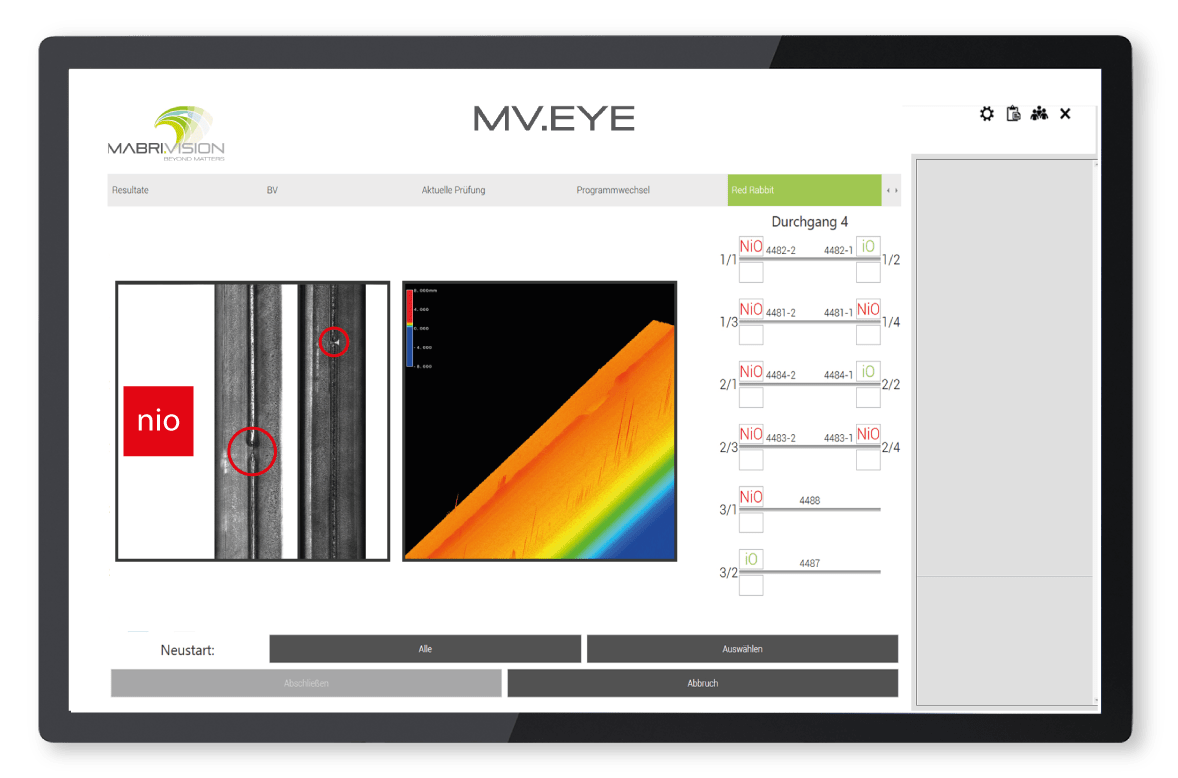

A MABRI.VISION inspection system offers precise defect detection in addition to checking position and presence. The data can then be exported and analyzed.

Benefit from precise weld inspection, which can detect, for example, breaks.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.