Optical quality control in medical technology production

Optical quality control in medical technology production

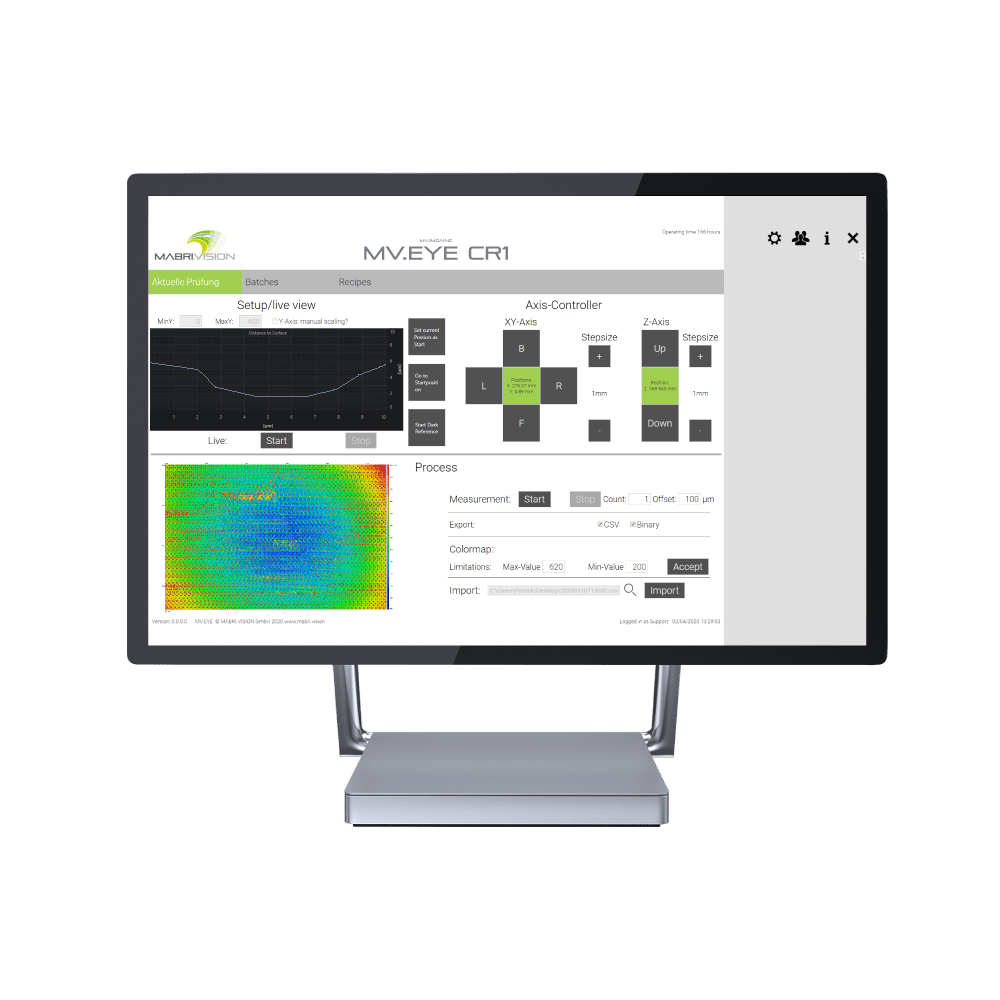

The MABRI.VISION testing platform for optical quality control in medical technology production offers seamless optical recording and evaluation of your products in the production process. Through the use of high-performance optics, shapes, tolerances and defects are reliably detected. In addition, the MABRI.VISION software MV.IMAGING supports you with the documentation, qualification and validation of your processes necessary in medical technology production. For this purpose, various software tools are made available to you, such as AuditTrail and databases.

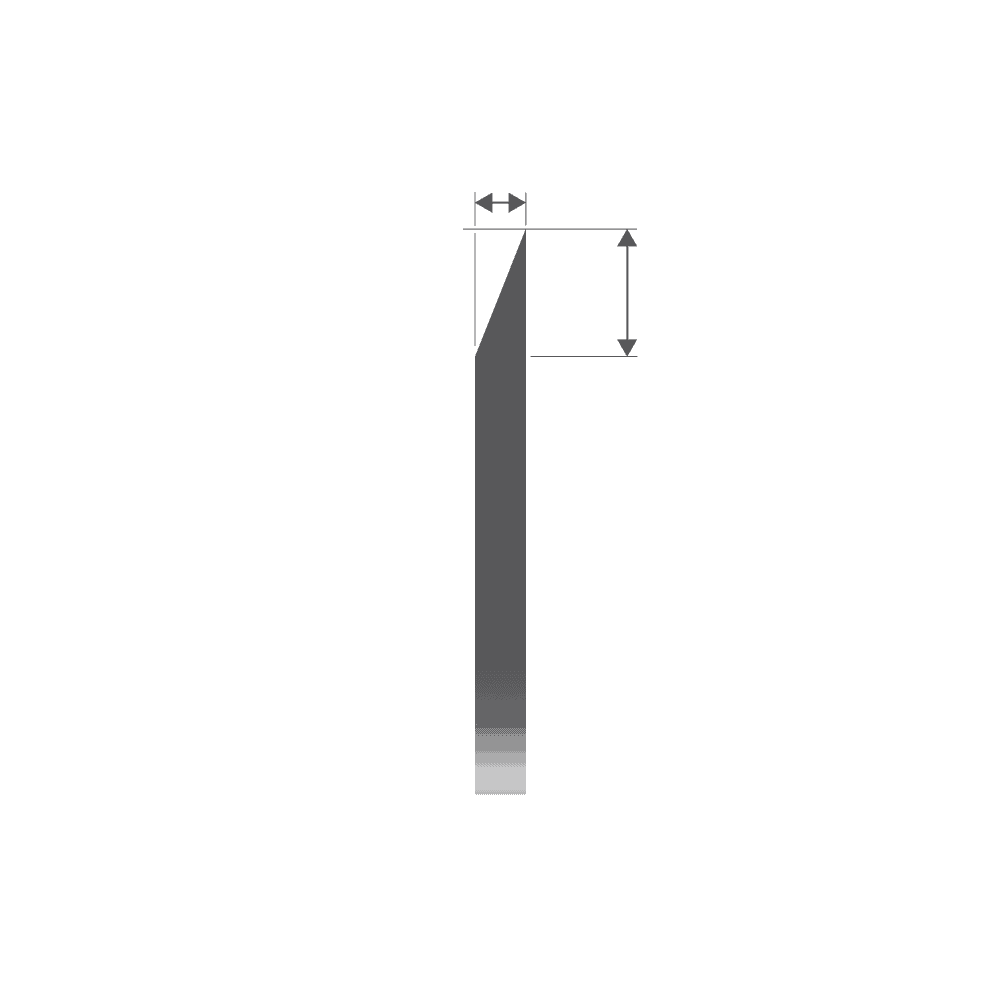

Form inspection.

The MABRI.VISION platform checks the shape, position and height of your products during the ongoing process and thereby provides you with all relevant data for subsequent process steps.

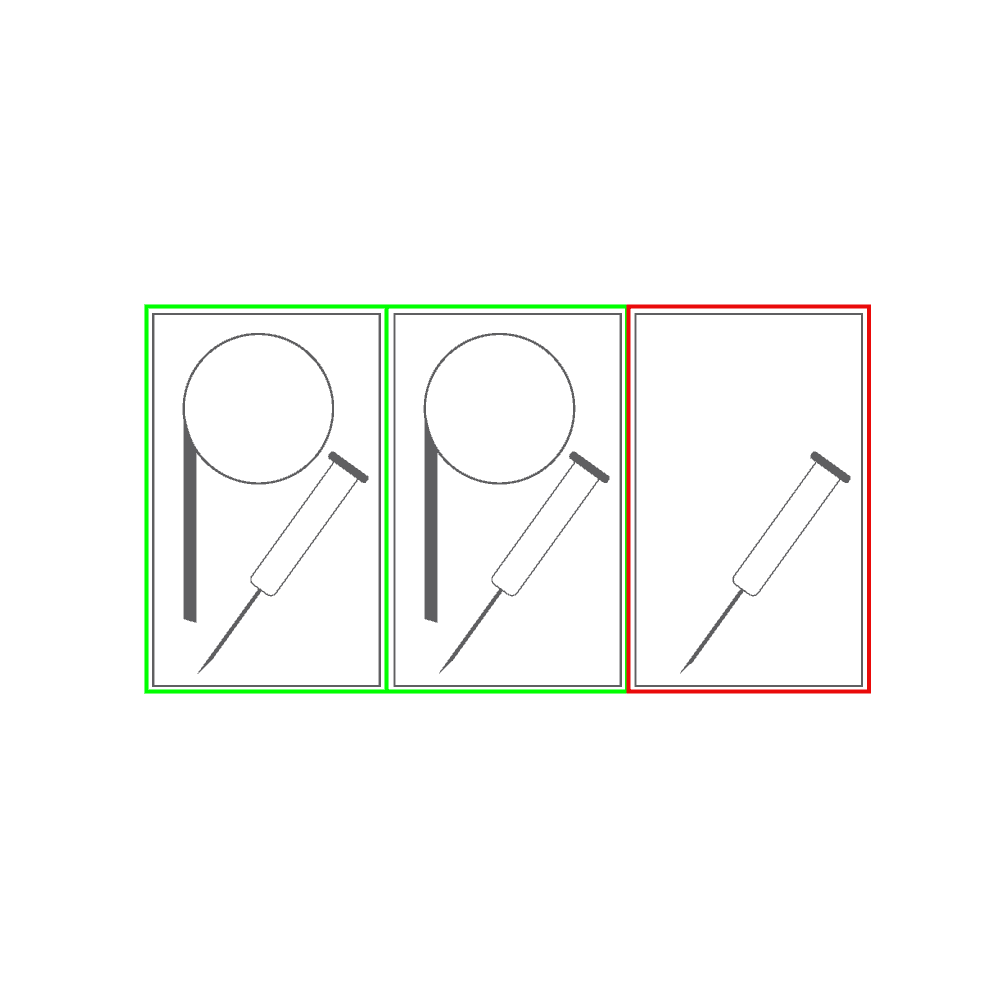

Presence exam.

The most advanced camera technology is used to check attendance. The testing is recipe-based and enables the production of clean and complete batches.

Defect inspection.

Benefit from reliable detection of surface defects such as scratches, blemishes and dents. By using 3D measurement technology, 3D shape deviations can also be detected.

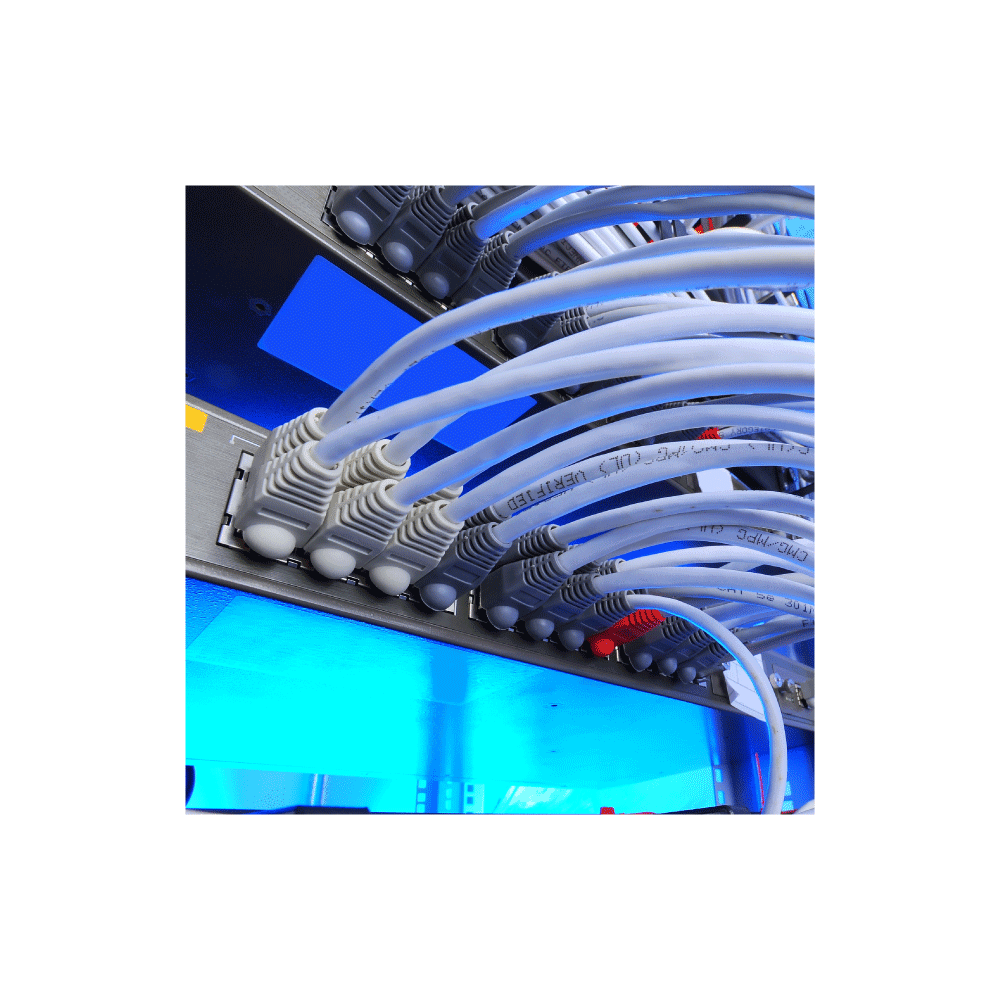

Interfaces.

The MABRI.VISION platform for 3D inspection of surfaces supports all common industrial interfaces, such as ProfiNet and EtherNet. If necessary, the system can be expanded to include customer-specific interfaces, such as the open interface standard OPC UA.

Cleanroom technology.

A cleanroom-compatible enclosure with a high-performance FFU fan filter unit and an optional stainless steel design with HEPA filter (clean room ISO class 5) meets the high requirements of medical technology. Retrofitting a ULPA filter is possible.

With the MV.IMAGING software, MABRI.VISION offers a variety of modules that support you in qualification and validation. You benefit from recipe databases, database backups, user management, change log and audit trail.

Specifications

TEST

| Megapixels | 0,5; 1; 2; 5; 7; 20 |

| lighting | Ring, rod, background, coax |

| resolution | up to 5104 x 4092 pixels |

| Application | Semi-finished products, assembly, packaging |

| Inspections | Form, presence, defects |

INTERFACES AND SOFTWARE

| Interfaces | ProfiNet, EtherNet |

| interface | Visualization of the test, statistics |

| software | MV.IMAGING |

| Functions and modules | Recipes, databases, user management |

ATTACHMENT

| Dimensions (W x D x H) | Dep. of implementation |

| Temperature range | 10°C - 40°C |

| rated capacity | Dep. of implementation |

| care | 230V |

Universal: can be used in a variety of ways.

Production of semi-finished products

In medical technology production, guarantee flawless products right from the production of primary materials and semi-finished products.

Assembly

Check the composition of different components in the process and sort out defective products.

Packaging

Check packaging in medical technology production for shape defects and presence and check prints, QR codes and barcodes.

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision