PLANT ENGINEERING

OPTICAL MEASURING TECHNOLOGY

If it needs to be examined more closely

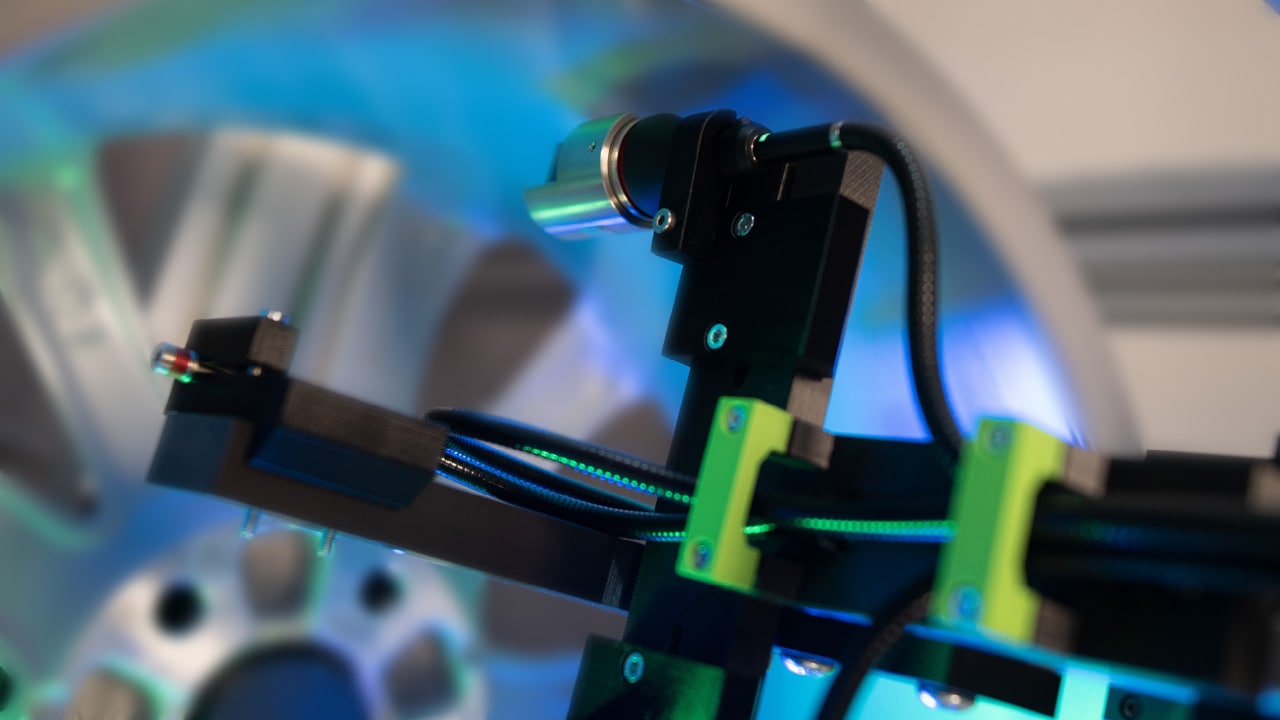

In addition to classic matrix and line scan cameras, we specialize in integrating precise optical measurement technologies into our testing systems. We use these systems, for example, to inspect microchannels in injection-molded components or to analyze the smallest medical component parts for defects. We rely on complete automation solutions, from workpiece carriers to automated feeding. Our software allows us to generate and analyze the necessary parameters from the measurement data.

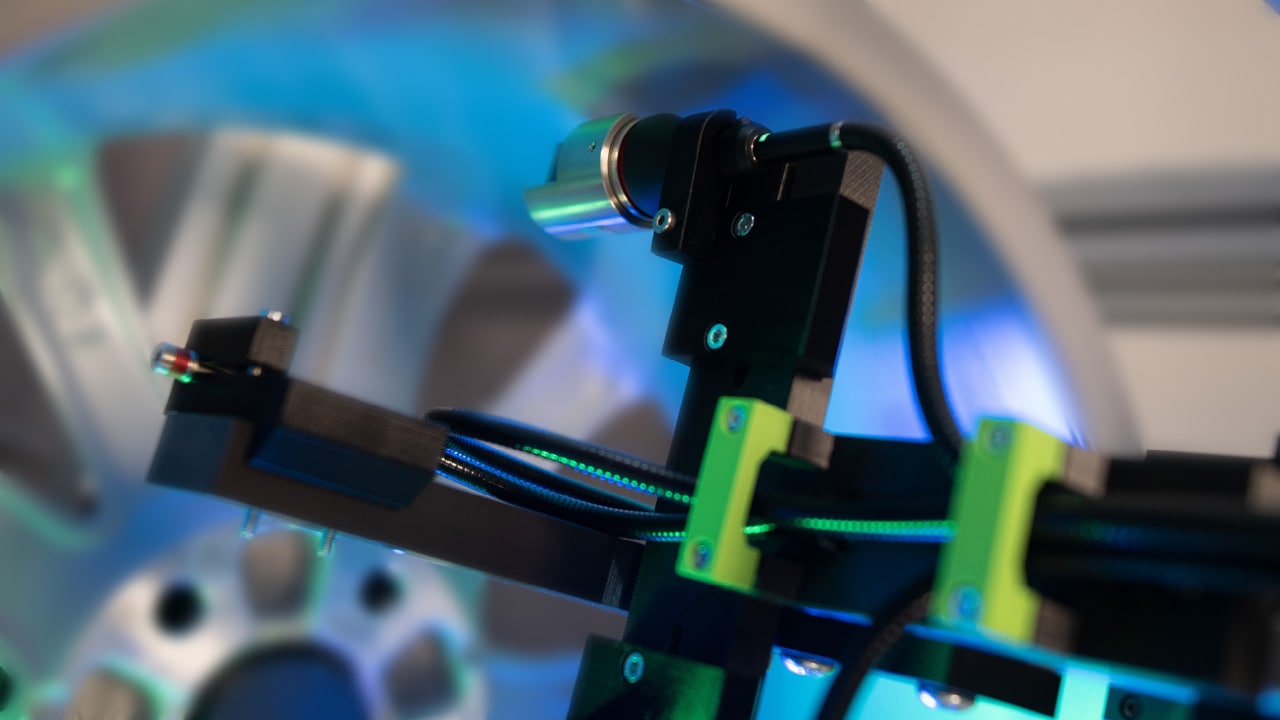

INTEGRATION OF OPTICAL MEASURING TECHNOLOGY

We accept the challenge

With our roots in metrology and quality management, we possess the necessary specialized knowledge to integrate high-precision optical measurement technology, such as chromatic confocal sensors or optical coherence tomography (OCT) sensors, into testing processes and systems. This enables us to inspect surfaces, shapes, and layers of high-precision structures in production.

- chromatic confocal sensors

- optical coherence tomography (OCT)

- 3D laser profile cutting sensors

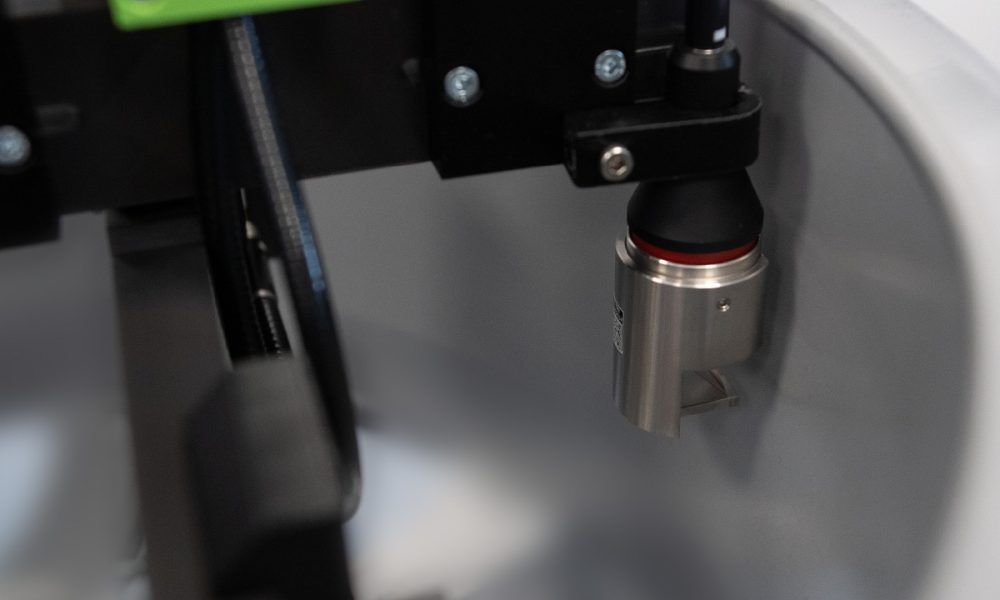

PLANT ENGINEERING & AUTOMATION

We automate quality control

When dealing with micrometer-level measurements, systems and processes must meet specific requirements to ensure precise and repeatable inspection. To address this, we have developed a modular system kit to build 2D and 3D measurement systems tailored to your specific QC processes. For feeding and positioning, we utilize workpiece carrier systems and cleanroom-compatible linear axes.

- Suitable modules: FFU, cleaning, lifting door, autofocus, cleanroom

- Special machine construction of testing systems

- Precision solutions with linear axes and granite base

![MICRO.SPECTOR MI1 – Cleanroom Operator_1 [MV.EYE-MI1 Microscope Employee Software] Optical metrology for optimizing your quality control](https://mabri.vision/wp-content/uploads/elementor/thumbs/MV.EYE-MI1-Reinraum-Bediener_1MV.EYE-MI1-Mikroskop-Mitarbeiter-Software-scaled-1-rd6tn6mt6pzsi51phx0nqblaya1h9s1l6rnscm9mr4.jpg)

SIGNAL & DATA PROCESSING

Automated derivation of key performance indicators

Our experts specialize in the evaluation of 2D and 3D data sets, such as surface inspection, shape inspection and wall thickness inspection.

From standard-compliant evaluation of standard parameters (e.g. roughness) to product-specific and individual parameters, we can cover all requirements.

- Application-specific evaluation of measurement data of all kinds

- Determination of individual parameters

- Data, fusion, filtering, and analysis

MEASURING TECHNOLOGY – OUR DNA

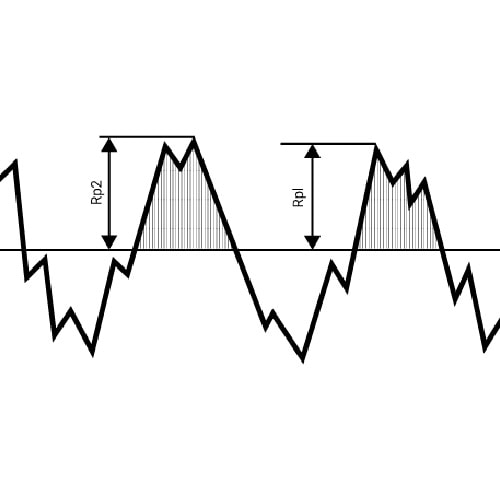

Roughness measurement technology

- Support in selecting function-relevant sizes

- Determination of 2D roughness parameters according to ISO 4287 & 13565

- Determination of 3D roughness parameters according to ISO 25178

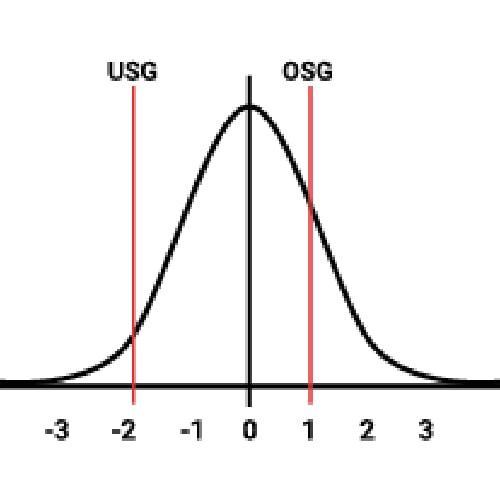

Process capability analysis

- Reporting on process capability

- Sensor selection for temporary/permanent process monitoring

- Identifying and resolving the causes of process capability deficiencies

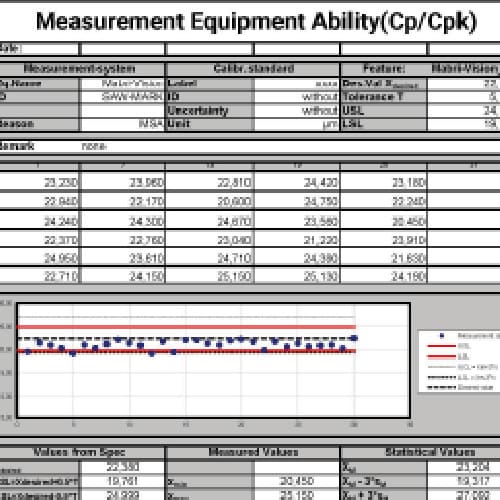

MSA Measurement Equipment Capability Analysis

- Systematic investigation of the measurement system capability

- Traceability to national calibration standards

- Advice on the selection of testing sensors

Six Sigma Toolbox

- Expertise in Six Sigma methods and processes

- Consulting and support in conducting error analyses

- Active support of improvement projects

SHOWCASE

Example applications

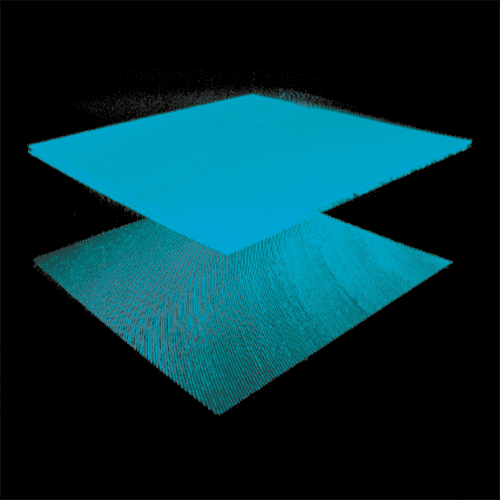

Inline layer thickness testing of plasters

We use a tomographic sensor to examine the layer structure of transdermal patches.

The advantage of the system is the speed of the testing process, which enables inline testing. At speeds of up to 40 mm/s, the presence and precise distribution of the active ingredient, as well as the shape and layer thickness, can be determined, among other things.

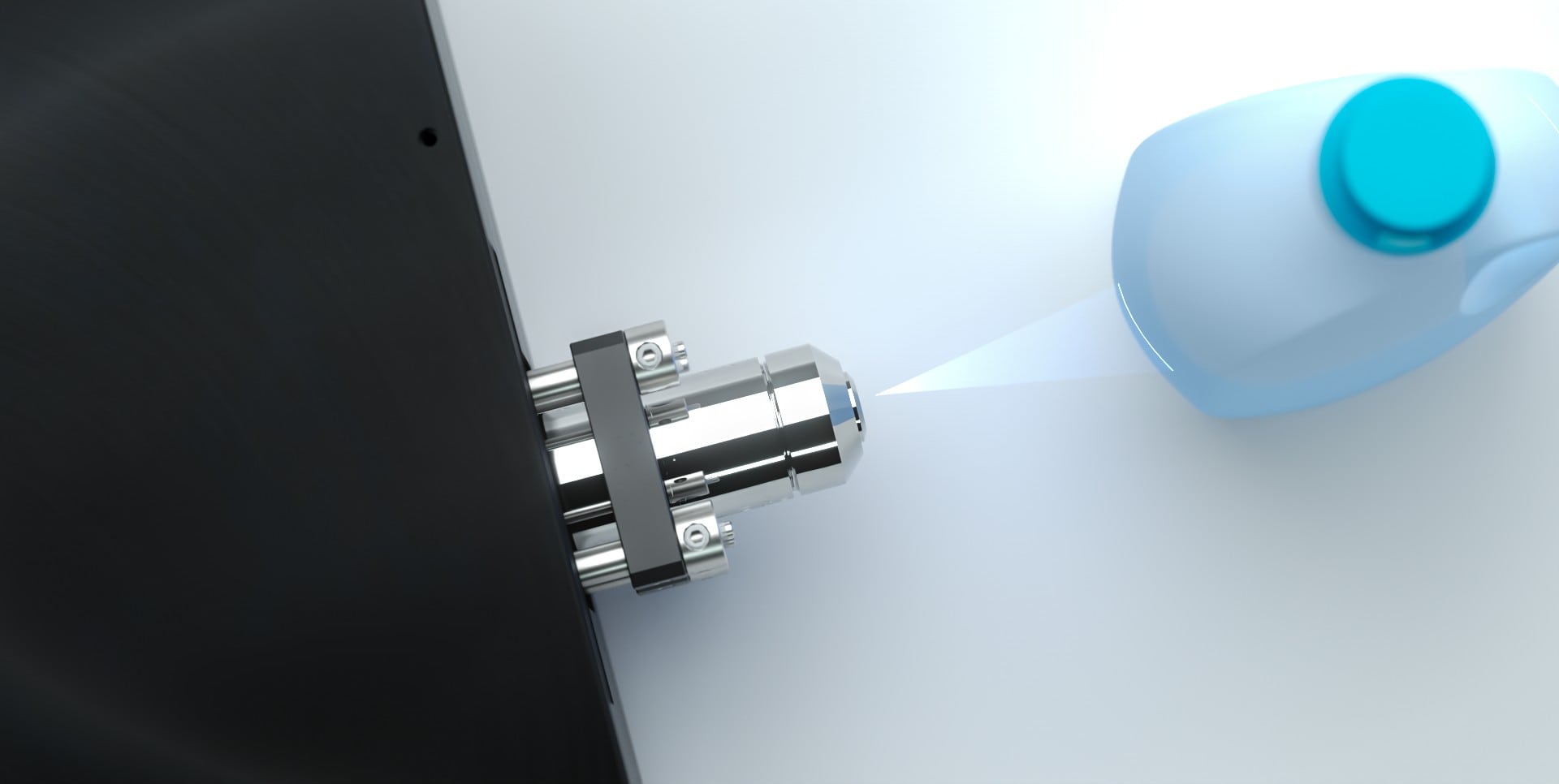

Inline hose wall thickness inspection system

The MABRI.VISION testing system INLINE.SECTOR F1 describes the future of quality control of plastic and silicone hoses: non-destructive and in production cycle.

A 360° sensor creates cross-sections for checking the inner and outer diameter, wall thickness and geometry of semi-transparent tubes, directly in your extrusion line.

Precise inspection of boreholes

In one version of the CARRIER.SPECTOR, we use chromatic confocal sensors to inspect components transported on a carrier. These sensors work by measuring light directed onto the component's surface from a point light source. The component's roundness is determined by analyzing the light scattering, enabling precise shape measurement. This technique is fast, efficient, and allows for continuous monitoring of the manufacturing process to ensure that the components meet the required specifications.

FAQs

What vision technologies does MABRI.VISION use?

For every new request, our Vision experts assess which technologies are best suited for the inspection. We primarily use matrix and line scan cameras, as well as 3D triangulation sensors. If other optical technologies are better suited for the inspection, we are also happy to use TDI cameras, chromatic confocal sensors, or interferometric sensors.

Do you also offer automation of manufacturing steps?

No – our specialization is the construction of testing systems. With our automation solutions, we implement the feeding and, after testing, the sorting of products and components.

We keep encountering defects, but we don't know how to test for them.

Over the years, we have built up extensive expertise in the field of optical metrology. Our experts will be happy to advise you on the design of testing processes. If it is uncertain whether a test can be implemented, we will also gladly conduct feasibility studies.

What are MABRI.VISION's delivery times?

This naturally depends on the type, size, and complexity of the optical inspection system. In direct comparison with our competitors, we often have shorter delivery times and can react more quickly.