Medical technology, pharmaceuticals, life sciences

Inspection system for microfluidic chips

MICRO.SPECTOR MI1

Inspection system for microfluidic chips

The MICRO.SPECTOR MI1 inspection system for microfluidic chips is an inline vision solution for automated 100% inspection of large-area and microstructured components. The fast and high-resolution image acquisition paired with AI-supported evaluation software makes it possible to reliably detect defects and check the dimensional accuracy of the chips. The MICRO.SPECTOR MI1 testing system can be operated stand-alone or fully automated in clean rooms.

Applications

- 100% testing of chips

- Detection and sorting of defective chips

- quality assurance

Areas of application

- Production of IVD chips

- PCR chips

- Microfluidics, Lab on a Chip

- arrays

Industry sectors

- Medical technology

- Pharma

- Life Sciences

What are we checking?

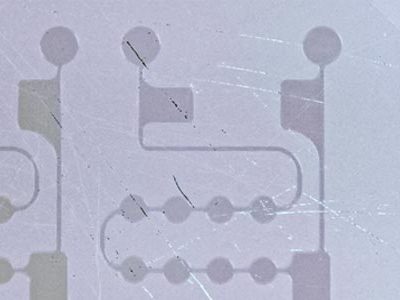

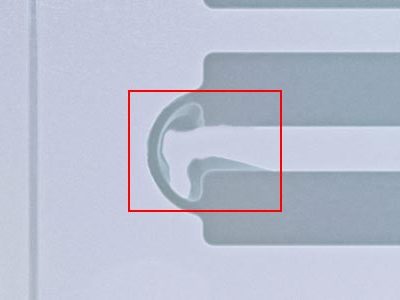

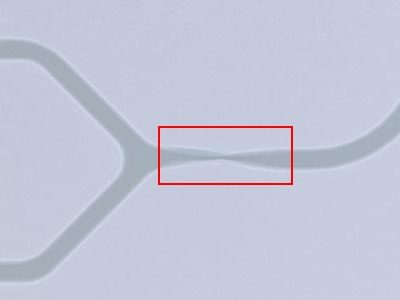

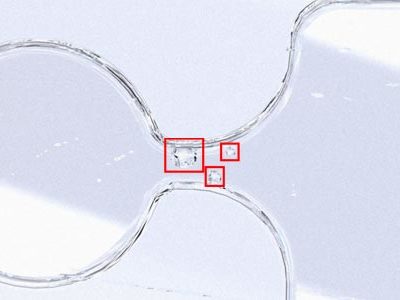

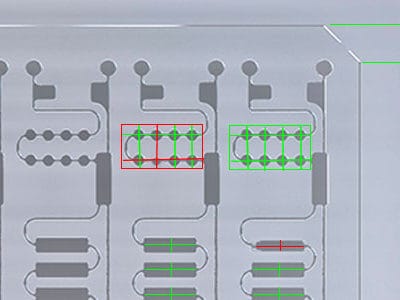

A wide variety of process-related errors can occur, particularly in the production of the finest structures. The MICRO.SPECTOR MI1 testing system enables 100% testing of microfluidic chips and detects the smallest defects and shape deviations. The system can be used as an end-of-line control or directly in the manufacturing process of components.

Scratches & fibers

Webbed feet & incorrect spraying

Thin spots & closures

Particles & Inclusions

Dimensional accuracy & tolerances

Advantages and special features

- 100% testing in production cycle

- Testing of all characteristics with a testing system

- Interface to your ERP and production system

- Can be flexibly adapted to your application

- manual assembly, robot assembly & goods carriers

- clean room suitable

- Databases, reports & statistics modules

- Best in class high-speed machine vision system

- AI-supported evaluation of defect cash registers

Applications and implementations

Transparent chips

Transparent chips have the advantage that many tests can be carried out using transmitted light or dark field illumination. Due to manufacturing reasons, defects often occur in the layer structure when the canal is closed, which we reliably detect with our vision system.

MTP format microstructures, black

Large-format chips represent the next class of microfluidic systems. Due to the miniaturization of the arrays, the MICRO.SPECTOR MI1 inspection system records and processes more than 1 million features and structures per MTP.

3D microstructures

If microstructures are to be tested in 3D, the MV.EYE MI1 testing system can also be equipped with 3D sensors. This allows structural sizes to be checked three-dimensionally and critical defects such as cracks, webs or missing features to be identified.

software

Modular

The MABRI.VISION software is designed to be modular. In addition to a variety of standard modules, we are happy to expand the software with suitable modules for your application. All common interfaces are available for seamless integration into your production process.

Databases

The MV.IMAGING software supports your quality assurance through the use of databases for production orders and recipes. The database interface is based on the specific requirements of your tests and evaluations. All data can be exported as structured test reports in .csv, .xls or .pdf format.

Statistics/evaluation

Our software platform offers a variety of visualization options. You maintain an overview of production processes and quality assurance through meaningful statistics. Our software experts are familiar with the specific requirements of different industries and design the software for process support using insightful key figures and useful tools such as good part counters, error and measurement image memories and advance warning limits.

Why MABRI.VISION

MABRI.VISION builds and develops high-quality machine vision solutions and modular testing systems for your production processes. Our modular system enables us to provide solutions for your testing tasks quickly and efficiently.

Innovative solutions, our passion!

Innovative solutions, our passion!

Innovation is the foundation for continuous growth in modern industry. We live this out every day and begins in the minds of our team of experts. The focus is always on the benefits and requirements of our customers. We passionately implement testing processes that range from AI-based computer vision solutions to 100% inline component measurement of sophisticated products. We rely on the latest generations of advanced technologies for our measurement technology. With this philosophy we want to make production processes more efficient and dynamic.

AI, processing, control - one software platform

AI, processing, control - one software platform

With the goals of Industry 4.0 and a continuous improvement process, the demands on test automation, interfaces and efficient evaluation algorithms are increasing. We at MABRI.VISION have recognized this trend and are taking it one step further. Our software team develops modular software platforms that combine all the components of modern testing systems. If necessary, we can expand evaluation algorithms with neural networks, map fast interfaces to system controls and integrate audit trails, batch reports, history graphs or databases as required.

A strong team, always there for you.

A strong team, always there for you.

As a customer, you are always at the forefront for us. Our team of vision experts, construction, software development, electrical, assembly and support is always there for you. Thanks to modern business processes and IT solutions, speed is a central goal. With our service solutions including 24/7 support, we support your production with efficient solutions.

End-to-end solutions, everything from a single source.

End-to-end solutions, everything from a single source.

You think in processes, we think in solutions: that's why we offer our customers turnkey testing systems that can be seamlessly integrated into your production processes. Our experts advise on planning and design at the beginning of a project. If technologies need to be evaluated, we carry out feasibility studies and inline tests. At MABRI.VISION we offer system design, programming and automation from a single source. We can optimize complex evaluations and tests directly with the system control and all customer interfaces.