Key areas

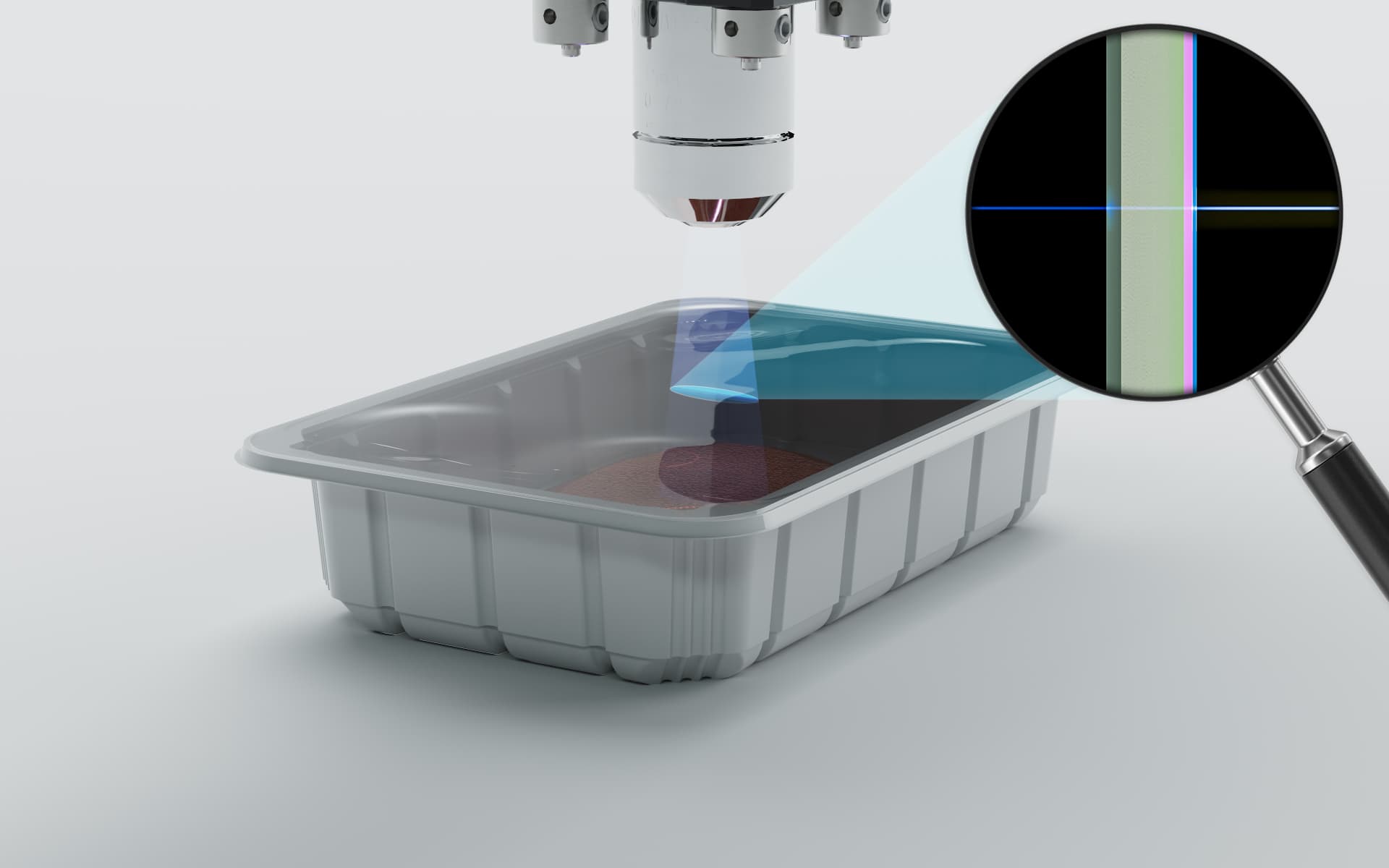

Inline measurement of barrier layers

Testing solutions for packaging, medical technology & pharmaceuticals

Summary

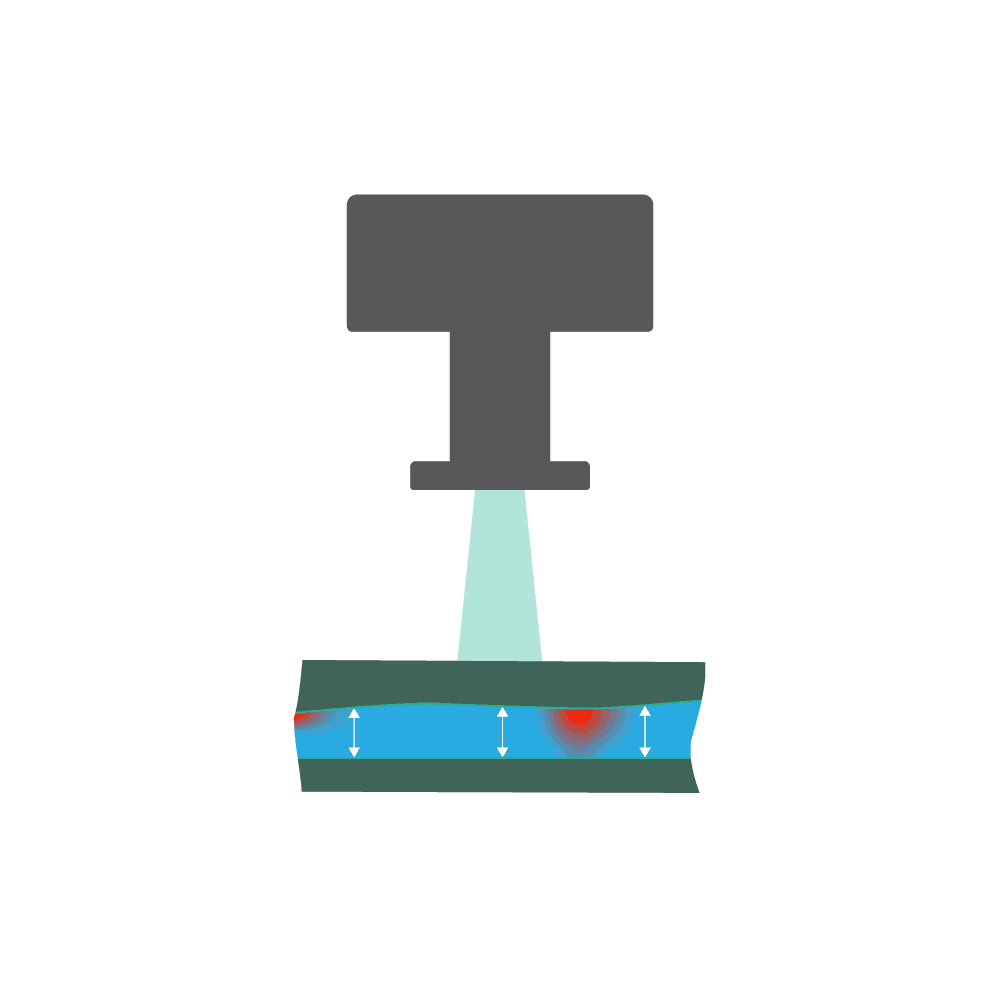

The MV.SENSE b1i optical inspection system measures the shape and wall thickness of translucent plastic packaging. The inline inspection is contactless and performed in sync with production, thus enabling 100% inline inspection of multi-layer packaging materials.

One important application is the non-destructive measurement of the thickness of barrier layers, for example those made of ethylene-vinyl alcohol copolymer (EVOH), in food packaging. The measuring system checks the total layer thickness as well as the thickness of the barrier layer.

The high measurement frequency of up to 200 kHz makes it suitable for use in production machines for 100% in-house inspection. MABRI.VISION supplies various systems, from point-based 1D measurement to 3D systems that scan a large measurement field at a measurement rate of up to 200 Hz.

Applications

+ Testing of plastic bottles

+ Testing of blisters

Tests

+ wall thickness

+ shape

+ barrier layers

+ transition points

Industries

+ Food

+ Packaging

+ Pharmaceuticals

+ Medical Technology

What are we checking?

The modular testing platform MV.EYE offers you a testing solution for all process steps in the production of steel and stainless steel abrasive tubes

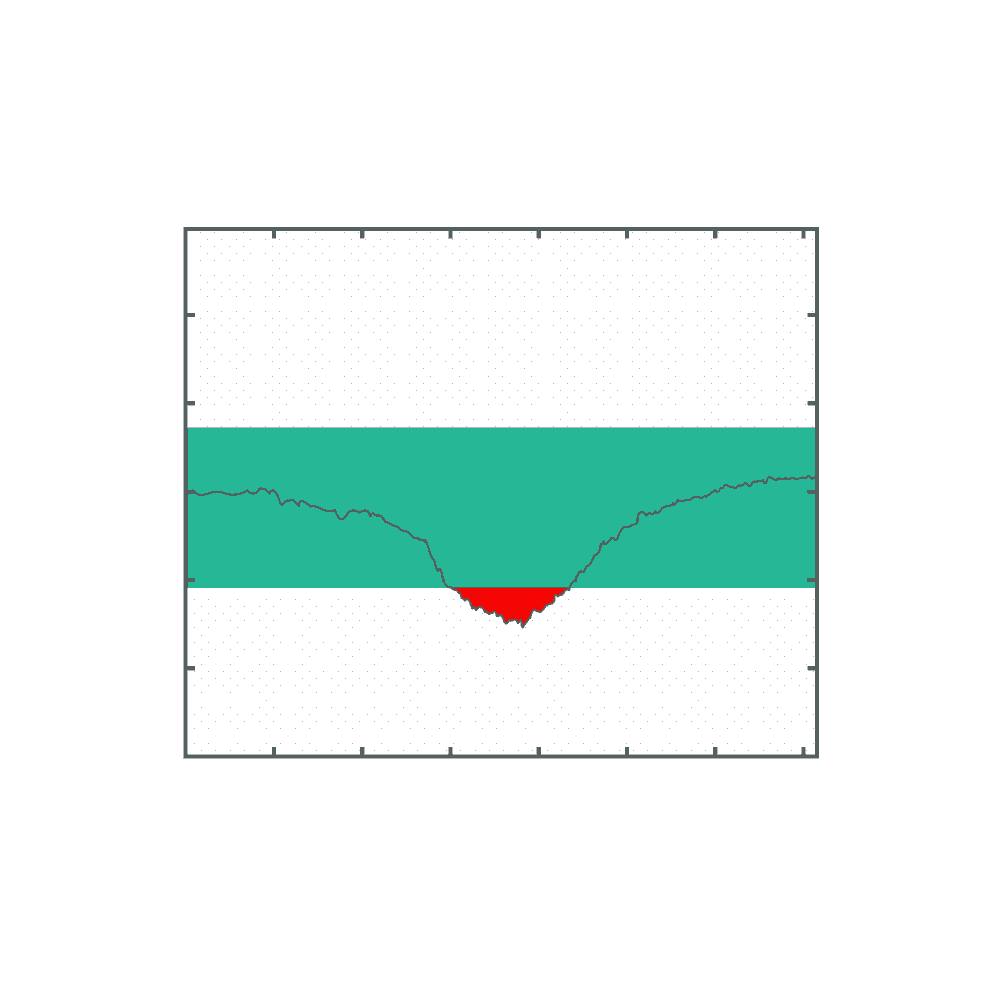

Wall thickness test

The test can be performed on all packaging made of semi-transparent plastics.

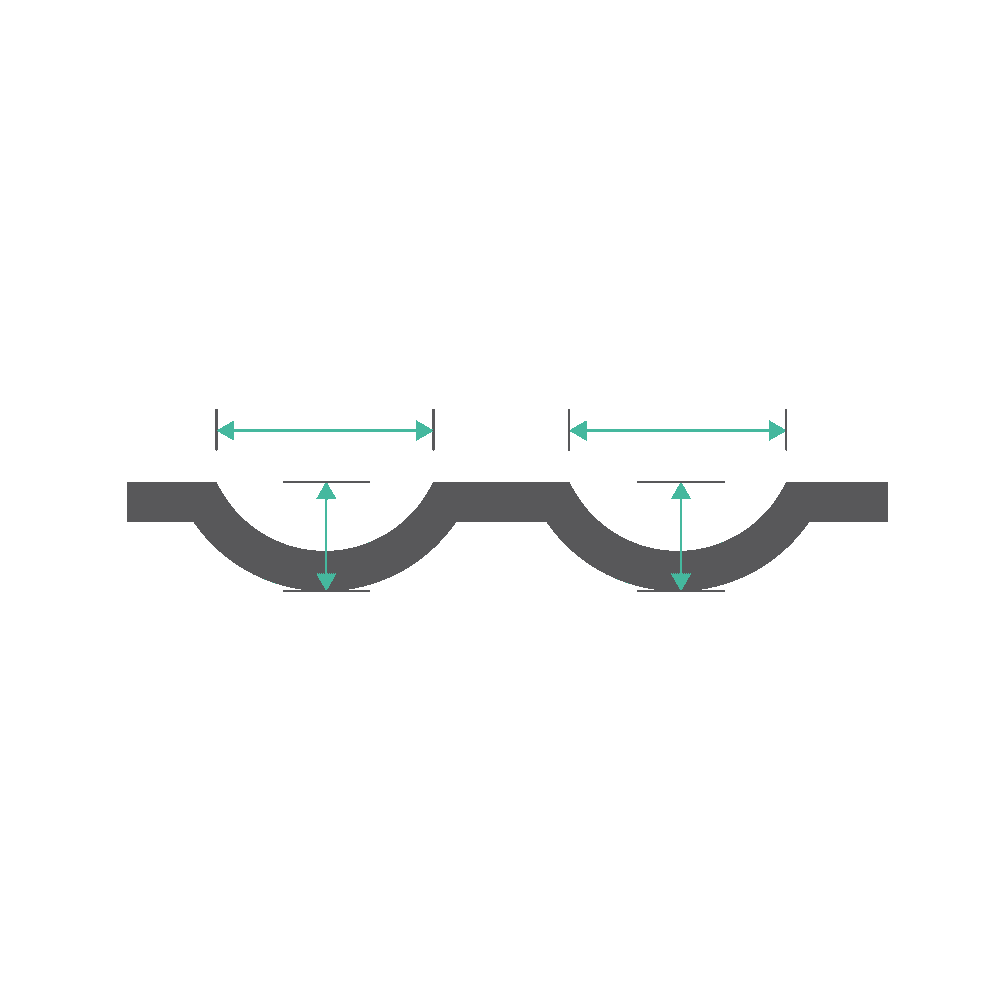

form check

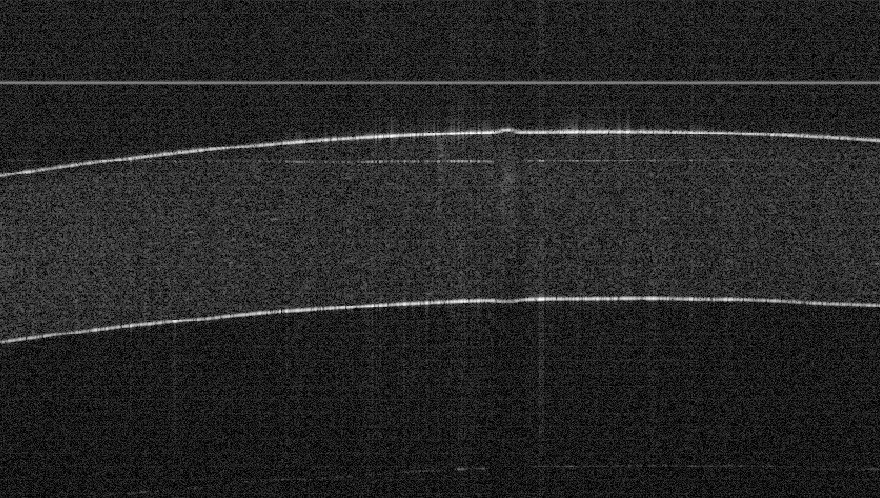

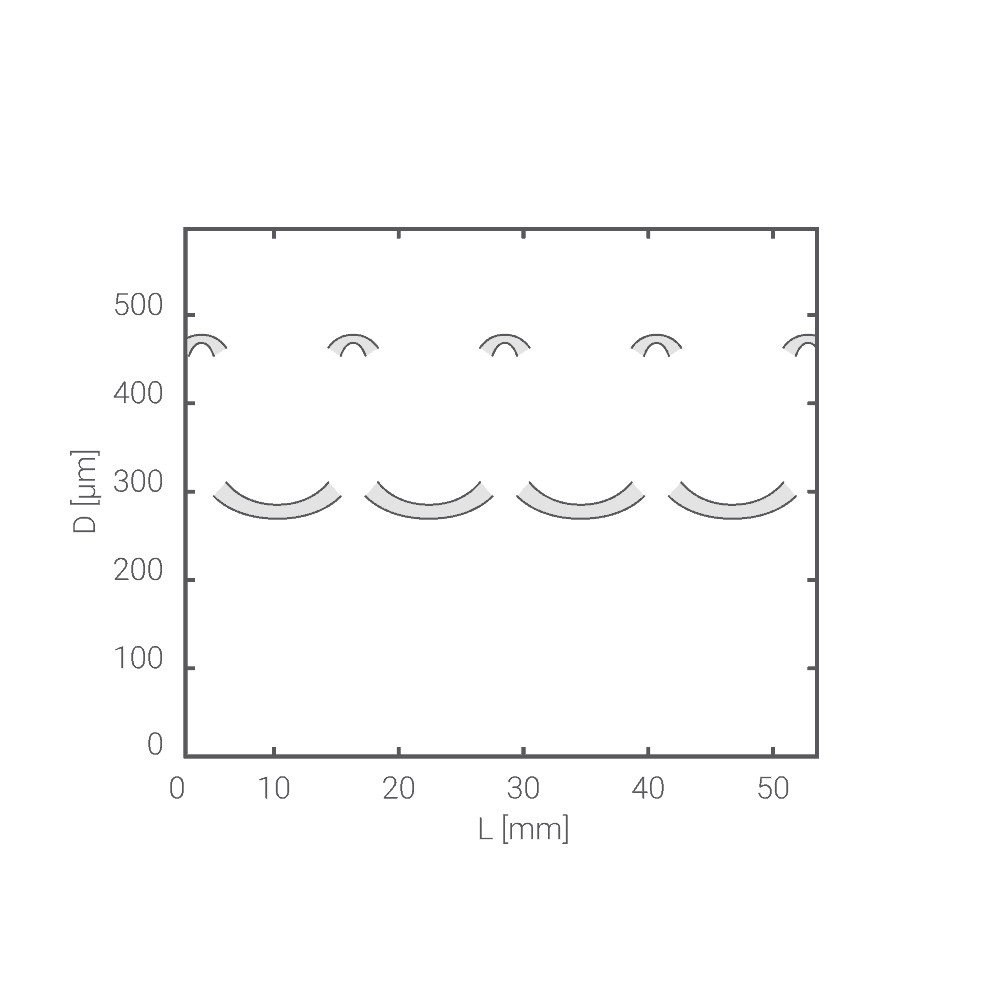

Cross-sectional images can be used in particular for checking the shape of films, such as blister packs. The width and height of fine structures can be precisely examined.

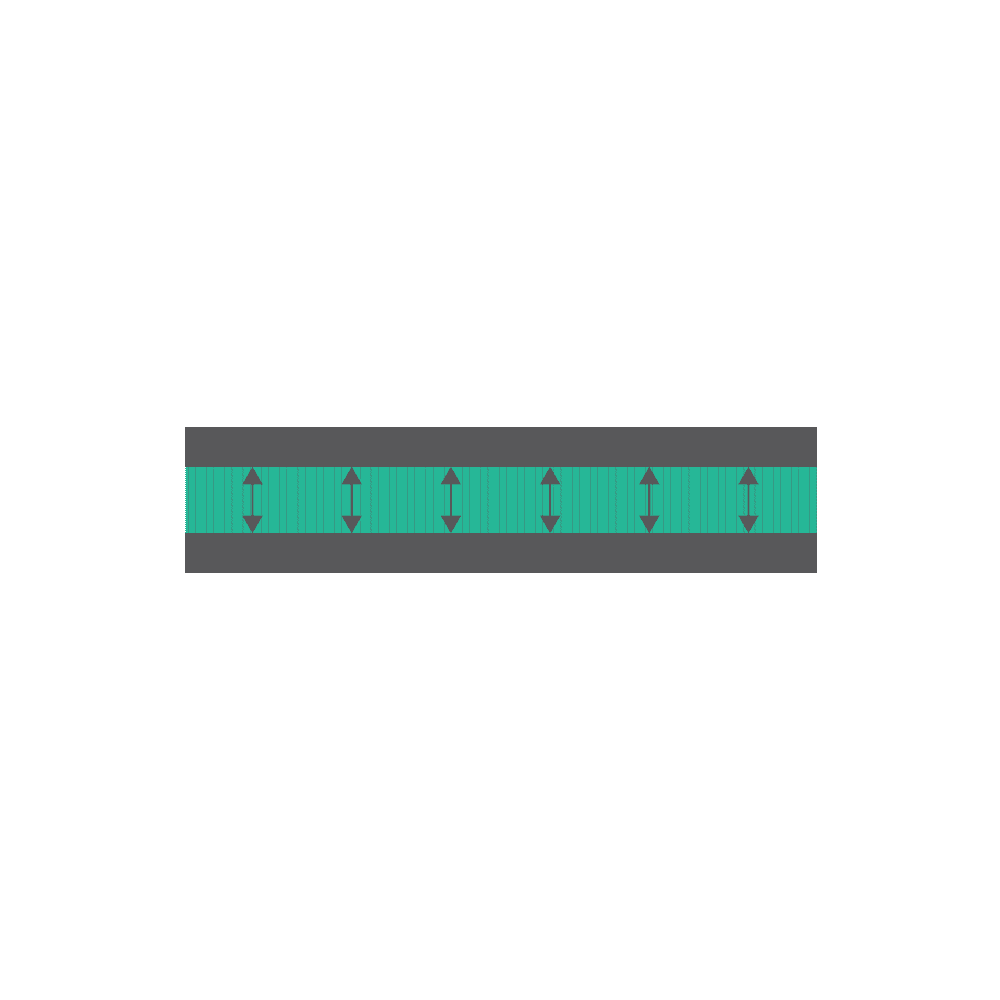

Testing of multi-shift operations

Individual layers can be separated at wall thicknesses of 10 µm and above. During the manufacturing process, tolerances of internal layers can be checked inline and non-destructively.

Wall thickness test

The test can be performed on all packaging made of semi-transparent plastics.

form check

Cross-sectional images can be used in particular for checking the shape of films, such as blister packs. The width and height of fine structures can be precisely examined.

Testing of multi-shift operations

Individual layers can be separated at wall thicknesses of 10 µm and above. During the manufacturing process, tolerances of internal layers can be checked inline and non-destructively.

Universal: versatile

Blister

Deep-drawn packaging is used in the pharmaceutical industry – this can be fully tested with the MV.SENSE b1i system.

Bottles

The MABRI.VISION testing system is ideally suited for testing plastic bottles and provides data on shape, wall thickness and quality defects.

Slides

Rely on 100% quality control and ensure high-quality and defect-free products through the use of MABRI.VISION testing technology.

Example applications

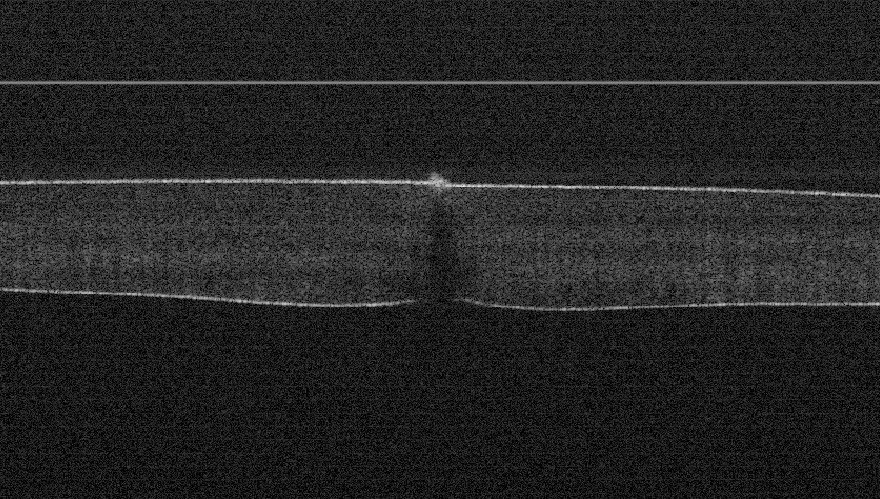

Wall thickness testing in extrusion blow molding

During extrusion blow molding, we inspect wall thickness and seam areas at critical points. This allows us to identify defects such as thin spots at an early stage of the process, which could later lead to cracking.

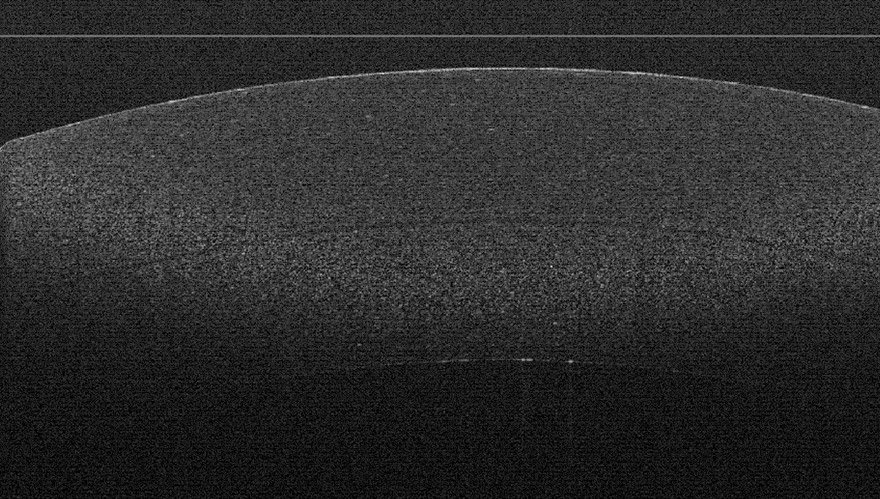

Wall thickness testing in injection stretch blow molding

In stretch blow molding of packaging, uniform material distribution and molding are crucial for subsequent functionality. MABRI.VISION sensors are used for wall thickness testing during the manufacturing process.

Wall thickness testing during deep drawing processes

In addition to wall thickness testing, MABRI.VISION sensors are also suitable for testing foil structures. Signal acquisition is performed using the same optics, thus avoiding shadowing effects that occur with conventional laser profile sensors.

versatile and flexible

Our testing systems are used in a wide variety of industries