Competencies

Deep learning

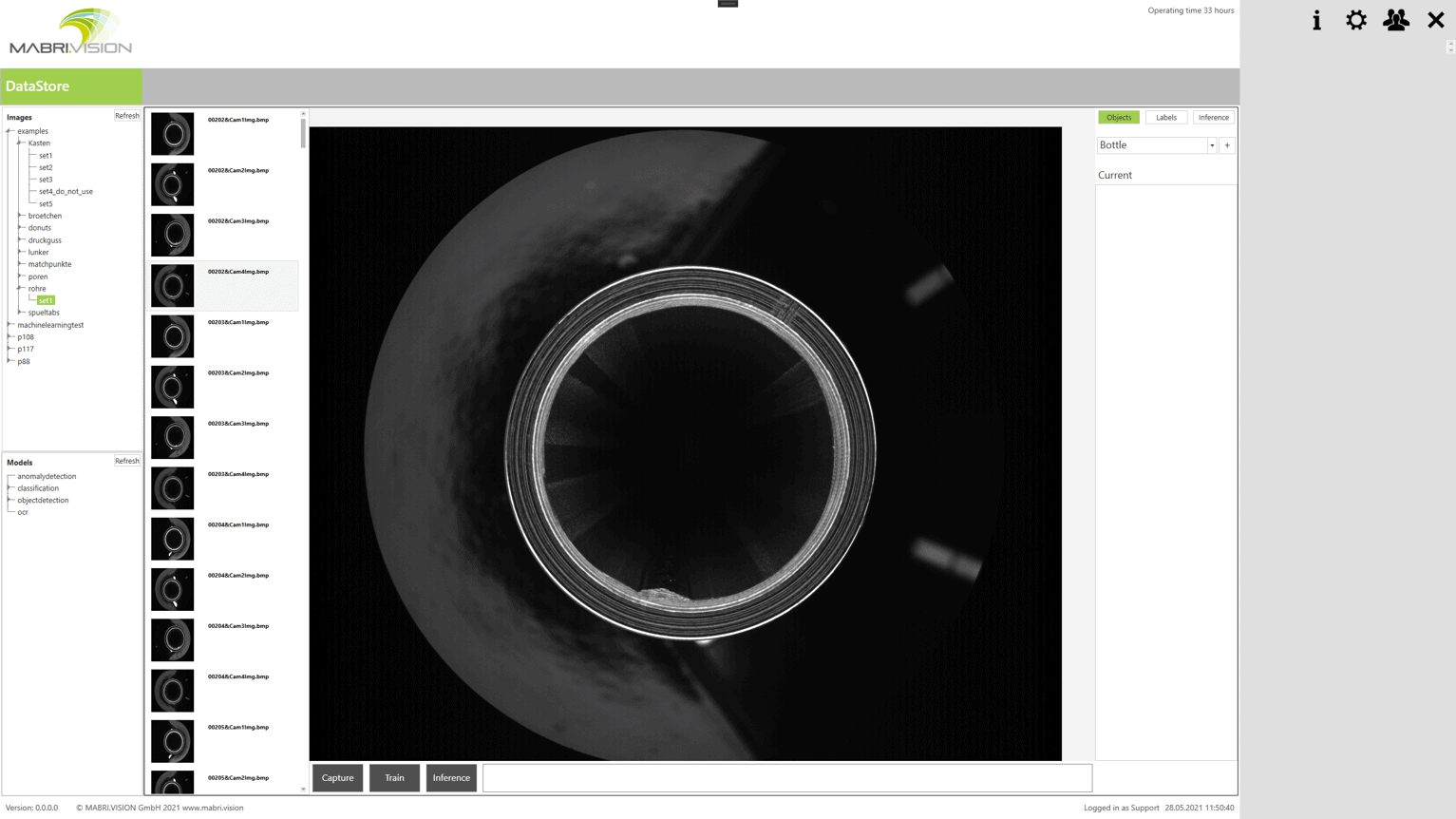

Our platform – Machine learning for industrial applications

MABRI.VISION has developed the DEEP.MV software platform for the application of modern deep learning and AI technologies in industrial environments. The platform combines all the necessary components and enables application at the factory level.

Applications

Our deep learning platform is ideally suited for applications where rule-based approaches are challenging or fail. This applies particularly to inspection applications with a wide range of variants and defect characteristics, such as varying surface and structural properties. The MABRI.VISION platform is optimally suited for applications where, due to complexity, inspection is primarily carried out manually using defect catalogs.

Classification | Detection and classification of objects and errors

Classification forms the basis for many tasks in quality assurance. In practice, it eliminates the need for time-consuming data labeling – categorization of images is sufficient.

Error detection in dishwasher tablets

scratch

opened

niO.

Web error

OK.

Web error

Hole

Object recognition | Examples: Completeness check, attendance check, counting, pick & place, and much more.

Completeness check

Location check

Attendance check

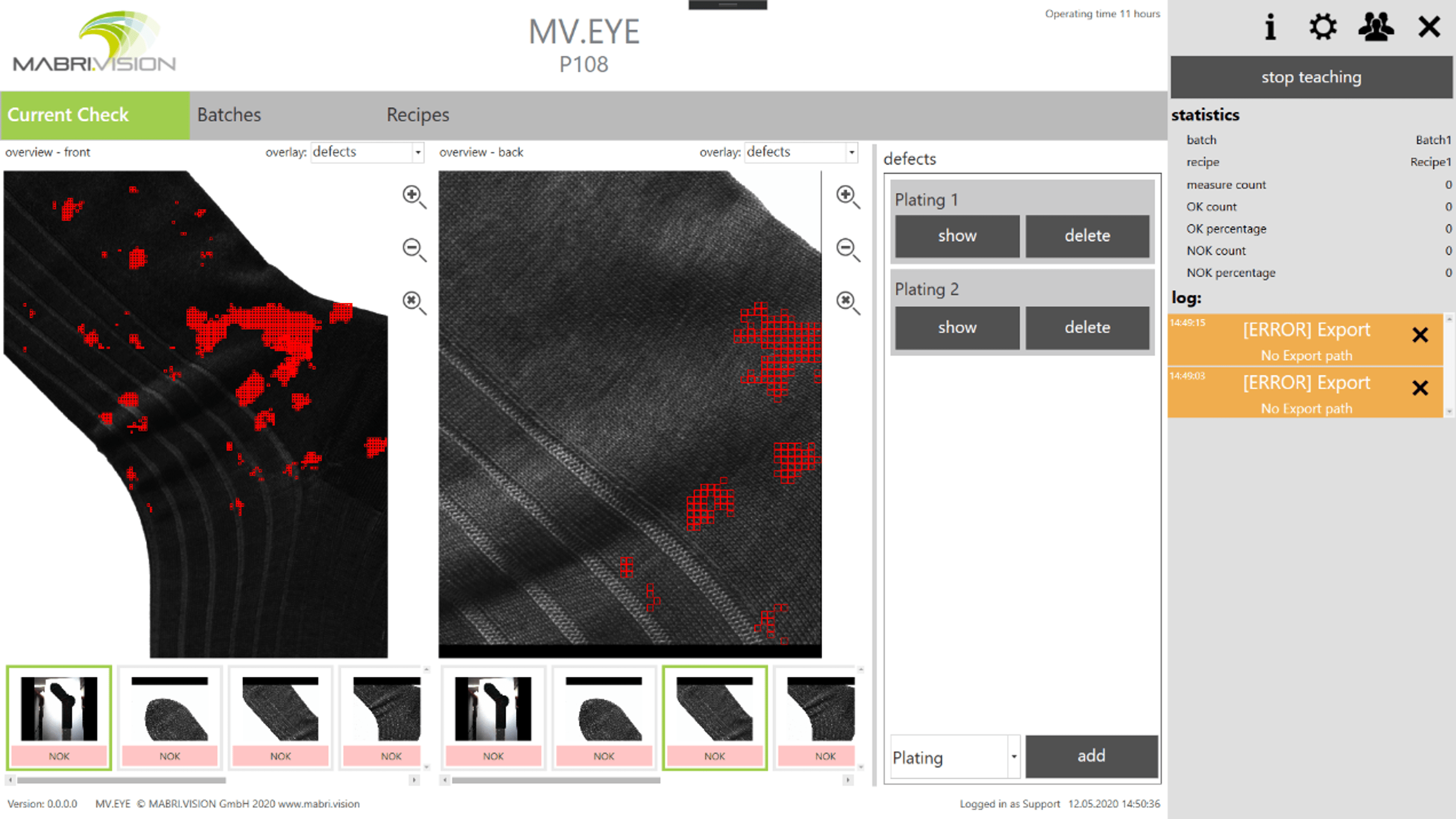

Defect detection | Surface defects, incomplete components, structural defects, color and shape defects, and much more.

Injection molding defects

scratch

Pores and grooves

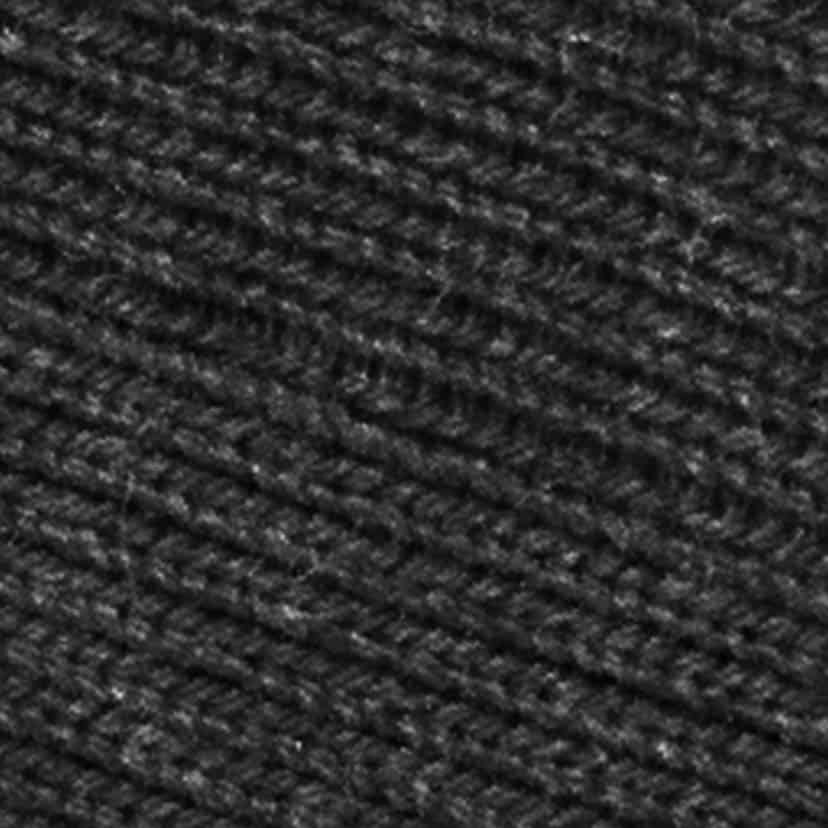

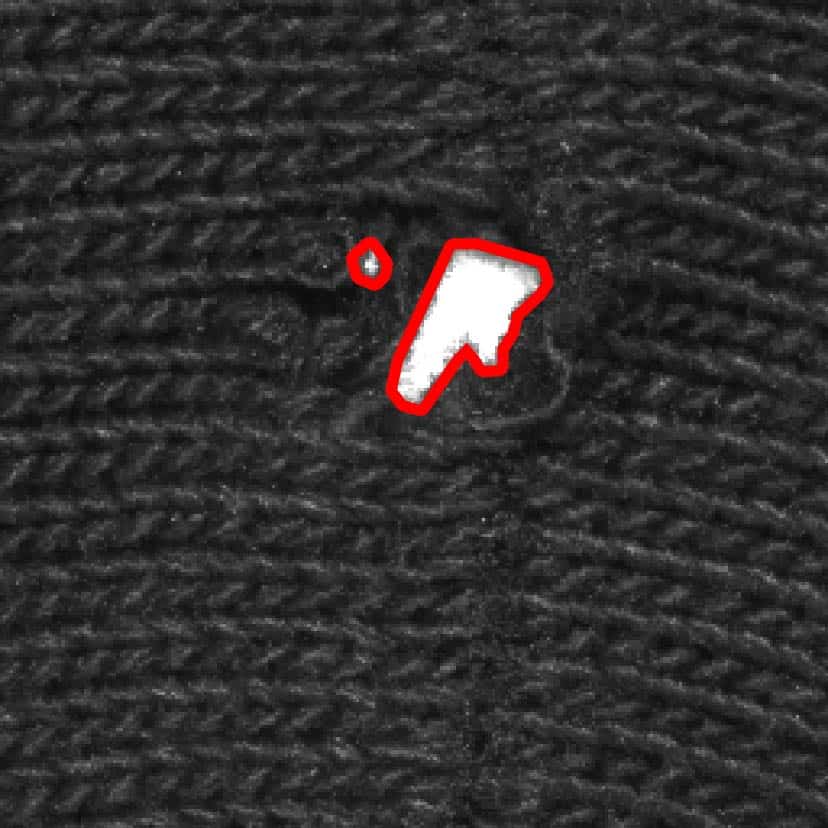

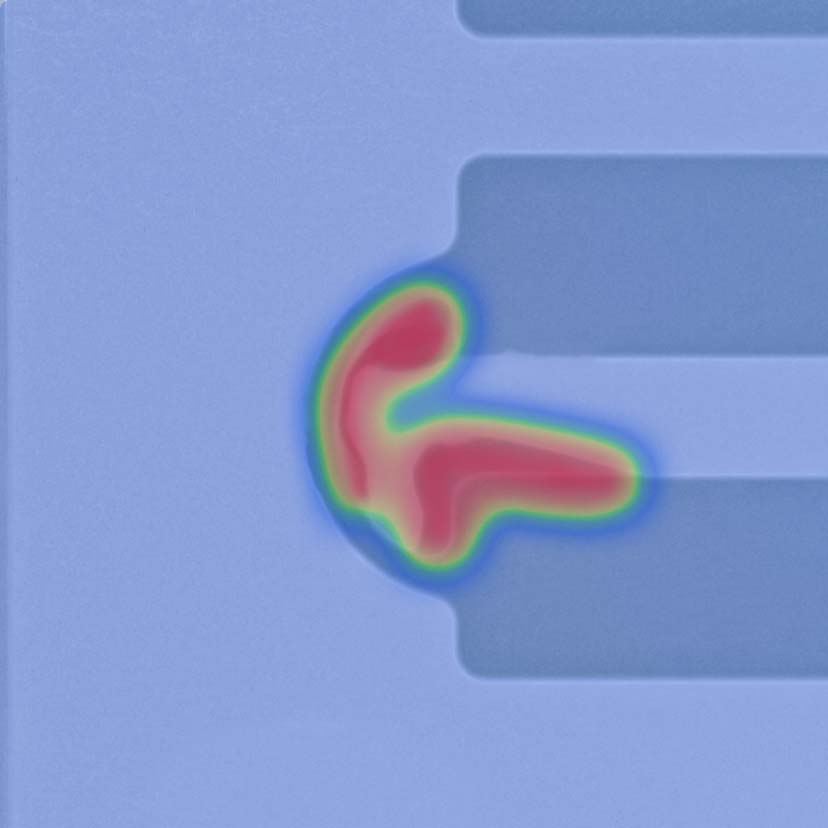

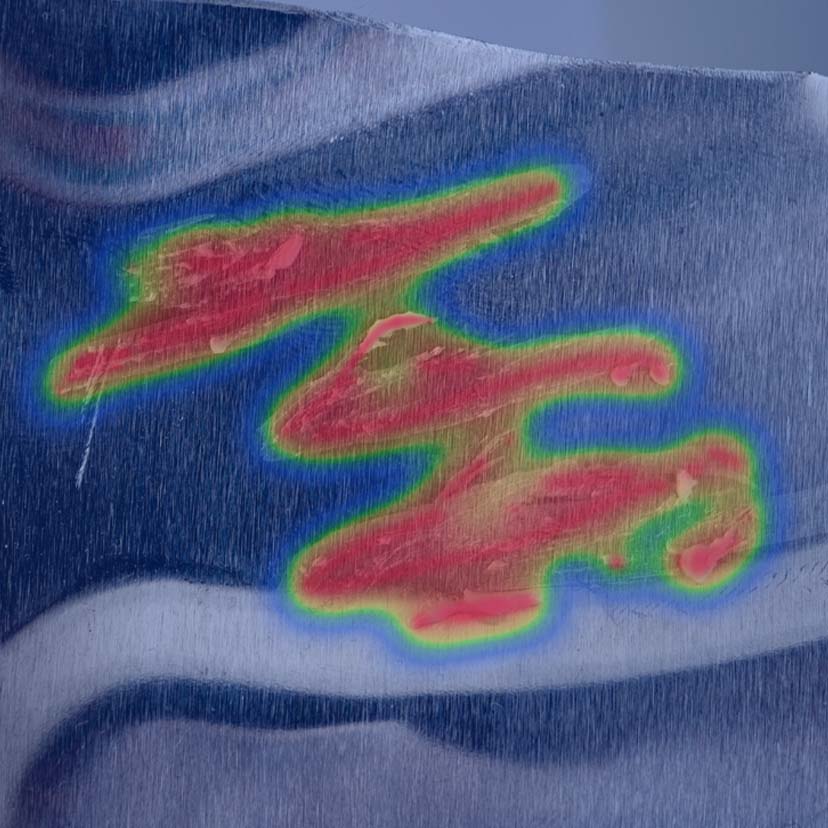

Segmentation | Detection of structures and image areas, surface defects, incomplete components, structural defects, color and shape defects, and much more.

Segmentation is always important when objects, structures, or errors need to be identified and isolated very precisely. This information can be used, for example, for process optimization

chip detection

textiles

dishwasher tablets

Incorrect sorting

Foreign body

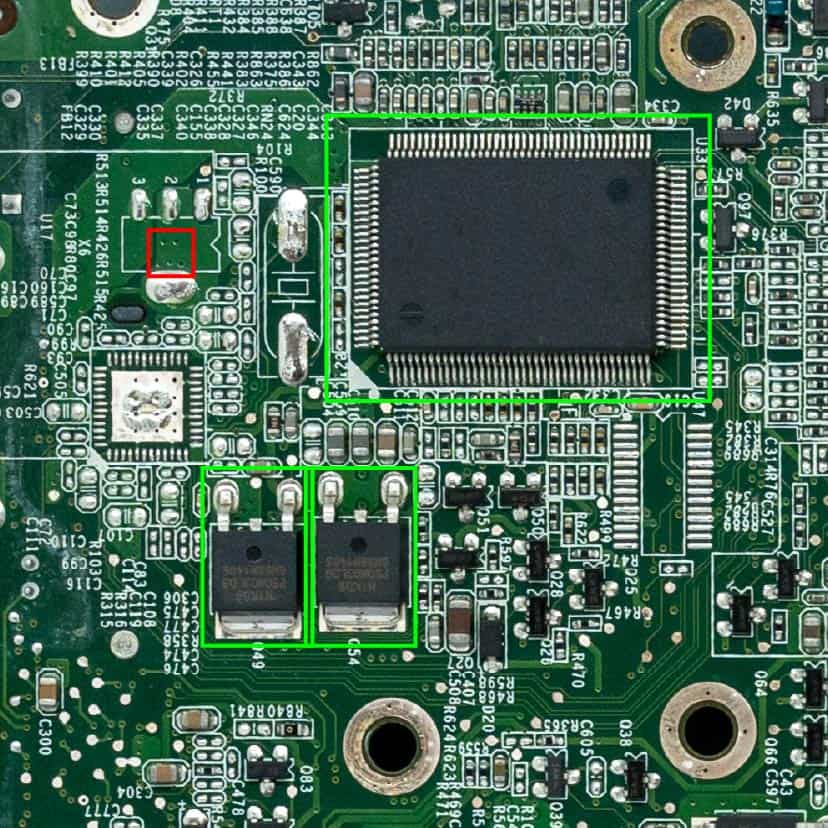

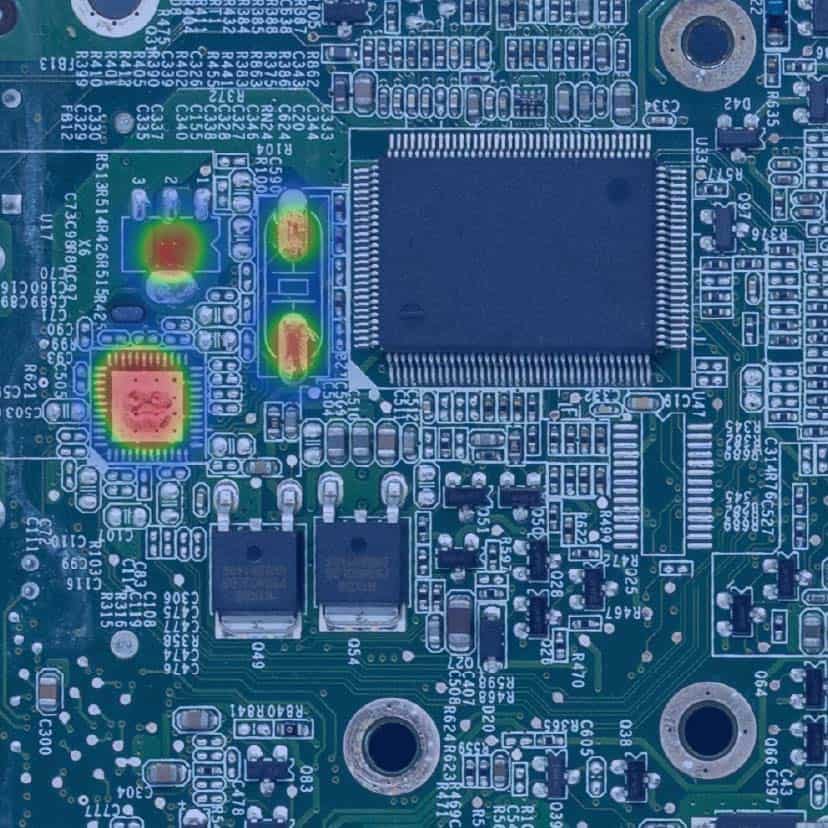

Anomaly detection | Errors on packaging, print image control, weaving defects and much more.

circuit boards

Microstructures

Surfaces (e.g. adhesive residue)

OCR | Text Recognition

DOT code on tires

Character recognition

Your advantages

Everything from a single source

MABRI.VISION provides everything you need for your application. This eliminates the need for fragmented and isolated solutions that are incompatible and therefore difficult to maintain. In addition to the software application, we primarily supply the necessary sensor systems, testing platforms, and service for your production process.

Save money

Our streamlined AI platform enables cost-effective solutions for challenging industrial applications. This eliminates the need for manual and time-consuming testing steps.

Solving complex problems

Deep learning technology enables applications that are very challenging or cannot be satisfactorily solved using traditional image processing. This opens up entirely new possibilities in quality assurance.

The right solution

As a universal solution provider for optical production metrology, we carefully analyze your application. We only use our deep learning technologies when and to the extent that they are truly beneficial for your specific application. This prevents inaccurate results and excessive development costs. Furthermore, we cover all other essential components of quality assurance, such as calibration and traceability.

Stay flexible

One challenge of current industrial development trends is modular production with ever-shorter production cycles. Machine learning methods allow you to remain flexible and adapt your production autonomously.

Future-proof

The field of deep learning is advancing very rapidly. Our AI platform is therefore constantly being expanded and relies on established standards in research and development. This continuous development ensures that you will always be able to use the latest technologies in the future.

Real-world example

Machine learning methods are a good option wherever rule-based approaches are difficult to implement.

Error detection on socks

Web error

Hole

Defect detection on metal pipes

Span

Weld defect

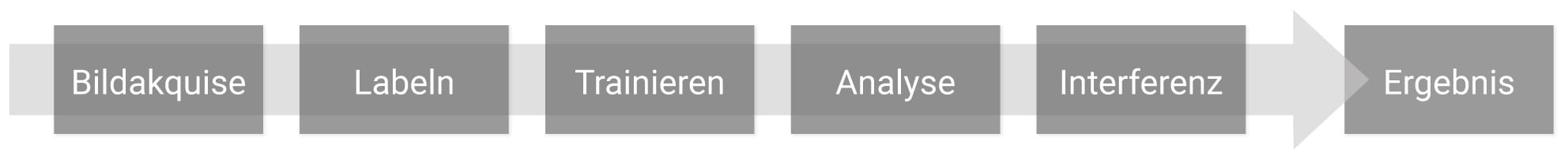

Process flow

Deep learning methods are based on artificial neural networks. These networks are inspired by (biological) neural networks, which are part of a nervous system. Artificial neural networks are structured in layers. A layer consists of several artificial neurons. Between an input and output layer are several hidden layers. The name "deep" neural network derives from these hidden layers.