MV.EYE I2

Inline testing of electronic modules for e-mobility

MV.EYE i2

Inline testing of electronic modules for e-mobility.

In the field of electromobility, complex components are produced in large numbers and at high speeds. The inspection process of a component with almost 70 inspection features takes up to four minutes with a conventional measuring device.

With the inline-capable MV.EYE i2 testing system, MABRI.VISION offers an innovative solution for measuring electronic modules, which has an average measuring cycle of 3 seconds. Different technologies are combined: imaging, laser triangulation and optical micrometers. The advantages of the MV.EYE i2 testing system include precise measurement results and speed. In addition, there is multimodality, customer-specific and space-saving solutions, scalability and data fusion of 2D and 3D measurement data.

Applications

- Testing injection molded parts

- Testing plastic-metal composites

Inspections

- Camera check

- Laser triangulation

- Optical micrometers

- shape

- presence

- Defects

Industry sectors

- E-mobility

- Automotive industry

- mechanical engineering

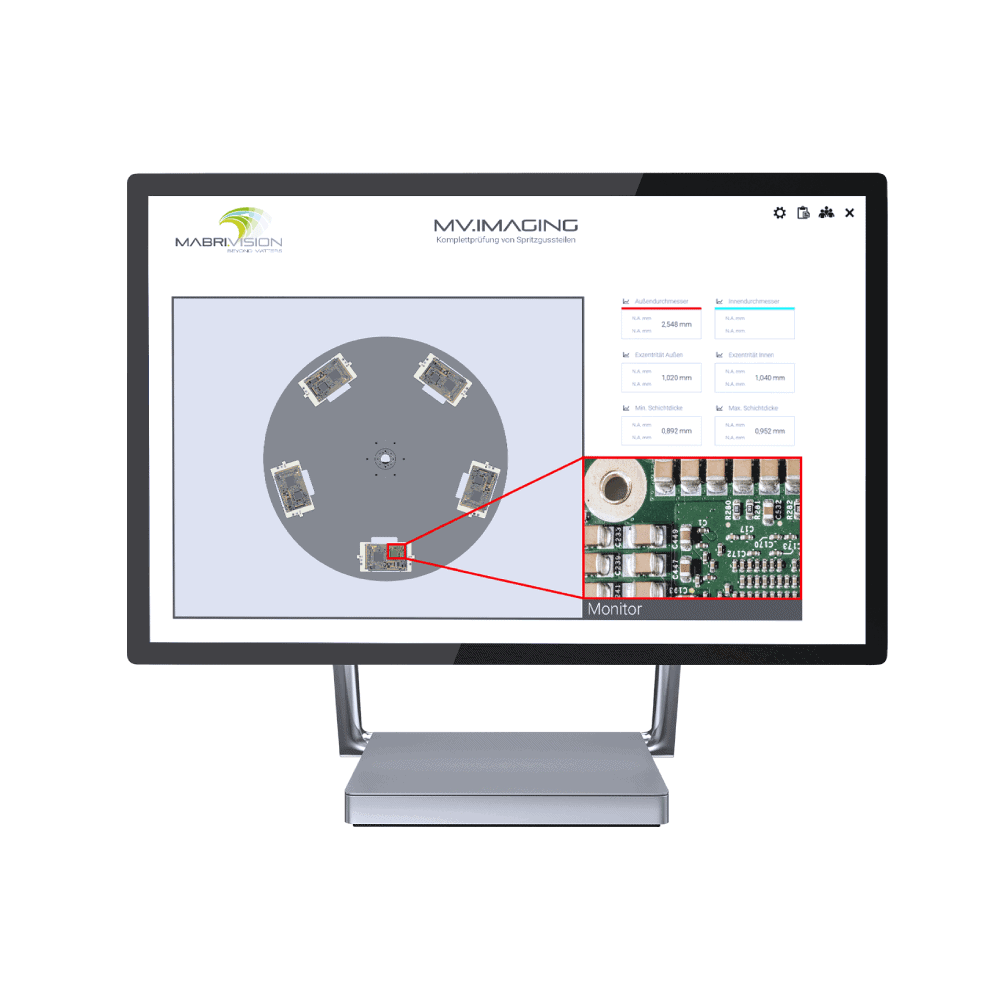

A high-resolution camera image can detect both the presence and position of features and defects. Bends and wobble circles of pins are determined with high precision. The stable steel construction of the system guarantees long-term use in your quality assurance.

Have your components of different sizes tested at different stations with the MV.EYE i2 testing system. A 3D profile measurement using a triangulation sensor generates precise height information and dimensional accuracy. Get 3D measurement data about contact positions.

An optical micrometer captures the test object telecentrically from different angles and creates a shadow image that enables precise height measurement. The system is equipped via a pneumatic lifting door and is possible both manually and automatically.

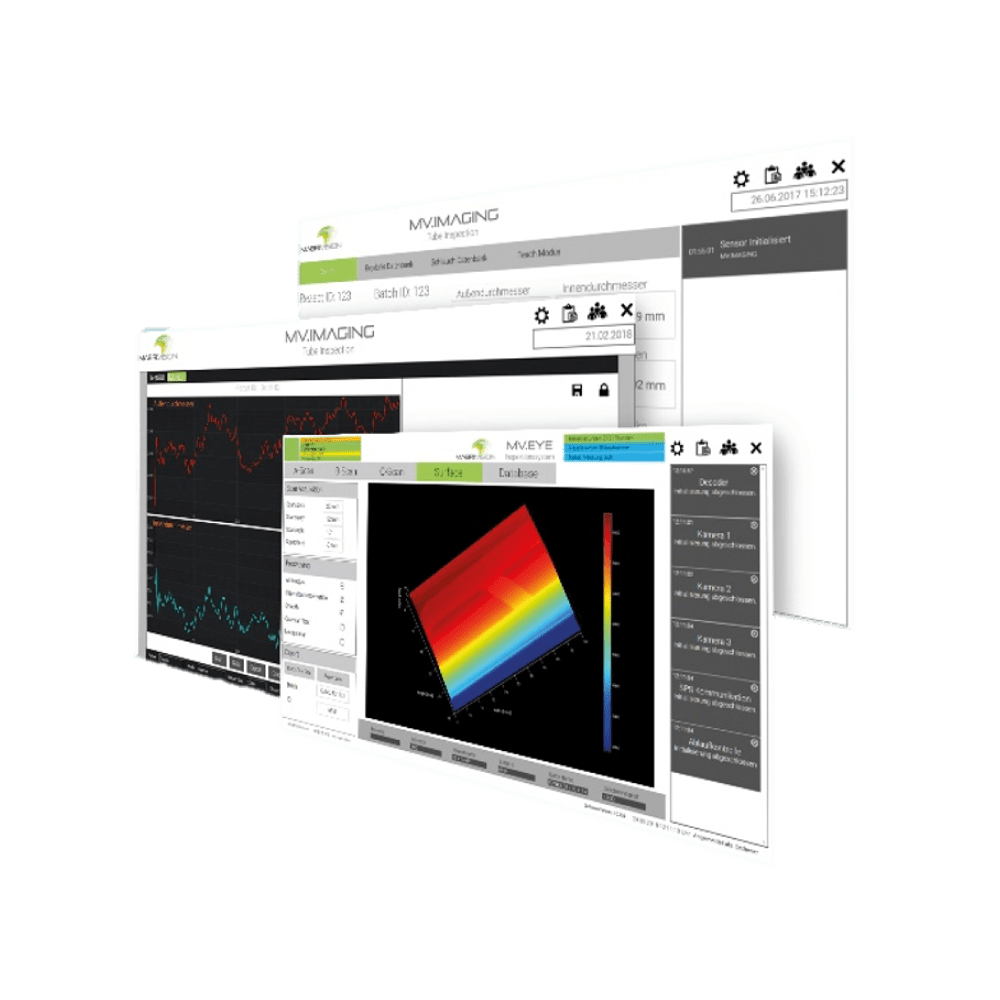

The MABRI.VISION software offers extended batch management. A recipe database allows you to change products quickly without having to reconfigure the parameters each time.

The MV.EYE I2 inspection system not only delivers precise image processing, but also merges the 2D and 3D measurement data obtained. Benefit from an extensive results database for your product improvement.

In order to identify and implement optimization potential in your production, the MABRI.VISION software MV.IMAGING offers you statistics and a variety of different analysis tools.

Specifications

TEST

| Test characteristics in time | 200 |

| Repeatability | 1 µm |

| resolution | up to 70 mpx |

| Measuring systems | up to 5 sensors in one system |

| Scan mode | 1, 2 and 3D measurements |

| Image field | 240 mm x 150 mm |

INTERFACES AND SOFTWARE

| Interfaces | Keyence, Digital I/O, ProfiNet |

| operating system | Keyence, Windows optimal |

| software | MV.IMAGING, Keyence |

ATTACHMENT

| care | 230V |

| Weight | from 550 kg |

| Dimensions | from 1 mx 1 m |

| Compressed air | 6 bars |

Universal: can be used in a variety of ways.

electromobility

Complete and high-precision quality control of injection molded parts in line with production. Smooth integration of testing into automated production processes.

mobility

Fast testing of components with a variety of test characteristics. Check swash circles of pins, contact heights and the 3D position of contacts in the process cycle.

mechanical engineering

Complete testing of plastic-metal composites in the field of mechanical and plant engineering. Benefit from a comprehensive results database and diverse analysis tools.

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision