MV.EYE BI1

Inline 3D shape inspection of baked goods.

MV.EYE BI1

Inline 3D shape inspection of baked goods.

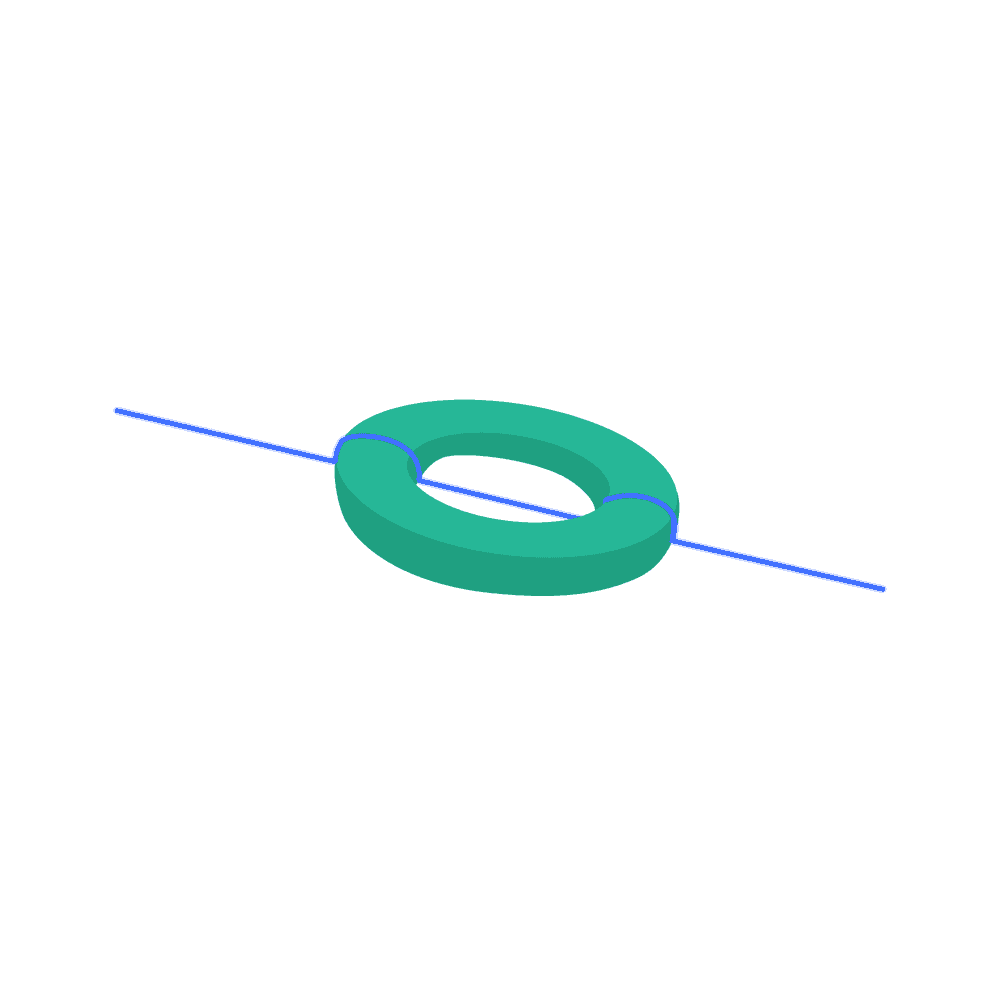

The MABRI.VISION testing system for 3D shape testing enables comprehensive testing of the length, width and height of baked goods. By using 3D profile lasers, high-resolution 3D information about the test objects is generated.

With up to 40,000 units/hour, testing can be integrated into your production process. The number of 3D profile sensors used is adapted to the requirements of your production: this means that complete testing can be ensured even on wide conveyor belts.

Applications

- Testing of baked goods

Inspections

- shape

- height

- presence

- Number

Industry sectors

- Groceries

Maintain an overview of your production and identify optimization potential by precisely recording all units produced.

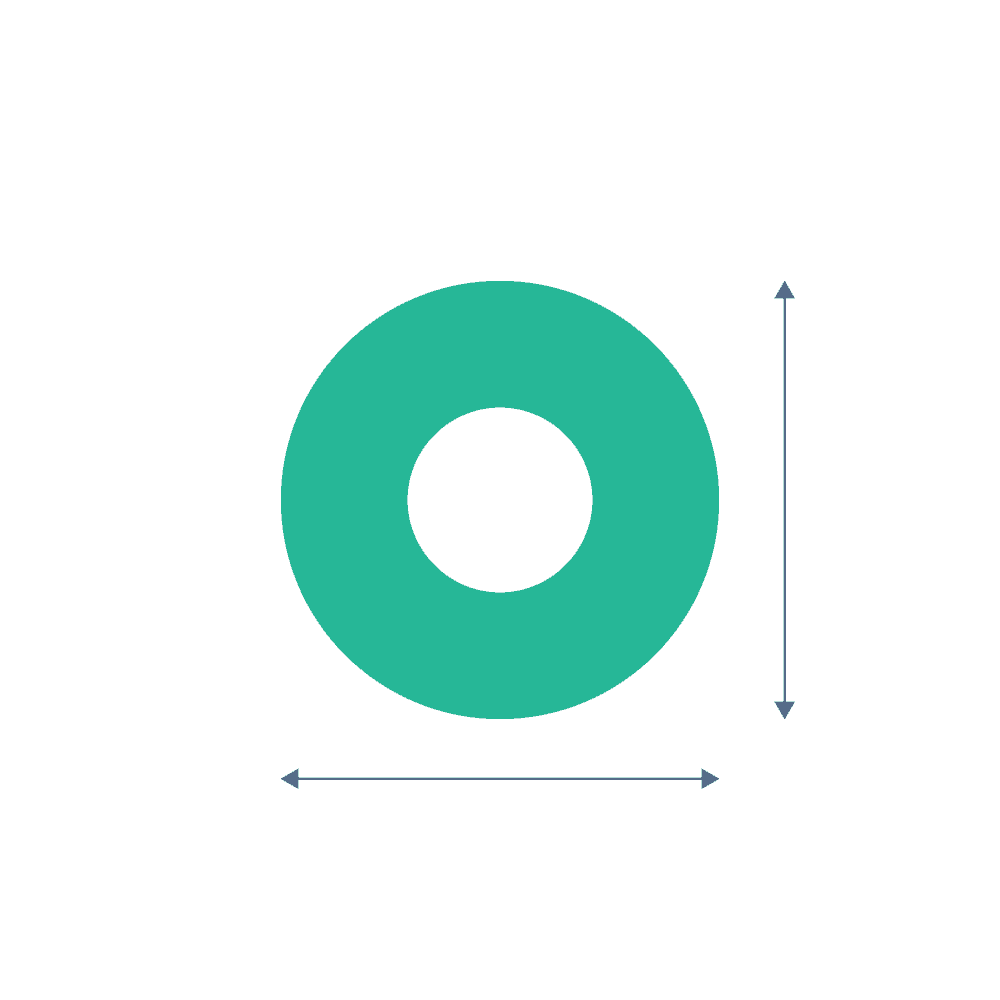

In addition to the exact lengths and widths of baked goods, our testing system records the core offset and checks whether deviations are within the tolerance range.

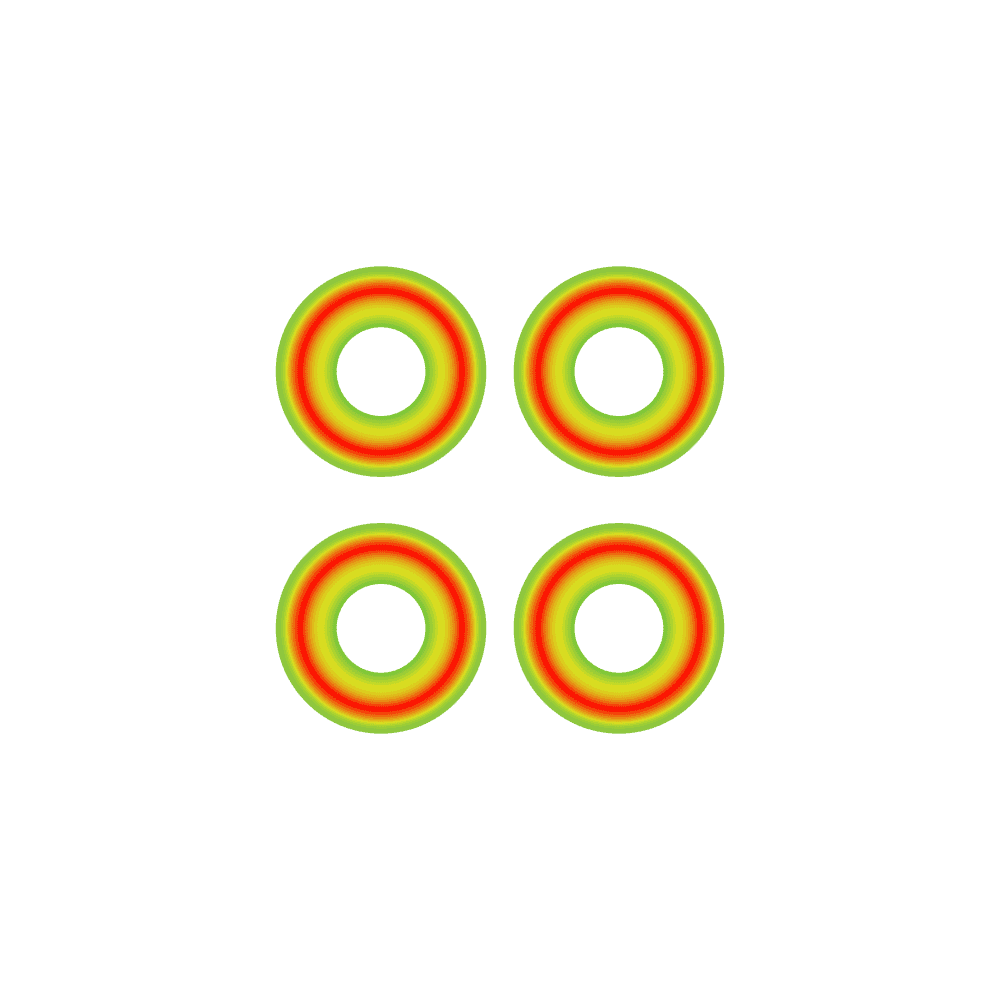

The height of the inspected objects is recorded by a 3D profile laser. In this way it can be checked whether the baked goods have risen evenly and meet the specified dimensions.

Our system enables the testing of a wide range of variations of baked products. The sensor process, which is robust to surface structures, delivers highly precise results, regardless of the color and structure of the test objects.

Thanks to the optical sensor technology of our testing system, any shapes and test features can be recognized. Check out a variety of pastries, from bagels to croissants to rolls of various shapes.

For quick inline testing, we rely on the use of 3D profile lasers, which provide 3D information about the test objects and enable non-contact and uncompromising quality control.

Specifications

TEST

| Type of examinees | Bakery products |

| speed | up to 40,000 units / hour |

| Inspections | Length, width, height, volume, shape |

| Working distance | 980 ± 400mm |

| Line width | 300 - 720mm |

| Repeatability z-axis | 10 µm |

| Repeatability x-axis | 25 µm |

| light source | 405 nm (blue), laser |

ATTACHMENT

| Dimensions (W x D x H) | (530 x 1,750 x 2,360) mm³ |

| Weight | 350kg |

| rated capacity | 1.9kW |

| care | 100 - 240V |

INTERFACES AND SOFTWARE

| Interfaces | ProfiNet, EtherNet, Digital I/O |

| interface | 24 inch monitor, touch |

| operating system | Windows, Keyence |

| software | MV.IMAGING, Keyence |

Universal: can be used in a variety of ways.

BAKERY PRODUCTS

Use the MABRI.VISION testing system in the production of baked goods and record the shape, color and structure of the products - whether bagels, croissants or rolls.

CONFECTIONERY

The inline-capable testing system MV.EYE BI1 can be optimally used for testing confectionery, chocolates or fruit gums. Get reliable data about quantities and shapes.

FRUIT VEGETABLE

Ensure complete testing even when it comes to fresh food, regardless of color or structure. A 3D profile laser enables maximum speeds.