Medical technology, pharmaceuticals, life sciences

High-precision testing of injection-molded components

What are we testing?

Injection molding defects

Incompletely filled mold part

Using 2D and 3D inspections, we assess the completeness of molded parts in critical areas such as thin spots or points far from the gate. We offer inline-capable inspection solutions even for the smallest structures on precision molded parts.

Entry points

Sink marks and demolding problems can negatively affect the appearance and function of molded parts. Our testing systems use highly accurate surface inspection methods to detect even the smallest deviations in shape during the manufacturing process.

ridge (web membrane)

Due to the nature of the process, burrs and flash can occur during molding processes. Especially in multi-component processes, these effects can negatively impact functionality. Our inspection systems detect critical contours, allowing us to identify burr formation early in the process.

Shape and dimensional accuracy

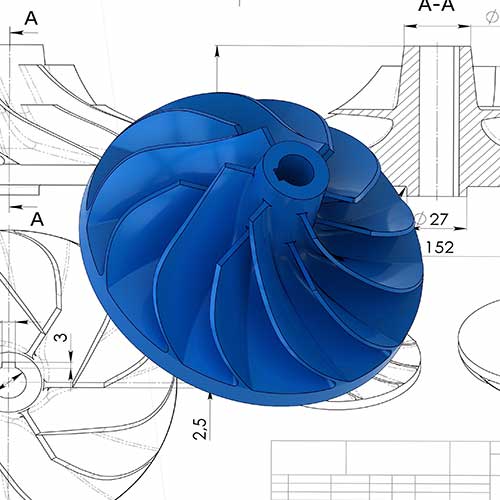

Form testing, dimensional accuracy

MABRI.VISION offers solutions for 100% inline component measurement of complex molded parts. In particular, components with pins for electronic contact must be checked for dimensional accuracy in shape and position for automated assembly processes.

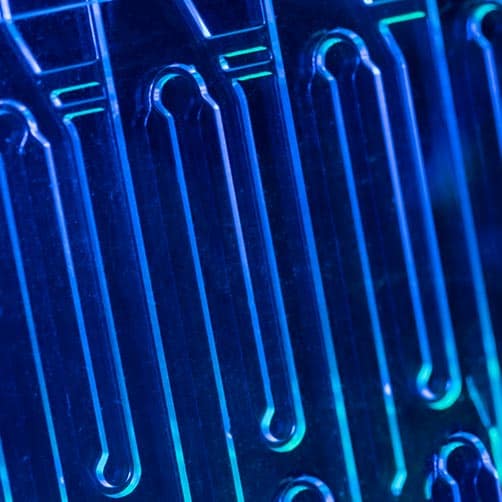

Structural parameters

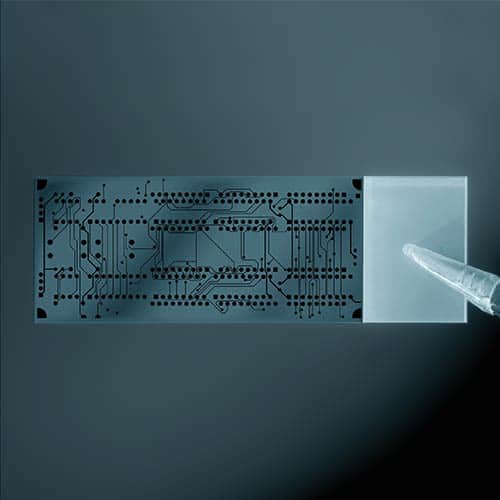

Even though injection molding processes result in only slight variations in shape, the smallest changes can have a significant impact on function. Our testing systems allow us to measure structural parameters, such as channel widths for in-vitro diagnostics, in order to minimize variations in flow characteristics and volume.

Defects

A multitude of factors, such as inclusions, diesel effect, dark spots, weld lines, and streaks, can directly influence the functional elements of molded parts. Depending on the inspection task, we capture the surfaces and analyze the data using both traditional and AI-based vision tools to detect even the smallest defects.

3D shape

silicone

Cavity number, 2D code, Data Matrix

2D Code, Data Matrix

Quickly capturing a large number of 2D codes, such as Data Matrix codes at varying intervals, can be challenging for traditional readers. MABRI.VISION has developed a platform for 2D codes (QR codes, Data Matrix codes) that is optimized for throughput and read rate.

Cavity number

If subsequent production processes or product quality depend on the cavity, the cavity number must be recorded at crucial points. MABRI.VISION offers vision solutions that can reliably record the cavity number using smart lighting concepts and deep learning.

Our solutions for testing injection-molded components

MABRI.VISION specializes in the development and implementation of complete vision solutions for use in production and research. Whether 100% inspection directly on the workpiece carrier system or in a cleanroom: by combining different high-performance optics, we meet your individual inspection requirements.

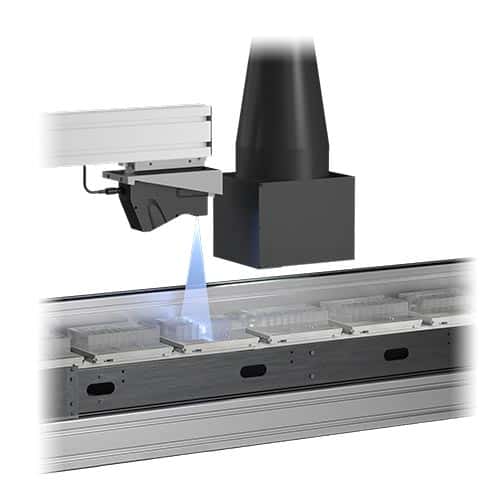

Inspection of the goods carrier system

Combination of 2D and 3D inspections for comprehensive 100% inline component measurement on the workpiece carrier.

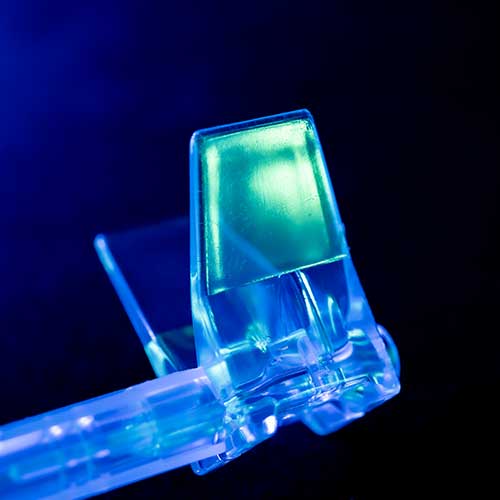

Inline high-speed microscopy

Our high-speed microscopy platform enables the inspection of the smallest injection-molded structures in real time.

Computer Vision 2D / 3D

Are you looking for a solution that can be integrated into your process? We offer a wide range of vision solutions.

Testing on the rotary clock

Our rotary indexing test system enables a wide variety of tests in a confined space, with manual or automatic loading.

Applications and implementations for injection molded parts

Microstructures in Vitro Diagnostics

Connectors and contacts

3D component inspection | Medical technology

Microdefects in silicone sealing rings