GANTRY.SPECTOR

The machine vision portal system for your production

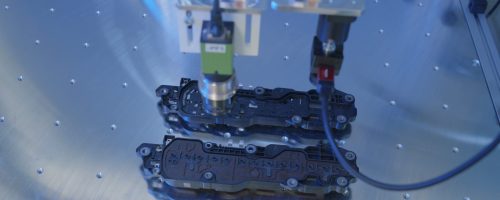

In today's fast-paced manufacturing environment, companies need reliable and adaptable quality control systems. The GANTRY.SPECTOR combines both – as a universal machine vision portal system, it's the answer to your individual inspection requirements. Thanks to its combination of state-of-the-art HALCON machine vision and advanced AI, it offers unparalleled precision and flexibility. Whether you position components manually or automatically, our scalable and user-friendly system optimizes your production efficiency and ensures that every component meets the highest quality standards. Discover how the GANTRY.SPECTOR can revolutionize your quality control.

Our advanced pipe testing systems cover all key quality control points – from precise inspection of the end face, inner and outer chamfers, to thorough examination of the surface and weld seam. Furthermore, we offer testing solutions for pipe inner diameters along the entire pipe length.

Trust MABRI.VISION for seamless quality control in your pipe production. Our testing systems for steel and stainless steel pipes minimize production errors and ensure consistently high quality for your pipe products.

Experience how our machine vision inspection systems optimize the efficiency and quality of your manufacturing processes. With MABRI.VISION, you invest in the highest quality and precision for your pipe production.

FEATURES AT A GLANCE

High-speed test:

Automate your 2D/3D component inspection for fast and efficient results.

Unrivaled precision:

Our axes achieve repeatability of up to 100nm and our cameras impress with a resolution of up to 0.3µm.

Software powerhouse:

Discover the benefits of advanced machine vision, adaptive workflows, and AI support.

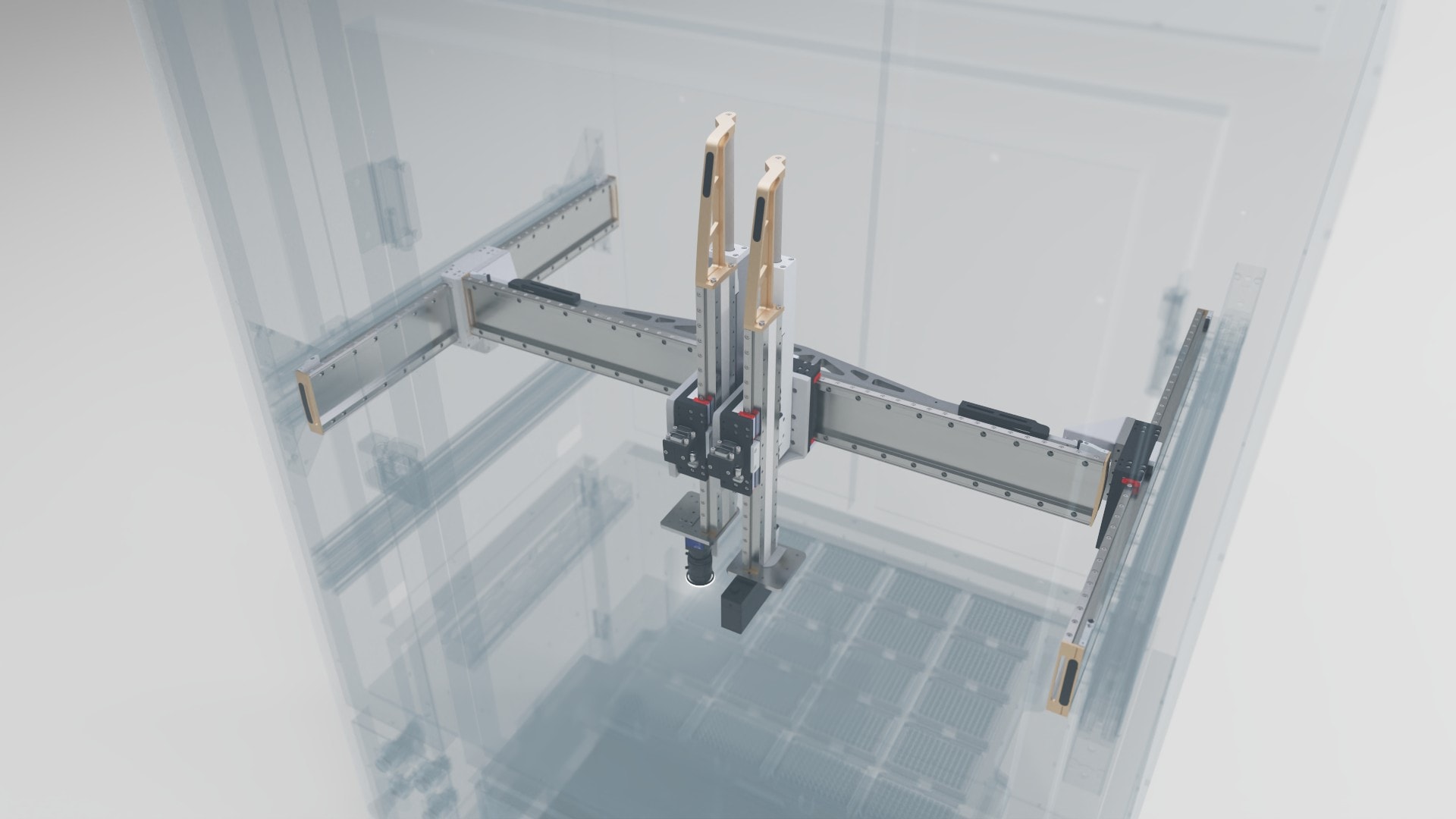

Flexible sensor integration

Thanks to the ability to integrate various sensors such as cameras and triangulation, the GANTRY.SPECTOR can be individually tailored to the specific testing requirements of the customer.

Scalability

Depending on customer needs, the axes can be manufactured in different sizes, making the system suitable for different production environments.

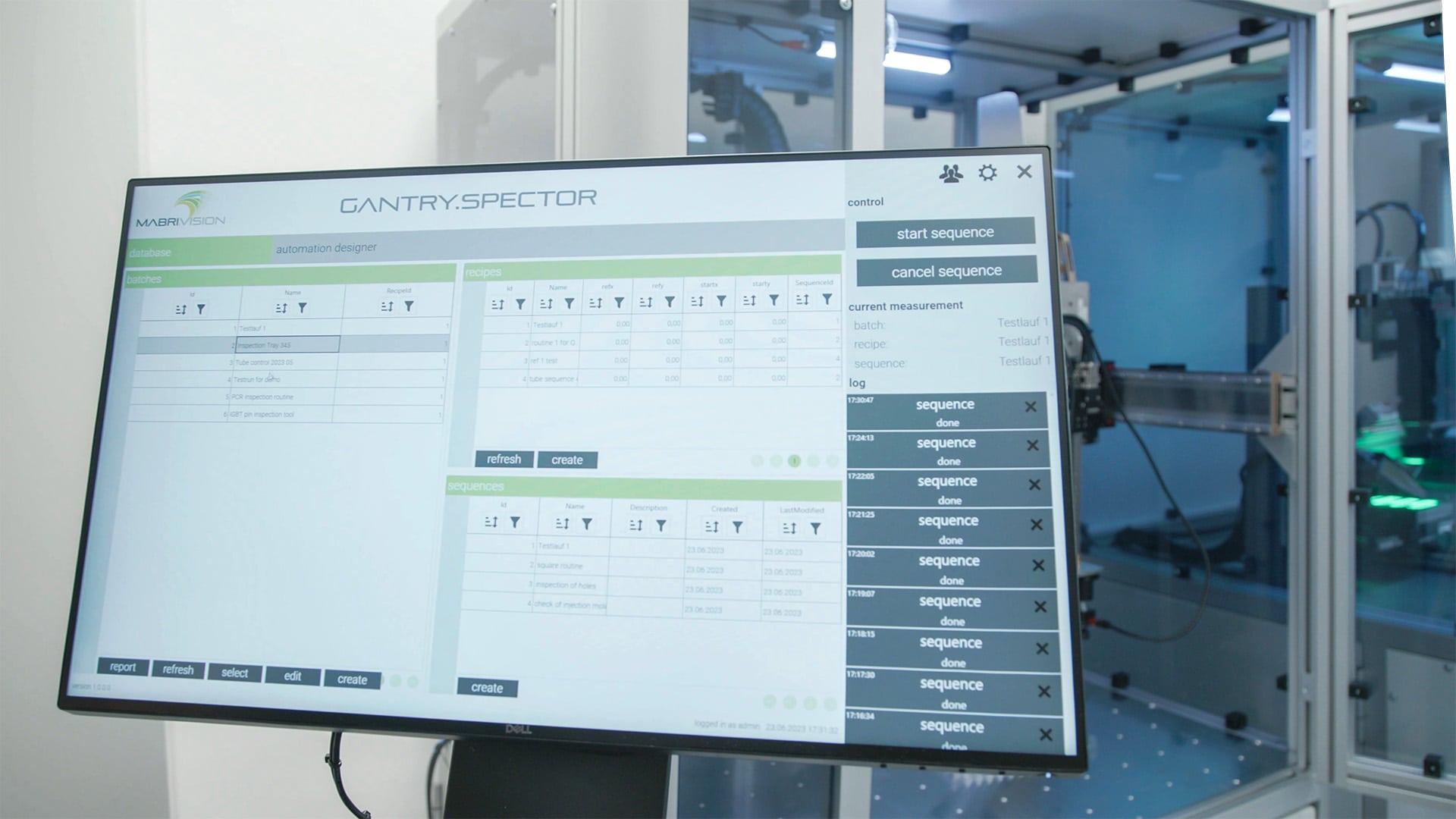

Self-directed testing processes

Whether you want to optimize existing testing recipes or create entirely new processes for fresh products – you are in control. This ensures not only maximum efficiency but also adaptability that keeps pace with the demands of your production.

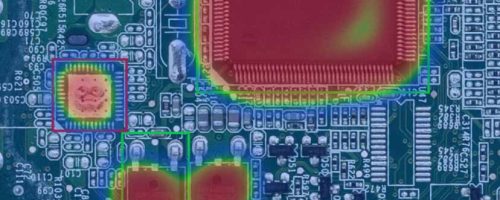

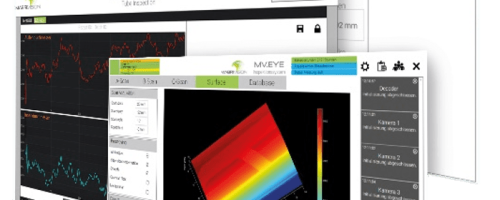

HALCON Machine Vision + AI

Our vision software combines HALCON's leading machine vision technology with artificial intelligence (AI)-based image processing. The result? A powerful synergy: fast detection and maximum precision.

Time savings & fast amortization

Maximize your efficiency with the GANTRY.SPECTOR. Every second counts in production. Our technology accelerates your quality control processes and ensures a rapid return on your investment.

Error minimization through automation

Human error is a thing of the past. Rely on the GANTRY.SPECTOR for consistent, automated, and error-free quality control.

LEARN MORE ABOUT OUR MV.BRIX PLATFORM

Software modules

Optimize your production processes with our customizable software modules for machine inspection and production integration. Achieve maximum efficiency and precision in machine image processing.

Cameras & sensors for greater precision

Integrate state-of-the-art matrix cameras, line scan cameras, and 3D profile section sensors into the GANTRY.SPECTOR for superior image quality and detailed component inspection. Our solutions are designed for maximum flexibility and performance in industrial camera applications.

Automation according to industry standards

From standard industrial interfaces to customized solutions such as PLC integration, control cabinet construction and cleanroom technology – our range of automation solutions ensures a seamless production process and maximum reliability.

Performance across the board

The GANTRY.SPECTOR in practical use

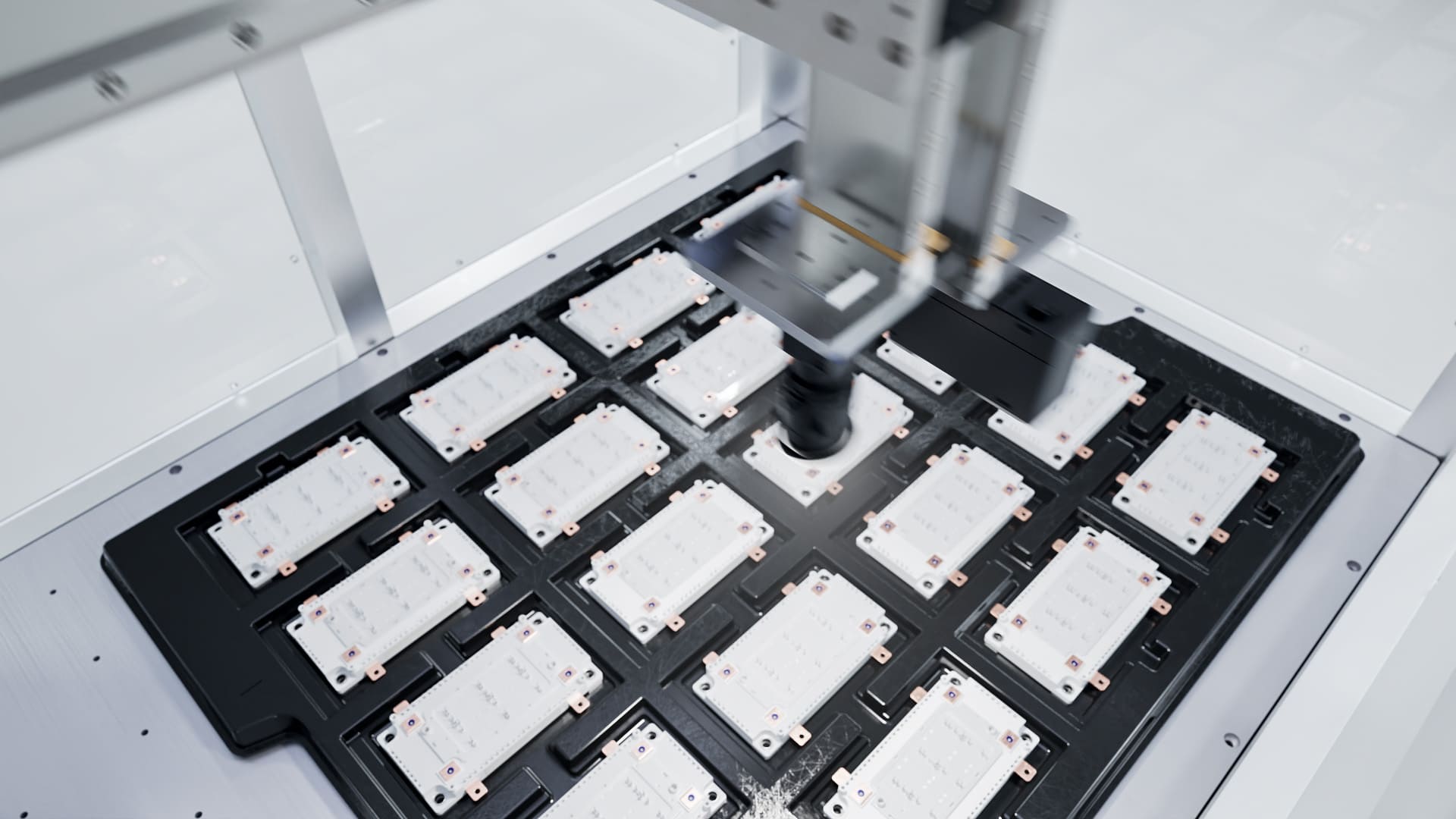

Testing of hybrid components

Reliable quality control for precisely manufactured hybrid components.

Final inspection of power modules

Automated final testing to ensure maximum functional reliability.

Testing of microfluidic systems

Highest precision in the analysis of complex microfluidic structures.

SPECIFICATIONS

FAQs about GANTRY.SPECTOR

Around the testing facility

What exactly can the GANTRY.SPECTOR check?

Our machine vision software allows us to inspect for dimensional accuracy, defects, anomalies, and presence, as well as read barcodes, QR codes, data matrix codes, and perform OCR. We would be happy to discuss your specific inspection requirements with you.

What types of cameras and sensors can be attached to the GANTRY.SPECTOR?

We integrate matrix cameras from 0.3 MP to 50 MP and line scan cameras up to 17k. For triangulation sensors, the line width ranges from 8 mm to 320 mm. Thanks to the platform-like nature of the GANTRY.SPECTOR, special sensors, such as code readers, can also be integrated.

Can additional cameras or sensors be installed later?

The GANTRY.SPECTOR is designed so that we can connect alternative cameras or sensors to the system. Customers cannot integrate their own cameras or sensors. The system features digital I/Os, allowing for the integration of other actuators, such as grippers.

How does the integration of the GANTRY.SPECTOR into existing production lines work?

The GANTRY.SPECTOR can be operated as a stand-alone system or integrated into a production line. If the system is to be integrated into your production processes, we will work with you to plan the mechanical and electrical interfaces. Components can be fed via conveyor technology, workpiece carriers, or robots. If you are looking for a turnkey solution, please contact us. We would be happy to assist you with the planning and implementation.

Which industrial interfaces are supported by your automation solutions?

The GANTRY.SPECTOR can be controlled via Profinet, TCP/IP, and Digital I/O.

Is the GANTRY.SPECTOR suitable for use in cleanroom environments?

We also offer a version of the GANTRY.SPECTOR that can be operated in cleanrooms. In addition to an FFU, we offer automatic lifting doors and cleaning units for the system.

Are there any restrictions regarding the size or type of components to be tested?

We are limited by the size of the installed linear axes. This results in a maximum testing volume of approximately 1,000 x 1,000 x 600 mm. If you require testing of a larger component, please contact us.

All about software

Which software modules are available for machine testing?

We are continuously integrating additional modules into our platform. Modules such as user management, batch management, automation designer, testing procedures, databases, and audit trails are already integrated. If you have specific requirements, please feel free to contact us.

How easy is it to adapt the system to specific production requirements?

The movement sequences of the axes can be adapted using our automation designer after operator training. We are also working on enabling our customers to independently adapt test recipes.

How does the GANTRY.SPECTOR differ from other machine vision systems?

The GANTRY.SPECTOR is a turnkey testing system that can be operated independently as a single cell. The large work area of the gantry system allows for the testing of components of varying sizes. This makes the system highly flexible and eliminates the need for setup. This flexibility makes the GANTRY.SPECTOR ideal for dynamic production planning.

Training & Service

What training or support do you offer for the use of the GANTRY.SPECTOR?

As part of the commissioning process, we offer basic training on the operation and maintenance of the GANTRY.SPECTORS. To customize program sequences, we recommend expert training, which we can conduct on-site at your production facility.

How is the quality and precision of the test results ensured?

We offer modules for calibrating the machine vision system. If desired, regular recalibration procedures can be defined and documented in the test plan. This ensures that the GANTRY.SPECTOR only performs calibrated tests.

What maintenance or service offerings do you provide for the GANTRY.SPECTOR?

We offer maintenance and service contracts for the GANTRY.SPECTOR at various levels of coverage. We would be happy to discuss a suitable offer with you.

Are there customer service or support services available in case of technical problems?

In case of technical or software problems, our customer service is available to assist you. Depending on your service agreement, we offer different response times and availability periods.

Precision meets innovation.

Discover how our machine vision inspection systems make a difference. Talk to an expert!