Complete solutions for industrial users

DEEP.MV – Deep learning applications in industrial image processing

DEEP.MV

Our platform - machine learning for industrial use

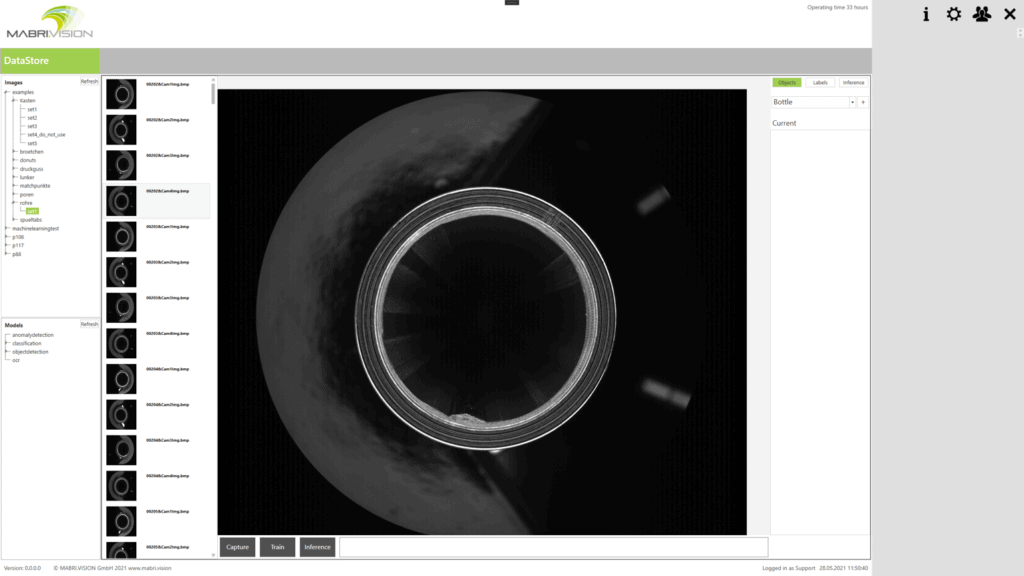

MABRI.VISION has developed the DEEP.MV software platform for the application of modern deep learning and AI technologies in the industrial environment. The platform combines all the necessary components and enables use at the plant level.

Possible uses

Our deep learning platform is ideal for applications where rule-based approaches are challenging or fail. This applies above all to test applications with a wide range of variants and error characteristics, such as varying surface and structural properties. The MABRI.VISION platform can be used optimally where, due to the complexity, primarily manual and manual checks are carried out using error catalogs.

The classification forms the basis for many quality assurance tasks. In the application, there is no need for time-consuming labeling of data - it is sufficient to categorize images.

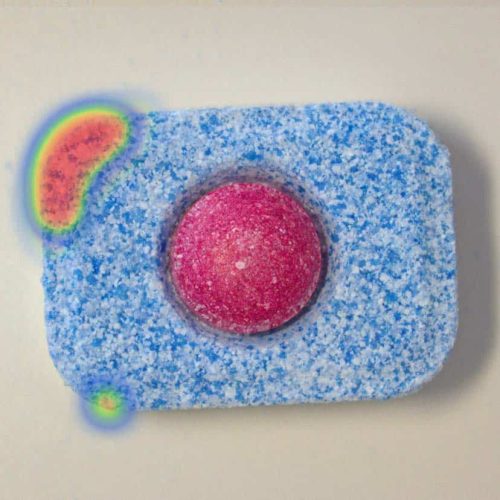

Error detection in flushing tabs

scratch

started

not ok

Web error

OK

Web error

Hole

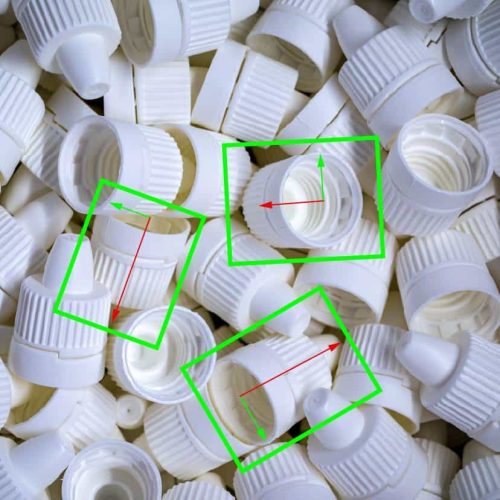

Completeness check

Position check

Attendance control

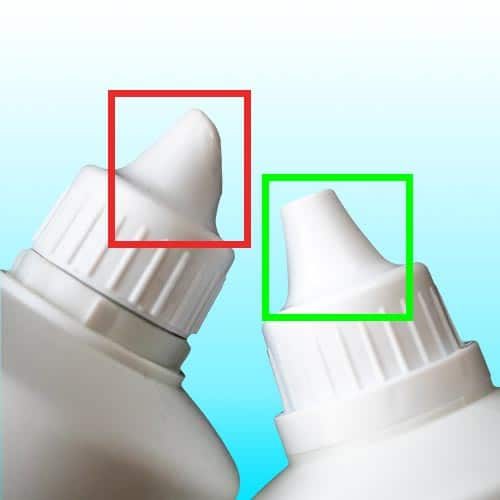

Injection molding defects

scratch

Pores and grooves

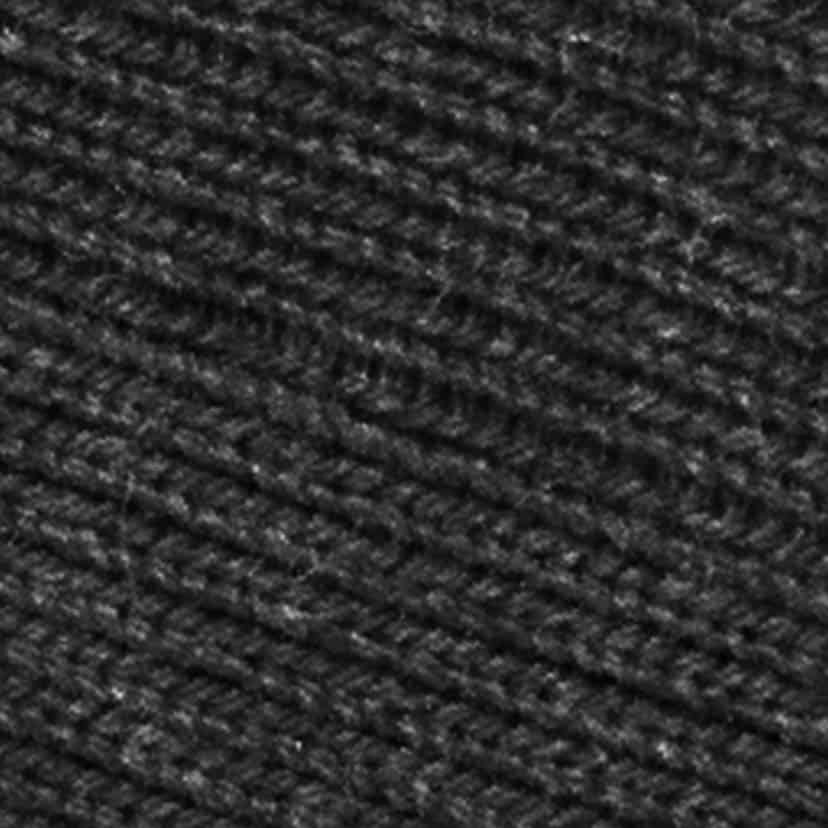

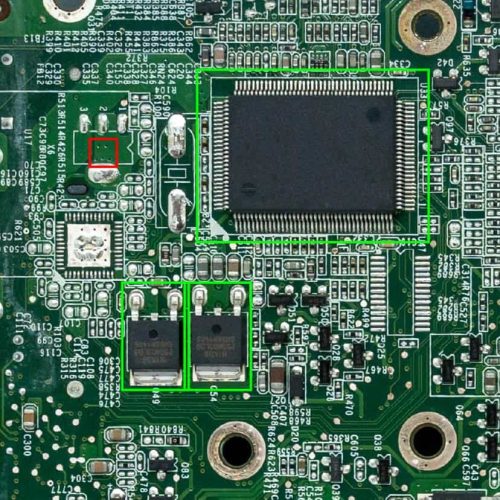

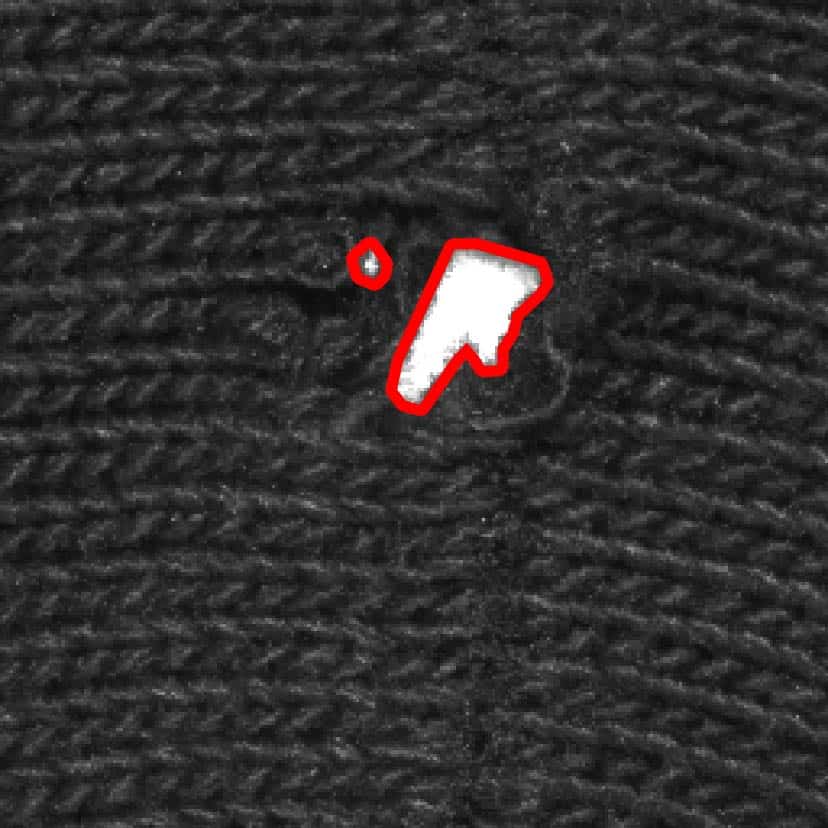

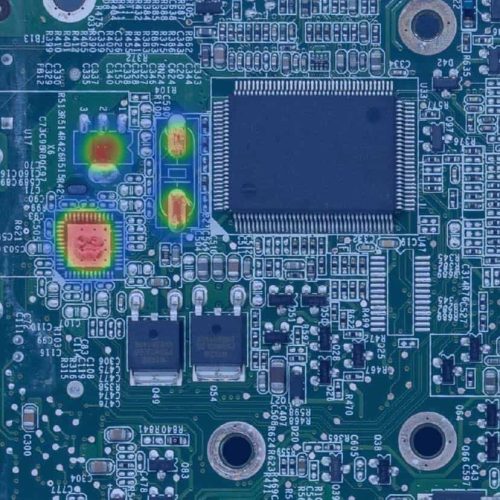

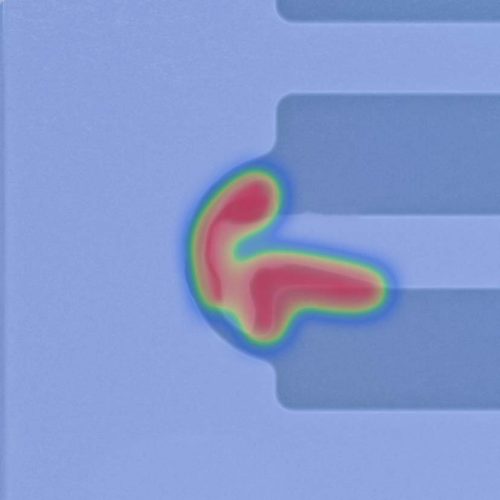

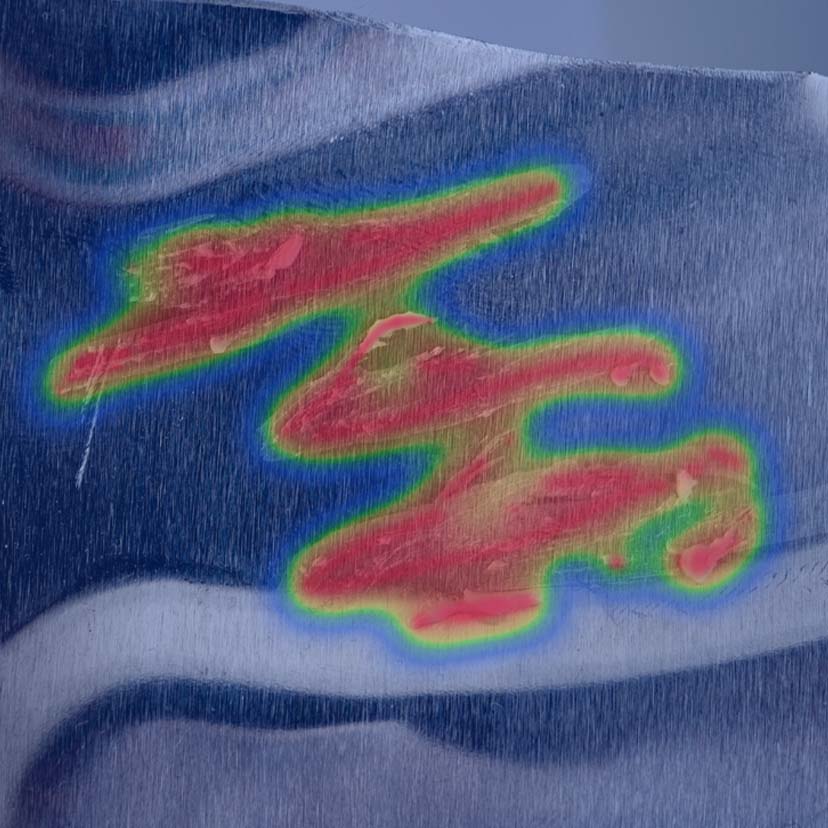

Segmentation is always important when objects, structures or errors need to be identified and isolated very precisely. This information can be used, for example, for process optimization

Chip detection

textiles

Rinse tabs

Incorrect sorting

foreign body

Circuit boards

Microstructures

Surfaces ex. Glue residue

DOT code on tires

Font recognition

Your advantages

- All from a single source

MABRI.VISION provides you with everything you need for your application. In this way, you avoid using partial and isolated solutions that do not interlock and are therefore difficult to maintain. In addition to the software application, we primarily supply the necessary sensor systems, test platforms and services for your production process.

- Save costs

By using our lean AI platform, challenging applications in the industrial environment can also be solved cost-effectively. Manual and time-consuming test steps can thus be omitted.

- Solving complex problems

Deep learning technology can be used to solve applications that are very challenging or cannot be solved satisfactorily with classic image processing. This opens up completely new possibilities in quality assurance.

- The right solution

As a universal solution provider for optical production metrology, we take a close look at your application. We only use our deep learning technologies when and to the extent that it makes sense for the application. In this way you avoid incorrect results and excessive development costs. In addition, we map all other essential components in quality assurance, including calibration and traceability.

- Stay flexible

One of the challenges of the current development trends in industry is modular production with ever shorter production cycles. Thanks to machine learning processes, you remain flexible and can adapt your production independently and adaptively.

- Future proof

Developments in the field of deep learning are progressing very quickly. Our AI platform is therefore constantly being expanded and relies on established standards in research and development. This continuous development enables you to always use the latest technologies in the future.

Practical example: Error detection on socks

Machine learning processes can be used wherever rule-based approaches are difficult to implement.

Web error

Hole

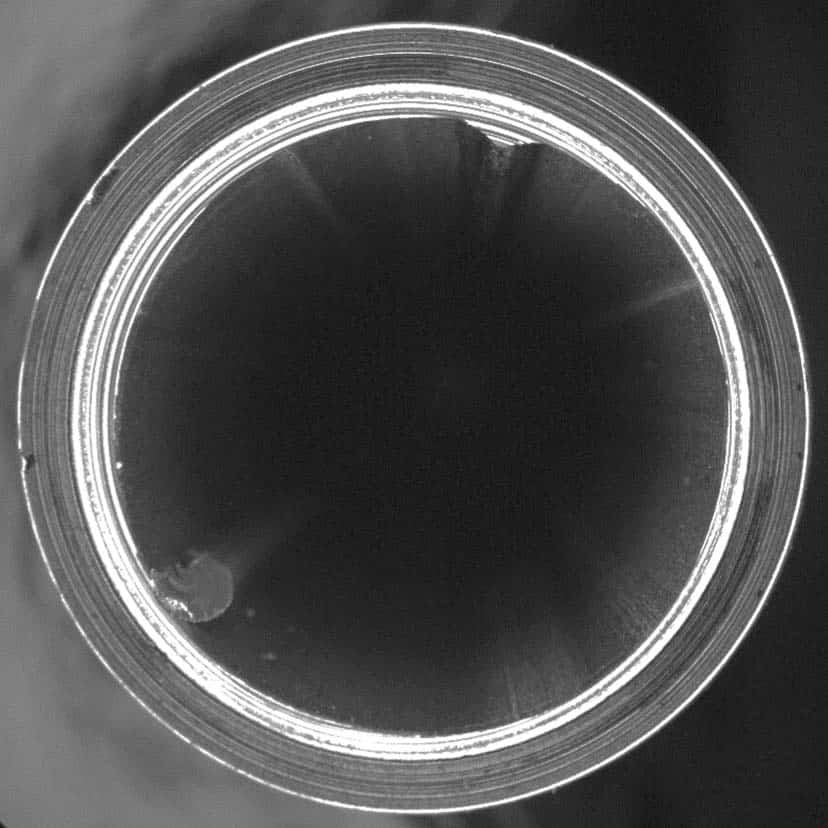

Practical example: Defect detection on metal pipes

Span

Weld seam defect

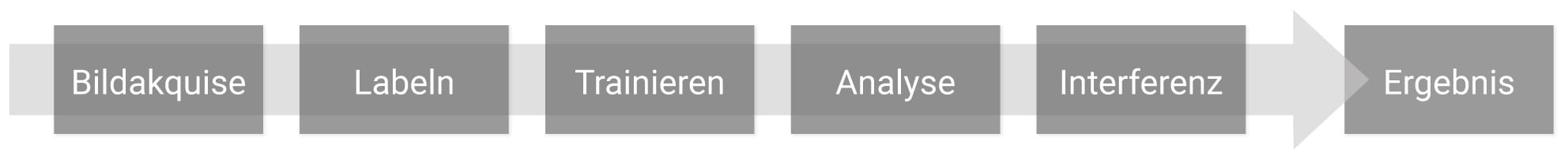

Process flow

Deep learning methods are based on artificial neural networks.

These networks are inspired by the (biological) neural networks, i.e. part of a nervous system. Artificial neural networks are built in layers. A layer or level consists of several artificial neurons. There are several hidden levels between an entrance and exit level. The name "deep" neural network gets the structure because of exactly these hidden levels.

Why MABRI.VISION

MABRI.VISION builds and develops high-quality machine vision solutions and modular testing systems for your production processes. Our modular system enables us to provide solutions for your testing tasks quickly and efficiently.

Innovative solutions, our passion!

Innovative solutions, our passion!

Innovation is the foundation for continuous growth in modern industry. We live this out every day and begins in the minds of our team of experts. The focus is always on the benefits and requirements of our customers. We passionately implement testing processes that range from AI-based computer vision solutions to 100% inline component measurement of sophisticated products. We rely on the latest generations of advanced technologies for our measurement technology. With this philosophy we want to make production processes more efficient and dynamic.

AI, processing, control - one software platform

AI, processing, control - one software platform

With the goals of Industry 4.0 and a continuous improvement process, the demands on test automation, interfaces and efficient evaluation algorithms are increasing. We at MABRI.VISION have recognized this trend and are taking it one step further. Our software team develops modular software platforms that combine all the components of modern testing systems. If necessary, we can expand evaluation algorithms with neural networks, map fast interfaces to system controls and integrate audit trails, batch reports, history graphs or databases as required.

A strong team, always there for you.

A strong team, always there for you.

As a customer, you are always at the forefront for us. Our team of vision experts, construction, software development, electrical, assembly and support is always there for you. Thanks to modern business processes and IT solutions, speed is a central goal. With our service solutions including 24/7 support, we support your production with efficient solutions.

End-to-end solutions, everything from a single source.

End-to-end solutions, everything from a single source.

You think in processes, we think in solutions: that's why we offer our customers turnkey testing systems that can be seamlessly integrated into your production processes. Our experts advise on planning and design at the beginning of a project. If technologies need to be evaluated, we carry out feasibility studies and inline tests. At MABRI.VISION we offer system design, programming and automation from a single source. We can optimize complex evaluations and tests directly with the system control and all customer interfaces.

Contact.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision