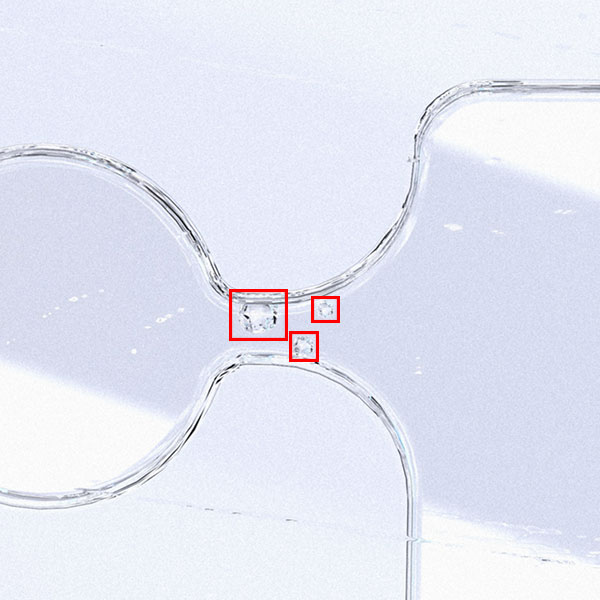

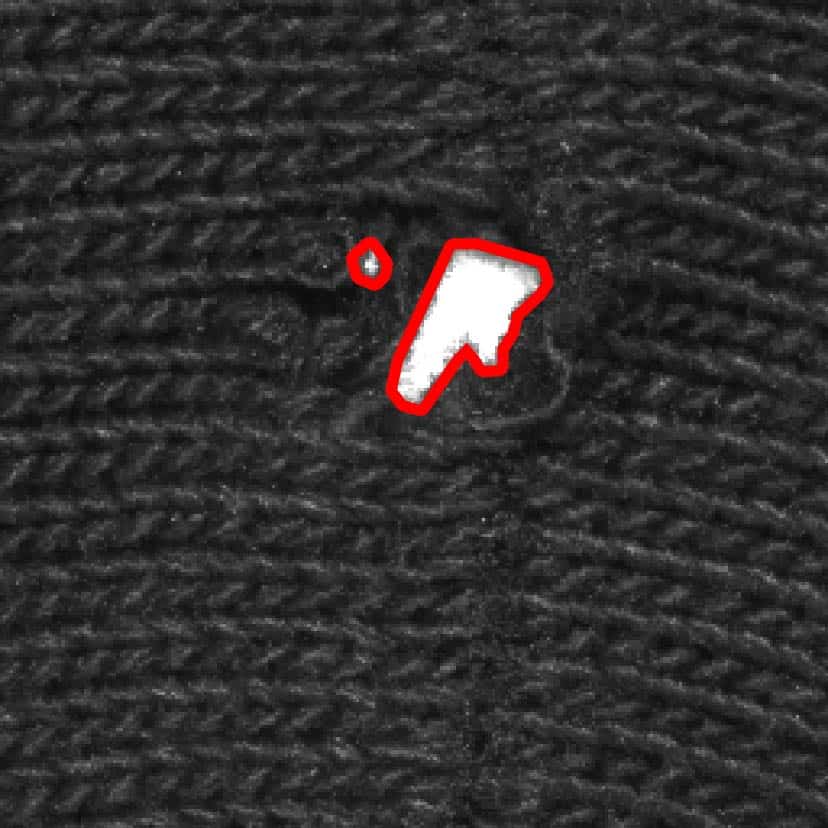

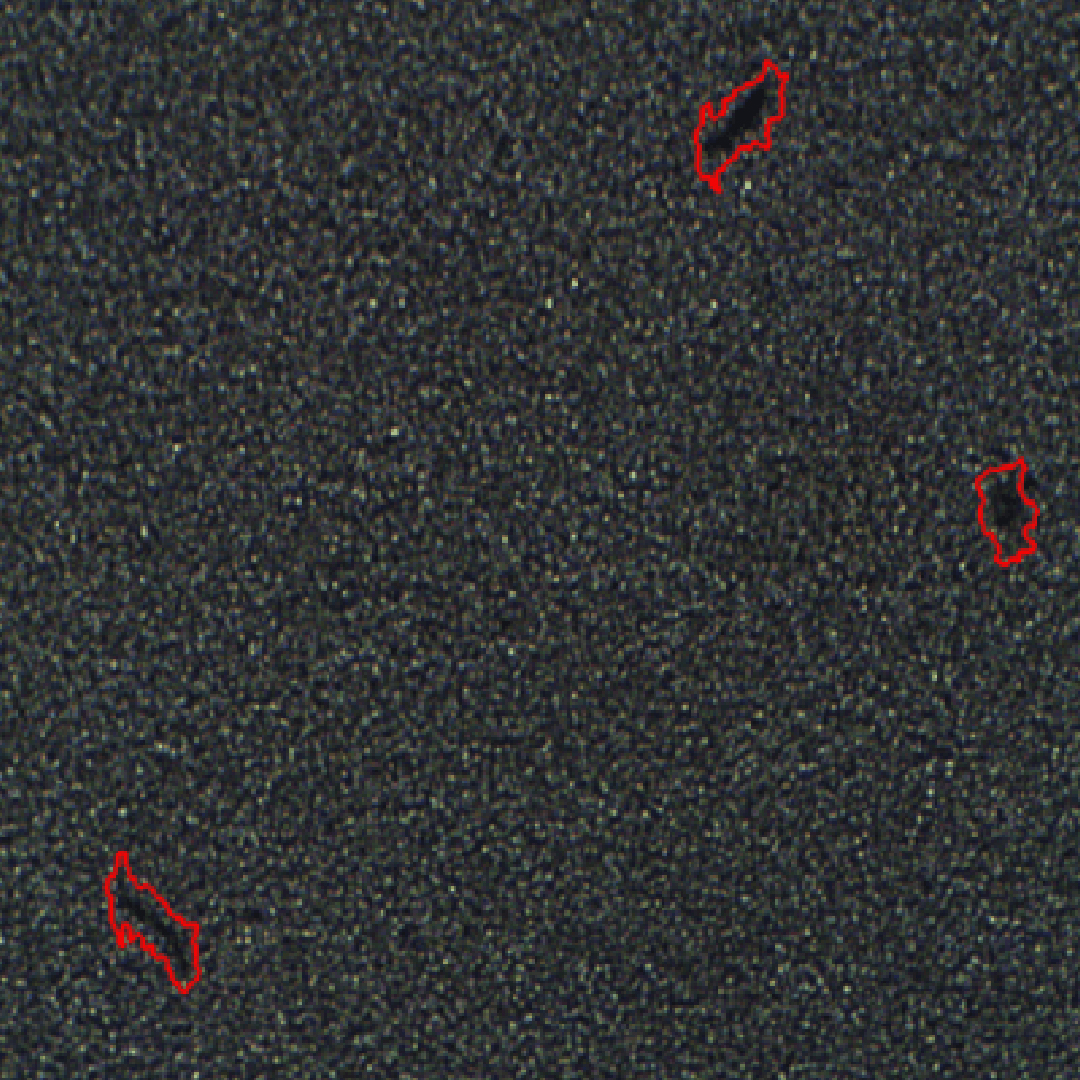

MABRI.VISION employs a variety of methods to detect defects and anomalies in products and materials. By using image processing algorithms, it is possible to identify defects such as cracks, holes, pores, burrs, or deformations in products or materials. The use of 3D sensors can also help detect defects that are not visible with 2D imaging.

The use of machine learning methods, such as neural networks , is another way to detect defects and anomalies. These methods can be trained to identify defects and anomalies based on pattern recognition and comparison. The use of deep learning technologies can also help improve defect and anomaly detection.

+49 241 56 527 930

info@mabri.vision