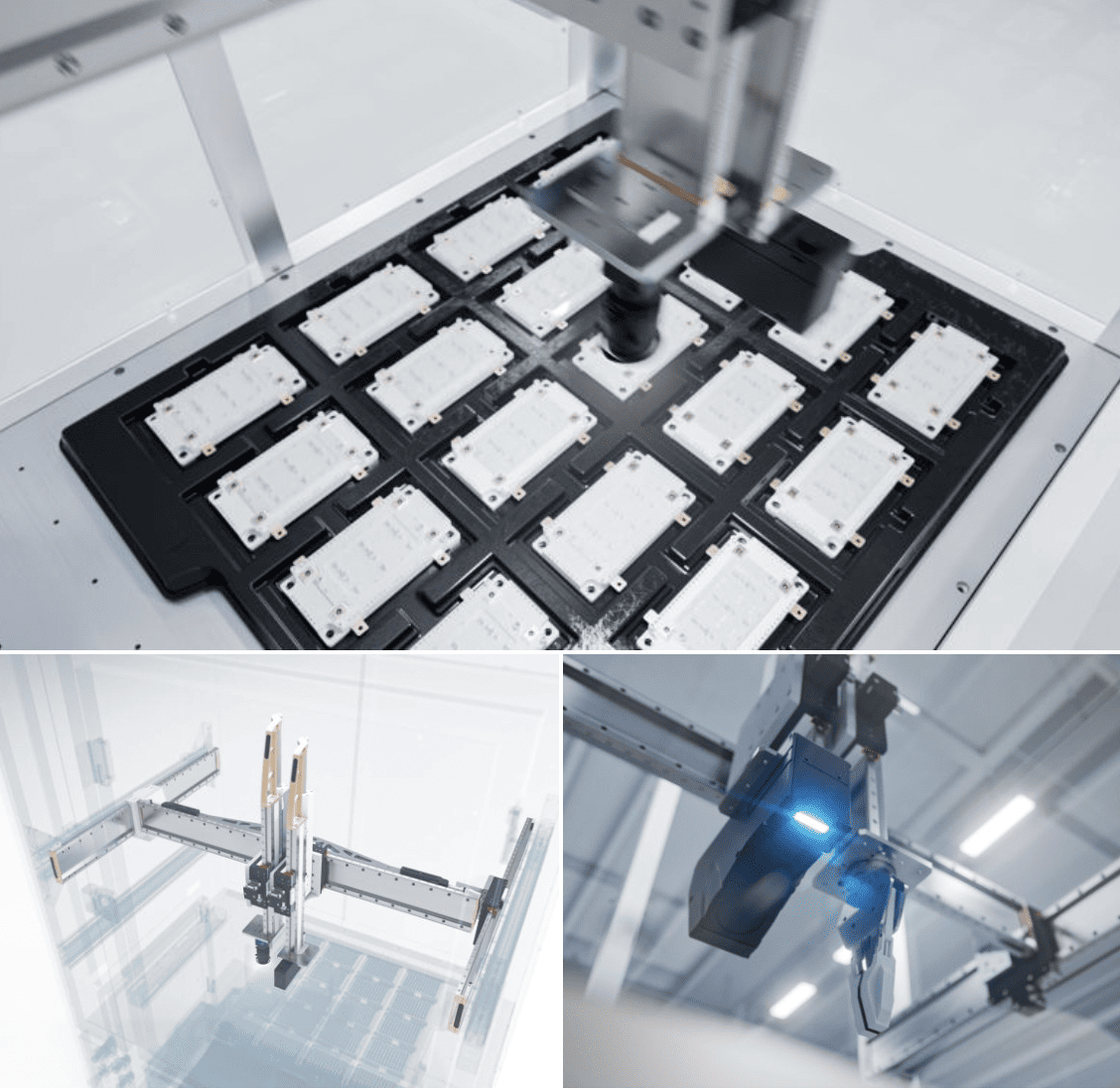

Wheel test with the VISION.SPECTOR TIRE EOL

Quality control with the VISION.SPECTOR TIRE EOL. Our VISION.SPECTOR TIRE EOL is a complete solution for end-of-line quality control. This system combines modern technology with efficient design to ensure comprehensive inspection and maximum accuracy. Product details: > Dimensions: 1.5 m x 1.85 m x 3 m > Technology: 3D laser, high-resolution 25MP matrix camera, line scan camera > Inspections: DOT code, rim design, match points, symbols, etc