2D inspection of packaging

2D inspection of packaging

Services

Checking for packaging defects

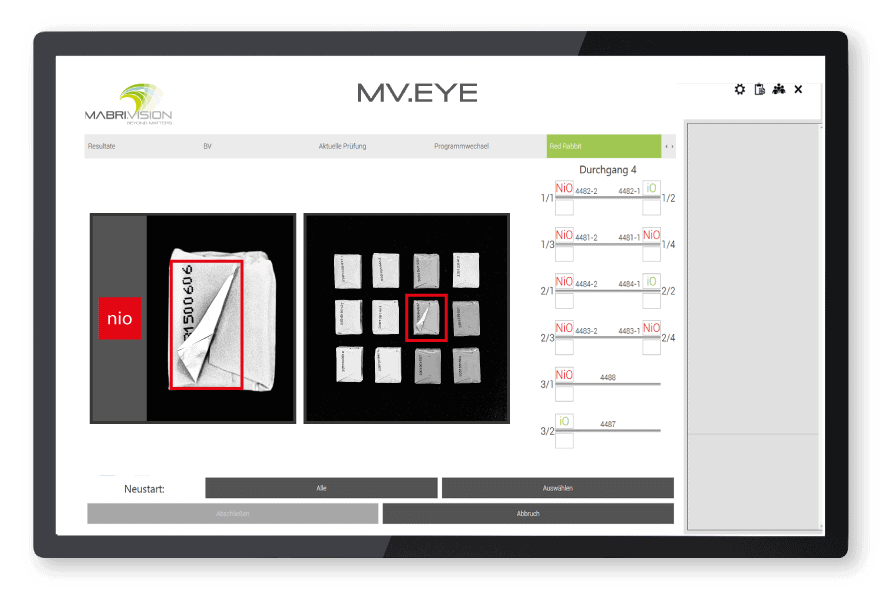

The MABRI.VISION inspection system enables you to perform inline 2D inspection of packaging, reliably detecting features and defects in line with production.

Inspection in motion

Your manufactured products are tested in motion. The MABRI.VISION testing system is integrated into your existing production line.

Shape, volume & location

MABRI.VISION builds inspection systems that, through the use of different technologies, are suitable for a wide variety of inspection steps. This allows not only the determination of presence and position, but also the detection of shapes and defects.

Feature recognition & counting

Optimize your production through continuous feature recognition and counting. The results are saved and can be imported and analyzed.

Contact

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision