With the MV.CHECK CI2 system, MABRI.VISION offers an inline inspection system for testing plugs, connectors, and pin headers. At speeds of up to 1000 contacts/min, precise testing of contacts and coding is possible in line with production cycles. The system offers all common interfaces and can be seamlessly integrated into existing processes.

The reliable testing of wobble dimensions and defects, such as bending of contacts, takes place in sync with the production cycle.

The MABRI.VISION MV.CHECK CI2 inspection system detects and verifies codes on your components. This ensures that production batches are free of constituent materials.

Don't compromise when inspecting your plugs and connectors. Our testing procedure guarantees reliable verification of the completeness of injection-molded parts.

Thanks to its recipe databases, the MV.CHECK CI2 system offers new solutions for testing different product variants. This allows you to test all production variants without having to configure the software for each one.

Thanks to the optical sensor technology of the MV.CHECK CI2 inspection system, all test characteristics are captured at maximum speed. To maximize throughput, processing takes place in parallel with data acquisition.

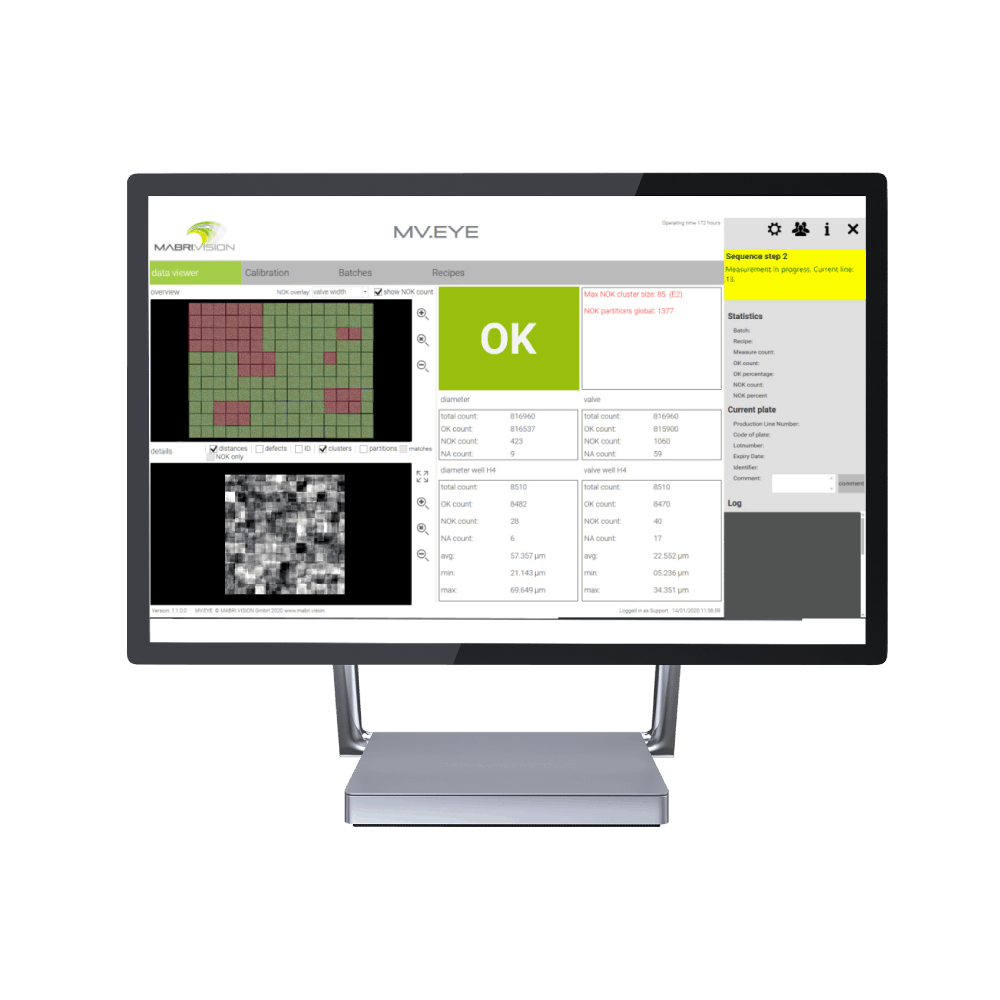

Comprehensive statistics and diverse analysis tools support efficient operation. This allows for the quick identification and implementation of optimization potential and product improvements.

100% quality inspection of circuit boards and connectors in electrical engineering. Reliable contact testing at high speed for maximum throughput.

Uncompromising and inline-capable testing of molded parts for use in the automotive industry. Speeds of up to 1,000 contacts/min are achieved.

The MABRI.VISION MV.EYE CI1 testing system is suitable for high-speed testing of components for the aerospace industry with a wide variety of test characteristics.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.