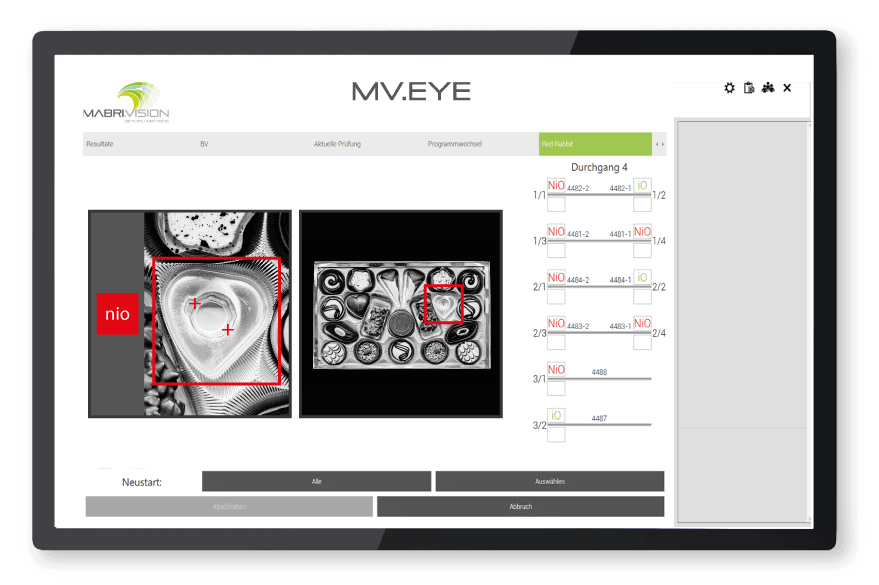

In the production of packaged foods, an inventory check is often required at the end of a production line. For example, in the production of chocolates, the completeness of the contents of a box is checked as a final step. With a MABRI.VISION inspection system, not only is the presence of all required components determined, but the shape, dimensional accuracy, and position are also detected using 3D profile lasers. The sensor technology, which is robust against surface structures, delivers highly precise results, regardless of the color and texture of the objects being inspected.

The inspection system performs checks in sync with your production cycle. Therefore, nothing stands in the way of expanding an existing system to include a vision system.

The parallel data acquisition and processing ensures high throughput in everyday production.

In addition to the physical examination, further examination modules can be implemented. These include, among other things, the identification of quality characteristics of your products.

The flexible use of 2D and 3D sensors makes it easy to implement even complex testing tasks.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.