Rotary indexer test systems

Rotary indexer test systems

Our rotary indexers are characterized by the combination of various technologies. Typical stations include camera inspection, shadow throw inspection using an optical micrometer, and surface measurement using a triangulation sensor.

Multimodality enables its use in various areas and is particularly popular where lean and efficient production processes are required.

The application possibilities are wide-ranging: from connector and circuit board testing to the testing of complex injection-molded parts and plastic-metal composites, MABRI.VISION offers complete solutions tailored to your production in an inline-capable system.

Robust

Our rotary indexing test systems are based on a solid granite structure to deliver reliable and repeatable test results even in demanding production environments.

Scalable

The test stations can be flexibly adapted to the requirements of your production and test characteristics, both in terms of number and design.

Flexible configuration

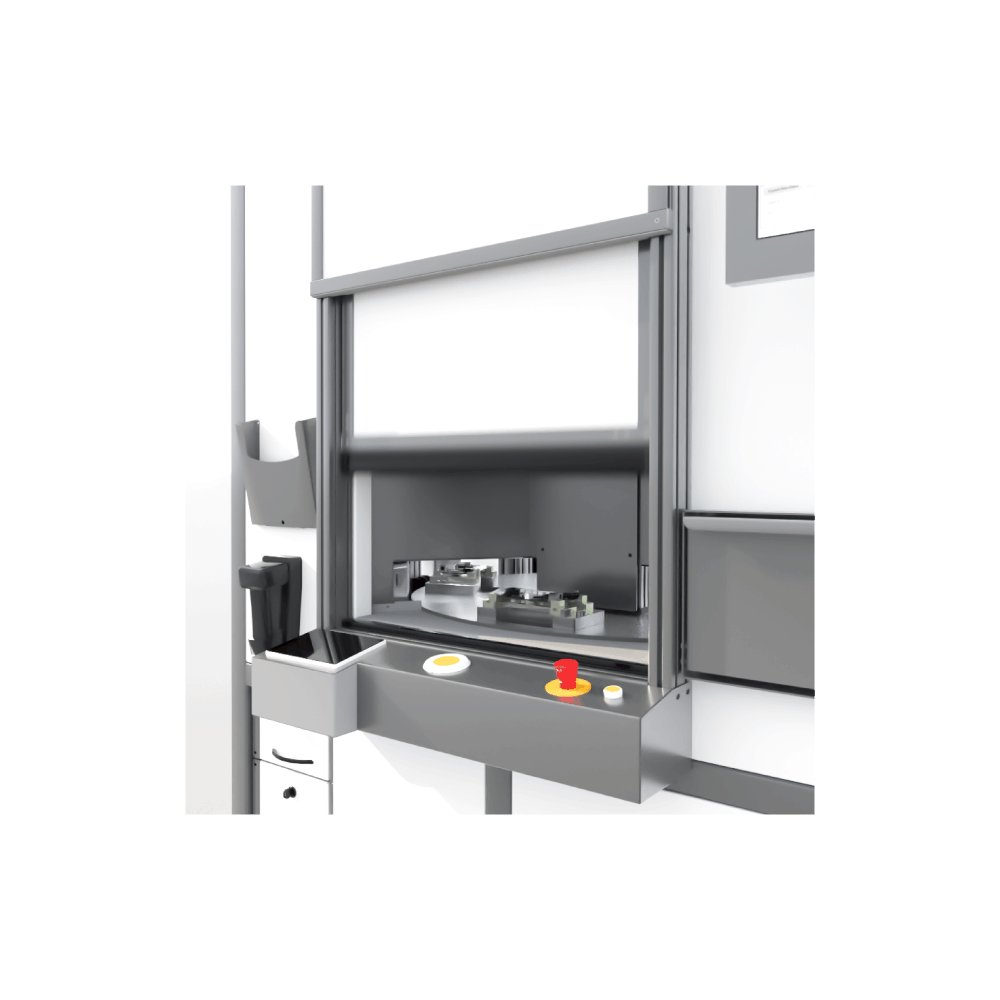

There are virtually no limits to the variety of parts that can be inspected. Loading is done via a lifting door and can be done manually or automatically.

Batch management

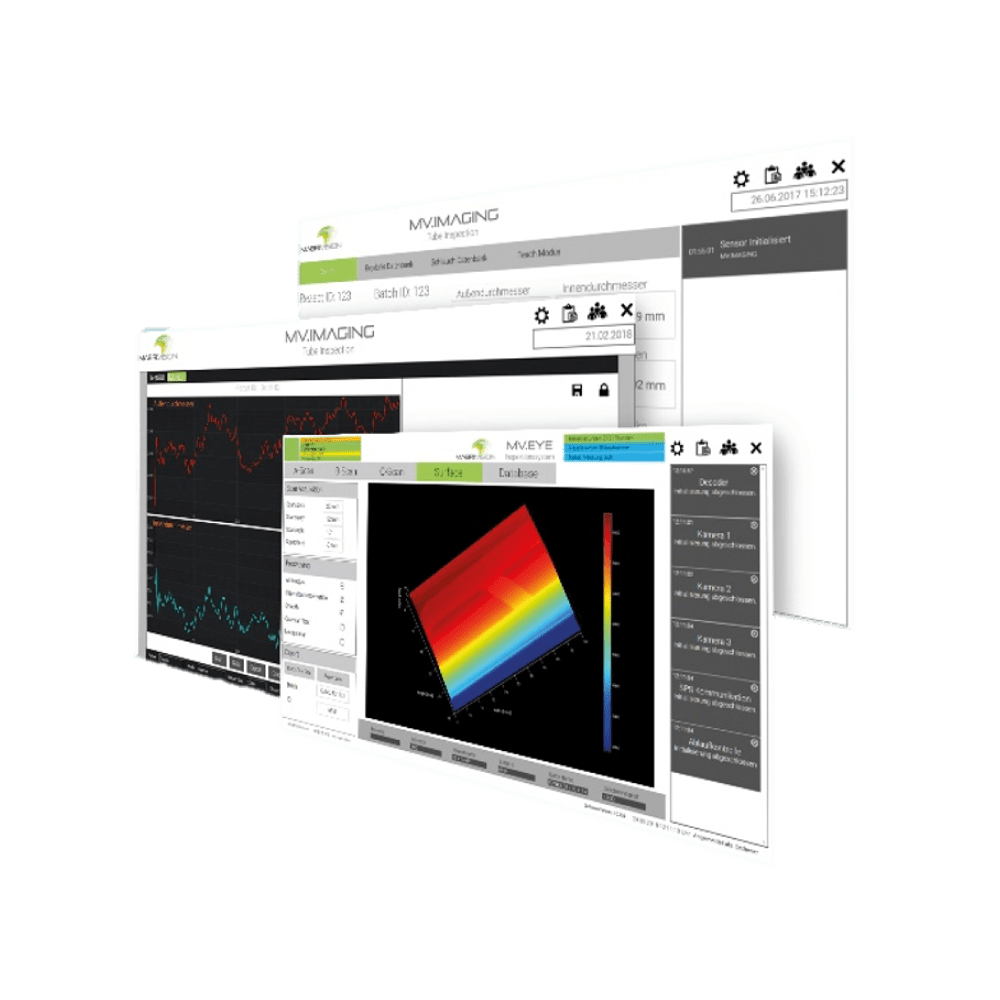

Our software offers advanced batch management. A recipe database enables quick product changes without having to readjust parameters. A results database forms the basis for continuous product improvement.

2D surveying

2D measurements can determine, for example, the presence of features, their exact position, or wobble circles. Furthermore, defects such as discoloration or scratches can be detected at this stage. Advantages include the speed and efficiency of this inspection step.

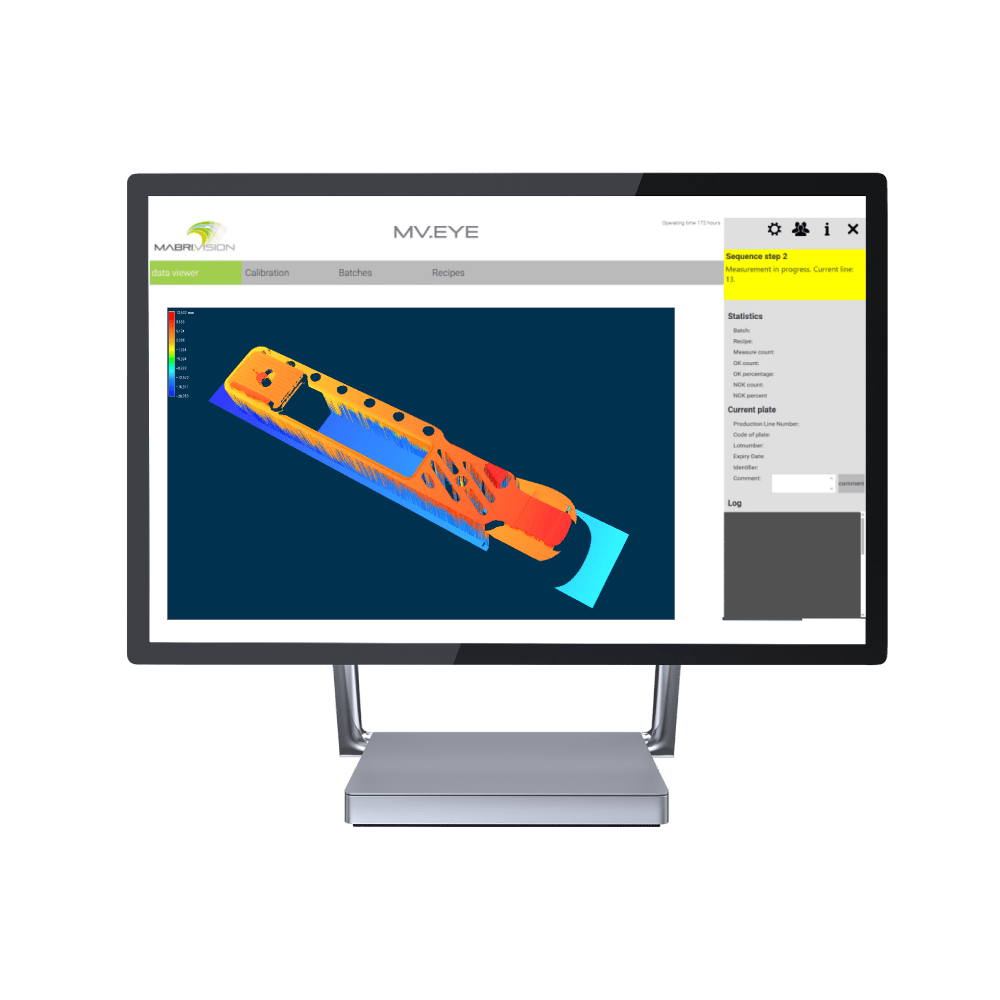

3D surveying

We use triangulation sensors to measure the surface of a component. Two optical section sensors perform a 3D profile measurement. This allows us to determine height information and dimensional accuracy in the lower micrometer range.

Specifications

Universal: versatile

ELECTRICAL ENGINEERING

Achieve micrometer-level accuracies with the robust MABRI.VISION MV.EYE testing system – whether testing connectors or circuit boards.

automobile

Thanks to their modular design, MABRI.VISION rotary indexers are ideally suited for testing complex components in the automotive industry. Test in sync with production.

MEDICAL TECHNOLOGY

In the medical industry, rely on comprehensive inline quality control of components and products and benefit from a scalable testing system.

Contact

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision