The MABRI.VISION inspection system enables reliable testing of shape and height and also provides information about positional tolerances.

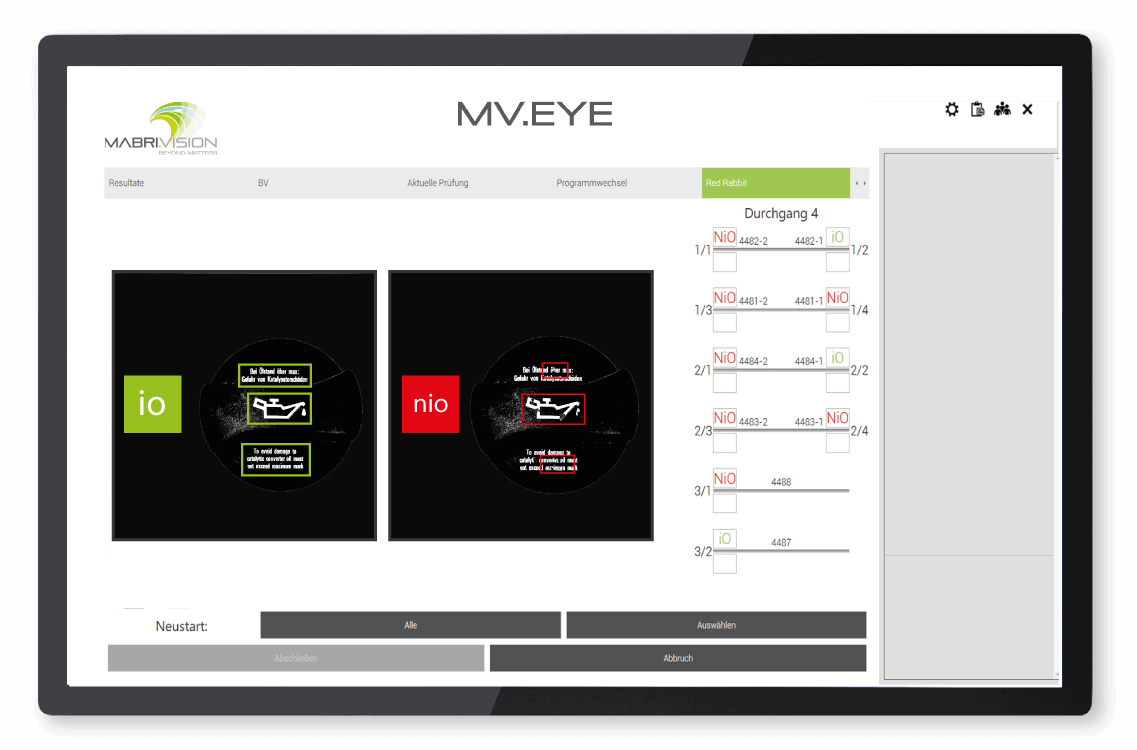

Detect defects on both the injection-molded part and the printed image during the production process. The application of the printed image is also checked.

The MABRI.VISION testing system performs a complete inspection of your injection-molded products, checking, among other things, the completeness of the printed image.

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.