D Layout not Blog K Messe 2019

TRADE FAIR NEWS

MABRI.VISION at the K trade fair 2019

At the "K" trade fair in Düsseldorf, MABRI.VISION will be showcasing the INLINE.SECTOR F1 optical measuring system for the inline inspection of translucent tubing, which is primarily used in medical technology. Unlike laser-based systems, it also measures the inner diameter and wall thickness. MABRI.VISION will also be showcasing systems for microstructure inspection and multimodal 2D and 3D image acquisition.

You can find us in Hall 8b at booth F39-03 . We look forward to seeing you at the K trade fair 2019!

360° INLINE HOSE TESTING

MABRI.VISION's new INLINE.SECTOR F1 testing system, which the company is presenting for the first time at the "K", enables highly accurate inline testing of translucent hoses – for example made of PVC, silicone or PMMA – during production in the extrusion plant.

The system measures the inner and outer diameters along eight axes and derives measurements such as minimum and maximum wall thickness, eccentricity, and ovality. The interferometric 360° sensor developed by MABRI.VISION offers higher resolution than X-ray systems while simultaneously providing a higher measurement frequency. Since the system uses only infrared light, no radiation protection measures are required.

Direct integration into the extrusion line enables precise process control during the production of translucent tubing and 100% production monitoring. Furthermore, it simplifies the setup of the extrusion system. Data storage ensures complete traceability.

Initial systems have passed their trial by fire at leading manufacturers of tubing for medical technology.

High-speed inline testing of large-area microstructures

The surface of plastic components with microstructures in the range of a few micrometers, for example injection-molded parts with lotus effect or lab-on-a-chip, could previously only be examined under a microscope on a sample basis and with a high expenditure of time, or scanned with low resolution.

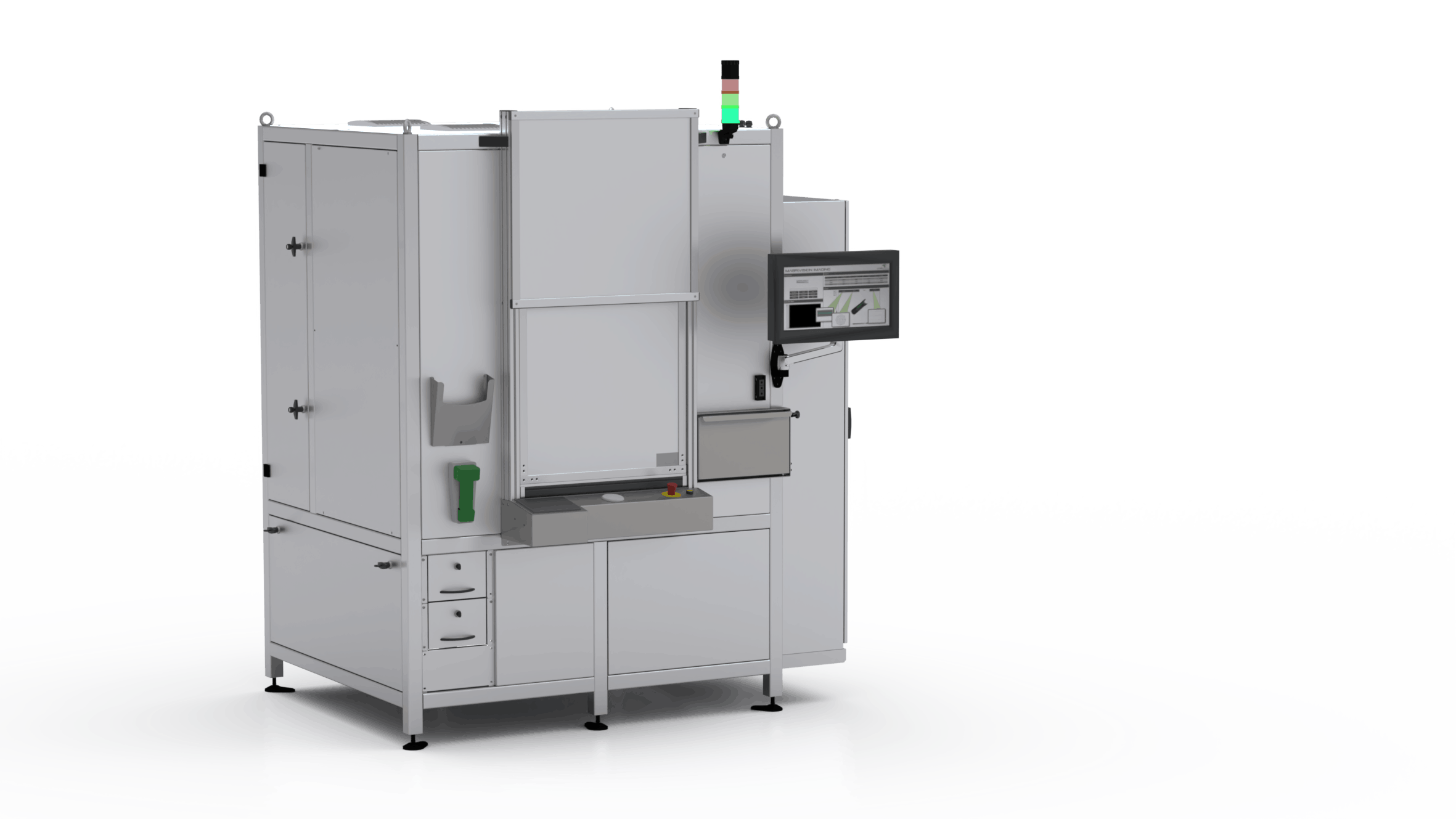

With the MV.EYE MI1 inspection system, MABRI.VISION now offers a fast, inline-capable solution for automated inspection during production. It scans the surface structure of components with dimensions up to 80 x 200 mm at a resolution better than 2 µm in less than 35 seconds. Depending on the production cycle time, the system thus has the potential for 100% microstructure inspection.

Complete inspection of injection-molded parts

The dimensional accuracy of complex injection-molded parts has traditionally been checked manually or only on a sample basis in many plants. With a large number of inspection features and high accuracy requirements, conventional systems – including coordinate measuring systems – reached their limits… especially when both 2D and 3D features had to be checked at a high cycle rate.

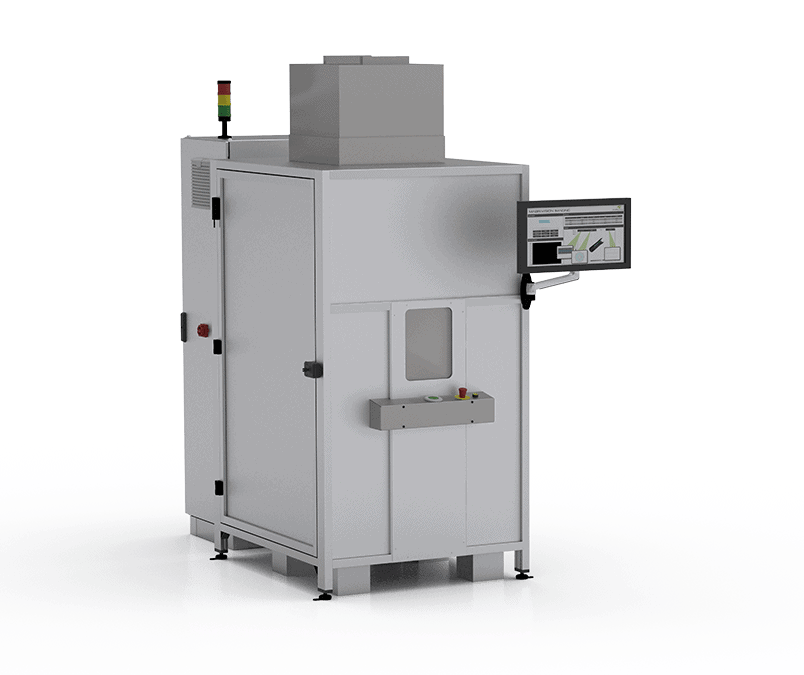

The new multimodal system MV.EYE i2 checks the form and position tolerances of components with high precision inline and in sync with production; it also detects surface defects and contamination. A typical measurement cycle takes only three seconds.

The MV.EYE i2 combines different technologies – imaging, optical micrometers, and laser triangulation – in a single system. The inspection cell includes a high-resolution camera system that, despite its large field of view of up to 200 x 200 mm, measures with a resolution of just a few micrometers. Height information is determined by an optical micrometer and laser triangulation.