MV.EYE LT1

Inline layer thickness testing of plasters

MV.EYE LT1

Inline layer thickness testing of plasters

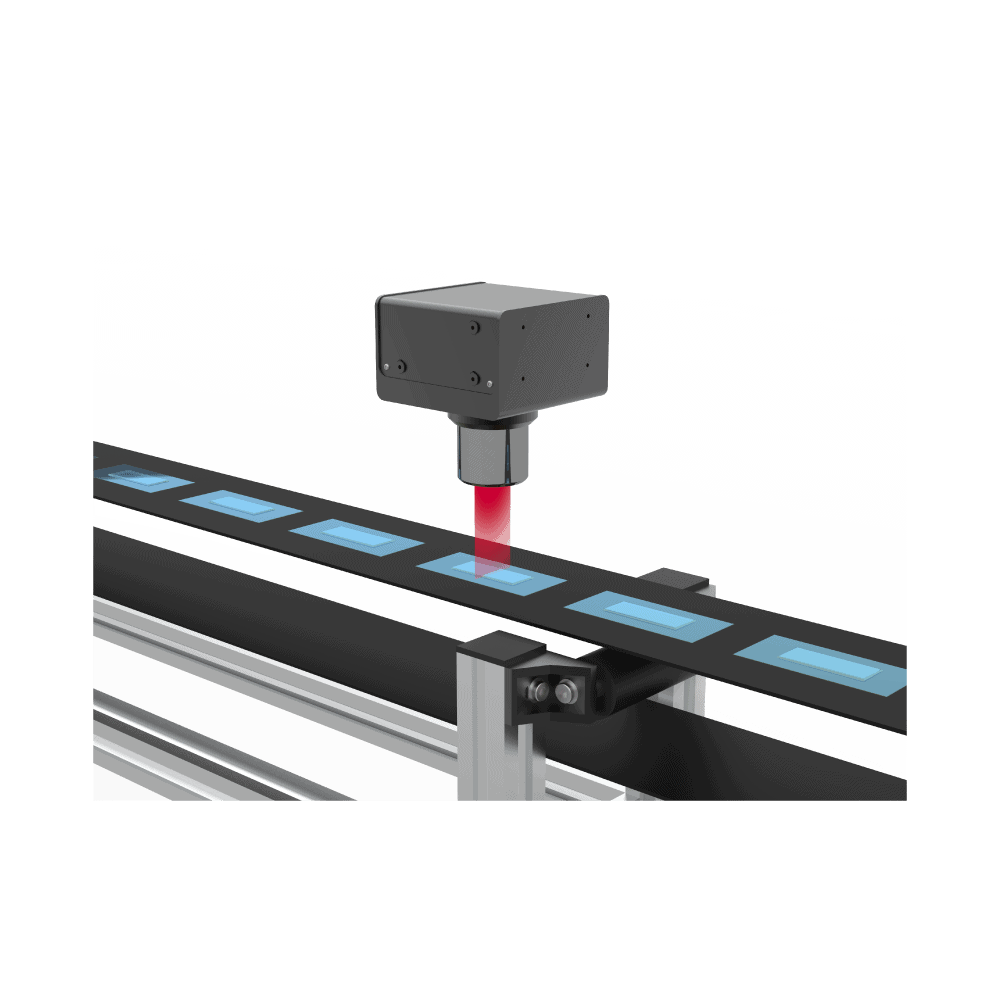

In the MV.EYE LT1 system, the layer structure of transdermal patches is tested using the MV.SENSE tomographic sensor from MABRI.VISION.

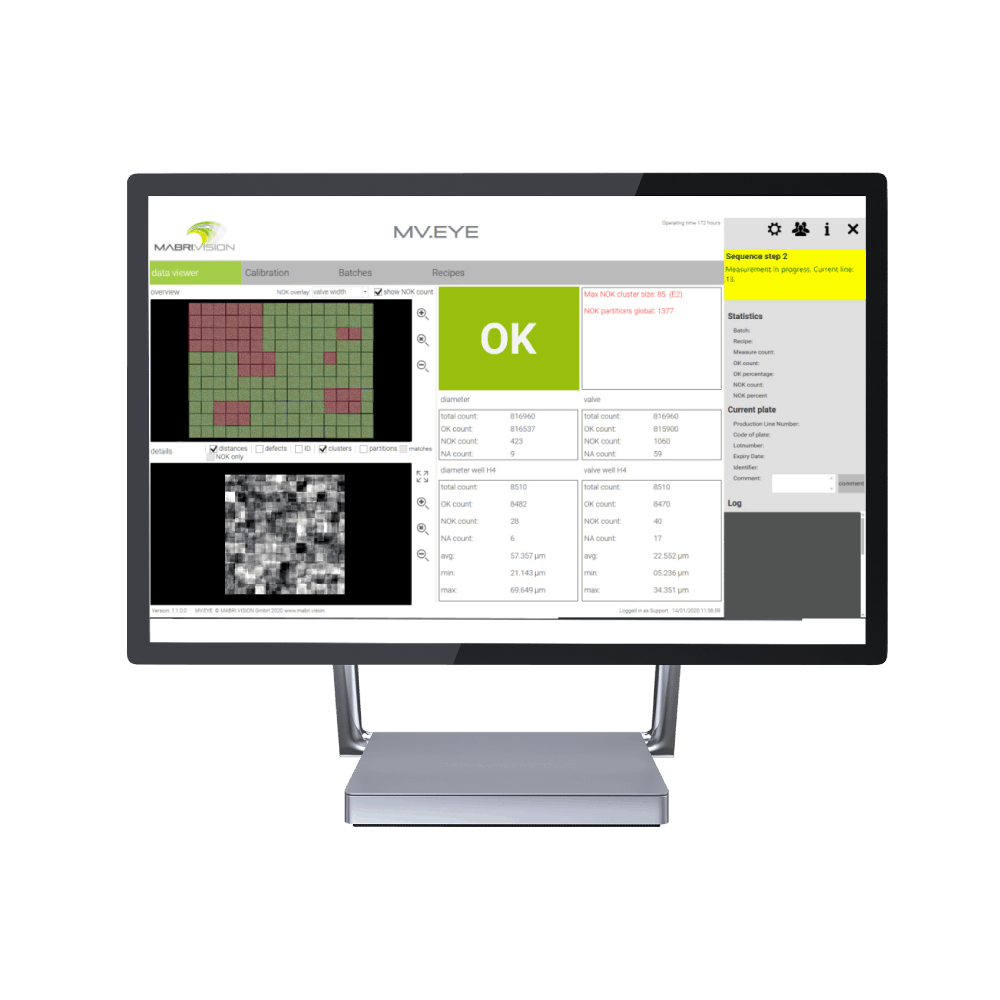

The advantage of the system is the speed of the testing process, which enables inline testing. At speeds of up to 40 mm/s, the presence and precise distribution of the active ingredient, as well as the shape and layer thickness, can be determined, among other things.

Applications

- Examination of paving structure

- Drug testing

Inspections

- Layer thickness

- shape

- presence

- volume

Industry sectors

- Medical technology

- Pharmaceutical industry

- Packaging industry

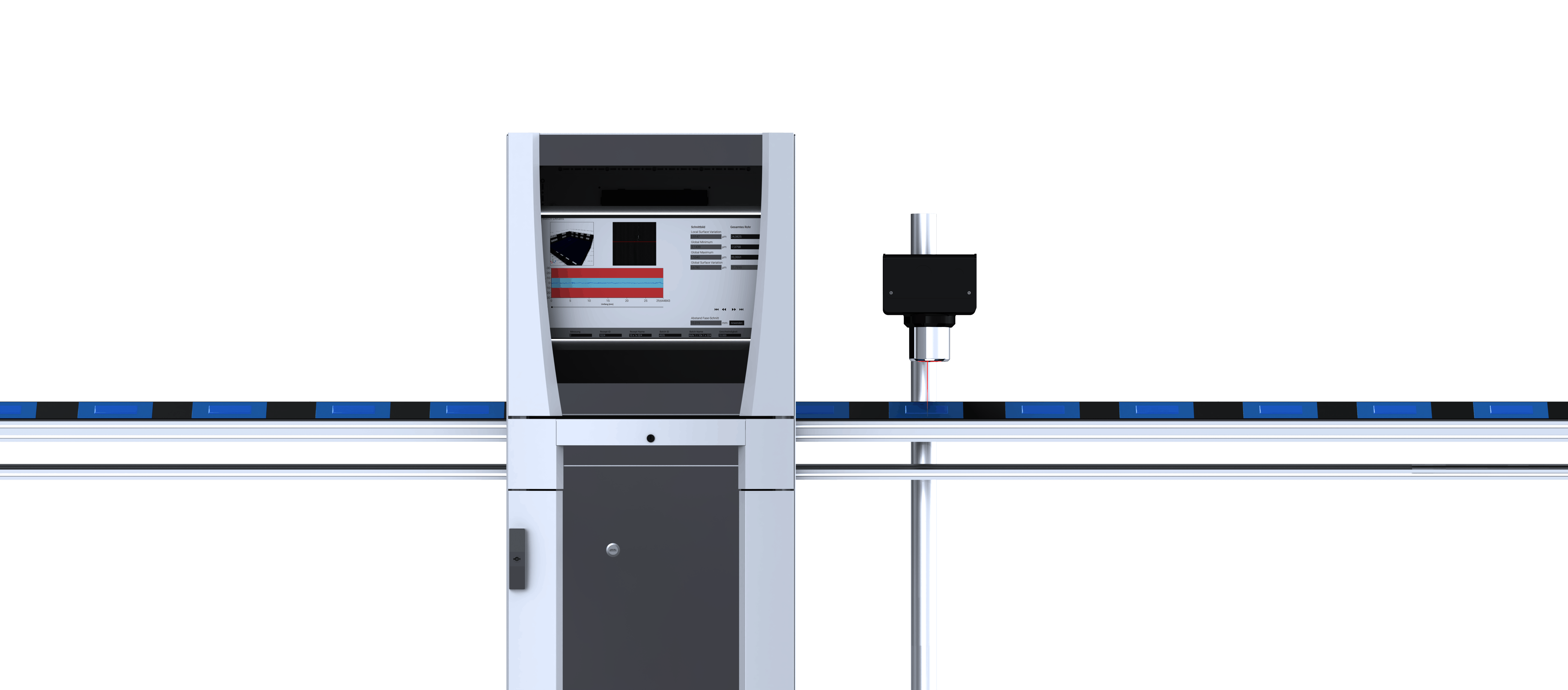

Inline skating compatible

The inspection of the relevant features takes place at speeds of up to 40 mm/s and can therefore be seamlessly integrated into your production line and processes.

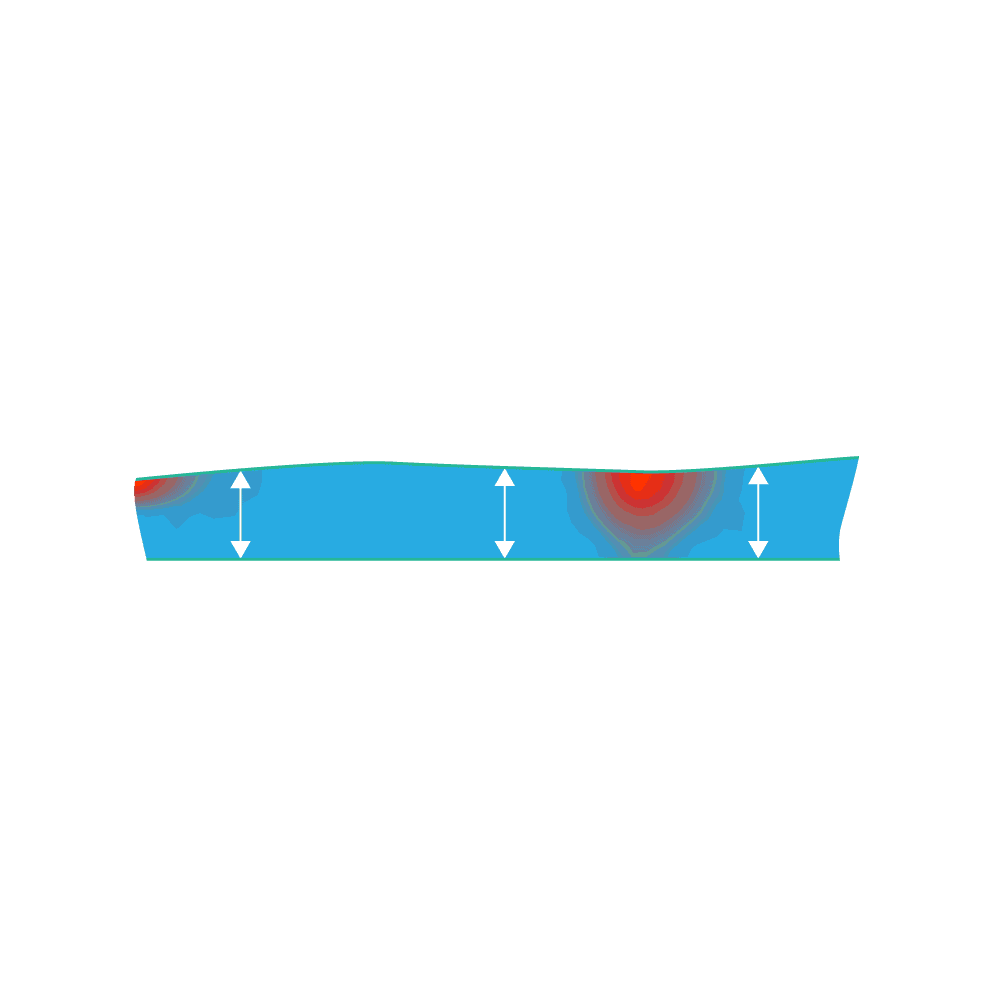

Layer thickness

The MABRI.VISION testing system MV.EYE LT1 enables precise and reliable layer thickness testing of plasters made of transparent and semi-transparent materials.

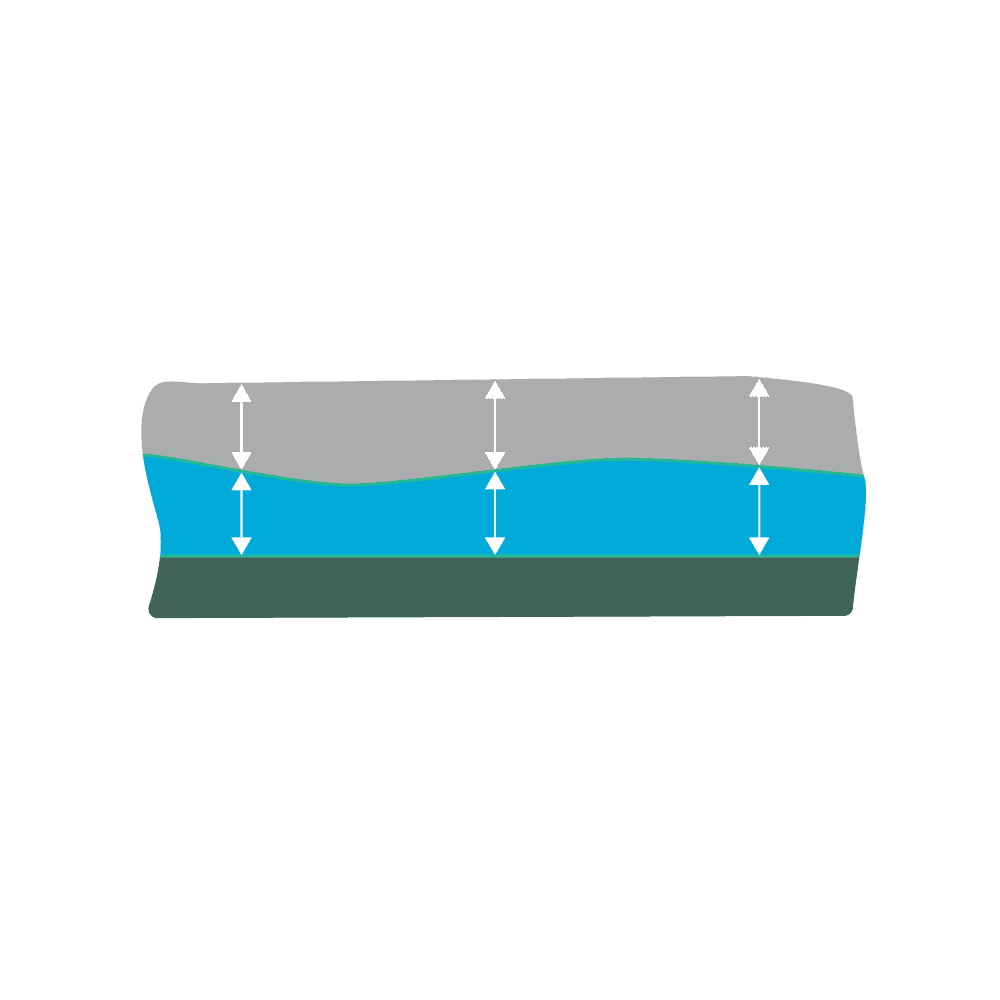

Multi-layer systems

Our sensors ensure non-destructive testing even in multi-layer systems. A flying-spot method guarantees rapid determination of the layer thickness distribution.

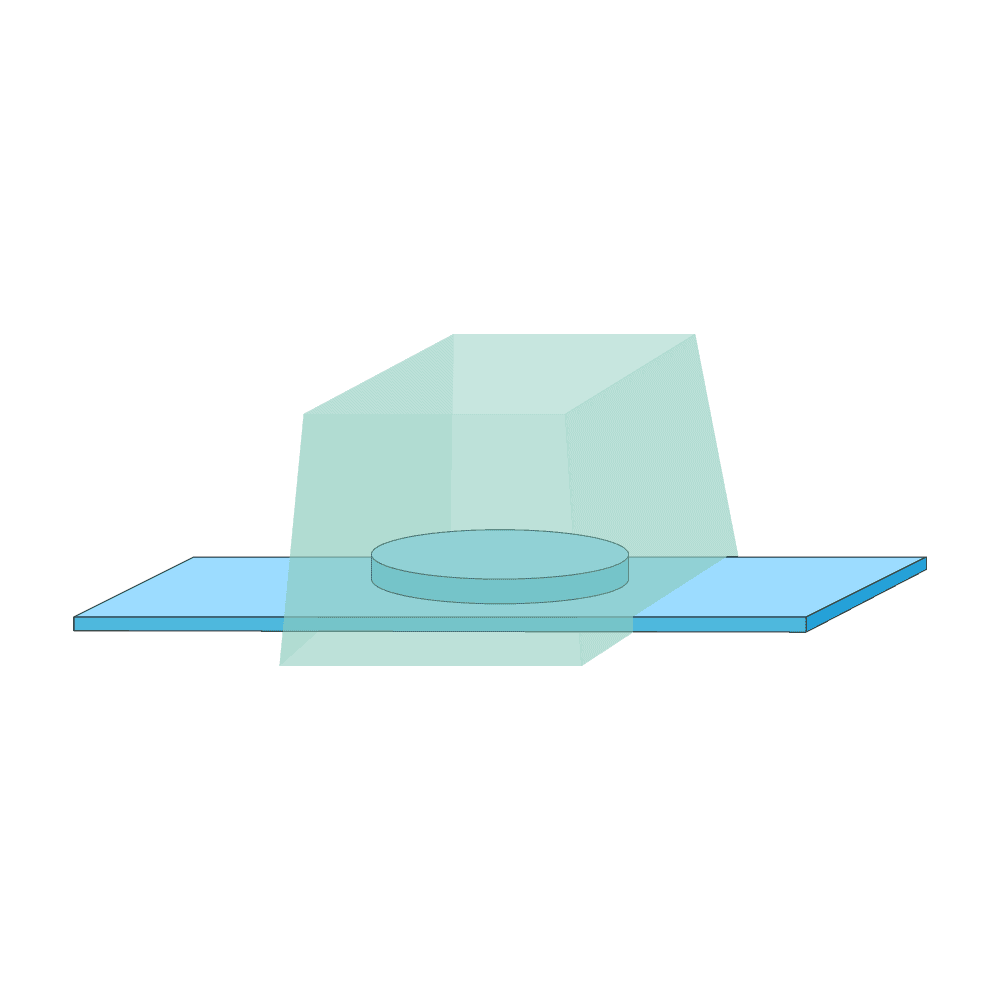

3D scan

The MV.EYE LT1 system offers a completely new possibility for 3D surface measurement of plastics, silicones, glass and other translucent materials.

Contactless

Data analysis

For quick and uncomplicated feedback to the operator, the software of our MV.EYE LT1 testing system offers a variety of different analysis tools.

Specifications

Universal: versatile

MEDICAL TECHNOLOGY

Rapid thickness testing of plasters for the medical industry or clinical use. Utilizing 3D scanning for precise surface measurements of translucent materials.

PHARMACEUTICAL INDUSTRY

Non-contact testing of microstructural layers on blisters, tablets, or drug patches. Integration of the testing process into automated production lines.

PACKAGING INDUSTRY

High-speed testing of packaging systems with a wide range of test characteristics. Measurements are performed completely non-destructively, even on multi-layer systems.

Contact

Do you need further information about a specific product group or do you have a specific product inquiry? Use our contact form or call us.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision