plant construction

Machine Vision

We automate quality control

MABRI.VISION is a leading provider of optical inspection systems and machine vision solutions, specializing in the construction of custom machines and the automation of QC processes across various industries. We offer our customers customized, comprehensive solutions that can be integrated into production process chains, thereby contributing to increased efficiency and quality.

Our goal is to offer our customers innovative and reliable solutions that optimize and automate their processes. We work closely with our customers to understand their requirements and develop customized solutions that meet their needs.

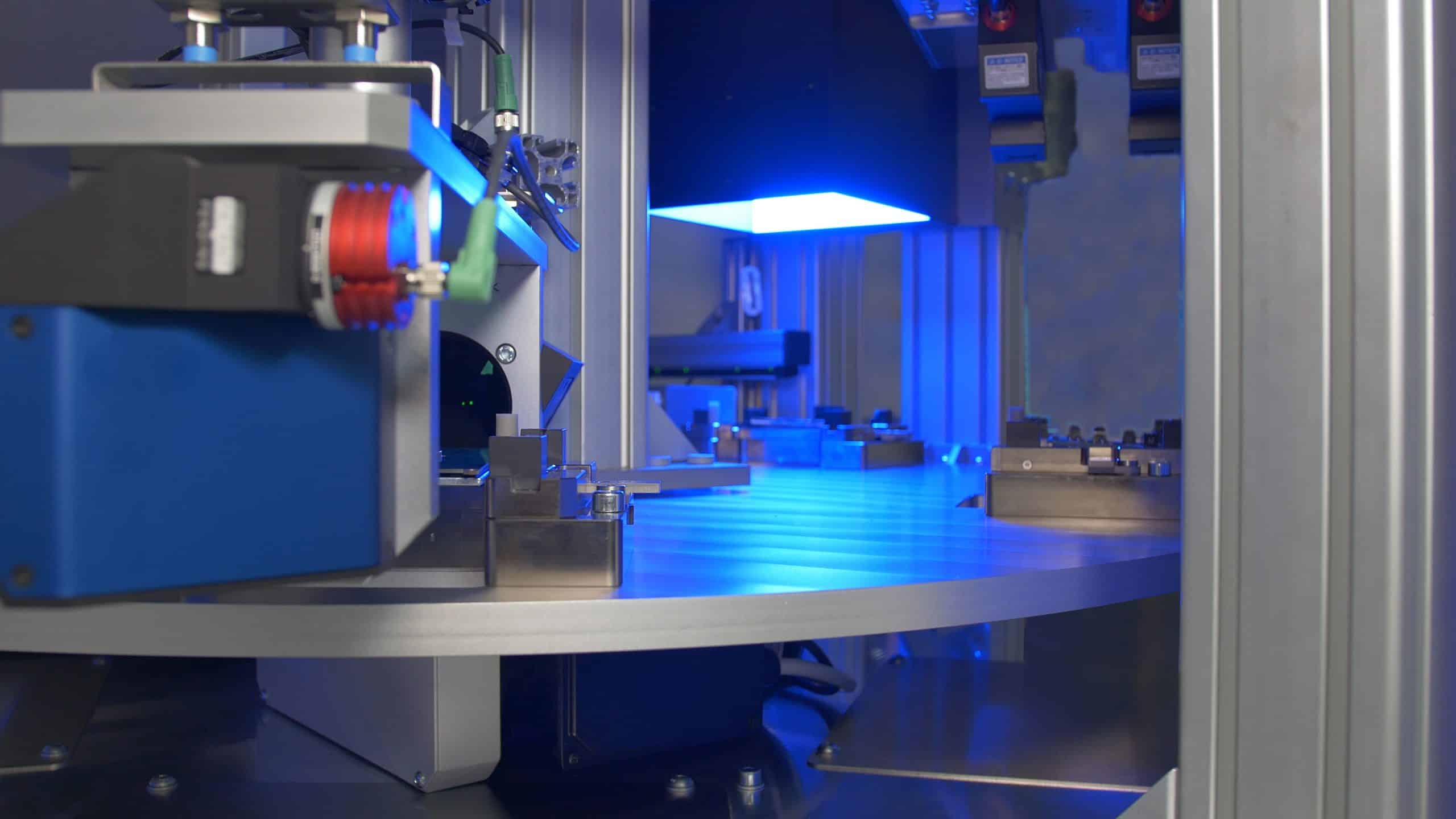

In plant engineering, we rely on our modular platforms, regardless of whether you are looking for a testing process with workpiece carriers, rotary indexers, conveyor technology, robotics, or the testing of strip goods and extruded products. We will certainly find a suitable solution.

MACHINE VISION + AUTOMATION

The best of both worlds

Over the years, we have expanded our expertise in machine vision to include automation, enabling us to offer our customers tailored solutions. We combine our know-how in measurement technology and automation to optimally integrate machine vision technologies into our customers' production environments.

- position, check, sort

- Conveyor technology, axes and robots

- Systems with multiple test stations

MODULAR KIT FOR PERFECTLY FITTING SOLUTIONS

We automate quality control

Our goal is to offer our customers tailor-made solutions. To achieve this, we use our modular system of hardware and software components, which allows us to address the specific requirements of our customers.

- Special machine construction of testing systems

- Modular system for software and hardware

- suitable solutions for your production

COMPLETE SOLUTIONS

Intelligent automation for the highest quality

Our goal: to automate QC processes in your production. That's why we offer our customers complete solutions, from planning and design to commissioning, all from a single source. Our experts are happy to support you from the initial design phase to scaling up to other plants.

- Turnkey plants

- Planning, design, commissioning from a single source

- End-to-end solutions with one partner

BENEFITS & ADVANTAGES

Cost reduction through reliable QC

Prevent complaints, increase customer satisfaction, improve safety.

Improved flexibility

Automated testing processes can react quickly to changes in production.

Improved scalability

Labor is scarce, and facilities can be easily scaled up.

Error reduction

Automated testing processes can help reduce manual errors.

Increased efficiency

Automated testing processes can work faster and more accurately than humans.

Increased productivity

Automated testing processes can operate around the clock, thus increasing productivity.

Our promise

High-quality and reliable systems

Our goal is to build innovative and high-quality systems for our customers.

The best of both worlds

Automation and metrological expertise: feeding, testing, sorting.

The "all-inclusive package"

Planning / Consulting, Service, Continuous Improvement.

"Hello - I have a problem."

Systems can be connected to our service cloud upon request and can report malfunctions directly.

Successful in the market

Many well-known companies trust in our technologies and testing facilities.

Customized solutions

Together with our customers, we plan testing facilities and processes based on our modular platforms.

Showcase

Example applications

QC solutions

Our MICRO.SPECTOR is designed for direct integration into your production chain. From barcode tracking, change log, audit trail and user management to direct connection to your management level, we offer all the necessary tools to make your QC more efficient and reliable.

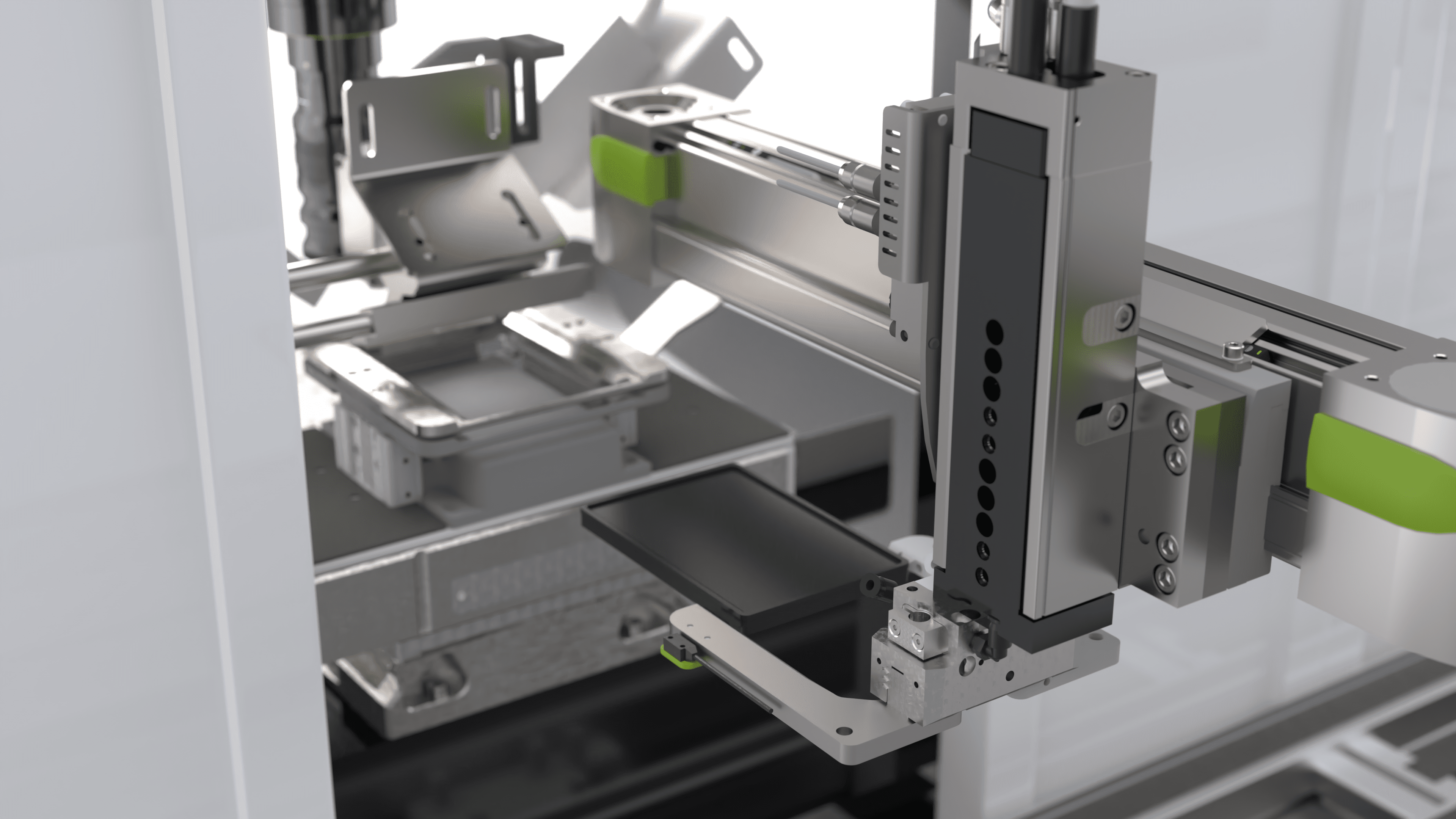

Automatic loading

In addition to the option of manual loading, for example for rotary indexing systems, MABRI.VISION offers the necessary automation technology and loading systems to automate even complex testing processes within the production cycle. This includes robotic systems and customized solutions.

Solutions with product carrier systems

Testing on workpiece carriers is easily and modularly implemented thanks to the controlled handling of the items being tested. MABRI.VISION offers systems with and without workpiece carrier systems for flexible integration into existing processes.

FAQs

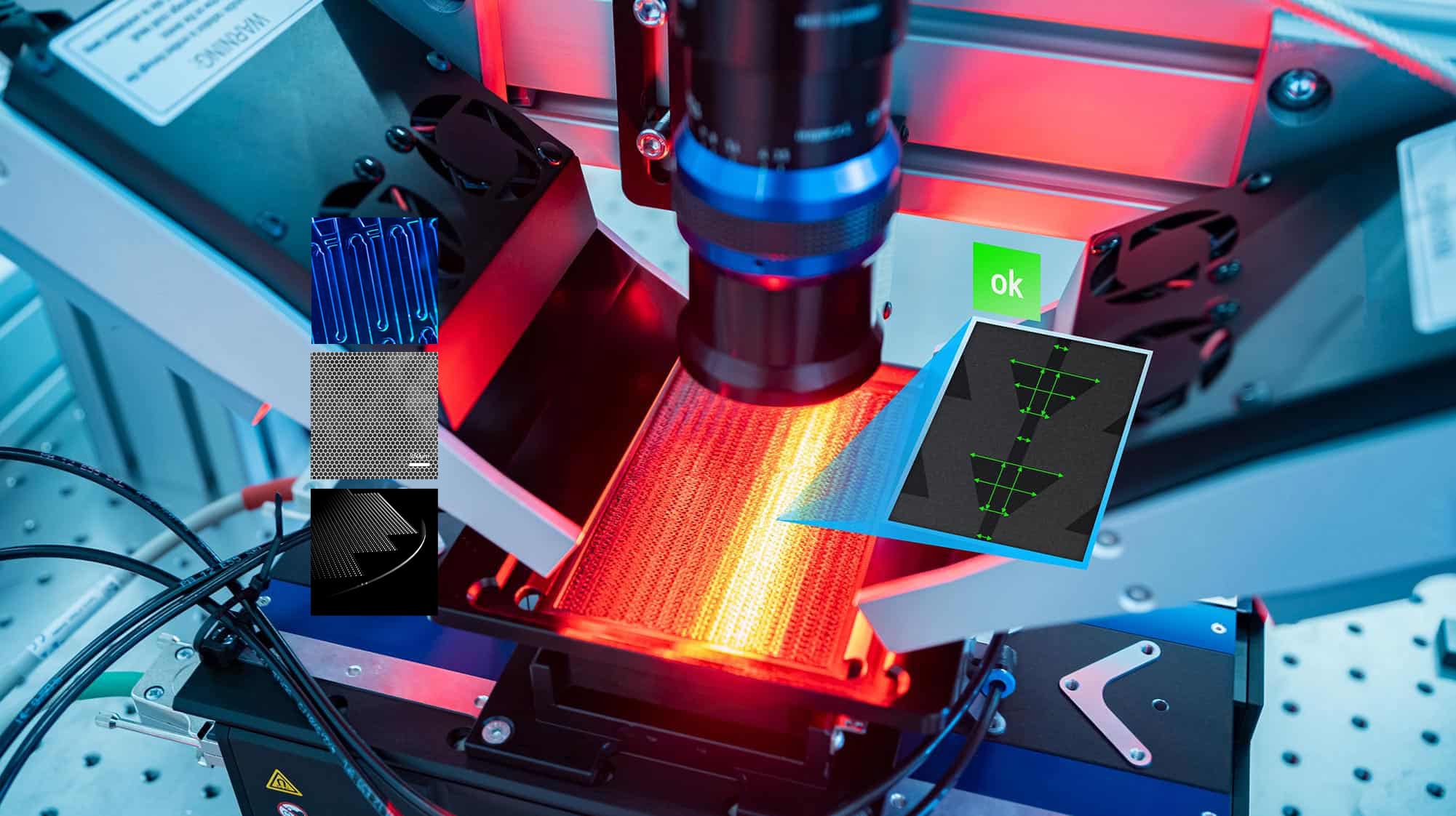

What vision technologies does MABRI.VISION use?

For every new request, our Vision experts assess which technologies are best suited for the inspection. We primarily use matrix and line scan cameras, as well as 3D triangulation sensors. If other optical technologies are better suited for the inspection, we are also happy to use TDI cameras, chromatic confocal sensors, or interferometric sensors.

Do you also offer automation of manufacturing steps?

No – our specialization is the construction of testing systems. With our automation solutions, we implement the feeding and, after testing, the sorting of products and components.

We keep encountering defects, but we don't know how to test for them.

Over the years, we have built up extensive expertise in the field of optical metrology. Our experts will be happy to advise you on the design of testing processes. If it is uncertain whether a test can be implemented, we will also gladly conduct feasibility studies.

What are MABRI.VISION's delivery times?

This naturally depends on the type, size, and complexity of the optical inspection system. In direct comparison with our competitors, we often have shorter delivery times and can react more quickly.