What we check

barcodes and data codes

Fast code recognition and reading

Barcode and data code recognition can be highly beneficial in many industrial applications, improving process efficiency and accuracy. However, several challenges can arise when using machine vision applications to read barcodes and data codes.

One of the biggest challenges is reading barcodes and data codes under difficult conditions, such as poor lighting or when the codes are dirty or damaged. The size of the codes and their distance from the machine vision camera can also lead to recognition difficulties.

MABRI.VISION specializes in developing solutions that can reliably read barcodes and data codes, even under challenging conditions. Our machine vision systems are robust and powerful, offering high accuracy and reliability. We work closely with our customers to develop customized solutions perfectly tailored to their specific requirements and challenges.

Do you have any questions? Contact us

Our sales team will be happy to assist you

+49 241 56 527 930

info@mabri.vision

Barcodes

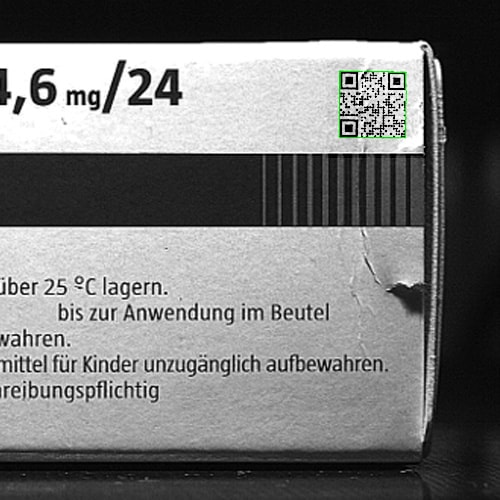

One hurdle in reading barcodes using machine vision is that these codes are sometimes difficult to access or of poor quality. For example, they may be obscured, damaged, or faded. In such cases, it is challenging to recognize and read the barcode.

However, there are several methods that can be used to overcome these challenges. One possibility is the use of special cameras and lighting techniques that allow the barcode to be recognized from different angles and under varying lighting conditions. The use of image enhancement and correction algorithms can also help make the barcode more visible and therefore easier to read.

Code quality packaging

- Code quality according to ISO/IEC 15415 and ISO/IEC 15416

- Lattice irregularity

- Read barcode

Reading damaged codes

- Read barcode

- Code Location

Read barcode deposit acceptance

- Read barcode

- Determination Code Quality

- Spectral signature

Data codes

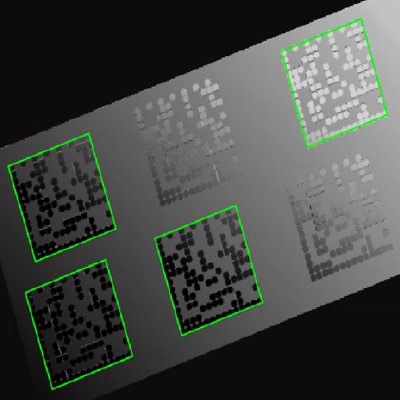

Machine vision solutions enable the fast and reliable detection and reading of data codes. This technology is frequently used in industry to obtain information about products and parts and to optimize production. Various challenges, such as shadows, distortions, and changing lighting conditions, complicate the reading process. MABRI.VISION has specialized in reliably reading these codes by developing suitable algorithms and image acquisition techniques.

Data code on sheet metal parts

- Read code

- Position

Matrix code on packaging

- Read code

- Symbol contrast

- Defects

Data code on molded part

- Read code

- Position

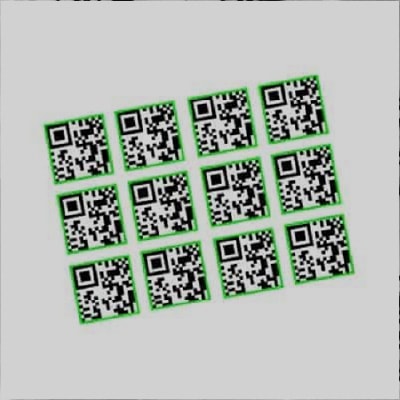

QR code on tires

- Read code

- Determination Code Quality

Multi-code print tokens

- Read multiple codes

- Code Location

- Code Quality