Areas of application of the VISION.SPECTOR TIRE testing systems

Discover the application areas of the VISION.SPECTOR Tire range

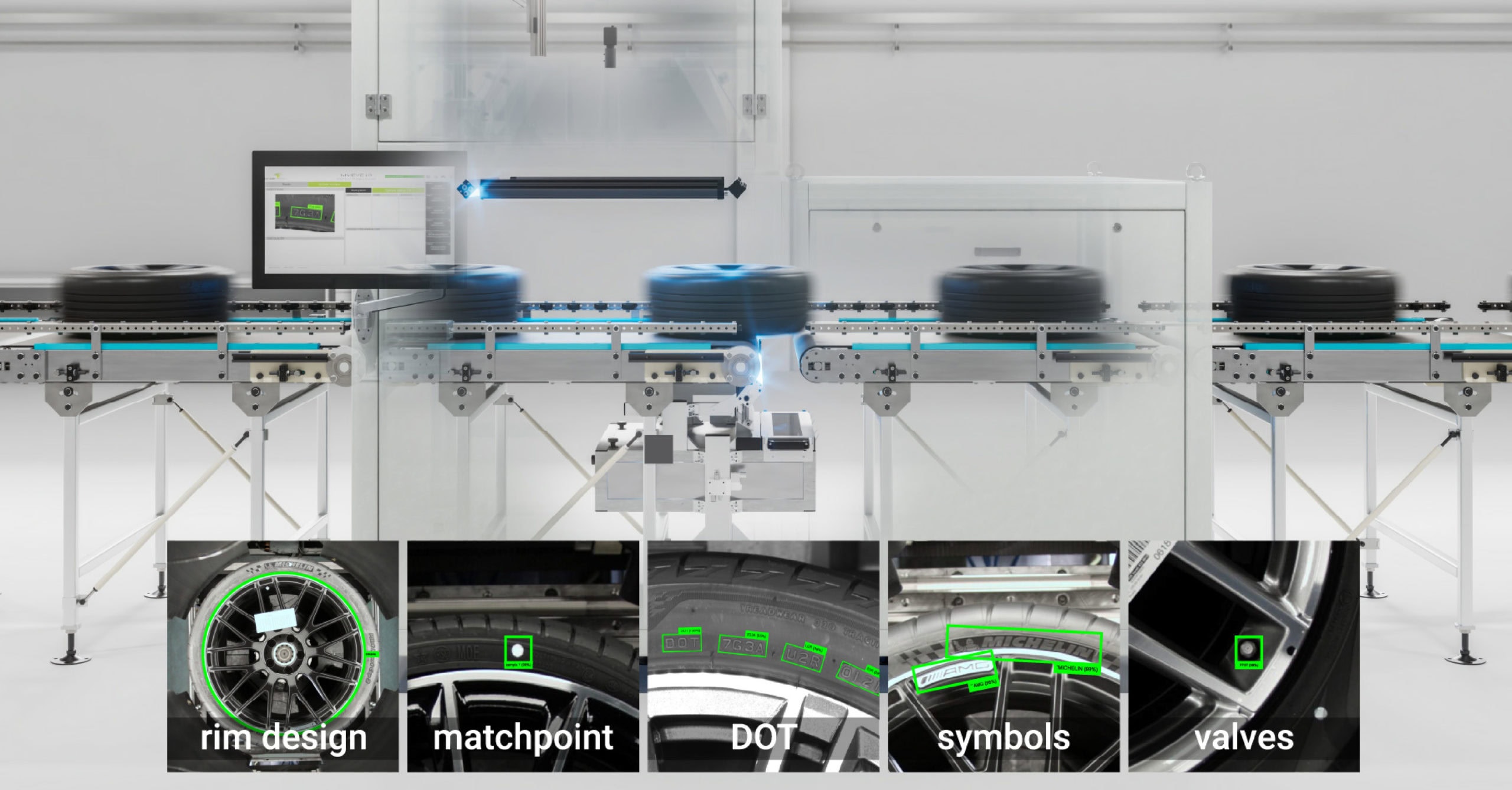

Our state-of-the-art TIRE DOT and VISION.SPECTOR TIRE EOL testing systems offer versatile applications for optimizing wheel assembly, tire and rim production, as well as storage and spare parts processes:

Application in wheel assembly:

Our system improves wheel assembly through the use of AI-supported image processing. It guarantees flawless assembly quality, accelerates the assembly process, and increases your productivity. Improve your workflow and minimize error rates!

Application in tire and rim production:

Make your quality control processes more productive! Our system precisely detects deviations and irregularities in material and design, ensures high production standards, and promotes the delivery of defect-free products.

Application in warehousing and spare parts business:

Efficiency in storage and sorting is crucial for your success. Our inspection system optimizes the classification of your products, simplifies warehouse organization, improves access speed to spare parts, and reduces warehousing costs.

For automated logistics systems, our technology is an effective component for increasing efficiency and quality assurance.

Further information about our tire inspection solutions can be found on our website:

> Machine vision inspection systems for wheels and tires

> Machine vision inspection systems for DOT and DOM testing

Please feel free to contact us for a personal consultation .