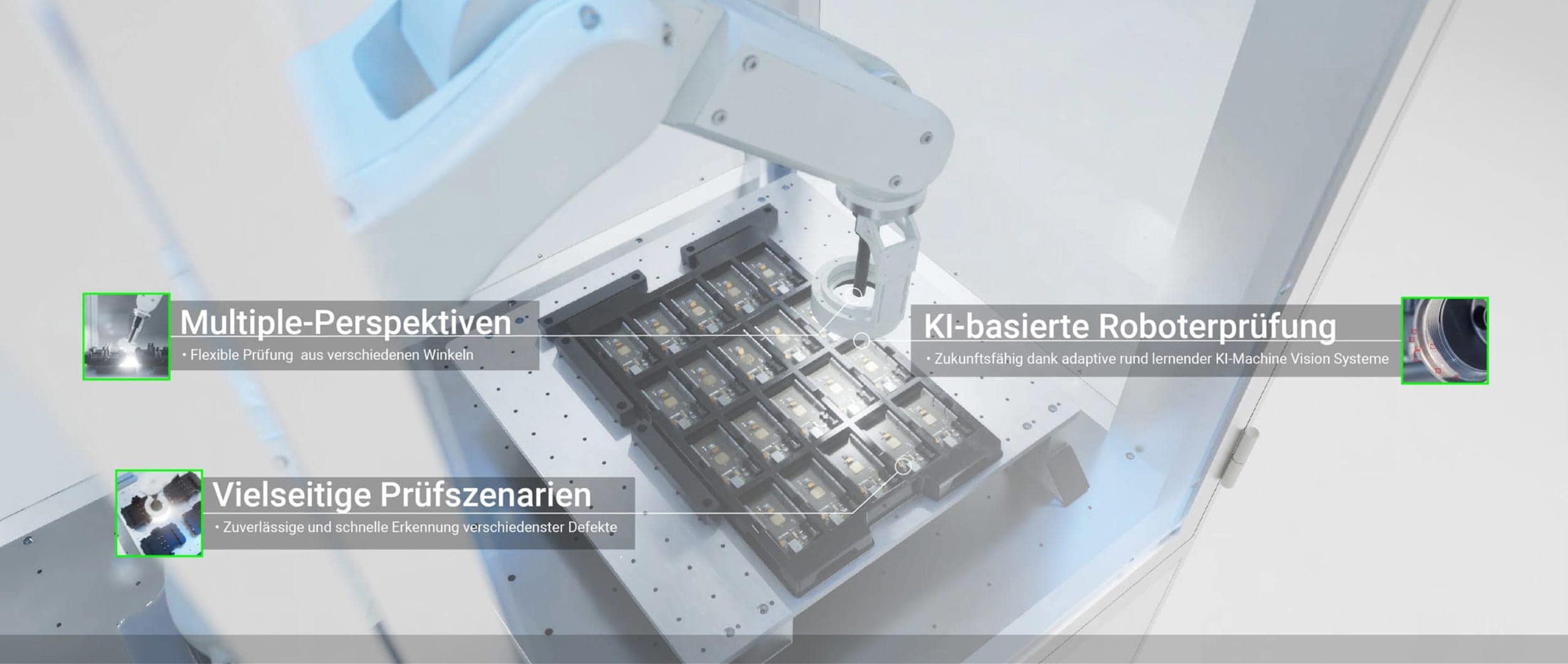

Testing with the ROBOT.SPECTOR

Tailor-made testing technology for maximum quality assurance with the ROBOT.SPECTOR

The ROBOT.SPECTOR – Tailor-made inspection technology for maximum quality assurance. In the dynamic world of manufacturing, it is crucial that every detail of your products is flawless. The ROBOT.SPECTOR has the ability to inspect components from any perspective – no detail remains hidden.

All-round view for complete component testing:

Our system tests components from different perspectives, uses modern image processing technologies and reaches even hard-to-access areas that other systems cannot capture.

Any orientation:

Test your components or products regardless of their position, ensuring comprehensive quality assurance.

Reliable defect detection and dimensional accuracy control:

The ROBOT.SPECTOR combines precise image processing with advanced analysis technology to reliably detect and classify even the smallest defects and deviations in dimensional accuracy.

Flexible sensor integration:

By integrating various sensors, such as cameras and triangulation, the ROBOT.SPECTOR can be individually adapted to the specific requirements of your production. The combination of 2D and 3D results offers high inspection accuracy.

Scalability:

Depending on your production needs, the ROBOT.SPECTOR can be flexibly adapted. Our ROBOT.SPECTOR inspection system is manufactured in different sizes, allowing the system to be perfectly adapted to various production environments.

For further details, please contact us directly – we look forward to your inquiry | Contact | MABRI.VISION