Aachen Corporate Run 2025

MABRI.VISION at the Aachen Corporate Run 2025: Our employees participated successfully in this year's Aachen Corporate Run with great motivation, energy, and team spirit. Events like this demonstrate once again..

With innovative inspection and automation, you can revolutionize your production and quality control. Innovative inspection conserves resources, ensures sustainability, improves market opportunities, and creates safety—for your company, your customers, and the user.

We develop, manufacture, and supply turnkey testing systems for demanding products and rapidly growing future markets. Proven application areas include the optical inspection of power electronics in e-mobility, microfluidic diagnostic chips in the healthcare sector, and the reading of codes on product surfaces.

With over 35 employees in Germany, we rely on innovative machine vision technologies to solve complex inspection tasks. Our range of services extends from the planning, design, construction, and integration of customized vision systems to on-site service and rapid availability.

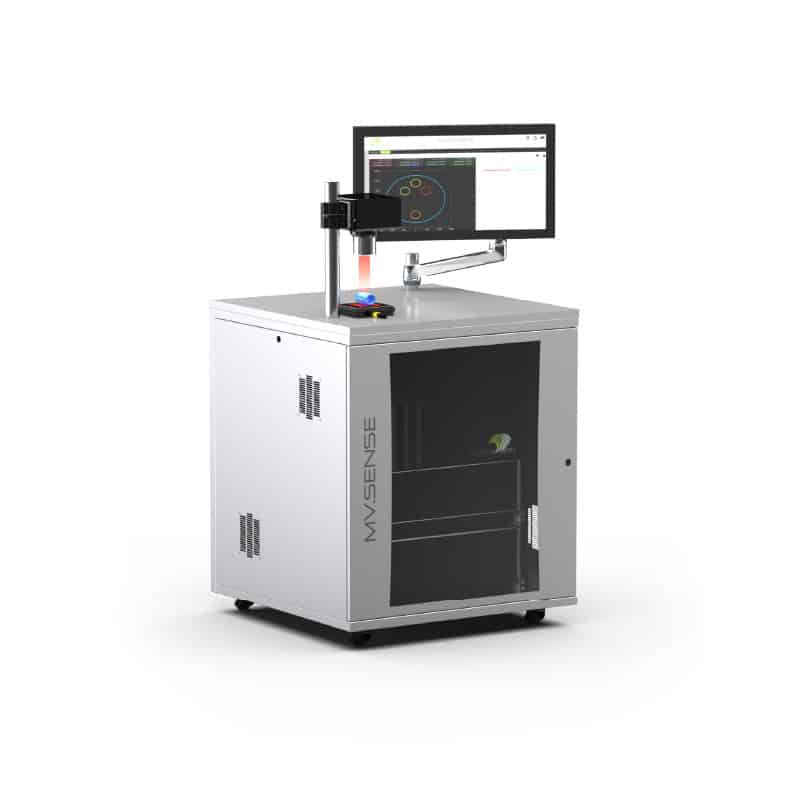

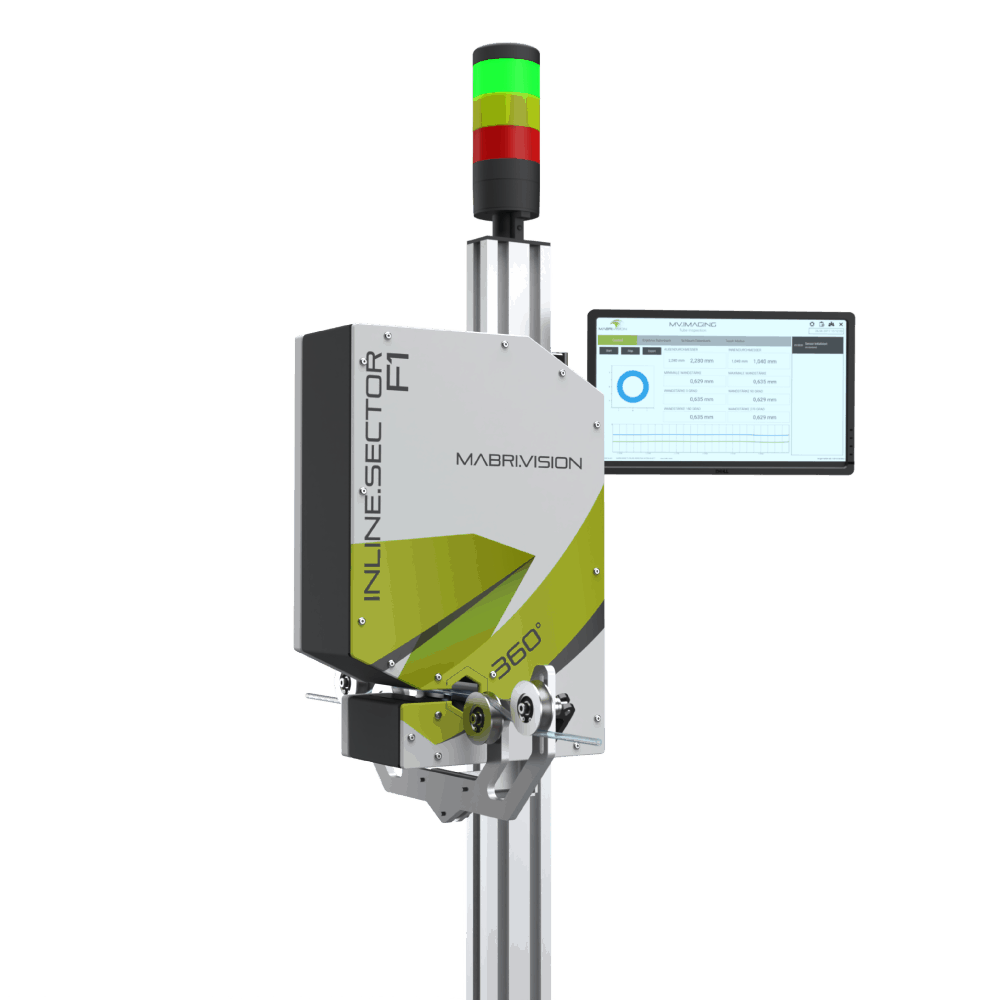

With a broad product portfolio, MABRI.VISION covers a wide range of quality testing needs. From laboratory test stations to fully automated testing systems integrated into production lines, we offer your company efficient solutions for your testing requirements.

layers & thickness scanner

microscopic 3D inspection

tube thickness inspection

industrial machine vision

carrier-based inspection

fast line scanning system

Universal: versatile in use

stand-alone systems

inline microscopic inspection

Discover exciting news about the MABRI.VISION team and current events and trade fair participations.

MABRI.VISION at the Aachen Corporate Run 2025: Our employees participated successfully in this year's Aachen Corporate Run with great motivation, energy, and team spirit. Events like this demonstrate once again..

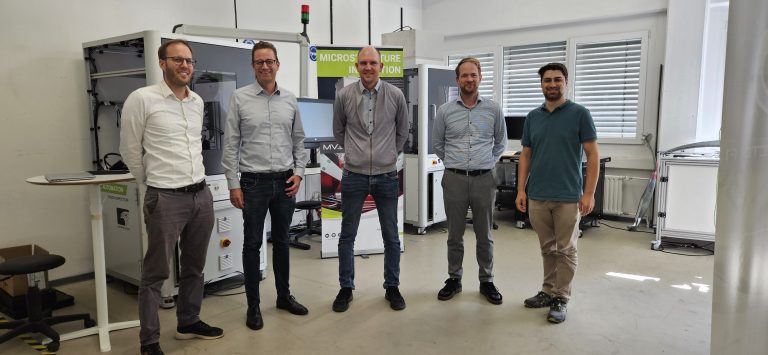

Visit from Denso: We had a visit from our partner DENSO last week. It was an exciting exchange that once again showed us how valuable strong partnerships are for the

Conclusion: Machine vision is changing quality assurance – sustainably. Automated image processing systems enable more precise, faster, and more consistent inspection processes. They create the foundation for data-driven optimization in the..

What are the limitations and challenges of machine vision? Machine vision is powerful – but not a sure thing. The systems require careful planning and adaptation

MABRI.VISION is a provider of testing systems and sophisticated special-purpose machinery from Aachen, Germany. Founded in 2015 as a spin-off from the Fraunhofer Institute for Production Technology IPT, our team has since developed the extensive expertise to turnkey testing systems for future markets.

Our team is more than just a team – it's a family. We value our partners and customers – they are an essential part of our success story.

Our team possesses outstanding expertise in quality assurance, metrology, image processing, software development, and plant engineering. We are passionate about developing innovative solutions for challenging testing tasks.

Our experts develop optimal plant concepts through interdisciplinary collaboration, joint design, feasibility studies, and testing.

At MABRI.VISION, we believe that innovation is the key to new, future-oriented solutions. Our team specializes in translating current developments and technical trends into smart concepts for challenging testing tasks. We at MABRI.VISION know that demanding challenges inspire new ideas and lead to further innovations.

That's what inspires and drives us forward.