WE BUILD MACHINE VISION TESTING SYSTEMS

Using state-of-the-art technology and a tailored approach, we transform your inspection requirements into precise vision solutions. From custom software to modular automation, we focus on efficiency and perfection in every step.

Latest technologies

By using state-of-the-art technologies, we guarantee top performance in hardware and software for our machine vision systems

Complete solution

From planning and software development to commissioning – with us you receive an end-to-end vision solution, with first-class service

Suitable for you

Your product is our focus: We design the testing process to perfectly suit your product, and not the other way around.

modular system

With our modular system, we guarantee maximum efficiency and flexibility in implementing your vision requirements.

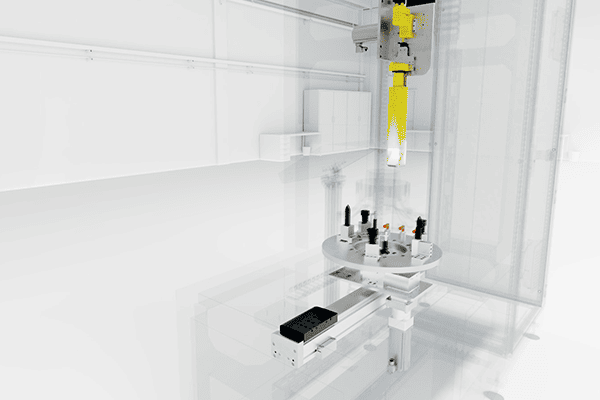

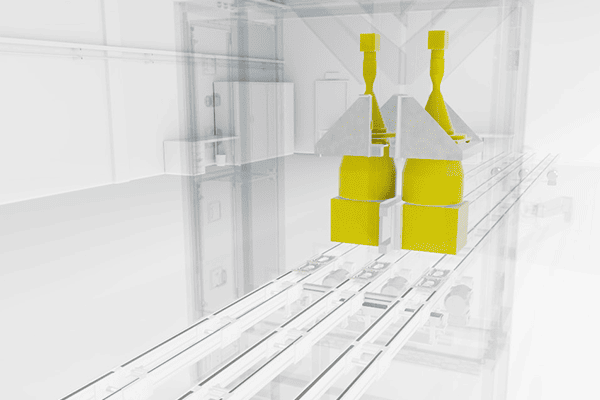

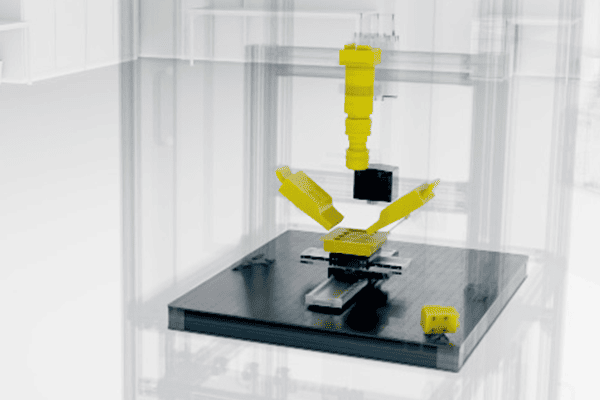

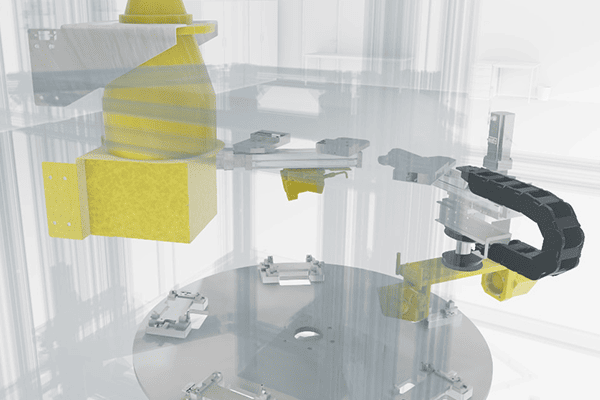

OUR TESTING PLATFORMS

Modularity meets technology

In our testing systems, we consistently rely on the same cameras, sensors, and software modules to ensure quality and reliability. Therefore, we have decided to categorize our platforms primarily according to the type of automation. This allows for targeted and efficient adaptation to your specific requirements.

AREAS OF OPERATION

Versatility in production

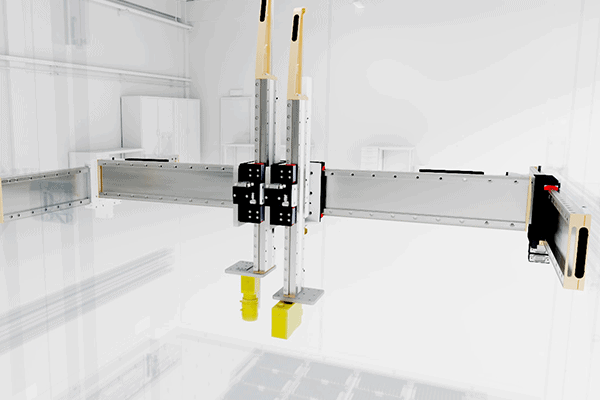

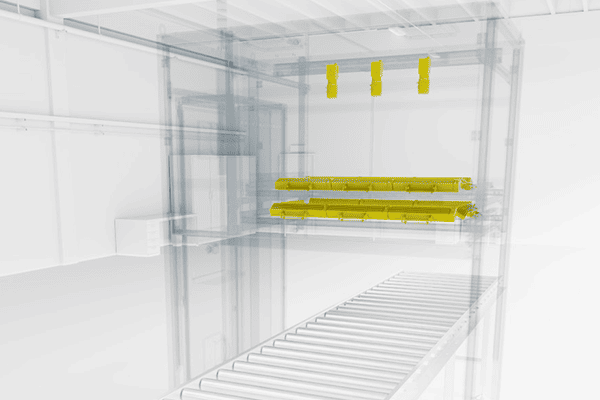

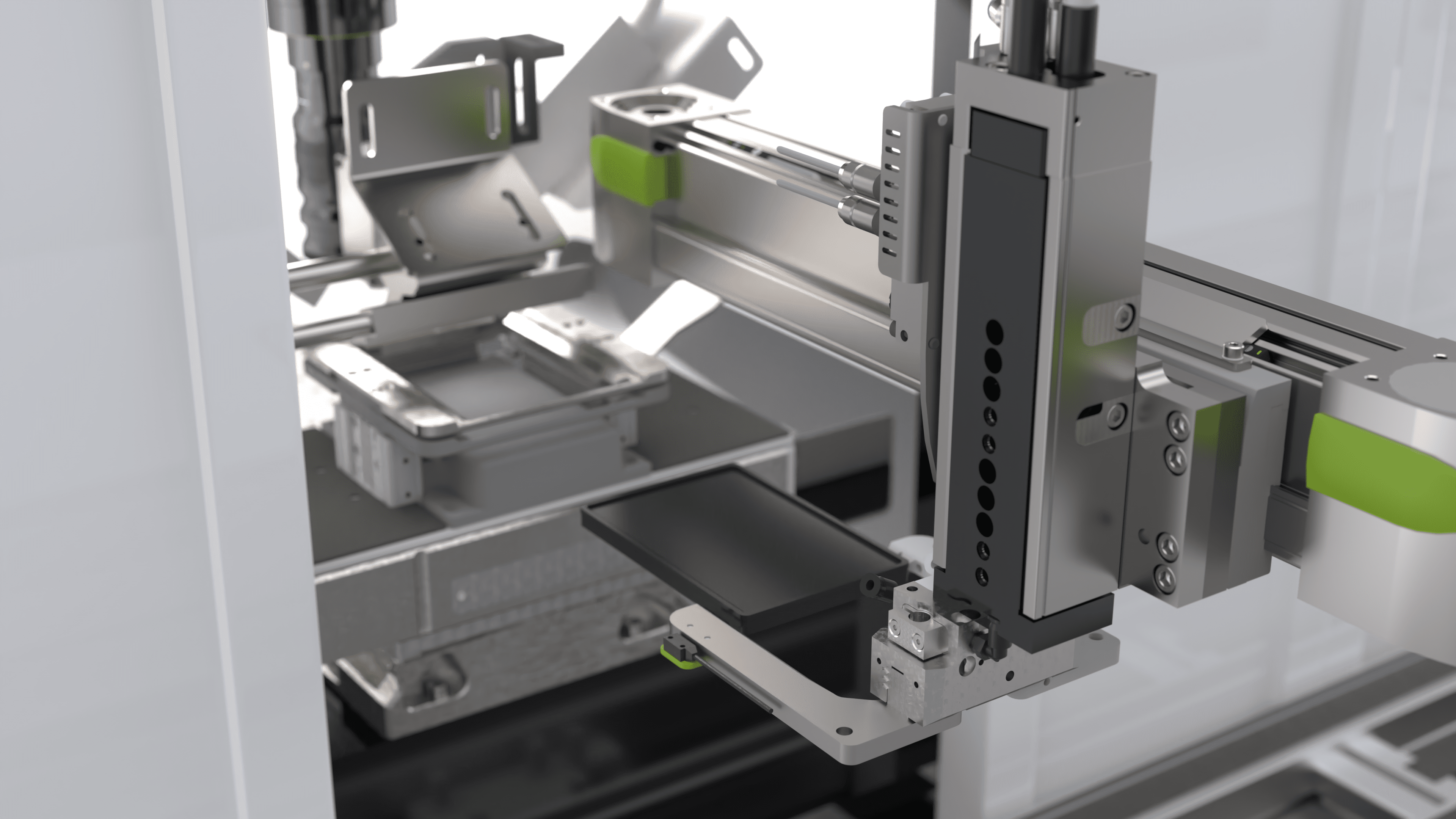

OUR BUILDING KIT

Maximum modularity for individual requirements

Our modular system allows us to address the specific testing requirements of our customers in a targeted and optimal manner. You receive a testing system that is precisely tailored to your needs, supported by state-of-the-art technology and expertise.

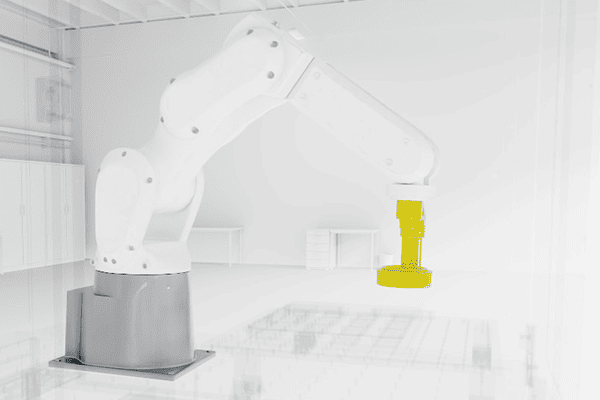

Automation modules

Key components for efficient automation:

- PLC

- Safety mechanisms

- Conveyor technology

- robotics

- communication

- Process control

- Sensor technology

Module Vision

State-of-the-art technologies for precise data acquisition:

- Matrix and line scan cameras

- Lenses

- bitelecentric lenses

- LED lighting (background, darkfield, dome, coaxial…)

- 3D profile section sensors

- chrome. conf. sensors

Module Software

Software modules for our plant control system:

- Automation Designer

- Vision Designer

- Databases

- Visualization

- User Interface

- Data analysis tools

- Interface integration

Module Examination

Machine Vision Module based on classical image processing and AI:

- Dimensional accuracy

- Defect detection

- Anomaly analysis

- AI & Codes/OCR

- Texture recognition

- Surface analysis

- Matrix code barcode

- Pattern recognition

Precision meets innovation.

Discover how our machine vision inspection systems make a difference. Talk to an expert!

FAQs about the Spector series

In which industries can their testing equipment be used?

Our testing equipment is suitable for a wide variety of industries, including automotive, semiconductor, health care, metal processing, food industry and many others.

Can we adapt a testing system to specific needs?

Yes, thanks to our modular system, we can design and optimize testing facilities individually according to the requirements and needs of our customers.

What technologies do we use in our machine vision systems?

We use state-of-the-art technologies, including high-resolution cameras, specialized lighting systems, 2D and 3D image processing, and advanced software modules for optimal image analysis.

How long does it take to implement one of our machine vision inspection systems in a production line?

The implementation time depends on the specific requirements and complexity of the project. After a thorough needs analysis, we can provide a precise timeframe. Contact us to discuss your requirements!

Do you offer training or support for our testing equipment?

Yes, we offer comprehensive training and continuous support to ensure that our customers can utilize the full potential of their machine vision testing system.