Your solution for efficient DOT code reading.

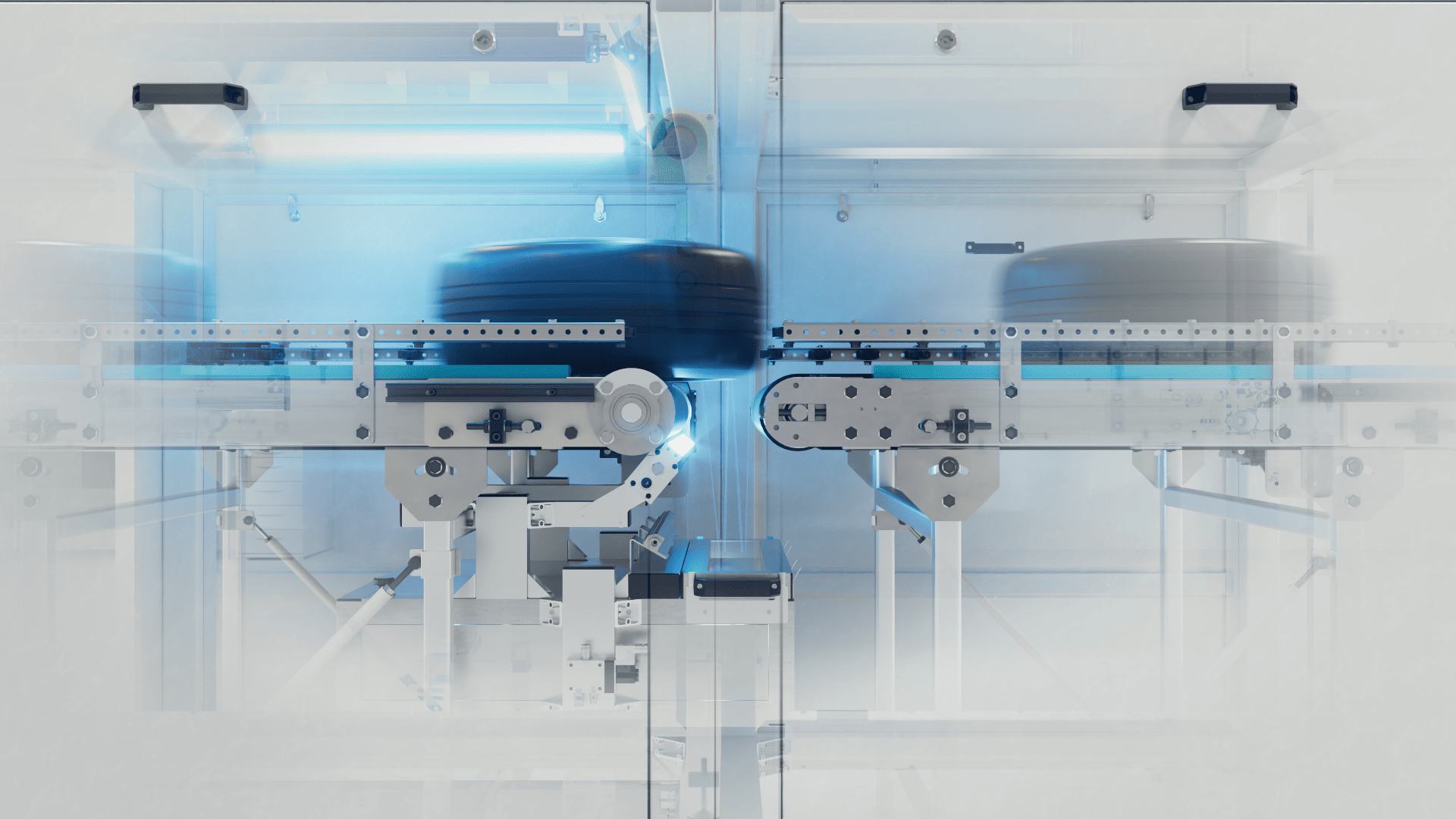

Discover the future of automated quality control for wheels and tires with VISION.SPECTOR TIRE DOT. Our inspection systems offer flexible application options – perfectly suited for use at the beginning of the assembly line as well as for final end-of-line quality inspection. Equipped with the latest machine vision technology, our systems guarantee accurate DOT code reading. Increase the quality standards and efficiency of your production processes with customized solutions from MABRI.VISION.

Dual perspective, maximum reliability: Our system enables a comprehensive inspection of both tire sides without the need for a turning unit. This not only improves efficiency but also the accuracy of your quality checks and minimizes potential sources of error.

VISION.SPECTOR TIRE DOT offers a complete inspection solution specifically focused on detecting DOT codes. Reduce the need for multiple specialized inspection stations with our integrated solution.

The system uses a belt conveyor to transport the wheels through the process; wheel centering is not required. This gentle handling minimizes the physical impact on the wheels while ensuring precise and efficient testing.

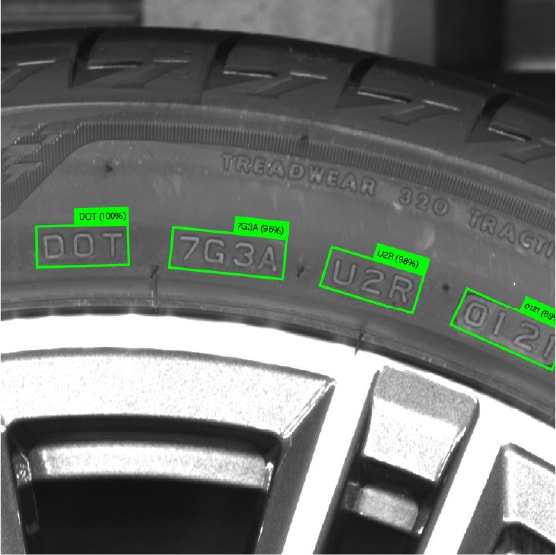

AI-based detection of DOT codes on both sides: By using artificial intelligence, DOT codes on the outside and inside of the tire are precisely identified, ensuring complete traceability and compliance.

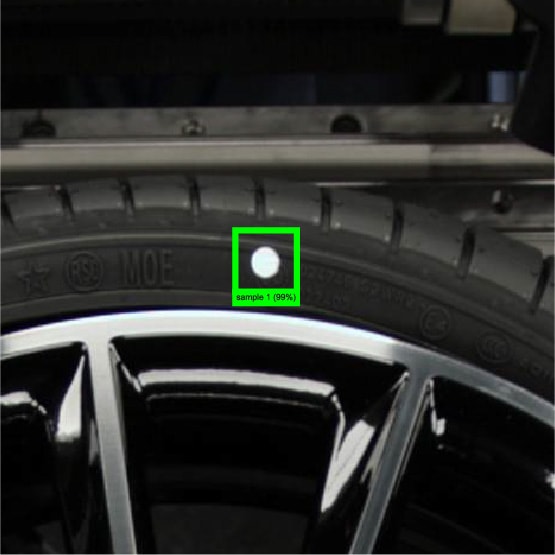

AI-based detection of DOM codes on both sides: By using artificial intelligence, DOM codes on the outer and inner sides of the tire are precisely identified. This detection enables comprehensive traceability of production data and ensures maximum compliance and quality assurance in your manufacturing.

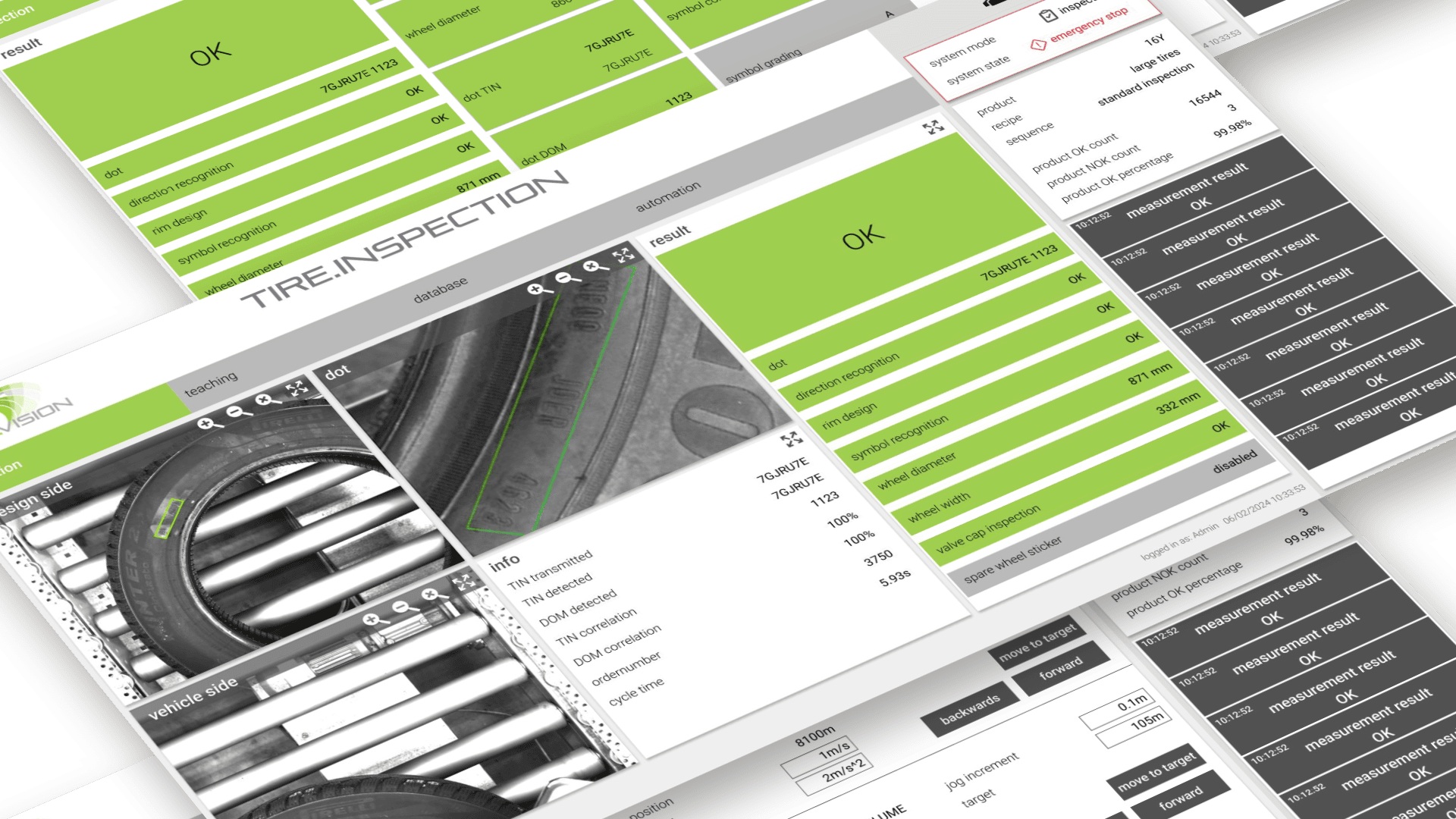

The VISION.SPECTOR TIRE DOT machine vision software is a solution for the automated inspection of DOT codes. With its ability to precisely identify DOT codes, it combines efficiency with accuracy. The intuitive user interface on a large screen allows for easy operation and quick adaptation to various inspection tasks, while the integrated data management improves traceability and quality control. Optimize your production line with software that delivers precision in end-of-line inspection.

Whether in wheel assembly, tire and rim production, or in the storage and spare parts business – VISION.SPECTOR TIRE DOT sets new standards in quality control and promotes the production and handling of flawless products.

The VISION.SPECTOR TIRE DOT inspection system is an indispensable tool for wheel assembly, optimizing quality assurance through highly precise AI-supported image processing. It enables fast and error-free verification of assembly quality, optimizes the assembly process, and increases overall productivity.

In tire and rim production, our system sets standards in quality control. It precisely identifies any deviations and irregularities in material and design, ensures production standards, and promotes the delivery of flawless products.

For the warehousing and spare parts business, the VISION.SPECTOR TIRE DOT inspection system offers an efficient solution for quality control and sorting of wheels and tires. Its ability to accurately classify products simplifies warehouse organization, improves access speed to spare parts, and minimizes storage costs. The system is a key component, especially for automated logistics concepts.

Discover how our machine vision inspection systems make a difference. Talk to an expert!