VISION.SPECTOR TIRE EOL & DOT

Your solution for efficient wheel and tire testing

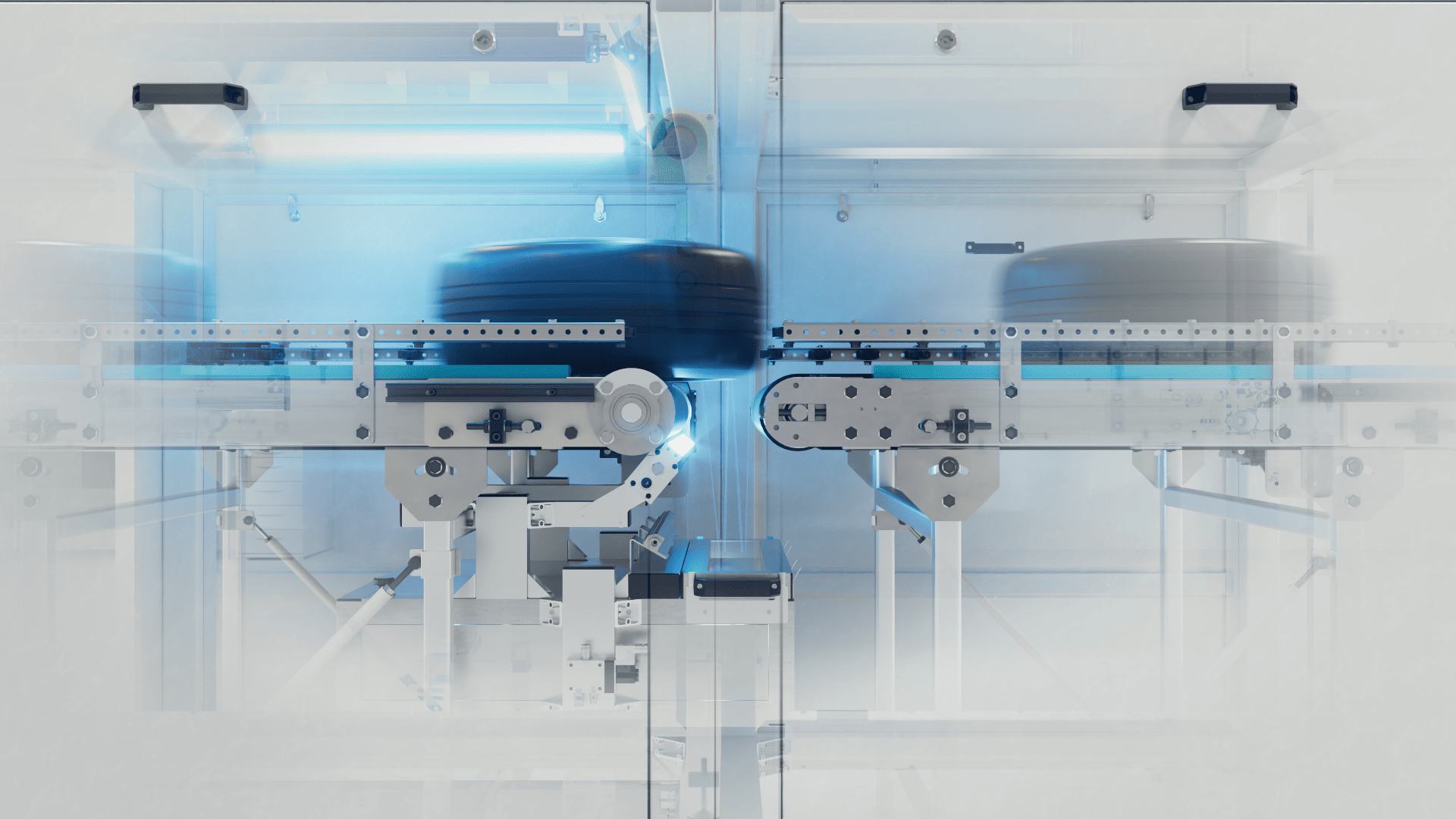

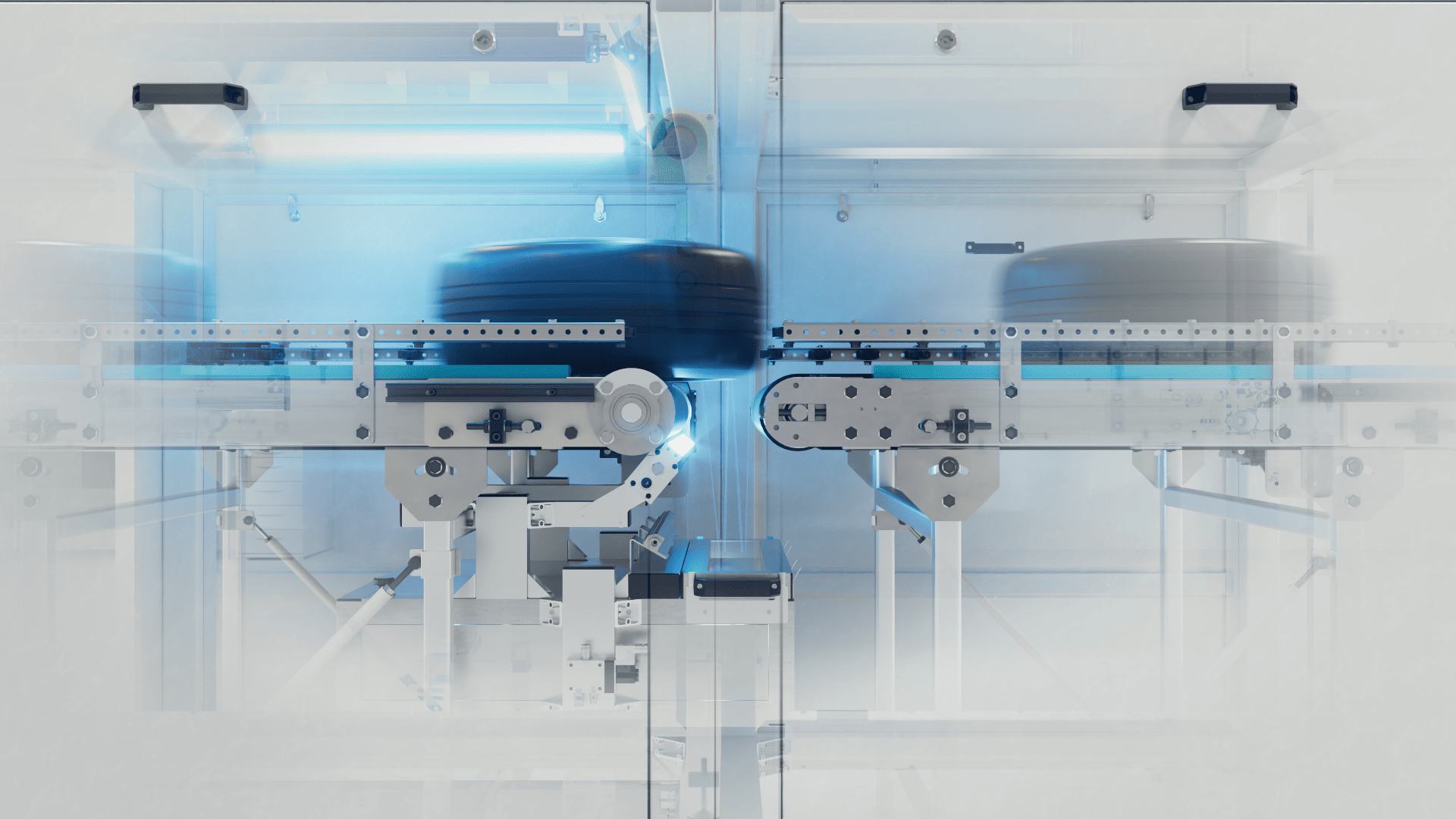

Discover the future of automated quality control for complete wheels with VISION.SPECTOR TIRE EOL & DOT. Our inspection systems offer flexible application possibilities – perfectly suited for use at the beginning of the assembly line as well as for final end-of-line quality inspection. Equipped with the latest machine vision technology, our systems guarantee accurate inspection of wheel diameter, tire geometry, rim design, valves, and matching points. In addition, the capture of DOT and DOM codes enables unprecedented quality assurance in your production. Increase the quality standards and efficiency of your production processes with customized solutions from MABRI.VISION.

FEATURES AT A GLANCE

Examination from both sides

Dual perspective, maximum reliability: Our system enables comprehensive inspection of both sides of the wheel without the need for a turning unit. This not only improves efficiency but also the accuracy of your quality checks and minimizes potential sources of error.

All-in-one solution for comprehensive quality control

VISION.SPECTOR TIRE EOL & DOT offers a complete testing solution that captures a wide range of parameters such as tire diameter, width, rim design, match points and valves, as well as DOT and DOM codes . Reduce the need for multiple specialized testing stations with our integrated solution.

Low impact: Gentle treatment, highest precision

The system uses a belt conveyor to transport the wheels through the process; wheel centering is not required. This gentle handling minimizes the physical impact on the wheels while ensuring precise and efficient testing.

WHAT WE CHECK

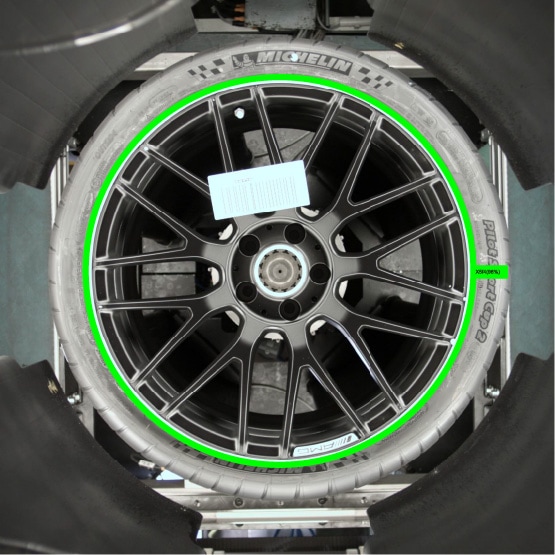

Rim design

Correct rim design verification: This check ensures that each wheel is fitted with the specified rim design.

Match point

Detection of the position of colored match points on tire and rim: This function detects the exact positioning of colored match points on the rim and tire, which is crucial for the correct mounting and balancing of the wheels.

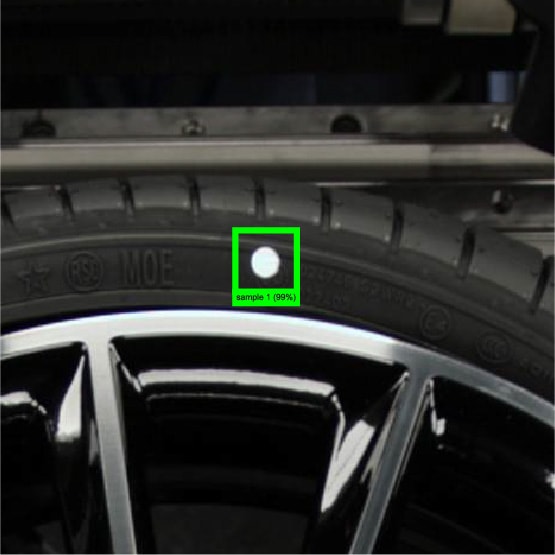

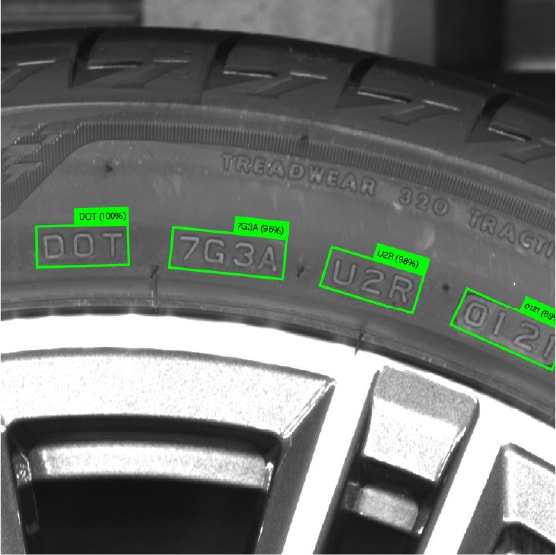

DOT

AI-based detection of DOT & DOM on both sides: By using artificial intelligence, DOT/DOM codes on the outside and inside of the tire are precisely identified, ensuring full traceability and compliance.

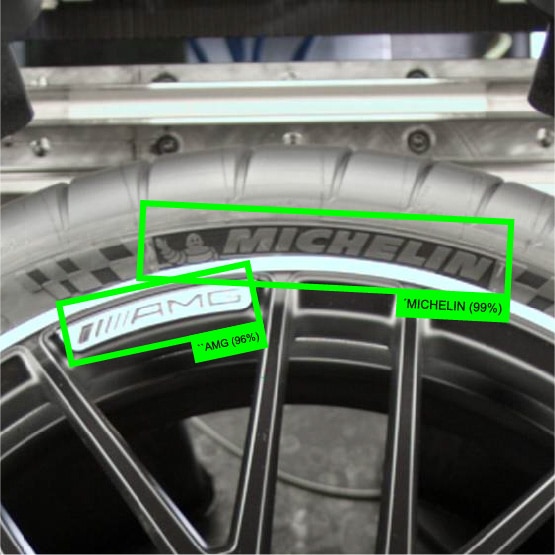

Symbols

Recognition of symbols on the tires: This test identifies specific symbols and markings on the tire that are important for safety regulations, tire specifications, or brand identification.

valves

Valve position and valve cap detection: This function checks whether the correct valve cap is installed. Simultaneously, the valve's position is detected.

WHEEL SPECIFICATIONS

Our plant software

Efficiency meets precision

The VISION.SPECTOR TIRE EOL & DOT machine vision software is a sophisticated solution for the automated inspection of wheels and tires. With its ability to precisely identify rim designs, match points, and DOT and DOM codes, it combines efficiency with accuracy. The intuitive user interface on a large screen allows for easy operation and rapid adaptation to various inspection tasks, while the integrated data management improves traceability and quality control. Optimize your production line with software that delivers precision in end-of-line inspection.

Diverse applications

From assembly to storage

Whether in wheel assembly, tire and rim production, or in the warehousing and spare parts business – VISION.SPECTOR TIRE EOL & DOT sets new standards in quality control and promotes the production and handling of flawless products.

Wheel assembly

The VISION.SPECTOR TIRE EOL & DOT inspection system is an indispensable tool for wheel assembly, optimizing quality assurance through highly precise AI-supported image processing. It enables fast and error-free verification of assembly quality, optimizes the assembly process, and increases overall productivity.

Tire and rim production

In tire and rim production, our system sets standards in quality control. It precisely identifies any deviations and irregularities in material and design, ensures production standards, and promotes the delivery of flawless products.

Storage & spare parts business

For the warehousing and spare parts business, the VISION.SPECTOR TIRE EOL & DOT inspection system offers an efficient solution for quality control and sorting of wheels and tires. Its ability to accurately classify products simplifies warehouse organization, improves access speed to spare parts, and minimizes storage costs. The system is a key component, especially for automated logistics concepts.

FAQ about the VISION.SPECTOR TIRE EOL & DOT testing system

Around the testing facility

What can the VISION.SPECTOR TIRE EOL & DOT testing system identify?

The VISION.SPECTOR TIRE EOL & DOT specializes in the precise identification and verification of rim designs, tire markings, including DOT and DOM codes on both sides, as well as the detection of valve positions and the presence of valve caps, supported by advanced AI-controlled image processing.

Which cameras and sensors are integrated into the VISION.SPECTOR TIRE EOL & DOT inspection system?

Our testing facility integrates state-of-the-art matrix and line cameras for comprehensive inspection, supported by advanced sensors specifically configured for the requirements of tire and wheel testing.

Can the VISION.SPECTOR TIRE EOL & DOT inspection system be retrofitted with additional cameras or sensors?

Yes, the testing system is designed modularly, so that additional cameras or sensors can be integrated to expand the functionality according to specific customer needs.

How does the VISION.SPECTOR TIRE EOL & DOT integrate into existing production lines?

Our testing system can be flexibly integrated into existing production environments, with customization options for mechanical and electrical interfaces to ensure seamless integration and communication with other system components

Which industrial interfaces does the VISION.SPECTOR TIRE EOL & DOT testing system support?

The test system supports common industrial interfaces such as Profinet and TCP/IP for easy connection to production control systems and efficient data transmission.

Are there any restrictions regarding the size or type of wheels and tires to be inspected?

The testing facility is designed for a wide range of tire and wheel sizes from the passenger car sector, with the possibility of developing individual solutions for exceptional dimensions or specific requirements.

All about software

Which software modules are available in the VISION.SPECTOR TIRE EOL & DOT testing system?

The system offers extensive software modules for user management, batch tracking, automated testing procedures, data management and much more to enable complete customization to your production requirements.

How easily can the testing system be adapted to specific production requirements?

The testing system and its software are highly configurable, allowing users to easily and flexibly adjust testing processes and parameters to achieve optimal test results.

Training & Service

What training or support services are available for the VISION.SPECTOR TIRE EOL & DOT testing system?

We offer comprehensive training and support for the commissioning, operation and maintenance of the test system to ensure high efficiency and reliability in operation.

How is the quality and precision of the test results ensured?

Regular calibrations and systematic quality controls through our software ensure consistently precise test results and reliable quality monitoring.

What maintenance or service offerings do you provide for the VISION.SPECTOR TIRE EOL & DOT testing system?

We offer customized maintenance and service packages to ensure optimal performance and longevity of the testing equipment, including technical support and regular updates.

Are there customer service or support services available in case of technical problems?

In case of technical or software problems, our customer service is available to assist you. Depending on your service agreement, we offer different response times and availability periods.

DOWNLOADS

BROCHURE VISION.SPECTOR TIRE EOL & DOT

Precision meets innovation.

Discover how our machine vision inspection systems make a difference. Talk to an expert!