Key areas

Electronic components

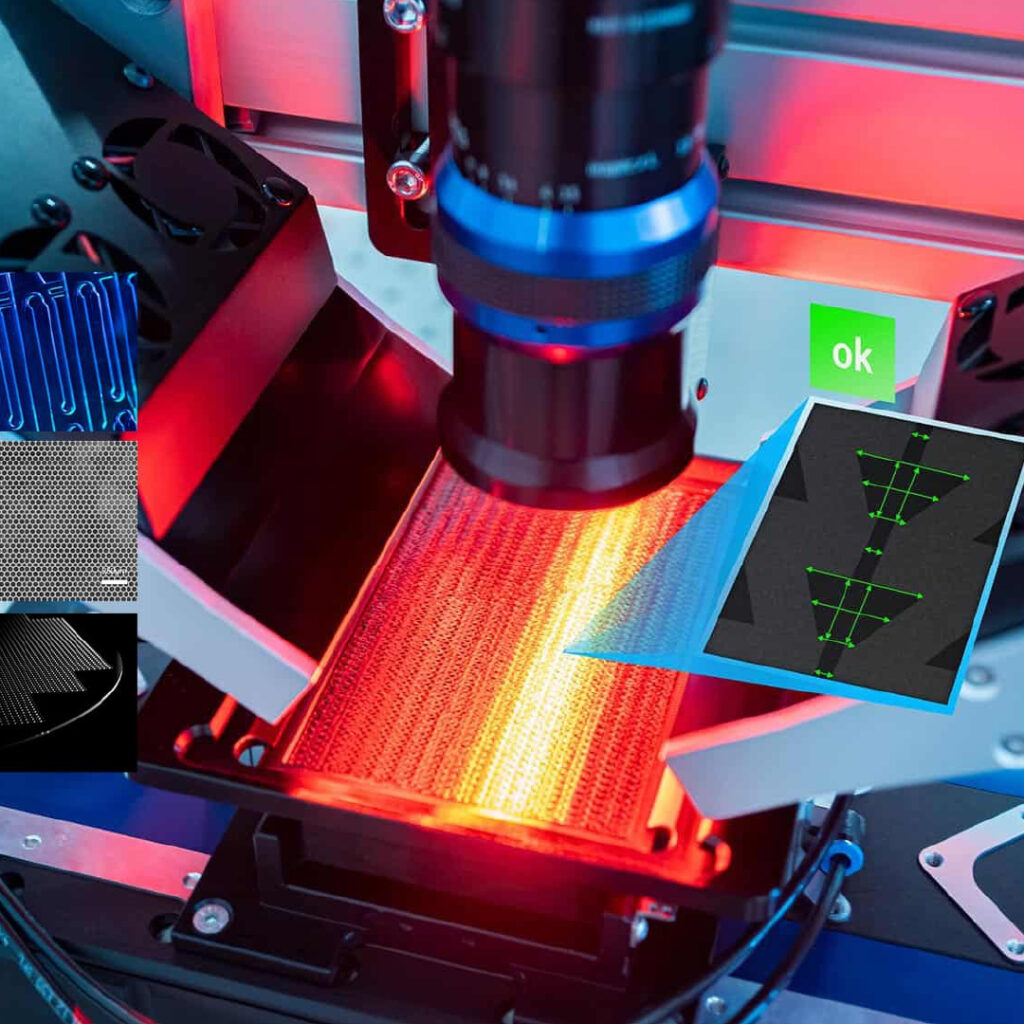

Testing solutions for the electronics industry

Quality testing of electronic and hybrid components

Electronic components play key roles in a rapidly growing number of products. The necessary production capacities place the highest demands on quality to reliably detect common defects such as housing breaks, bends, incorrect component placement, form errors, burrs, and undermolding. Our AOI (Automated Optical Inspection) solutions are specialized in reliably detecting these defects during the process and verifying dimensional accuracy. In addition to traditional inspection criteria, we utilize AI-supported algorithms to

We efficiently detect anomalies in electronic components such as power modules, plugs, connectors, and circuit boards. For inspecting miniaturized electronic components or wafers, we offer in-process inspection solutions with high-speed microscopes. For highly integrated and hybrid components, we have developed vision systems with 3D scanners to detect even the smallest defects and shape deviations. Our systems can be operated stand-alone with manual loading or integrated into a production line with workpiece carriers or conveyor technology.

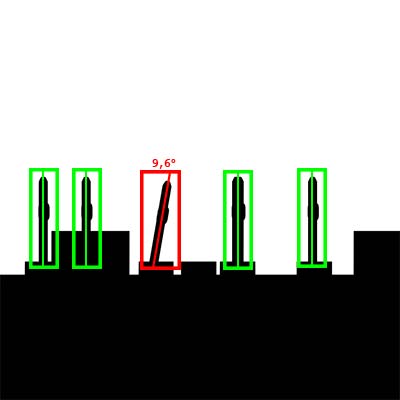

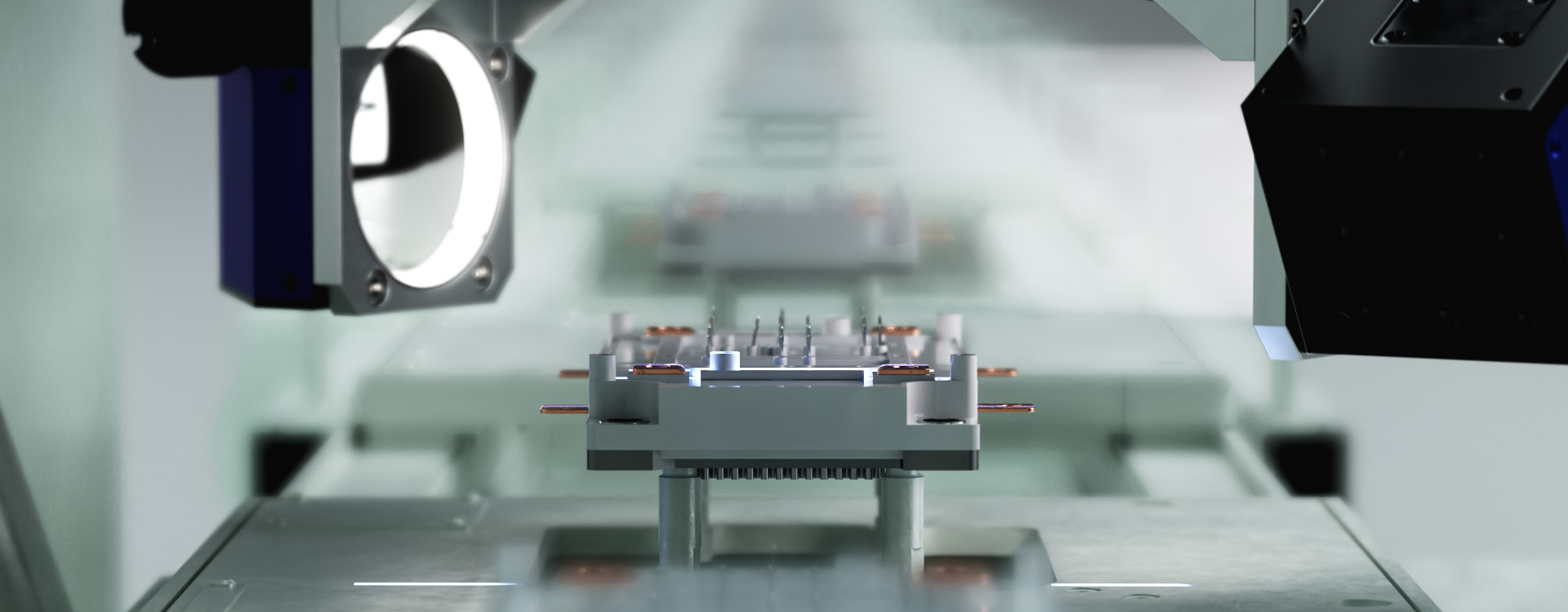

Connectors and pins

With speeds of up to 1000 contacts/min, precise testing of contacts and coding is possible in the production cycle.

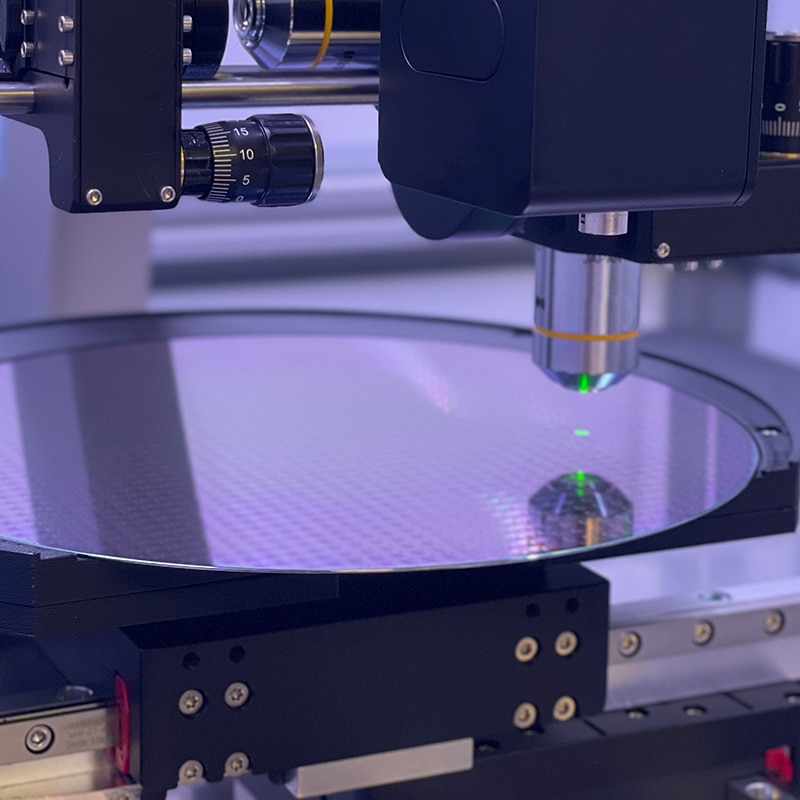

Wafer

We offer in-process testing solutions with high-speed microscopes for testing wafers and microstructured components.

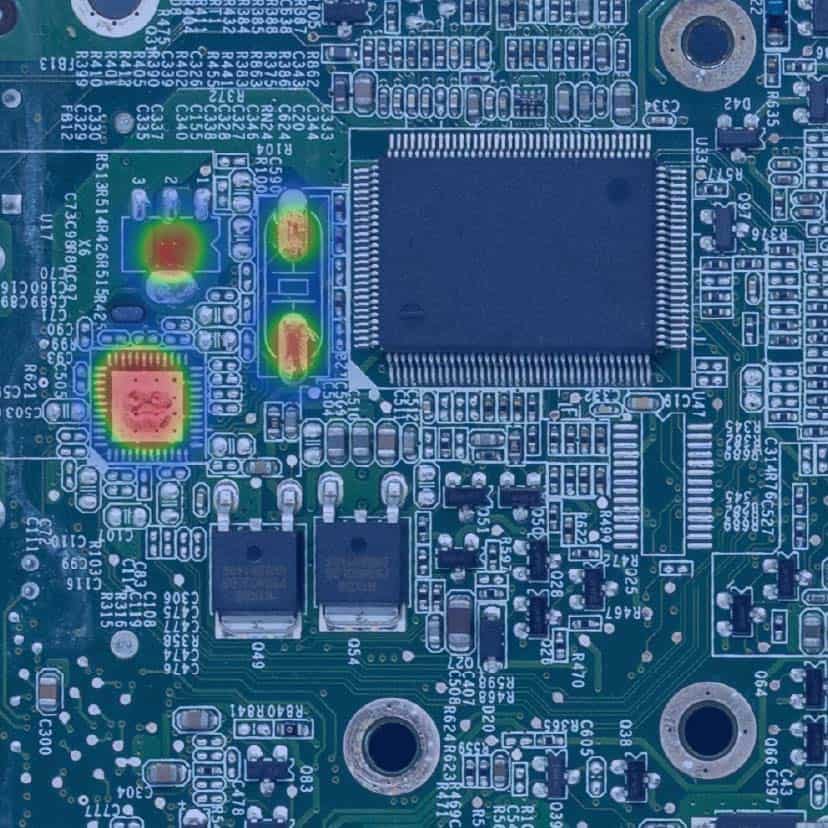

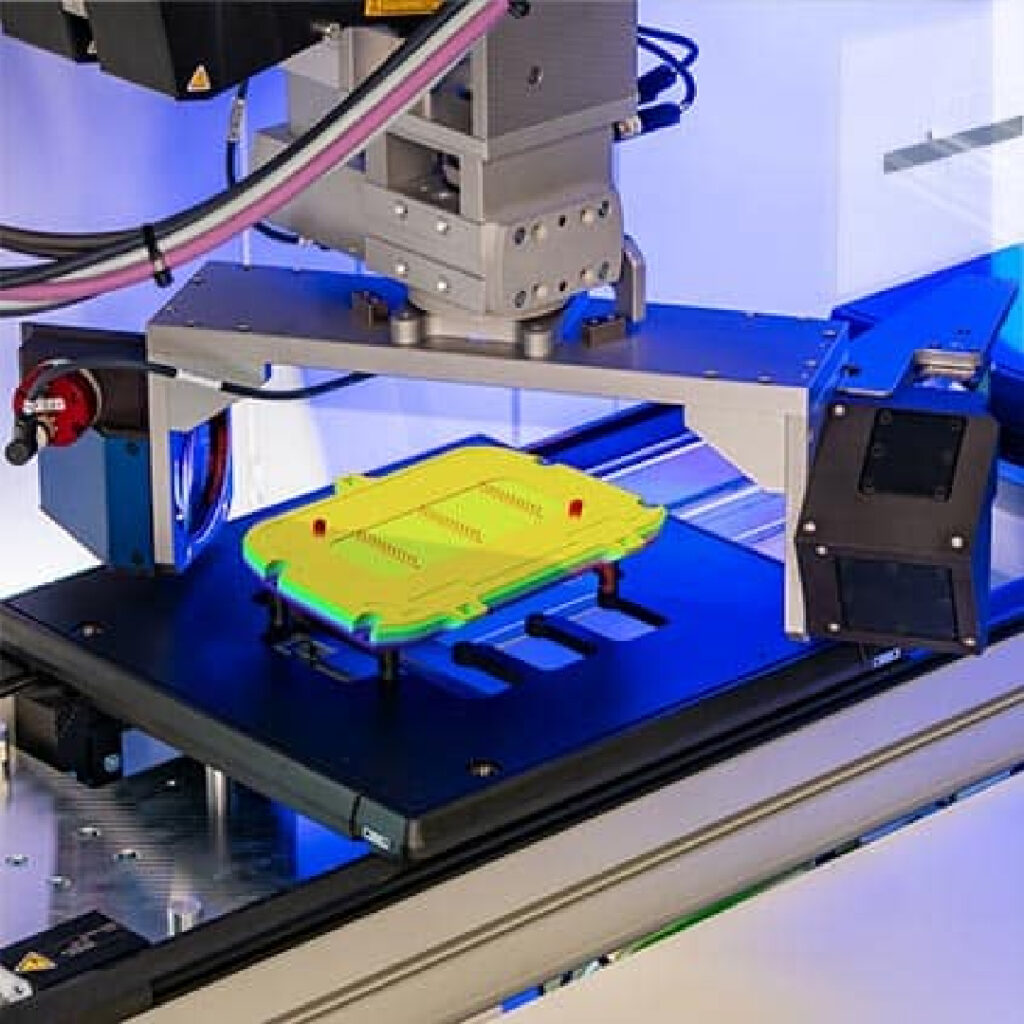

highly integrated systems

In our testing systems, we merge the test results from our cameras and sensors in order to be able to comprehensively test complex component groups.

Hybrid components

We offer solutions for 2D/3D inspection of microarrays. Application areas include microlenses, stacks, sequencing, LOAC, fluidics, sensors, and medical instruments.

Testing solutions for electronic components

Discover our product portfolio

MV.CHECK Inspection Systems

Machine Vision: MABRI.VISION develops and builds machine vision inspection systems and solutions for your production processes.

Rotary indexer test systems

Our rotary indexing testing systems for quality assurance of your products are characterized by the combination of various technologies.

High-speed microscope - Automated testing

MABRI.VISION offers an inline-capable and cycle-time-neutral high-speed microscope for the automated inspection of microstructured components.

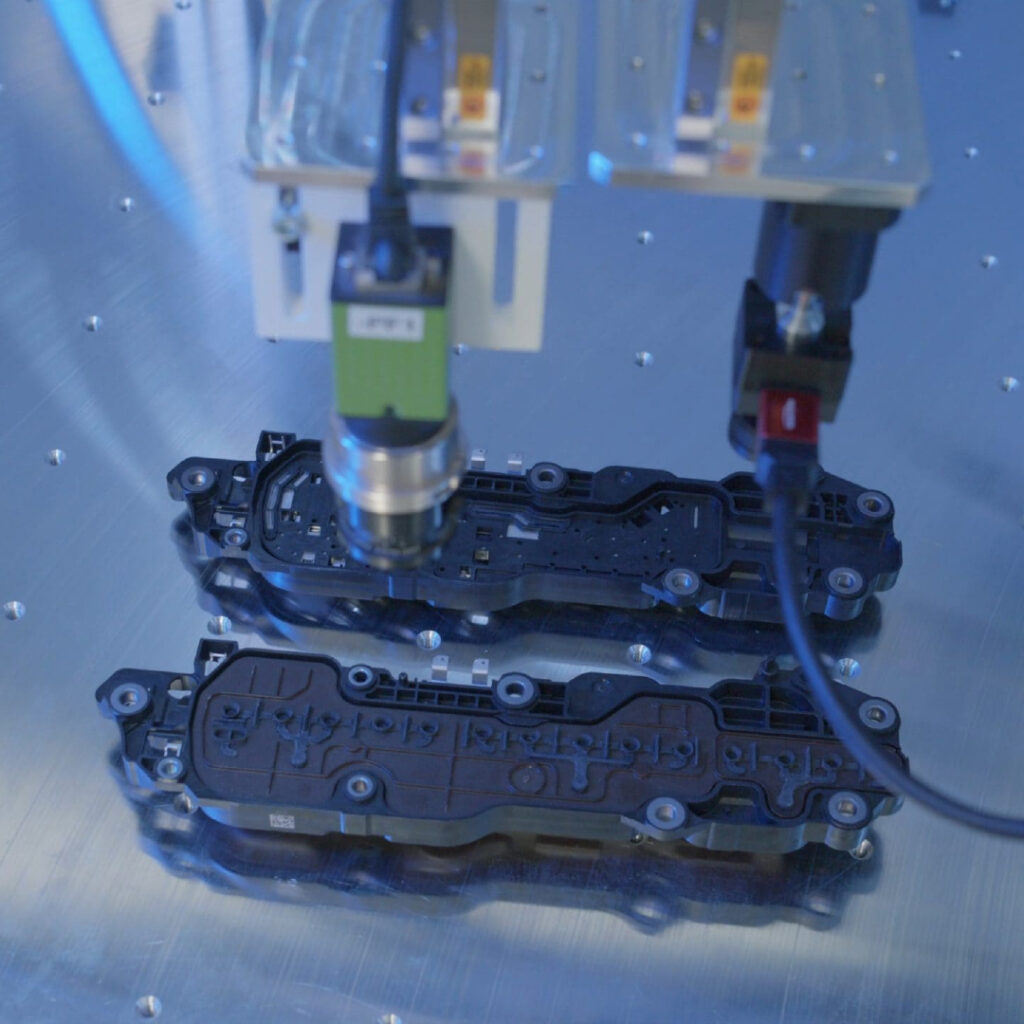

Inline 2D/3D measurement on the product carrier

We offer 2D/3D measurement on the workpiece carrier for your quality assurance with our MV.EYE i2 WT inspection system. Seamless and directly on the workpiece carrier.

Interested?

We'll call you back!

Do you need more information about a specific product group or do you have a specific product inquiry? Please use our contact form or give us a call.

- MABRI.VISION GmbH Philipsstraße 8 52068 Aachen

- +49 241 5652 7930

- info@mabri.vision