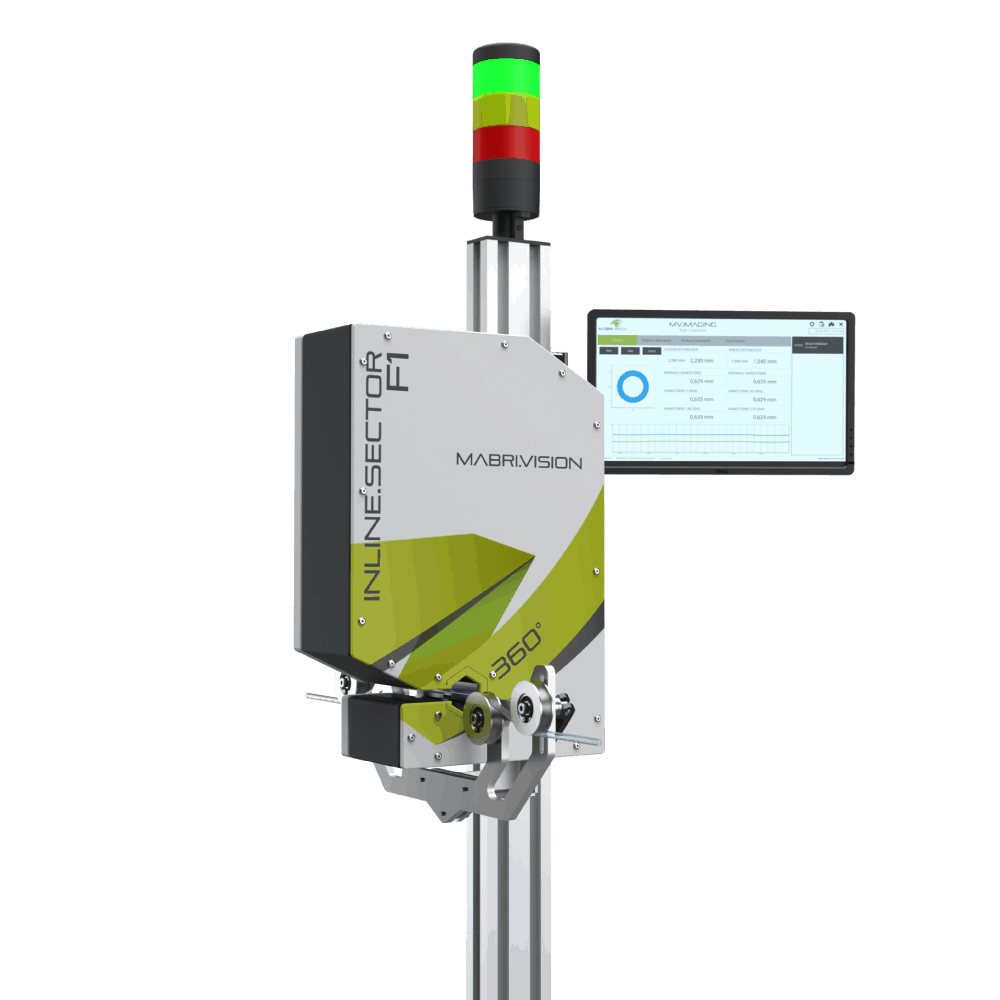

INLINE SECTOR F1

Inline hose wall thickness testing system

Inline hose wall thickness testing system - INLINE.SECTOR F1

The future of hose testing

The MABRI.VISION INLINE.SECTOR F1 testing system describes the future of quality control for plastic and silicone hoses: non-destructive and in line with production cycles.

Efficient and in motion

A 360° sensor creates cross-sections for checking the inner and outer diameter, wall thickness and geometry of semi-transparent tubes: directly in your extrusion line.

Innovation – our passion!

Testing processes must integrate seamlessly into production workflows. MABRI.VISION therefore relies on innovative solutions to support your testing process.

Your advantage

Save material.

The MABRI.VISION INLINE.SECTOR F1 testing system performs hose testing non-destructively and continuously. This ensures consistently reliable tolerances and reduces your material consumption.

ramp up production faster.

Continuous monitoring by the INLINE.SECTOR F1 enables you to accelerate the setup of your production line. This helps you avoid initial error reports and saves you production time.

100% quality assurance.

Inline check

The INLINE.SECTOR F1 inspects hoses directly in your extrusion line for applications with the highest demands. The non-contact measuring method enables, among other things, the testing of wall thickness, shape, and offset.

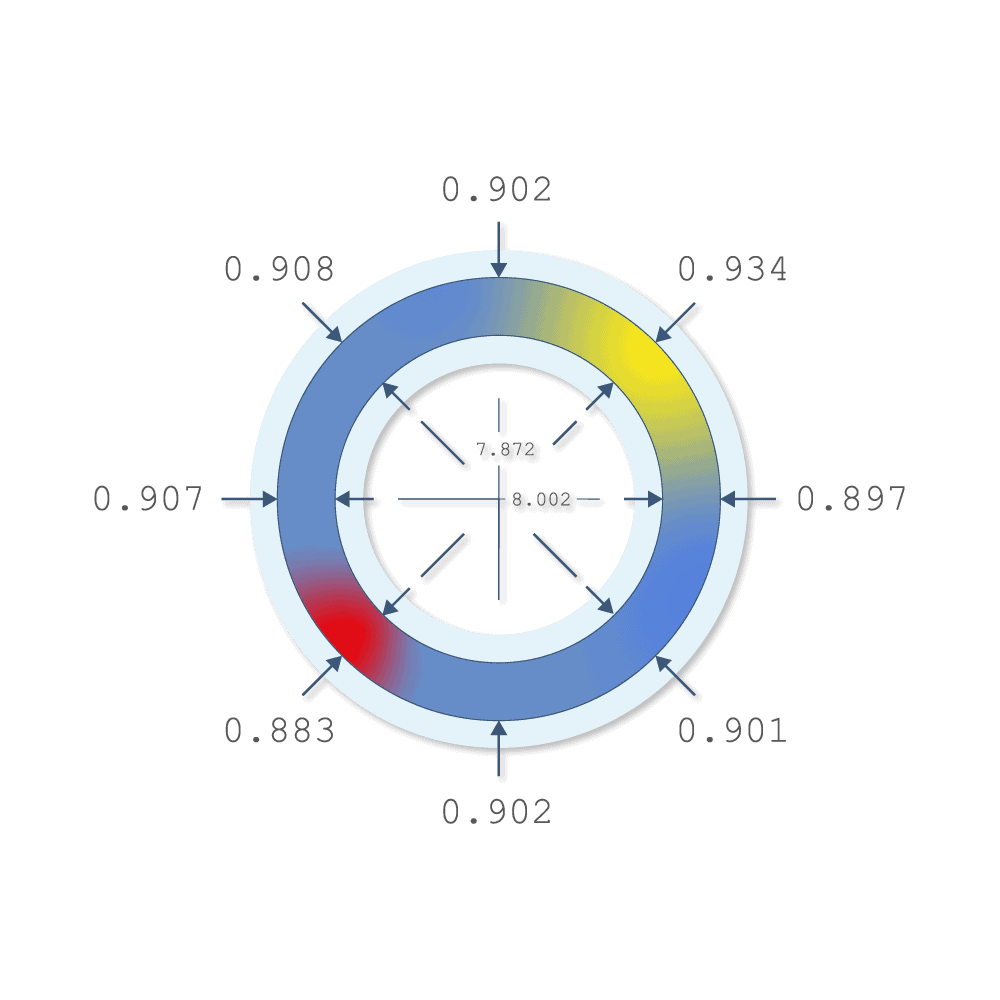

wall thickness

MABRI.VISION's inline testing system enables simultaneous measurement of wall thickness from up to 16 directions. Testing is performed simultaneously with your production and is completely non-destructive.

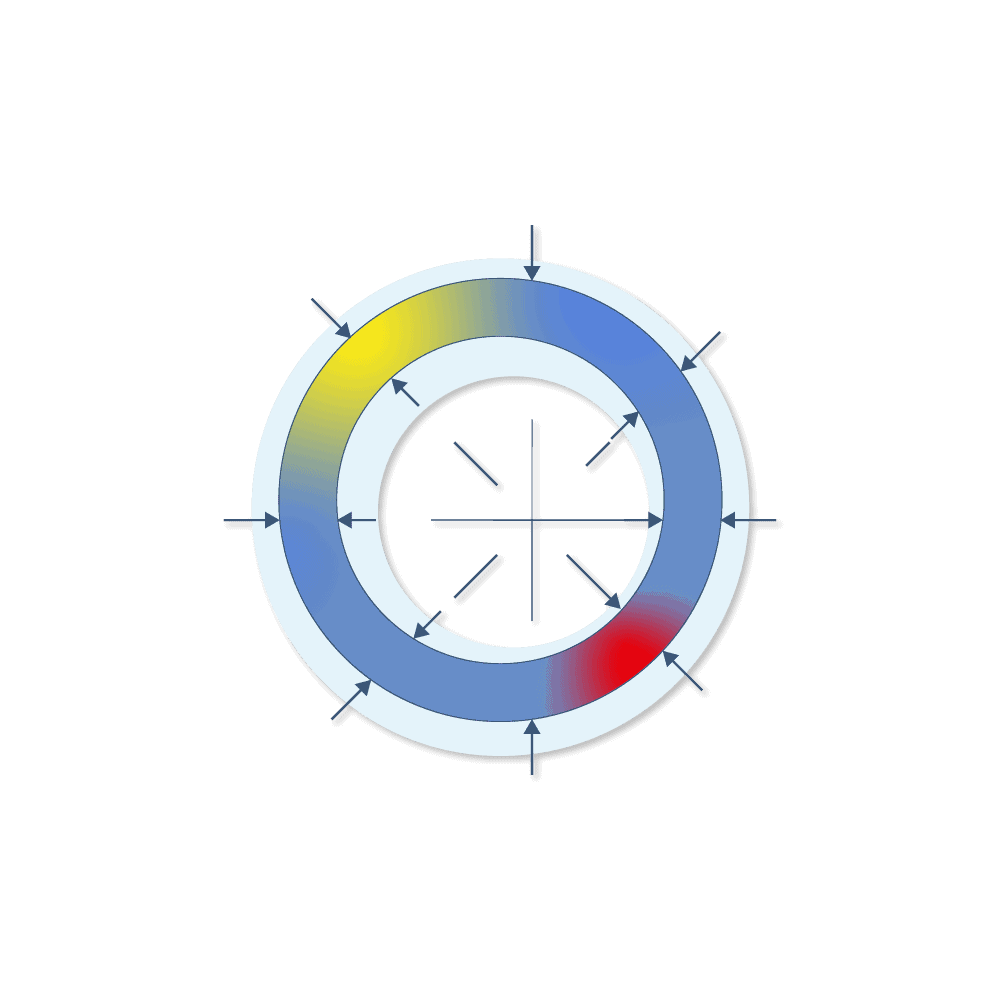

Core offset

Precise testing of core offset on semi-transparent tubes (both colorless and colored) with a diameter of 0.5 mm – 20 mm and a wall thickness of 0.1 mm – 4 mm.

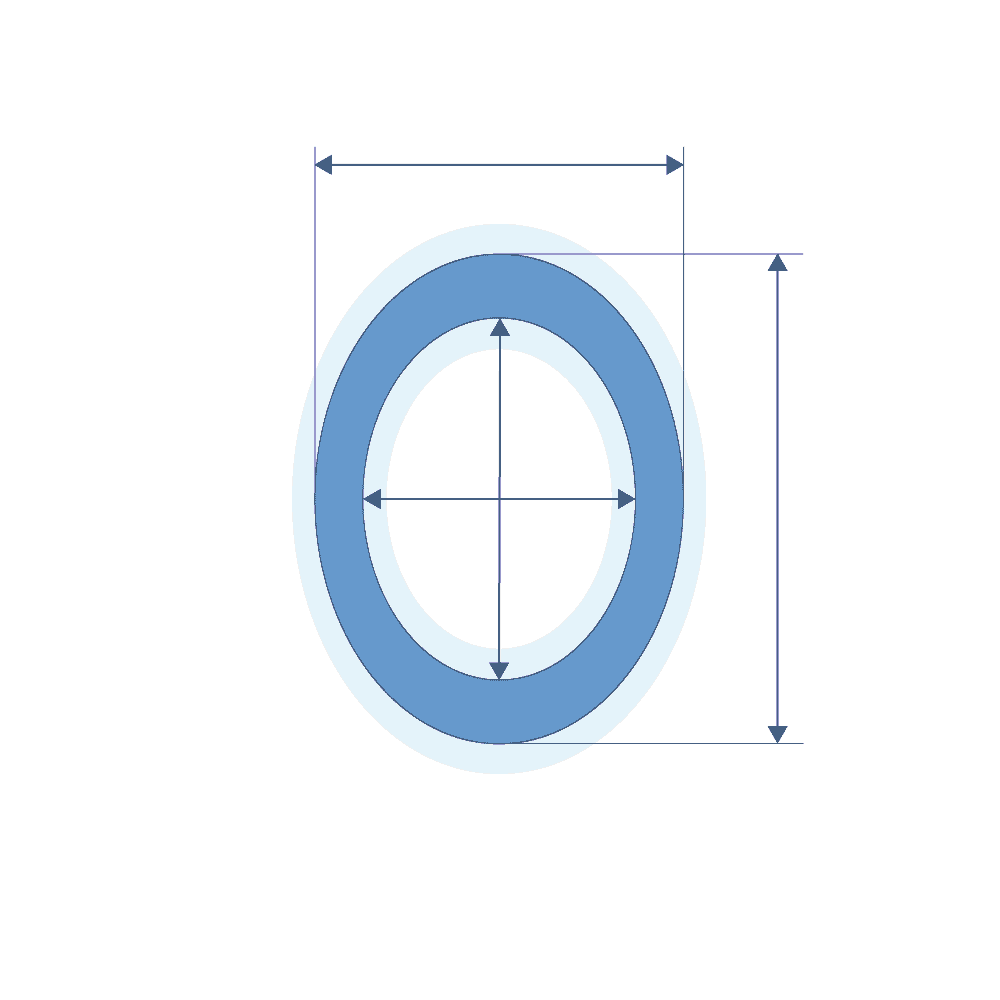

Inner and outer diameters

Measurement of inner and outer diameter, minimum and maximum wall thickness, ovality, and core offset. Obtain a complete cross-sectional image of your single-lumen tubing.

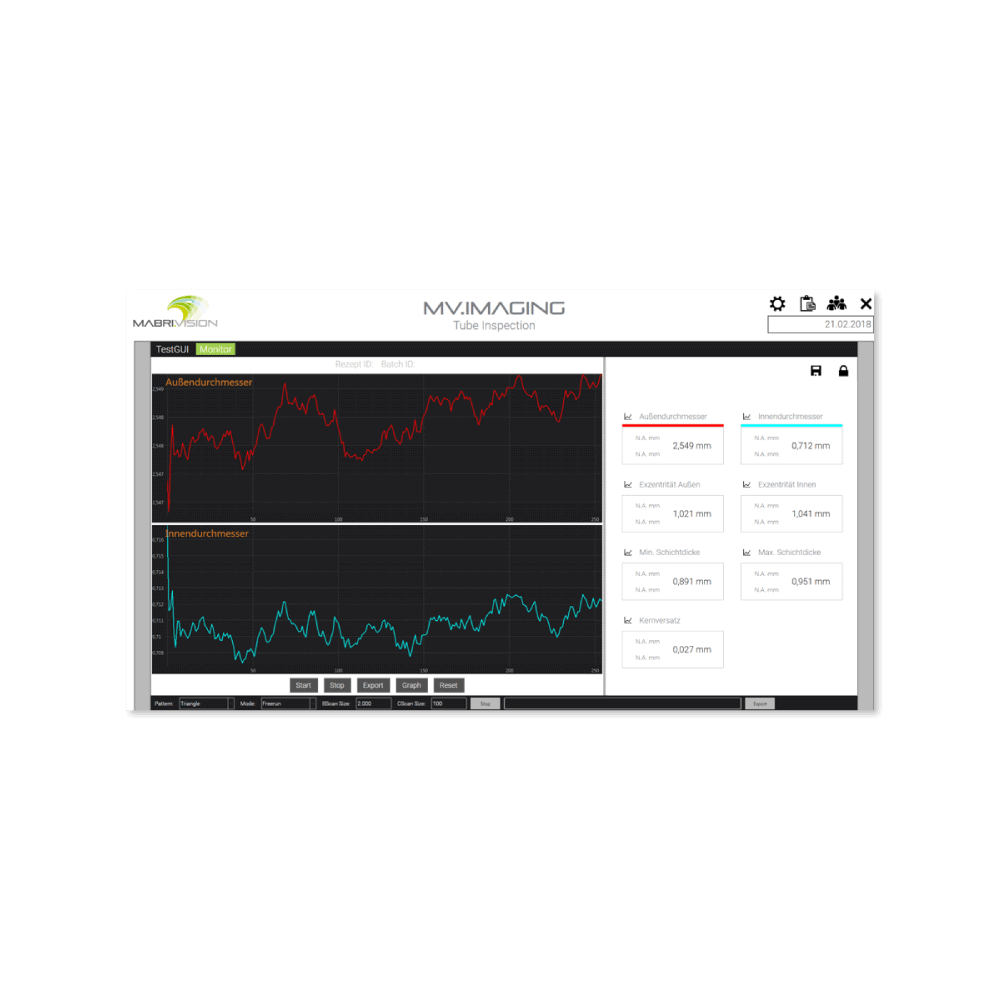

History & Statistics

Generated measurement data is stored and can be analyzed and exported. The database functionality can be extended to meet your requirements, for example, to include time-series graphs for any process parameters.

clear

Benefit from a clear interface for visualizing and analyzing the tests. Interfaces to your systems can be expanded as needed (for example, Profinet, Profibus, digital I/O and analog).

Powerful and intuitive software

The high-performance MABRI.VISION software provides a customized solution for the inline reconstruction of hose geometry from sensor data. Our software experts utilize innovative reconstruction algorithms and processing performance optimized for inline testing.

Users have access to a wide range of analysis tools for intuitive and straightforward evaluation. This allows you to perform a comprehensive hose test and identify and implement optimization potential in your production.

Universal: versatile in its applications

MEDICAL TECHNOLOGY

100% quality control is of fundamental importance in medical technology. The INLINE.SECTOR F1 testing system enables complete testing of transparent and semi-transparent tubing in the medical industry.

INFUSION

When testing infusion tubing for defects and geometric properties, precision and reliability are paramount – properties that MABRI.VISION unconditionally fulfills with the INLINE.SECTOR F1.

Dialysis & Blood Donation

The MABRI.VISION INLINE.SECTOR F1 testing system offers 100% inline testing for tubing used in dialysis and blood donation. Rely on MABRI.VISION's expertise in this field.